alternator MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 8 of 909

NEW STANDARDS

GI–5

GINEW STANDARDS TABLEA6E202800020201•The following is a comparison of the previous standard and the new standard.

NEW STANDARDS

New Standard Previous Standard

Remark

Abbrevi-

ationNameAbbrevi-

ationName

AP Accelerator Pedal—Accelerator Pedal

ACL Air Cleaner—Air Cleaner

A/C Air Conditioning—Air Conditioning

BARO Barometric Pressure—Atmospheric Pressure

B+ Battery Positive VoltageV

BBattery Voltage

—Brake Switch—Stoplight Switch

—Calibration Resistor—Corrected Resistance #6

CMP sensor Camshaft Position Sensor—Crank Angle Sensor

CAC Charge Air Cooler—Intercooler

CLS Closed Loop System—Feedback System

CTP Closed Throttle Position—Fully Closed

—Closed Throttle Position Switch—Idle Switch

CPP Clutch Pedal Position—Clutch Position

CIS Continuous Fuel Injection System EGI Electronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP sensor Control Sleeve Position Sensor #6

CKP sensor Crankshaft Position Sensor—Crank Angle Sensor 2

DLC Data Link Connector—Diagnosis Connector

DTM Diagnostic Test Mode—Test Mode #1

DTC Diagnostic Trouble Code—Service Code(s)

DI Distributor Ignition—Spark Ignition

DLI Distributorless Ignition—Direct Ignition

EI Electronic Ignition—Electronic Spark Ignition #2

ECT Engine Coolant Temperature—Water Thermo

EM Engine Modification—Engine Modification

—Engine Speed Input Signal—Engine RPM Signal

EVAP Evaporative Emission—Evaporative Emission

EGR Exhaust Gas Recirculation—Exhaust Gas Recirculation

FC Fan Control—Fan Control

FF Flexible Fuel—Flexible Fuel

4GR Fourth Gear—Overdrive

—Fuel Pump Relay—Circuit Opening Relay #3

FSO

solenoidFuel Shut Off Solenoid FCV Fuel Cut Valve #6

GEN Generator—Alternator

GND Ground—Ground/Earth

HO2S Heated Oxygen Sensor—Oxygen Sensor With heater

IAC Idle Air Control—Idle Speed Control

—IDM Relay—Spill Valve Relay #6

—Incorrect Gear Ratio——

—Injection Pump FIP Fuel Injection Pump #6

—Input/Turbine Speed Sensor—Pulse Generator

IAT Intake Air Temperature—Intake Air Thermo

KS Knock Sensor—Knock Sensor

MIL Malfunction Indicator Lamp—Malfunction Indicator Light

MAP Manifold Absolute Pressure—Intake Air Pressure

MAF sensor Mass Air Flow Sensor—Airflow Sensor

MFI Multiport Fuel Injection—Multiport Fuel Injection

OBD On Board Diagnostic—Diagnosis/Self Diagnosis

Page 744 of 909

CONVENTIONAL BRAKE SYSTEM

P–11

P

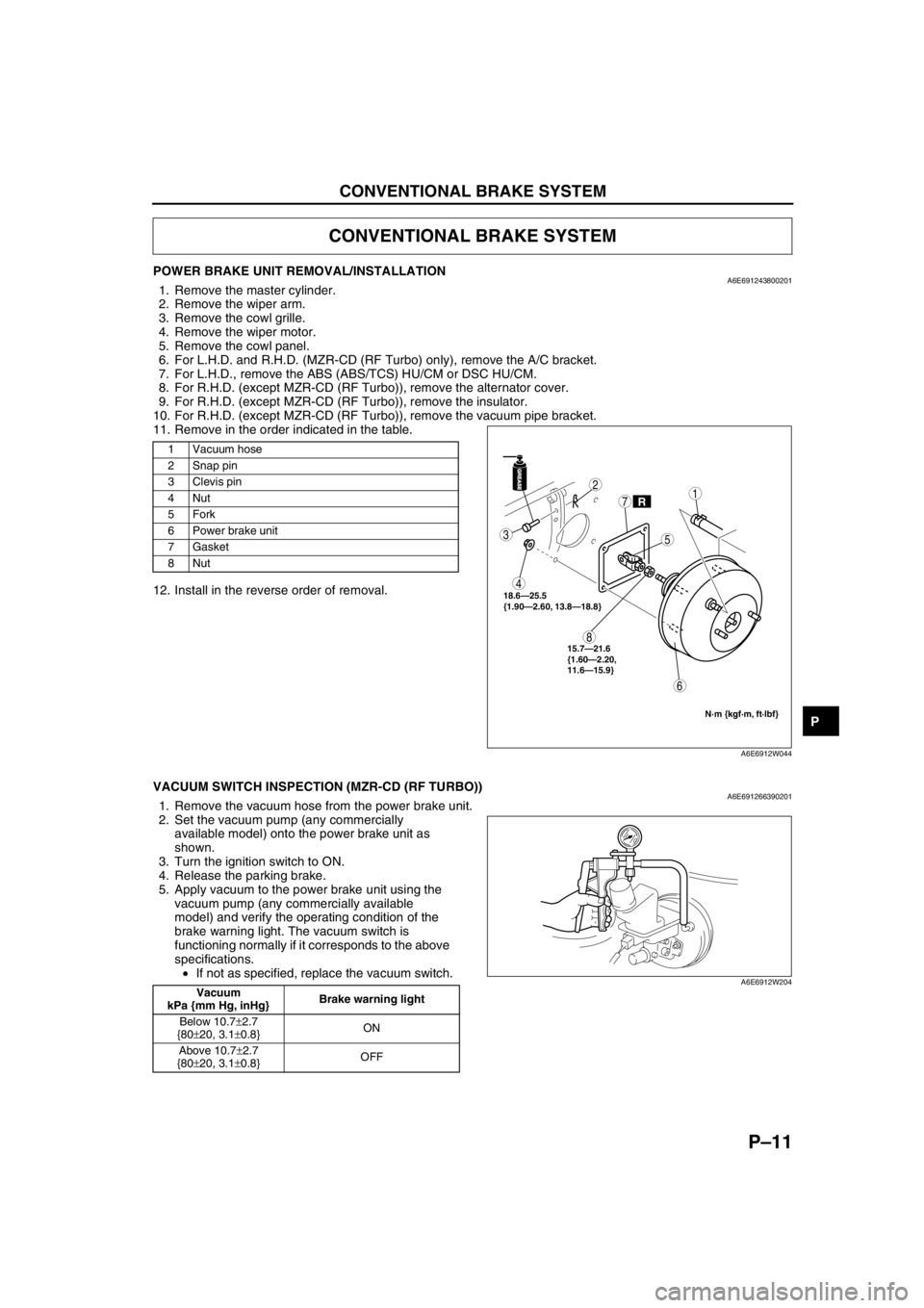

POWER BRAKE UNIT REMOVAL/INSTALLATIONA6E6912438002011. Remove the master cylinder.

2. Remove the wiper arm.

3. Remove the cowl grille.

4. Remove the wiper motor.

5. Remove the cowl panel.

6. For L.H.D. and R.H.D. (MZR-CD (RF Turbo) only), remove the A/C bracket.

7. For L.H.D., remove the ABS (ABS/TCS) HU/CM or DSC HU/CM.

8. For R.H.D. (except MZR-CD (RF Turbo)), remove the alternator cover.

9. For R.H.D. (except MZR-CD (RF Turbo)), remove the insulator.

10. For R.H.D. (except MZR-CD (RF Turbo)), remove the vacuum pipe bracket.

11. Remove in the order indicated in the table.

12. Install in the reverse order of removal.

End Of Sie

VACUUM SWITCH INSPECTION (MZR-CD (RF TURBO))A6E6912663902011. Remove the vacuum hose from the power brake unit.

2. Set the vacuum pump (any commercially

available model) onto the power brake unit as

shown.

3. Turn the ignition switch to ON.

4. Release the parking brake.

5. Apply vacuum to the power brake unit using the

vacuum pump (any commercially available

model) and verify the operating condition of the

brake warning light. The vacuum switch is

functioning normally if it corresponds to the above

specifications.

•If not as specified, replace the vacuum switch.

End Of Sie

CONVENTIONAL BRAKE SYSTEM

1 Vacuum hose

2 Snap pin

3Clevis pin

4Nut

5Fork

6 Power brake unit

7Gasket

8Nut

GREASEGREASE

R

3

4

8

6

2

7

5

1

18.6—25.5

{1.90—2.60, 13.8—18.8}

N·m {kgf·m, ft·lbf}

15.7—21.6

{1.60—2.20,

11.6—15.9}

A6E6912W044

Vacuum

kPa {mm Hg, inHg}Brake warning light

Below 10.7±2.7

{80±20, 3.1±0.8}ON

Above 10.7±2.7

{80±20, 3.1±0.8}OFFA6E6912W204