fuse MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 145 of 909

TROUBLESHOOTING

F1–57

F1

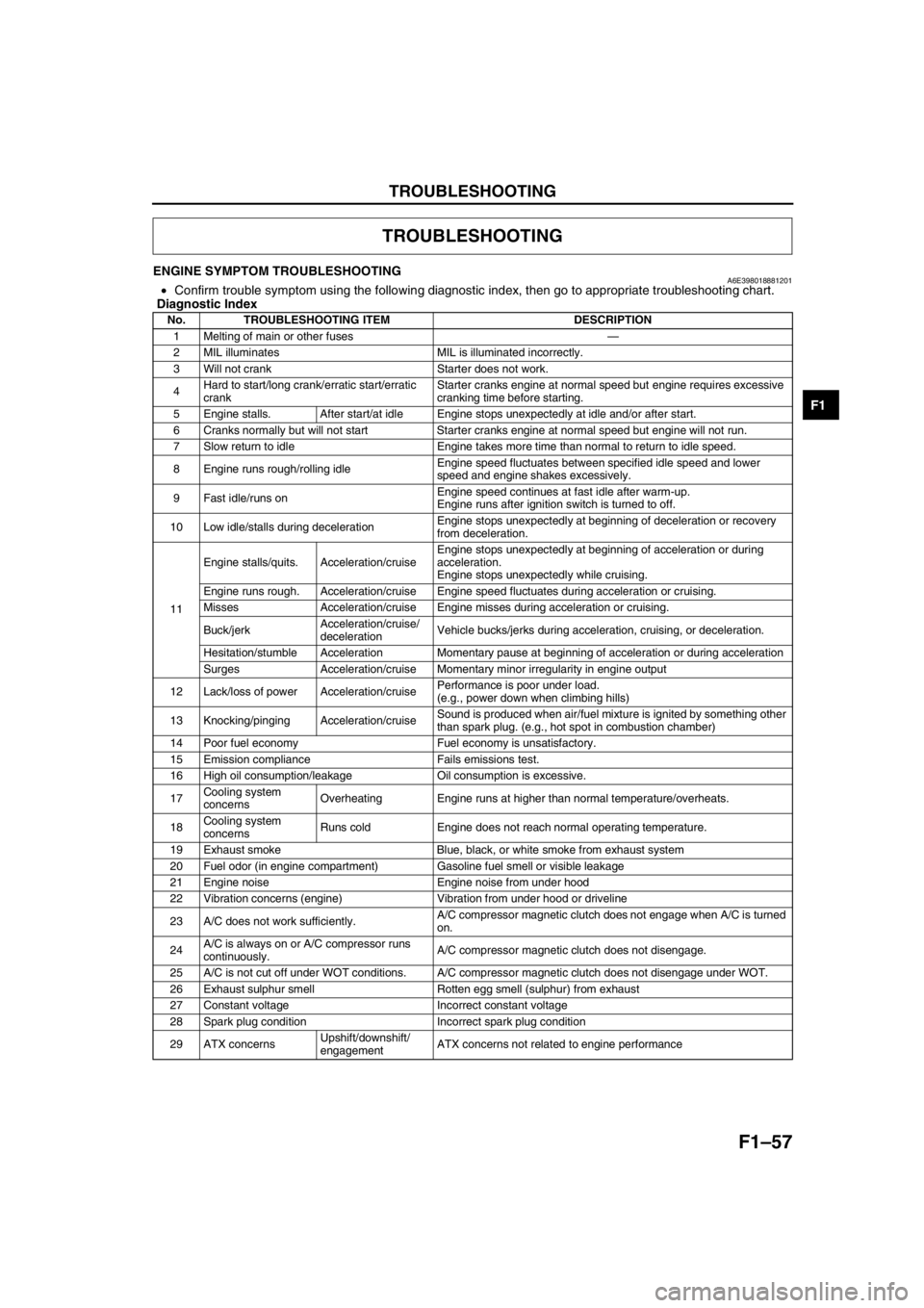

ENGINE SYMPTOM TROUBLESHOOTINGA6E398018881201•Confirm trouble symptom using the following diagnostic index, then go to appropriate troubleshooting chart.

Diagnostic Index

End Of Sie

TROUBLESHOOTING

No. TROUBLESHOOTING ITEM DESCRIPTION

1 Melting of main or other fuses—

2 MIL illuminates MIL is illuminated incorrectly.

3 Will not crank Starter does not work.

4Hard to start/long crank/erratic start/erratic

crankStarter cranks engine at normal speed but engine requires excessive

cranking time before starting.

5 Engine stalls. After start/at idle Engine stops unexpectedly at idle and/or after start.

6 Cranks normally but will not start Starter cranks engine at normal speed but engine will not run.

7 Slow return to idle Engine takes more time than normal to return to idle speed.

8 Engine runs rough/rolling idleEngine speed fluctuates between specified idle speed and lower

speed and engine shakes excessively.

9 Fast idle/runs onEngine speed continues at fast idle after warm-up.

Engine runs after ignition switch is turned to off.

10 Low idle/stalls during decelerationEngine stops unexpectedly at beginning of deceleration or recovery

from deceleration.

11Engine stalls/quits. Acceleration/cruiseEngine stops unexpectedly at beginning of acceleration or during

acceleration.

Engine stops unexpectedly while cruising.

Engine runs rough. Acceleration/cruise Engine speed fluctuates during acceleration or cruising.

Misses Acceleration/cruise Engine misses during acceleration or cruising.

Buck/jerkAcceleration/cruise/

decelerationVehicle bucks/jerks during acceleration, cruising, or deceleration.

Hesitation/stumble Acceleration Momentary pause at beginning of acceleration or during acceleration

Surges Acceleration/cruise Momentary minor irregularity in engine output

12 Lack/loss of power Acceleration/cruisePerformance is poor under load.

(e.g., power down when climbing hills)

13 Knocking/pinging Acceleration/cruiseSound is produced when air/fuel mixture is ignited by something other

than spark plug. (e.g., hot spot in combustion chamber)

14 Poor fuel economy Fuel economy is unsatisfactory.

15 Emission compliance Fails emissions test.

16 High oil consumption/leakage Oil consumption is excessive.

17Cooling system

concernsOverheating Engine runs at higher than normal temperature/overheats.

18Cooling system

concernsRuns cold Engine does not reach normal operating temperature.

19 Exhaust smoke Blue, black, or white smoke from exhaust system

20 Fuel odor (in engine compartment) Gasoline fuel smell or visible leakage

21 Engine noise Engine noise from under hood

22 Vibration concerns (engine) Vibration from under hood or driveline

23 A/C does not work sufficiently.A/C compressor magnetic clutch does not engage when A/C is turned

on.

24A/C is always on or A/C compressor runs

continuously.A/C compressor magnetic clutch does not disengage.

25 A/C is not cut off under WOT conditions. A/C compressor magnetic clutch does not disengage under WOT.

26 Exhaust sulphur smell Rotten egg smell (sulphur) from exhaust

27 Constant voltage Incorrect constant voltage

28 Spark plug condition Incorrect spark plug condition

29 ATX concernsUpshift/downshift/

engagementATX concerns not related to engine performance

Page 146 of 909

F1–58

TROUBLESHOOTING

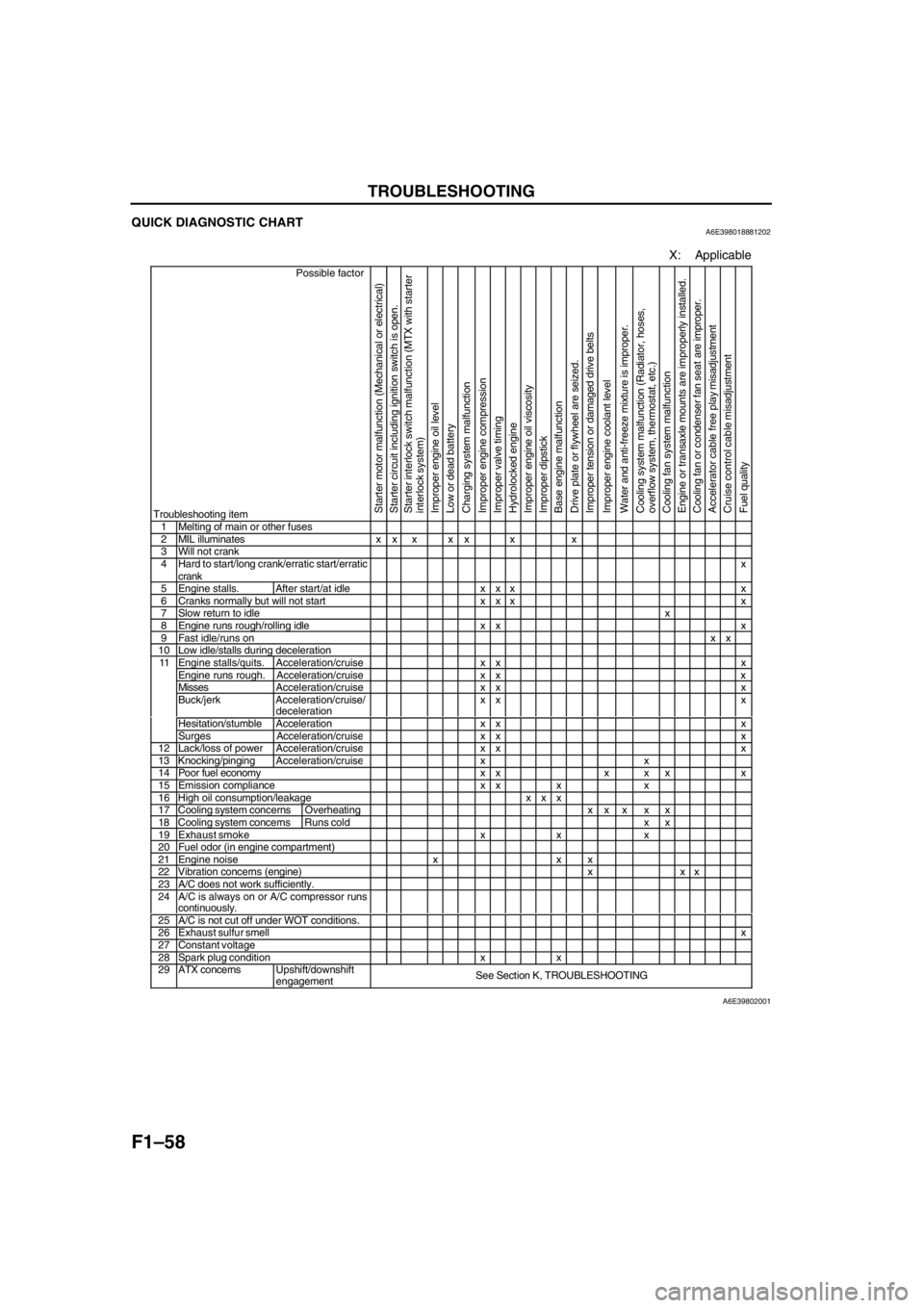

QUICK DIAGNOSTIC CHARTA6E398018881202

X: Applicable

Possible factor

Troubleshooting item

Starter motor malfunction (Mechanical or electrical)

Starter circuit including ignition switch is open.

Starter interlock switch malfunction (MTX with starter

interlock system)

Improper engine oil level

Low or dead battery

Charging system malfunction

Improper engine compression

Improper valve timing

Hydrolocked engine

Improper engine oil viscosity

Improper dipstick

Base engine malfunction

Drive plate or flywheel are seized.

Improper tension or damaged drive belts

Improper engine coolant level

Water and anti-freeze mixture is improper.

Cooling system malfunction (Radiator, hoses,

overflow system, thermostat, etc.)

Cooling fan system malfunction

Engine or transaxle mounts are improperly installed.

Cooling fan or condenser fan seat are improper.

Accelerator cable free play misadjustment

Cruise control cable misadjustment

Fuel quality

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crank4 Hard to start/long crank/erratic start/erratic

crankx

5 Engine stalls. After start/at idle x x x x6 Cranks normally but will not start x x x x7 Slow return to idlex8 Engine runs rough/rolling idle x x x9 Fast idle/runs onxx10 Low idle/stalls during decelerationEngine stalls/quits. Acceleration/cruise x x xEngine runs rough. Acceleration/cruise x x xMissesAcceleration/cruise x x xBuck/jerk Acceleration/cruise/

decelerationxx x

Hesitation/stumble Acceleration x x x

11

Surges Acceleration/cruis

exx x12 Lack/loss of powerAcceleration/cruisexx x13 Knocking/pingingAcceleration/cruisexx14 Poor fuel economy x x x x x x15 Emission compliance x x x x16 High oil consumption/leakage x x x17 Cooling system concerns Overheatingxx x x x18 Cooling system concernsRuns cold x x19 Exhaust smoke x x x20 Fuel odor (in engine compartment)21 Engine noise x x x22 Vibration concerns (engine) x x x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smellx27 Constant voltage28 Spark plug condition x x29 ATX concernsUpshift/downshift

engagementSee Section K, TROUBLESHOOTING

A6E39802001

Page 147 of 909

TROUBLESHOOTING

F1–59

F1

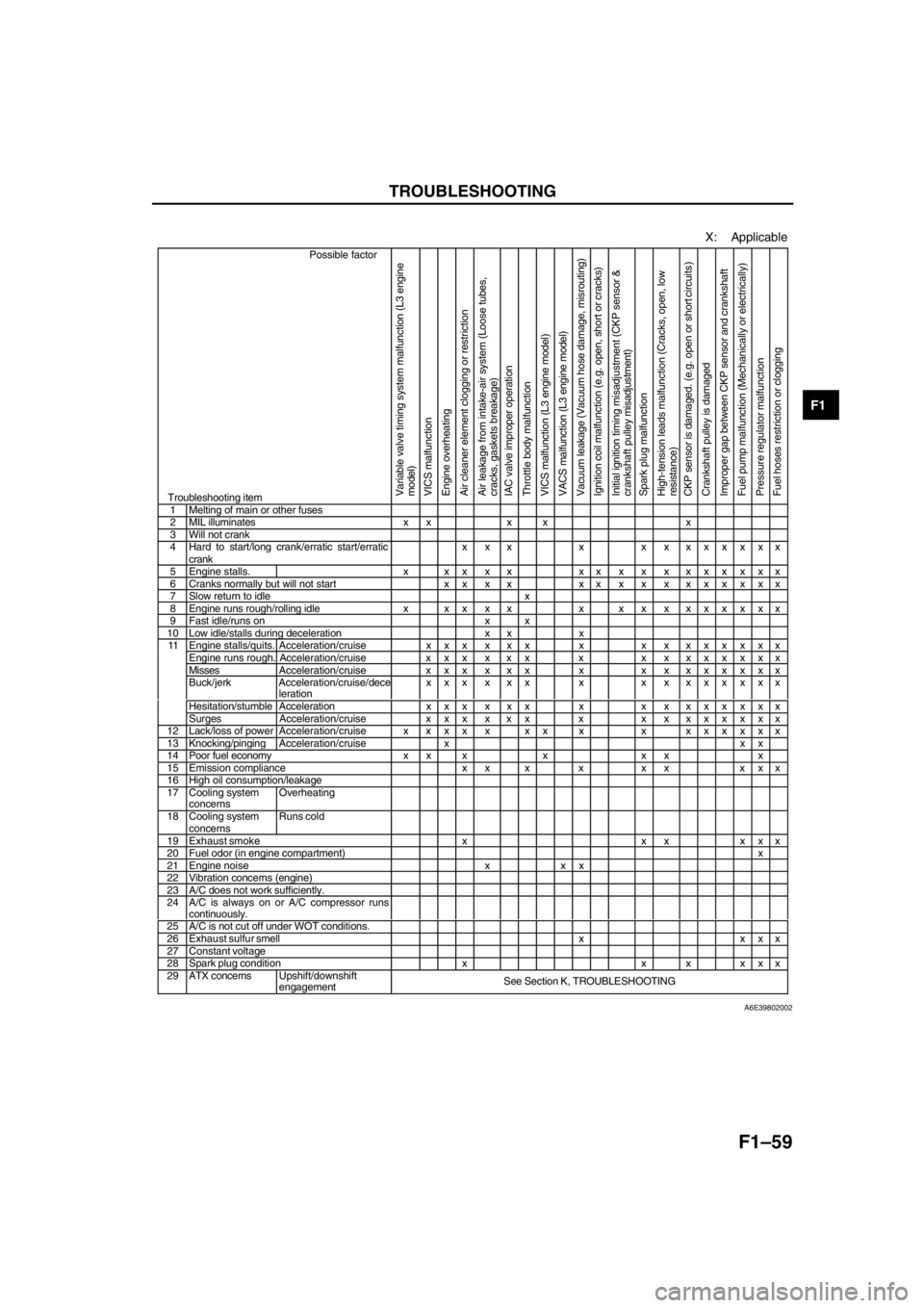

X: Applicable

Possible factor

Troubleshooting itemVariable valve timing system malfunction (L3 engine

model)

VICS malfunction

Engine overheating

Air cleaner element clogging or restriction

Air leakage from intake-air system (Loose tubes,

cracks, gaskets breakage)

IAC valve improper operation

Throttle body malfunction

VICS malfunction (L3 engine model)

VACS malfunction (L3 engine model)

Vacuum leakage (Vacuum hose damage, misrouting)

Ignition coil malfunction (e.g. open, short or cracks)

Initial ignition timing misadjustment (CKP sensor &

crankshaft pulley misadjustment)

Spark plug malfunction

High-tension leads malfunction (Cracks, open, low

resistance)

CKP sensor is damaged. (e.g. open or short circuits )

Crankshaft pulley is damaged

Improper gap between CKP sensor and crankshaft

Fuel pump malfunction (Mechanically or electrically)

Pressure regulator malfunction

Fuel hoses restriction or clogging

1 Melting of main or other fuses2 MIL illuminates x x x x x3 Will not crank4 Hard to start/long crank/erratic start/erratic

crankx x x x x x xxxxxx

5 Engine stalls. x x x x x xxxxxxxxxxx6 Cranks normally but will not start x x x x xxxxxxxxxxx7 Slow return to idle x8 Engine runs rough/rolling idle x x x x x x x x xxxxxxx9 Fast idle/runs on x x10 Low idle/stalls during deceleration x x xEngine stalls/quits. Acceleration/cruise x x x x x x x x xxxxxxxEngine runs rough. Acceleration/cruise x x x x x x x x xxxxxxxMissesAcceleration/cruise x x x x x x x x xxxxxxxBuck/jerk Acceleration/cruise/dece

lerationxxx x xx x x x xxxxxx

Hesitation/stumble Acceleration x x x x x x x x xxxxxxx

11

Surges Acceleration/cruise x x x x x x x x xxxxxxx

12 Lack/loss of powerAcceleration/cruise x x x x x x x x xxxxxxx13 Knocking/pingingAcceleration/cruise x x x14 Poor fuel economy x x x x x x x15 Emission compliance x x x x x x x x x16 High oil consumption/leakage17 Cooling system

concernsOverheating

18 Cooling system

concernsRuns cold

19 Exhaust smoke x x x x x x20 Fuel odor (in engine compartment)x21 Engine noise x x x22 Vibration concerns (engine)23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smell x x x x27 Constant voltage28 Spark plug condition x x x x x x29 ATX concernsUpshift/downshift

engagementSee Section K, TROUBLESHOOTING

A6E39802002

Page 148 of 909

F1–60

TROUBLESHOOTING

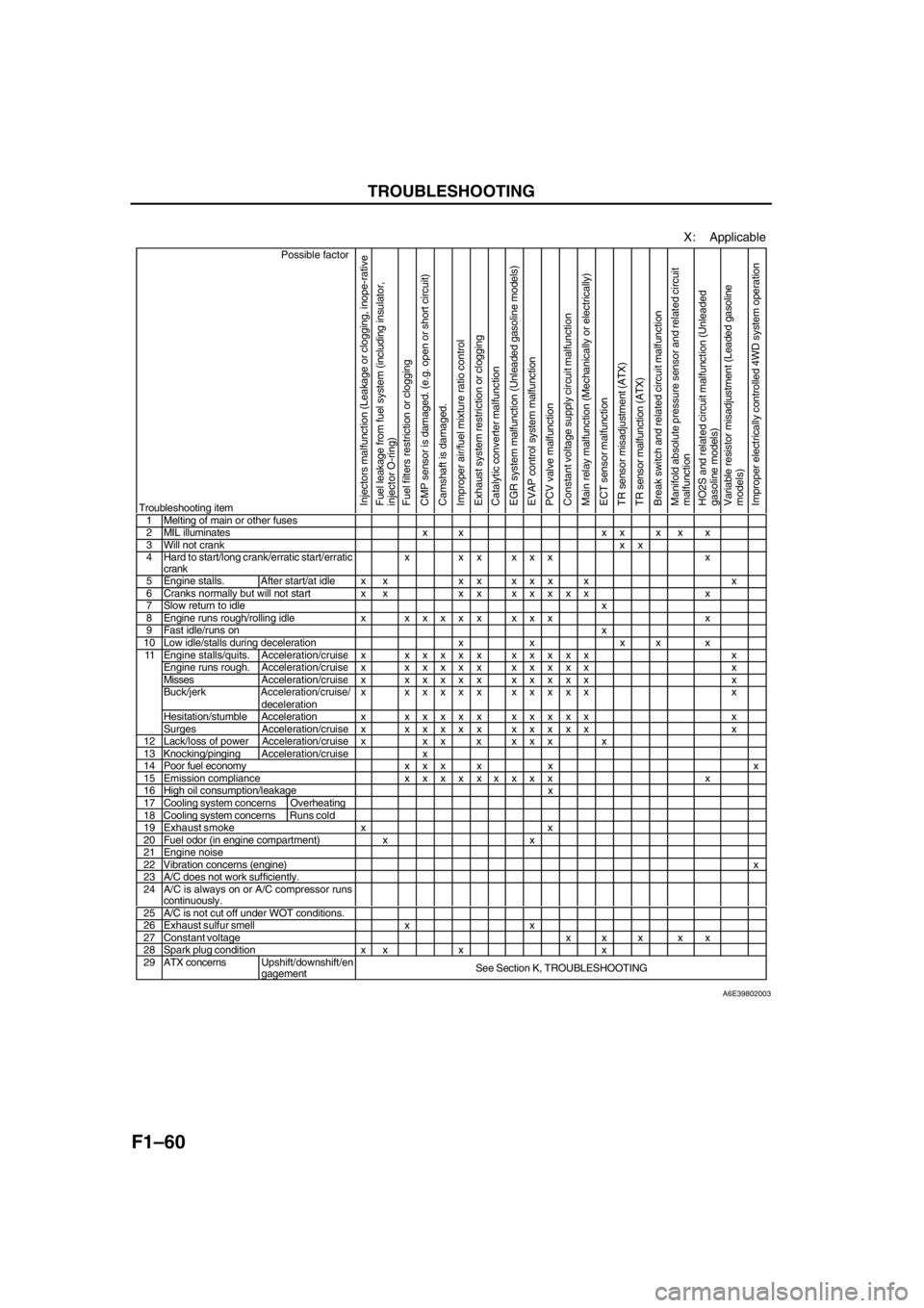

X: Applicable

Possible factor

Troubleshooting item

Injectors malfunction (Leakage or clogging, inope-rative

Fuel leakage from fuel system (including insulator,

injector O-ring)

Fuel filters restriction or clogging

CMP sensor is damaged. (e.g. open or short circuit)

Camshaft is damaged.

Improper air/fuel mixture ratio control

Exhaust system restriction or clogging

Catalytic converter malfunction

EGR system malfunction (Unleaded gasoline models)

EVAP control system malfunction

PCV valve malfunction

Constant voltage supply circuit malfunction

Main relay malfunction (Mechanically or electrically)

ECT sensor malfunction

TR sensor misadjustment (ATX)

TR sensor malfunction (ATX)

Break switch and related circuit malfunction

Manifold absolute pressure sensor and related circuit

malfunction

HO2S and related circuit malfunction (Unleaded

gasoline models)

Variable resistor misadjustment (Leaded gasoline

models)

Improper electrically controlled 4WD system operation

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crankxx4 Hard to start/long crank/erratic start/erratic

crankx xx xxx x

5 Engine stalls. After start/at idle x x x x x x x x x6 Cranks normally but will not start x x x xxxxxx x7 Slow return to idlex8 Engine runs rough/rolling idle xxxxxx xxx x9 Fast idle/runs onx10 Low idle/stalls during deceleration x x x x xEngine stalls/quits.Acceleration/cruisex xxxxx xxxxx xEngine runs rough. Acceleration/cruisex xxxxx xxxxx xMissesAcceleration/cruisex xxxxx xxxxx xBuck/jerk Acceleration/cruise/

decelerationx xxxxx xxxxx x

Hesitation/stumble Acceleration xxxxxx xxxxx x

11

Surges Acceleration/cruise xxxxxx xxxxx x

12 Lack/loss of power Acceleration/cruise x x x x x x x x13 Knocking/pingingAcceleration/cruise x14 Poor fuel economy x x x x x x15 Emission compliancexxxxxxxxx x16 High oil consumption/leakage x17 Cooling system concerns Overheating18 Cooling system concernsRuns cold19 Exhaust smoke x x20 Fuel odor (in engine compartment) x x21 Engine noise22 Vibration concerns (engine)x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smell x x27 Constant voltage x x x x x28 Spark plug condition x x x x29 ATX concernsUpshift/downshift/en

gagementSee Section K, TROUBLESHOOTING

A6E39802003

Page 149 of 909

TROUBLESHOOTING

F1–61

F1

End Of Sie

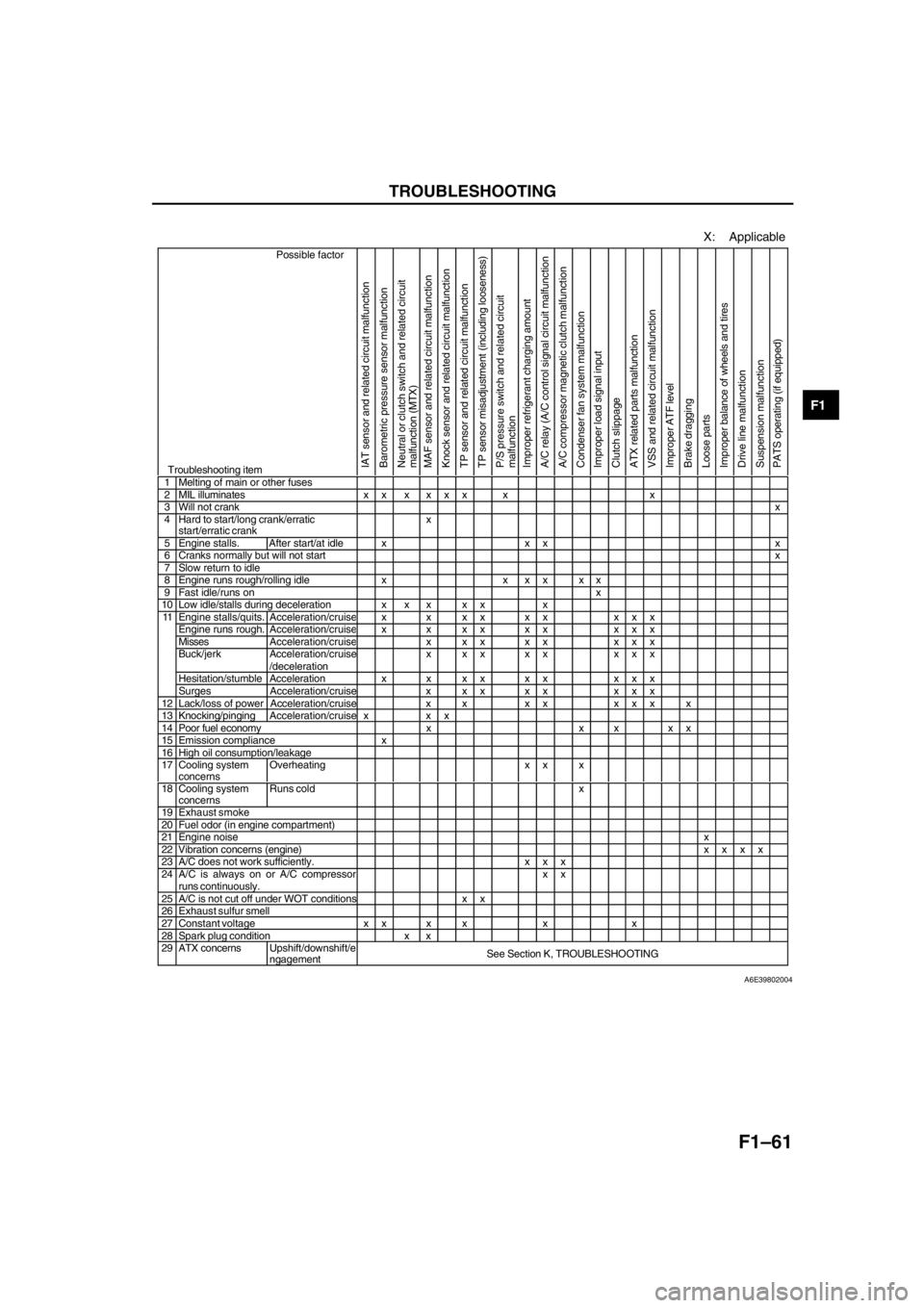

X: Applicable

Possible factor

Troubleshooting itemIAT sensor and related circuit malfunction

Barometric pressure sensor malfunction

Neutral or clutch switch and related circuit

malfunction (MTX)

MAF sensor and related circuit malfunction

Knock sensor and related circuit malfunction

TP sensor and related circuit malfunction

TP sensor misadjustment (including looseness)

P/S pressure switch and related circuit

malfunction

Improper refrigerant charging amount

A/C relay (A/C control signal circuit malfunction

A/C compressor magnetic clutch malfunction

Condenser fan system malfunction

Improper load signal input

Clutch slippage

ATX related parts malfunction

VSS and related circuit malfunction

Improper ATF level

Brake dragging

Loose parts

Improper balance of wheels and tires

Drive line malfunction

Suspension malfunction

PATS operating (if equipped)

1 Melting of main or other fuses2 MIL illuminates x x x x x x x x3 Will not crankx4 Hard to start/long crank/erratic

start/erratic crankx

5 Engine stalls. After start/at idle x x x x6 Cranks normally but will not startx7 Slow return to idle8 Engine runs rough/rolling idle x x x x x x9 Fast idle/runs onx10 Low idle/stalls during deceleration x x x x x xEngine stalls/quits.Acceleration/cruisex x xx xx xxxEngine runs rough. Acceleration/cruisex x xx xx xxxMissesAcceleration/cruisex xx xx xxxBuck/jerk Acceleration/cruise

/decelerationx xx xx xxx

Hesitation/stumble Acceleration x x x x x x x x x

11

Surges Acceleration/cruise x x x x x x x x

12 Lack/loss of power Acceleration/cruise x x x x x x x x13 Knocking/pingingAcceleration/cruise x x x14 Poor fuel economy x x x x x15 Emission compliance x16 High oil consumption/leakage17 Cooling system

concernsOverheating x x x

18 Cooling system

concernsRuns cold x

19 Exhaust smoke20 Fuel odor (in engine compartment)21 Engine noisex22 Vibration concerns (engine)xxxx23 A/C does not work sufficiently. x x x24 A/C is always on or A/C compressorruns continuously.xx25 A/C is not cut off under WOT conditions x x26 Exhaust sulfur smell27 Constant voltage x x x x x x28 Spark plug condition x x29 ATX concernsUpshift/downshift/e

ngagementSee Section K, TROUBLESHOOTING

A6E39802004

Page 154 of 909

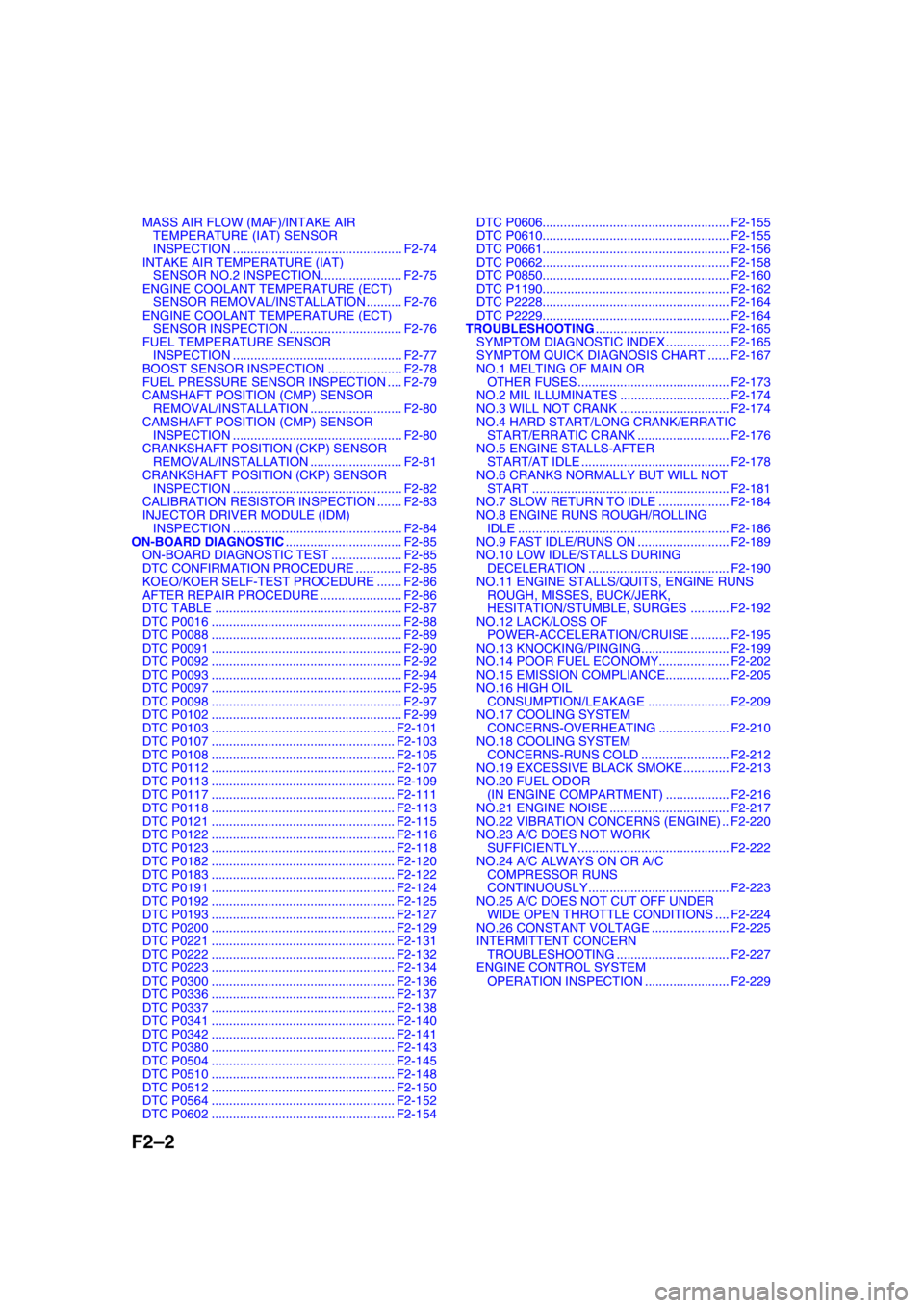

F2–2

MASS AIR FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT) SENSOR

INSPECTION ................................................ F2-74

INTAKE AIR TEMPERATURE (IAT)

SENSOR NO.2 INSPECTION....................... F2-75

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR REMOVAL/INSTALLATION .......... F2-76

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR INSPECTION ................................ F2-76

FUEL TEMPERATURE SENSOR

INSPECTION ................................................ F2-77

BOOST SENSOR INSPECTION ..................... F2-78

FUEL PRESSURE SENSOR INSPECTION .... F2-79

CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION .......................... F2-80

CAMSHAFT POSITION (CMP) SENSOR

INSPECTION ................................................ F2-80

CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION .......................... F2-81

CRANKSHAFT POSITION (CKP) SENSOR

INSPECTION ................................................ F2-82

CALIBRATION RESISTOR INSPECTION ....... F2-83

INJECTOR DRIVER MODULE (IDM)

INSPECTION ................................................ F2-84

ON-BOARD DIAGNOSTIC................................. F2-85

ON-BOARD DIAGNOSTIC TEST .................... F2-85

DTC CONFIRMATION PROCEDURE ............. F2-85

KOEO/KOER SELF-TEST PROCEDURE ....... F2-86

AFTER REPAIR PROCEDURE ....................... F2-86

DTC TABLE ..................................................... F2-87

DTC P0016 ...................................................... F2-88

DTC P0088 ...................................................... F2-89

DTC P0091 ...................................................... F2-90

DTC P0092 ...................................................... F2-92

DTC P0093 ...................................................... F2-94

DTC P0097 ...................................................... F2-95

DTC P0098 ...................................................... F2-97

DTC P0102 ...................................................... F2-99

DTC P0103 .................................................... F2-101

DTC P0107 .................................................... F2-103

DTC P0108 .................................................... F2-105

DTC P0112 .................................................... F2-107

DTC P0113 .................................................... F2-109

DTC P0117 .................................................... F2-111

DTC P0118 .................................................... F2-113

DTC P0121 .................................................... F2-115

DTC P0122 .................................................... F2-116

DTC P0123 .................................................... F2-118

DTC P0182 .................................................... F2-120

DTC P0183 .................................................... F2-122

DTC P0191 .................................................... F2-124

DTC P0192 .................................................... F2-125

DTC P0193 .................................................... F2-127

DTC P0200 .................................................... F2-129

DTC P0221 .................................................... F2-131

DTC P0222 .................................................... F2-132

DTC P0223 .................................................... F2-134

DTC P0300 .................................................... F2-136

DTC P0336 .................................................... F2-137

DTC P0337 .................................................... F2-138

DTC P0341 .................................................... F2-140

DTC P0342 .................................................... F2-141

DTC P0380 .................................................... F2-143

DTC P0504 .................................................... F2-145

DTC P0510 .................................................... F2-148

DTC P0512 .................................................... F2-150

DTC P0564 .................................................... F2-152

DTC P0602 .................................................... F2-154DTC P0606..................................................... F2-155

DTC P0610..................................................... F2-155

DTC P0661..................................................... F2-156

DTC P0662..................................................... F2-158

DTC P0850..................................................... F2-160

DTC P1190..................................................... F2-162

DTC P2228..................................................... F2-164

DTC P2229..................................................... F2-164

TROUBLESHOOTING...................................... F2-165

SYMPTOM DIAGNOSTIC INDEX .................. F2-165

SYMPTOM QUICK DIAGNOSIS CHART ...... F2-167

NO.1 MELTING OF MAIN OR

OTHER FUSES ........................................... F2-173

NO.2 MIL ILLUMINATES ............................... F2-174

NO.3 WILL NOT CRANK ............................... F2-174

NO.4 HARD START/LONG CRANK/ERRATIC

START/ERRATIC CRANK .......................... F2-176

NO.5 ENGINE STALLS-AFTER

START/AT IDLE .......................................... F2-178

NO.6 CRANKS NORMALLY BUT WILL NOT

START ........................................................ F2-181

NO.7 SLOW RETURN TO IDLE .................... F2-184

NO.8 ENGINE RUNS ROUGH/ROLLING

IDLE ............................................................ F2-186

NO.9 FAST IDLE/RUNS ON .......................... F2-189

NO.10 LOW IDLE/STALLS DURING

DECELERATION ........................................ F2-190

NO.11 ENGINE STALLS/QUITS, ENGINE RUNS

ROUGH, MISSES, BUCK/JERK,

HESITATION/STUMBLE, SURGES ........... F2-192

NO.12 LACK/LOSS OF

POWER-ACCELERATION/CRUISE ........... F2-195

NO.13 KNOCKING/PINGING......................... F2-199

NO.14 POOR FUEL ECONOMY.................... F2-202

NO.15 EMISSION COMPLIANCE.................. F2-205

NO.16 HIGH OIL

CONSUMPTION/LEAKAGE ....................... F2-209

NO.17 COOLING SYSTEM

CONCERNS-OVERHEATING .................... F2-210

NO.18 COOLING SYSTEM

CONCERNS-RUNS COLD ......................... F2-212

NO.19 EXCESSIVE BLACK SMOKE ............. F2-213

NO.20 FUEL ODOR

(IN ENGINE COMPARTMENT) .................. F2-216

NO.21 ENGINE NOISE .................................. F2-217

NO.22 VIBRATION CONCERNS (ENGINE) .. F2-220

NO.23 A/C DOES NOT WORK

SUFFICIENTLY ........................................... F2-222

NO.24 A/C ALWAYS ON OR A/C

COMPRESSOR RUNS

CONTINUOUSLY........................................ F2-223

NO.25 A/C DOES NOT CUT OFF UNDER

WIDE OPEN THROTTLE CONDITIONS .... F2-224

NO.26 CONSTANT VOLTAGE ...................... F2-225

INTERMITTENT CONCERN

TROUBLESHOOTING ................................ F2-227

ENGINE CONTROL SYSTEM

OPERATION INSPECTION ........................ F2-229

Page 192 of 909

F2–40

INTAKE-AIR SYSTEM

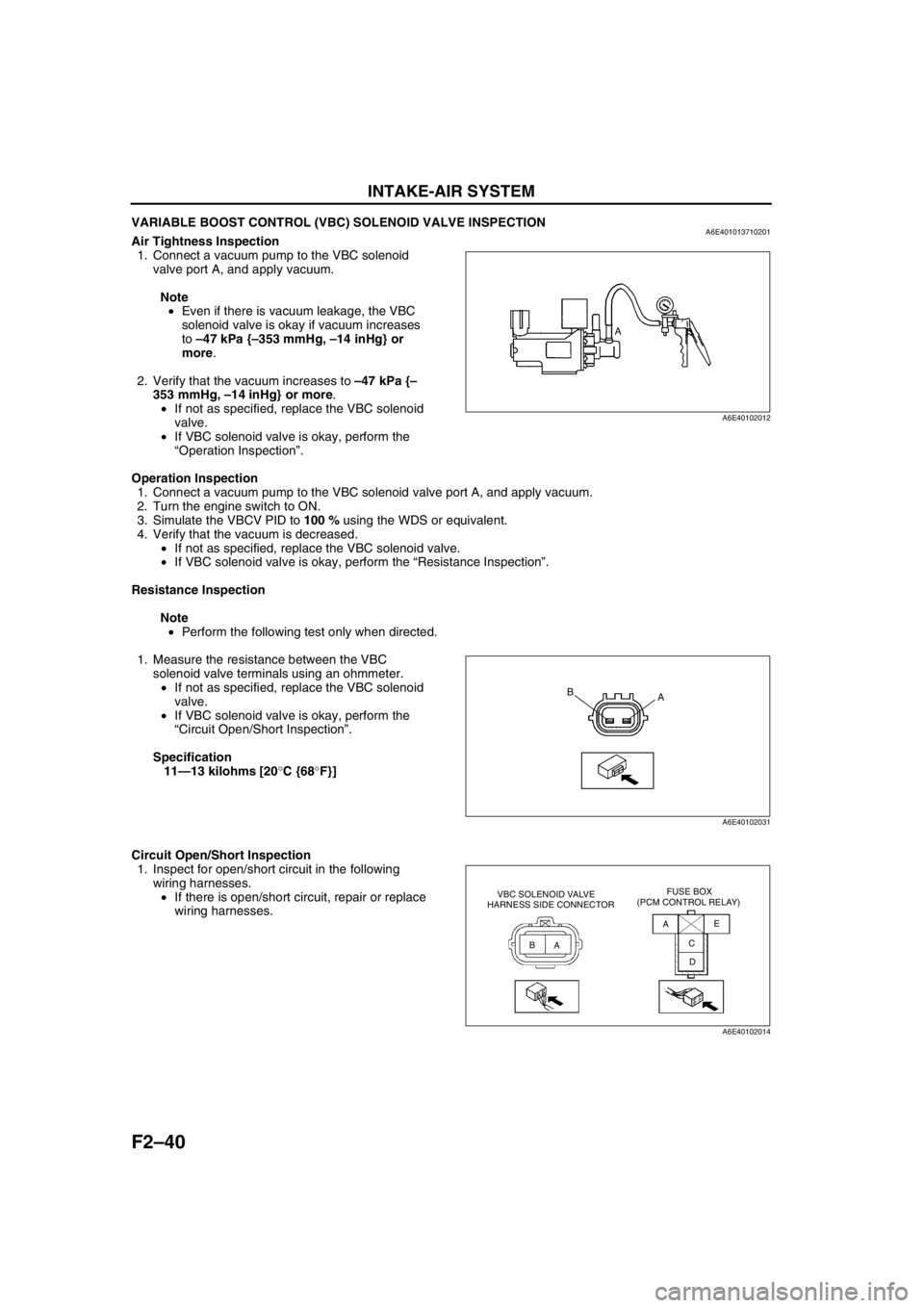

VARIABLE BOOST CONTROL (VBC) SOLENOID VALVE INSPECTIONA6E401013710201Air Tightness Inspection

1. Connect a vacuum pump to the VBC solenoid

valve port A, and apply vacuum.

Note

•Even if there is vacuum leakage, the VBC

solenoid valve is okay if vacuum increases

to –47 kPa {–353 mmHg, –14 inHg} or

more.

2. Verify that the vacuum increases to –47 kPa {–

353 mmHg, –14 inHg} or more.

•If not as specified, replace the VBC solenoid

valve.

•If VBC solenoid valve is okay, perform the

“Operation Inspection”.

Operation Inspection

1. Connect a vacuum pump to the VBC solenoid valve port A, and apply vacuum.

2. Turn the engine switch to ON.

3. Simulate the VBCV PID to 100 % using the WDS or equivalent.

4. Verify that the vacuum is decreased.

•If not as specified, replace the VBC solenoid valve.

•If VBC solenoid valve is okay, perform the “Resistance Inspection”.

Resistance Inspection

Note

•Perform the following test only when directed.

1. Measure the resistance between the VBC

solenoid valve terminals using an ohmmeter.

•If not as specified, replace the VBC solenoid

valve.

•If VBC solenoid valve is okay, perform the

“Circuit Open/Short Inspection”.

Specification

11—13 kilohms [20°C {68°F}]

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

A

A6E40102012

A B

A6E40102031

AA

BC

DE VBC SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

A6E40102014

Page 194 of 909

F2–42

INTAKE-AIR SYSTEM

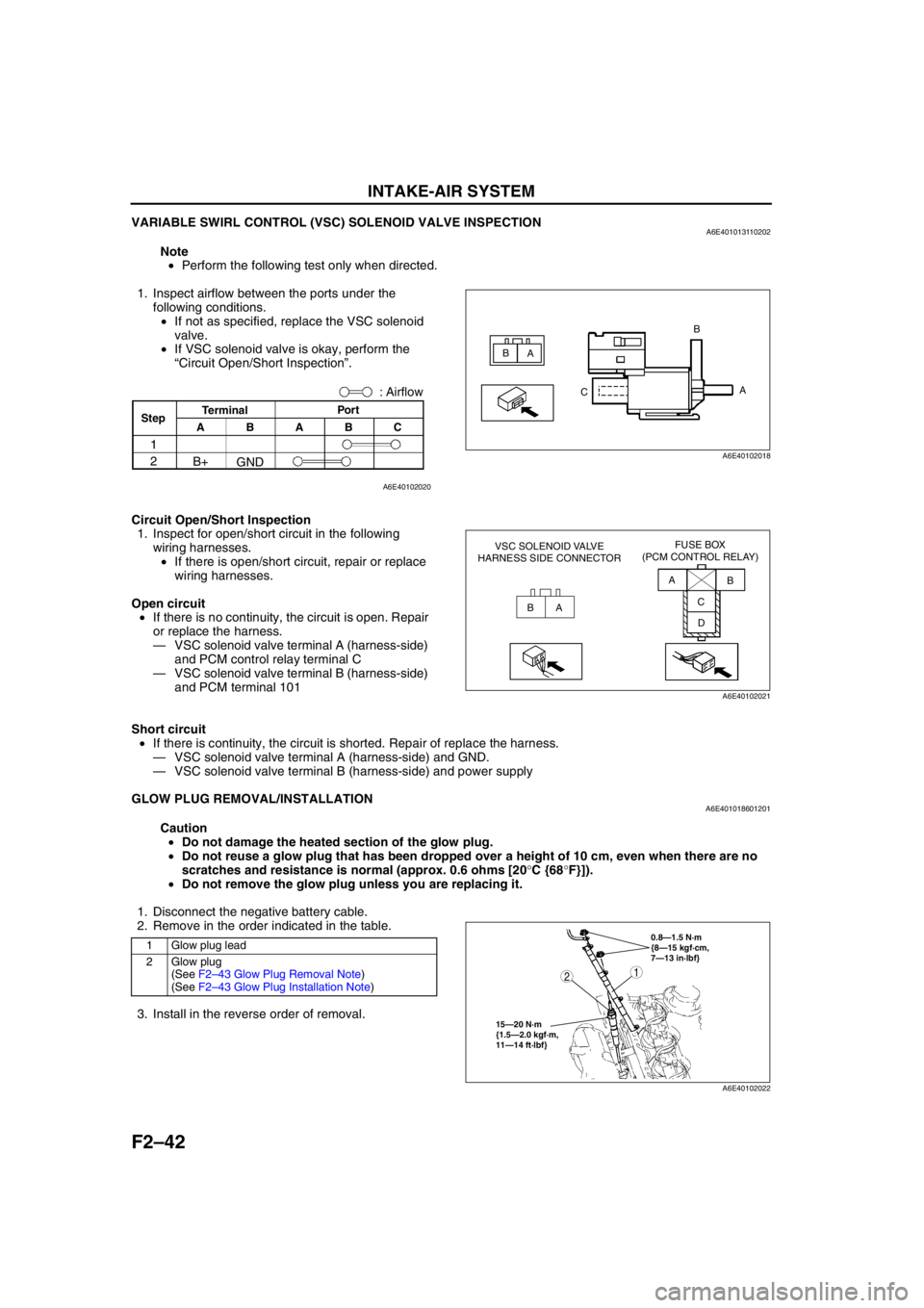

VARIABLE SWIRL CONTROL (VSC) SOLENOID VALVE INSPECTIONA6E401013110202

Note

•Perform the following test only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the VSC solenoid

valve.

•If VSC solenoid valve is okay, perform the

“Circuit Open/Short Inspection”.

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—VSC solenoid valve terminal A (harness-side)

and PCM control relay terminal C

—VSC solenoid valve terminal B (harness-side)

and PCM terminal 101

Short circuit

•If there is continuity, the circuit is shorted. Repair of replace the harness.

—VSC solenoid valve terminal A (harness-side) and GND.

—VSC solenoid valve terminal B (harness-side) and power supply

End Of Sie

GLOW PLUG REMOVAL/INSTALLATIONA6E401018601201

Caution

•Do not damage the heated section of the glow plug.

•Do not reuse a glow plug that has been dropped over a height of 10 cm, even when there are no

scratches and resistance is normal (approx. 0.6 ohms [20°C {68°F}]).

•Do not remove the glow plug unless you are replacing it.

1. Disconnect the negative battery cable.

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

A

A B

B

C

A6E40102018

: Airflow

Por t

C B

A

GND B+

ABTerminal

Step

1

2

A6E40102020

BAA

B

C

D VSC SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

A6E40102021

1 Glow plug lead

2Glow plug

(See F2–43 Glow Plug Removal Note)

(See F2–43 Glow Plug Installation Note)0.8—1.5 N·m

{8—15 kgf·cm,

7—13 in·lbf}

15—20 N·m

{1.5—2.0 kgf·m,

11—14 ft·lbf}

12

A6E40102022

Page 212 of 909

F2–60

EMISSION SYSTEM

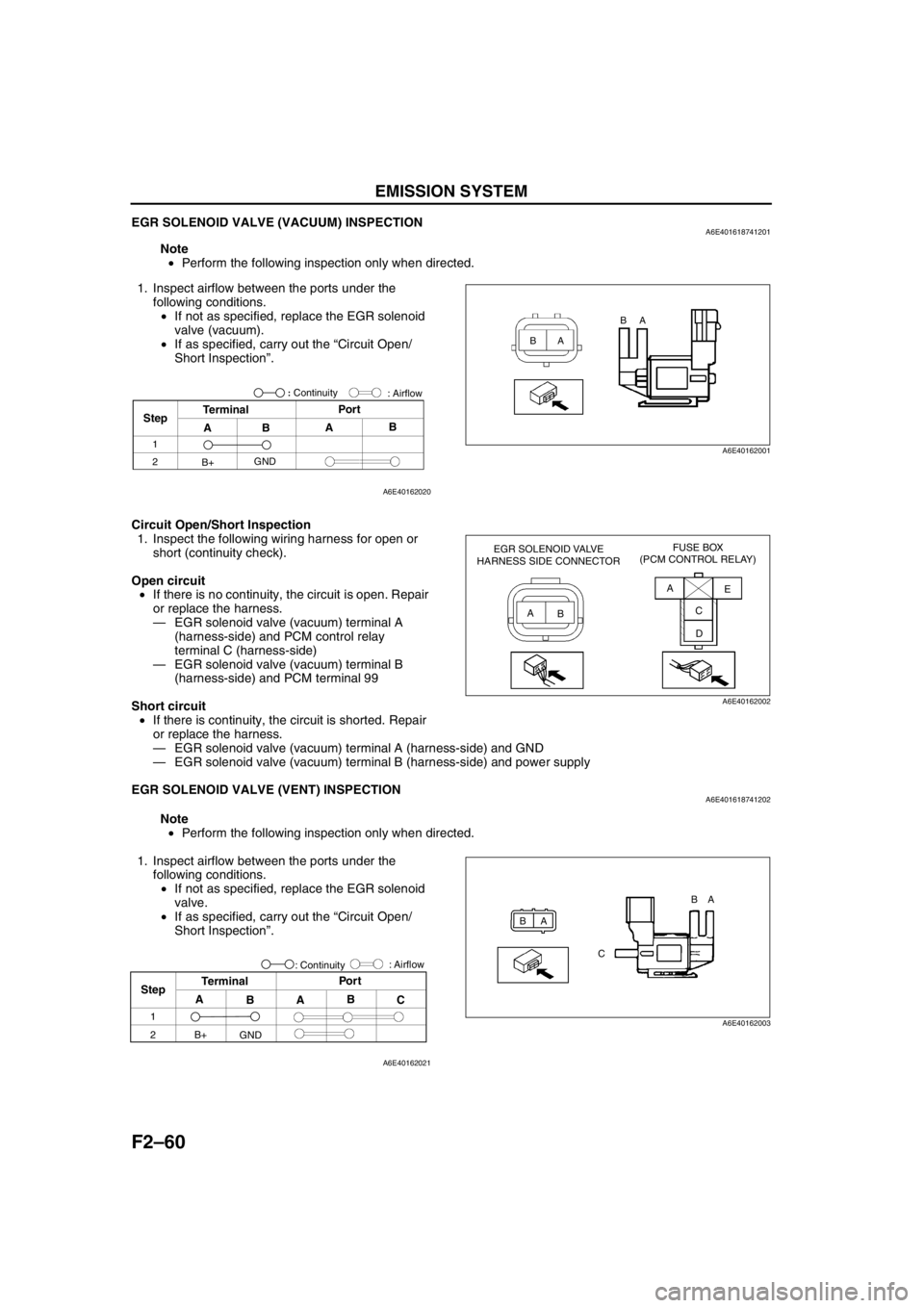

EGR SOLENOID VALVE (VACUUM) INSPECTIONA6E401618741201

Note

•Perform the following inspection only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the EGR solenoid

valve (vacuum).

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Circuit Open/Short Inspection

1. Inspect the following wiring harness for open or

short (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—EGR solenoid valve (vacuum) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—EGR solenoid valve (vacuum) terminal B

(harness-side) and PCM terminal 99

Short circuit

•If there is continuity, the circuit is shorted. Repair

or replace the harness.

—EGR solenoid valve (vacuum) terminal A (harness-side) and GND

—EGR solenoid valve (vacuum) terminal B (harness-side) and power supply

End Of Sie

EGR SOLENOID VALVE (VENT) INSPECTIONA6E401618741202

Note

•Perform the following inspection only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the EGR solenoid

valve.

•If as specified, carry out the “Circuit Open/

Short Inspection”.

BAA B

A6E40162001

StepTerminal

ABAB Por t

1

2

B+GND: Airflow

: Continuity

A6E40162020

EGR SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

A

BA

E

C

D

A6E40162002

BA

CBA

A6E40162003

Step

1

2

A

BAB

C Por t

Terminal

: Airflow

B+

GND: Continuity

A6E40162021

Page 213 of 909

EMISSION SYSTEM

F2–61

F2

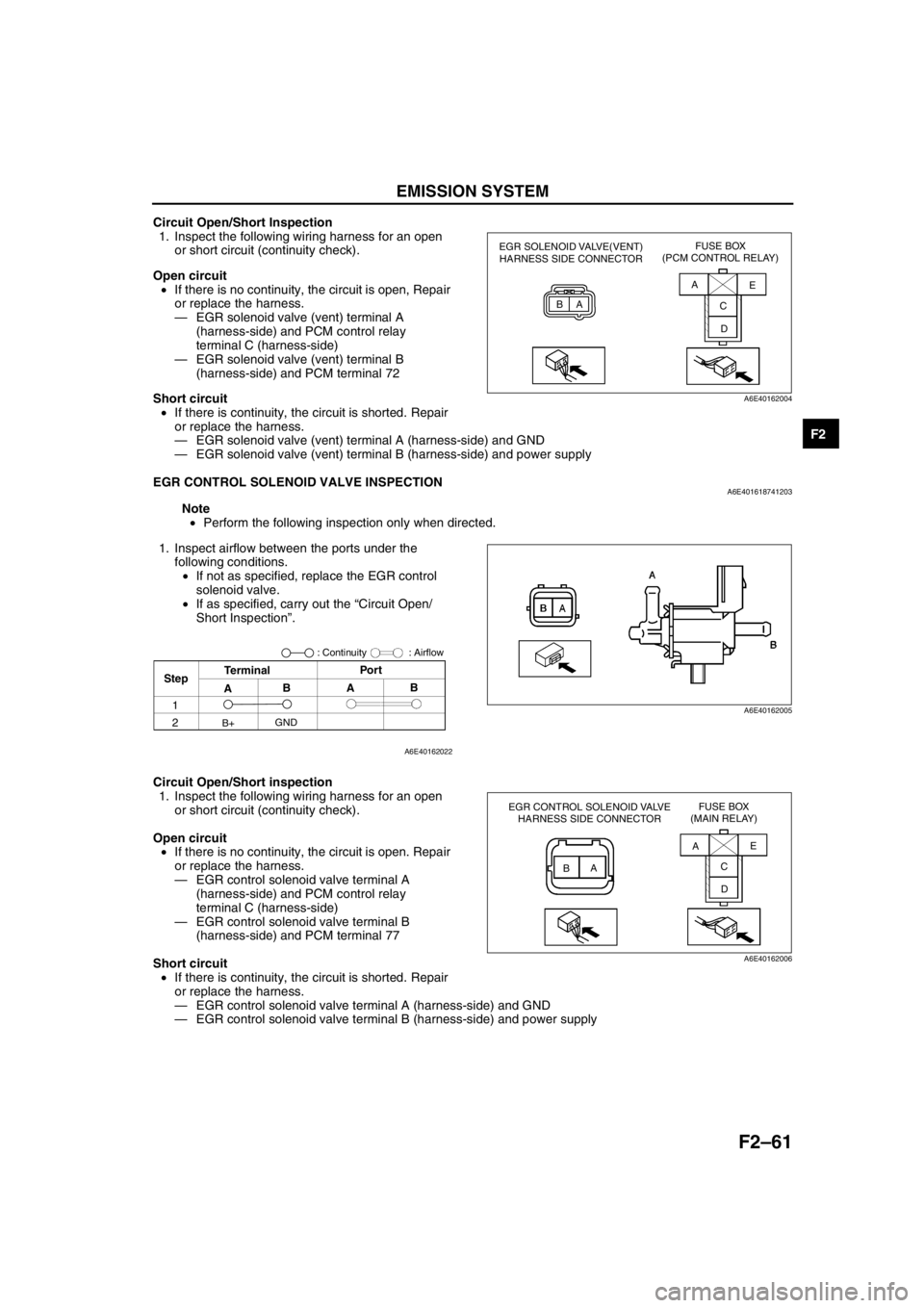

Circuit Open/Short Inspection

1. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open, Repair

or replace the harness.

—EGR solenoid valve (vent) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—EGR solenoid valve (vent) terminal B

(harness-side) and PCM terminal 72

Short circuit

•If there is continuity, the circuit is shorted. Repair

or replace the harness.

—EGR solenoid valve (vent) terminal A (harness-side) and GND

—EGR solenoid valve (vent) terminal B (harness-side) and power supply

End Of Sie

EGR CONTROL SOLENOID VALVE INSPECTIONA6E401618741203

Note

•Perform the following inspection only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the EGR control

solenoid valve.

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Circuit Open/Short inspection

1. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—EGR control solenoid valve terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—EGR control solenoid valve terminal B

(harness-side) and PCM terminal 77

Short circuit

•If there is continuity, the circuit is shorted. Repair

or replace the harness.

—EGR control solenoid valve terminal A (harness-side) and GND

—EGR control solenoid valve terminal B (harness-side) and power supply

End Of Sie

EGR SOLENOID VALVE(VENT)

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

BAA

C

DE

A6E40162004

B

AA

B

A6E40162005

StepTerminalPor t

: Airflow

ABAB

GND

B+

1

2

: Continuity

A6E40162022

EGR CONTROL SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(MAIN RELAY)

BAAE

C

D

A6E40162006