oil type MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 33 of 909

B2–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E230202000201•MZR-CD (RF Turbo) engine is newly adopted as Mazda6 (GG, GY).

•The construction of MZR-CD (RF Turbo) engine and operation which were newly adopted for the Mazda6 (GG,

GY) are the same as the current Mazda MPV(LW) MZR-CD (RF Turbo) engine model and current Mazda 323

(BJ) RF Turbo engine model except for the following components. (See Mazda MPV Workshop Manual

Supplement 1737-1*-02C.), (See Mazda 323 Workshop Manual Supplement 1633-10-98G.)

—Engine mount

•The construction and the operation of the engine mount for the new Mazda6 (GG, GY) MZR-CD (RF Turbo)

engine model is the same as the current Mazda6 (GG). (See Mazda6 Training Manual 3359-1*-02C)

End Of Sie

FEATURESA6E230202000202Improved engine performance

•Coated pistons have been adopted.

Reduced engine noise and vibration

•An aluminium alloy oil pan upper block has been adopted.

•An eight counter weight crankshaft has been adopted.

•A crankshaft pulley cover has been adopted.

•An engine cover with insulator has been adopted.

•A pendulum type engine mount has been adopted.

Improved serviceability

•A serpentine type drive belt has been adopted.

•An auto tensioner that automatically adjusts the drive belt tension has been adopted.

Improved design

•An engine cover has been adopted.

End Of Sie

SPECIFICATIONSA6E230202000203

End Of Sie

OUTLINE

ItemSpecifications

New Mazda6 (GG, GY) Current Mazda MPV (LW)

MZR-CD (RF Turbo) MZR-CD (RF Turbo)

TypeDiesel, 4-cycle

Cylinder arrangement and number In-line, 4-cylinder

Combustion chamber Direct injection

Valve system SOHC, belt-driven, 16-valve

Displacement (ml {cc, cu in}) 1,998 {1.998, 122.9}

Bore × stroke (mm {in}) 86.0 × 86.0 {3.39 × 3.39}

Compression ratio 18.4

Compression pressure

(kPa {kgf/cm

2, psi} [rpm])3,500 {35.7, 507.7} [250]

Valve timingINOpen BTDC (°)6

Close ABDC (°)30

EXOpen BBDC (°)41

Close ATDC (°)8

Valve clearance

[engine cold]IN (mm {in}) 0.12 —0.18 {0.005—0.007} (0.15±0.03 {0.006±0.0011})

EX (mm {in}) 0.32—0.38 {0.013—0.014} (0.35±0.03 {0.014±0.0011})

Page 66 of 909

D–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E330202000201•The construction and the operation of the oil cooler and the oil filter for the new Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model is the same as the current Mazda MPV (LW) MZR-CD (RF Turbo) engine model. (See

Mazda MPV Workshop Manual Supplement 1737-1*-02D.)

•The construction and the operation of the lubrication system except for the oil cooler and oil filter for the new

Mazda6 (GG, GY) MZR-CD (RF Turbo) engine model is the same as the current Mazda 626, 626 Station

Wagon (GF, GW) RF Turbo engine model. (European specs.) (See Mazda 626, 626 Station Wagon RF Turbo

Workshop Manual Supplement 1614-10-98D.)

•The construction and the operation of the lubrication system for the new Mazda6 (GG, GY) L8, LF, and L3

engine models is the same as the current Mazda6 (GG) engine model L8, LF, and L3 engine models. (See

Mazda6 Training Manual 3359-1*-02C, Mazda6 Workshop Manual 1730-1*-02C.)

End Of Sie

SPECIFICATIONSA6E330202000202Gasoline engine

* : Always verify the oil level with the dipsticks since the engine oil capacity differs according to dipstick

specifications. (See Mazda6 Workshop Manual 1730-1*-02C Section D.)

Recommended Engine Oil (Gasoline Engine)

•The maintenance intervals on the scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

OUTLINE

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3*

Lubrication system Force-fed type

Oil coolerWater-cooled

Oil pressure

(approximate quantity)

[oil temperature: 100°C

{212°F}](kPa {kgf/cm

2, psi})

min [rpm]234—521

{2.39—5.31, 33.9—75.5}

[3,000]395—649

{4.03—6.61,

57.3—94.1}

[3,000]

Oil pumpType Trochoid gear type

Relief pressure

(approximate

quantity) (kPa {kgf/cm

2,

psi})500—600

{5.09—6.11, 72.6—87.0}

Oil filterType Full-flow, Paper element

Bypass pressure

(approximate

quantity)(kPa kgf/cm

2, psi})80—120

{0.9—1.2, 12.8—17.0}

Oil capacity

(approximate

quantity)Total

(dry engine)(L {US qt, lmp qt}) 4.6 {4.8, 4.0} Dipstick A: 4.2 {4.4, 3.7}

Dipstick B: 5.1 {5.4, 4.5}

Oil replacement (L {US qt, lmp qt}) 3.9 {4.0, 3.4} Dipstick A: 3.1 {3.3, 2.7}

Dipstick B: 4.0 {4.2, 3.5}

Oil and oil filter

replacement(L {US qt, lmp qt}) 4.3 {4.5, 3.8} Dipstick A: 3.5 {3.7, 3.1}

Dipstick B: 4.4 {4.6, 3.9}

ItemSpecification

New Mazda6

(GG, GY), Current Mazda6

(GG)New Mazda6

(GG, GY), Current Mazda6

(GG)

L8, LF, L3

Engine oil GradeAPI SL

ACEA A3

Viscosity (SAE) 5W-30, 10W-40 5W-20

RemarksMazda genuine Dexelia oil e.g. —

Page 67 of 909

OUTLINE

D–3

D

Diesel engine

Bold frames: New specifications

Recommended Engine Oil (Diesel Engine)

•The maintenance intervals on the scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Bold frames: New specifications

End Of Sie

ItemSpecification

New Mazda6

(GG, GY)Current

Mazda 626, 626

Station Wagon

(GF, GW)Current

Mazda MPV

(LW)

MZR-CD (RF Turbo) RF TurboMZR-CD (RF

Turbo)

Lubrication system Force-fed type—

Oil cooler Water-cooled—

Oil pressure

(approximate quantity)

[oil temperature: 100°C {212°F}](kPa {kgf/cm

2, psi})

min [rpm]147 {1.5, 21} [1,000],

343 {3.5, 50} [3,000]—

Oil pumpType Trochoid gear type—Trochoid gear type

Relief pressure

(approximate

quantity)(kPa {kgf/cm

2, psi})

[rpm]580—700

{5.9—7.1,

84.1—101.5}

[3,000]—580—700

{5.9—7.1,

84.1—101.5}

[3,000]

Oil filterTypeFull-flow,

Paper element—Full-flow,

Paper element

Bypass pressure

(approximate

quantity)(kPa kgf/cm

2, psi})78—118

{0.8—1.2,

11.3—17.1} —78—118

{0.8—1.2,

11.3—17.1}

Oil capacity

(approximate

quantity)Total

(dry engine)(L {US qt, lmp qt}) 5.5 {5.8, 4.8} 5.4 {5.7, 4.8} —

Oil replacement (L {US qt, lmp qt}) 4.8 {5.1, 4.2} 4.5 {4.8, 4.0}—

Oil and oil filter

replacement(L {US qt, lmp qt}) 5.0 {5.3 ,4.4} 4.7 {5.0, 4.1} —

ItemSpecification

New Mazda6

(GG, GY)Current

Mazda 626, 626

Station Wagon

(GF, GW)

MZR-CD (RF Turbo) RF Turbo

Engine oil GradeAPI CF CD, CE, CF-4 CD

ACEA B1 or B3 B3 B3 or B4—

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30 5W-30, 10W-30

RemarksMazda genuine

Dexelia oil e.g.——

Page 72 of 909

D–8

ENGINE OIL

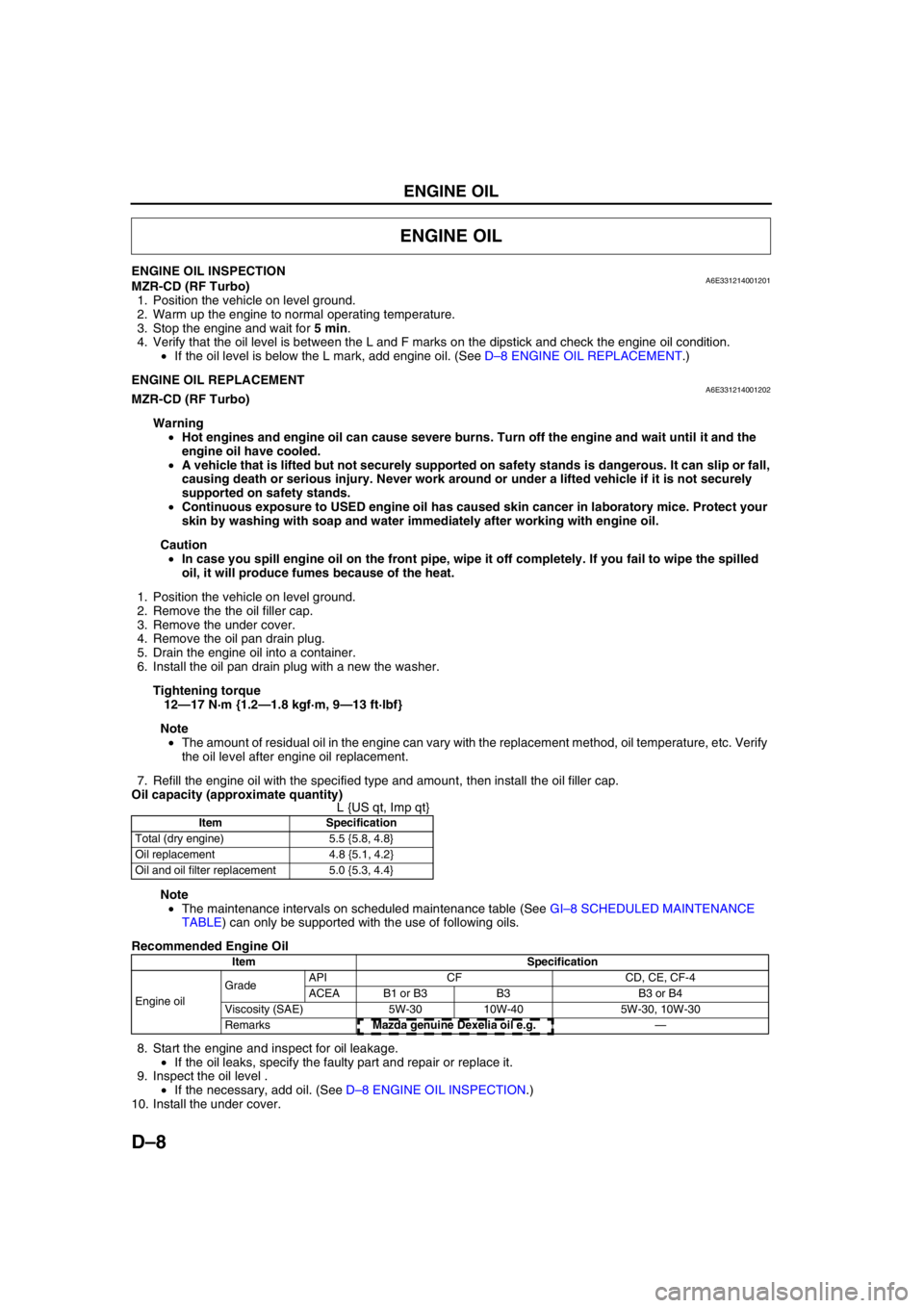

ENGINE OIL INSPECTIONA6E331214001201MZR-CD (RF Turbo)

1. Position the vehicle on level ground.

2. Warm up the engine to normal operating temperature.

3. Stop the engine and wait for 5 min.

4. Verify that the oil level is between the L and F marks on the dipstick and check the engine oil condition.

•If the oil level is below the L mark, add engine oil. (See D–8 ENGINE OIL REPLACEMENT.)

End Of SieENGINE OIL REPLACEMENTA6E331214001202MZR-CD (RF Turbo)

Warning

•Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

•A vehicle that is lifted but not securely supported on safety stands is dangerous. It can slip or fall,

causing death or serious injury. Never work around or under a lifted vehicle if it is not securely

supported on safety stands.

•Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after working with engine oil.

Caution

•In case you spill engine oil on the front pipe, wipe it off completely. If you fail to wipe the spilled

oil, it will produce fumes because of the heat.

1. Position the vehicle on level ground.

2. Remove the the oil filler cap.

3. Remove the under cover.

4. Remove the oil pan drain plug.

5. Drain the engine oil into a container.

6. Install the oil pan drain plug with a new the washer.

Tightening torque

12—17 N·m {1.2—1.8 kgf·m, 9—13 ft·lbf}

Note

•The amount of residual oil in the engine can vary with the replacement method, oil temperature, etc. Verify

the oil level after engine oil replacement.

7. Refill the engine oil with the specified type and amount, then install the oil filler cap.

Oil capacity (approximate quantity)

L {US qt, Imp qt}

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Recommended Engine Oil

8. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

9. Inspect the oil level .

•If the necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Install the under cover.

End Of Sie

ENGINE OIL

Item Specification

Total (dry engine) 5.5 {5.8, 4.8}

Oil replacement 4.8 {5.1, 4.2}

Oil and oil filter replacement 5.0 {5.3, 4.4}

Item Specification

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3 B3 B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

Page 74 of 909

D–10

OIL PAN

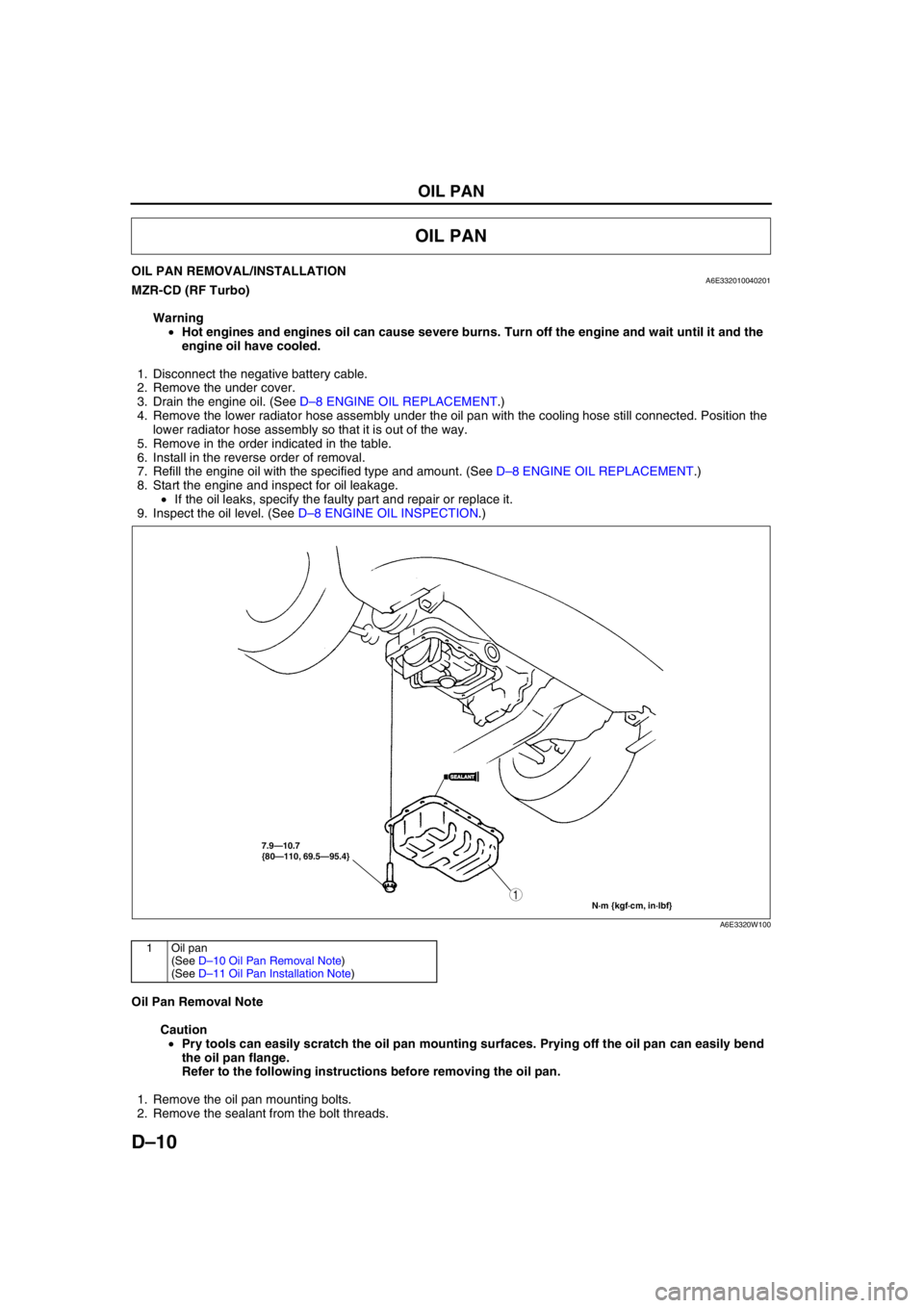

OIL PAN REMOVAL/INSTALLATIONA6E332010040201MZR-CD (RF Turbo)

Warning

•Hot engines and engines oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine oil. (See D–8 ENGINE OIL REPLACEMENT.)

4. Remove the lower radiator hose assembly under the oil pan with the cooling hose still connected. Position the

lower radiator hose assembly so that it is out of the way.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Refill the engine oil with the specified type and amount. (See D–8 ENGINE OIL REPLACEMENT.)

8. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

9. Inspect the oil level. (See D–8 ENGINE OIL INSPECTION.)

.

Oil Pan Removal Note

Caution

•Pry tools can easily scratch the oil pan mounting surfaces. Prying off the oil pan can easily bend

the oil pan flange.

Refer to the following instructions before removing the oil pan.

1. Remove the oil pan mounting bolts.

2. Remove the sealant from the bolt threads.

OIL PAN

7.9—10.7

{80—110, 69.5—95.4}

N·m {kgf·cm, in·lbf}

1

SEALANTSEALANT

A6E3320W100

1Oil pan

(See D–10 Oil Pan Removal Note)

(See D–11 Oil Pan Installation Note)

Page 90 of 909

F1–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E390218881201•The fuel and emission control systems are essentially carried over from the current Mazda6 (GG), except for

the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E390218881202System simplification

•Controller area network has been adopted with TCM communication (4WD).

TCM adoption

•DTC for CAN (TCM communication) has been adopted.

Modifications to match the vehicle characteristics

•The idle speed has been modified.

•Fuel pump (transfer) has been adopted.

End Of Sie

SPECIFICATIONSA6E390218881203

*1: Without the BARO sensor

*2: With the BARO sensor

Bold frames: New specifications

End Of Sie

OUTLINE

Item 2WD 4WD

Air cleaner element Type Paper element (oil permeated)

IAC valve Type Duty control

Fuel injectorType Hi-ohmic

Type of fuel delivery Top-feed

Type of drive Voltage

Pressure regulatorRegulating pressure

(kPa {kgf/cm

2, psi})440 {4.5, 64}

Fuel tankCapacity

(L {US qt, lmp qt})64 {68, 56} 62 {65, 54}

Fuel SpecificationUnleaded

(RON 90*

1/95*2 or above)Unleaded (RON 95 or above)

Catalyst Type TWC (monolythic)

EGR control Type Stepping motor type

Evaporative emission control

systemType Canister type

PCV system Type Closed type

Page 127 of 909

CONTROL SYSTEM

F1–39

F1

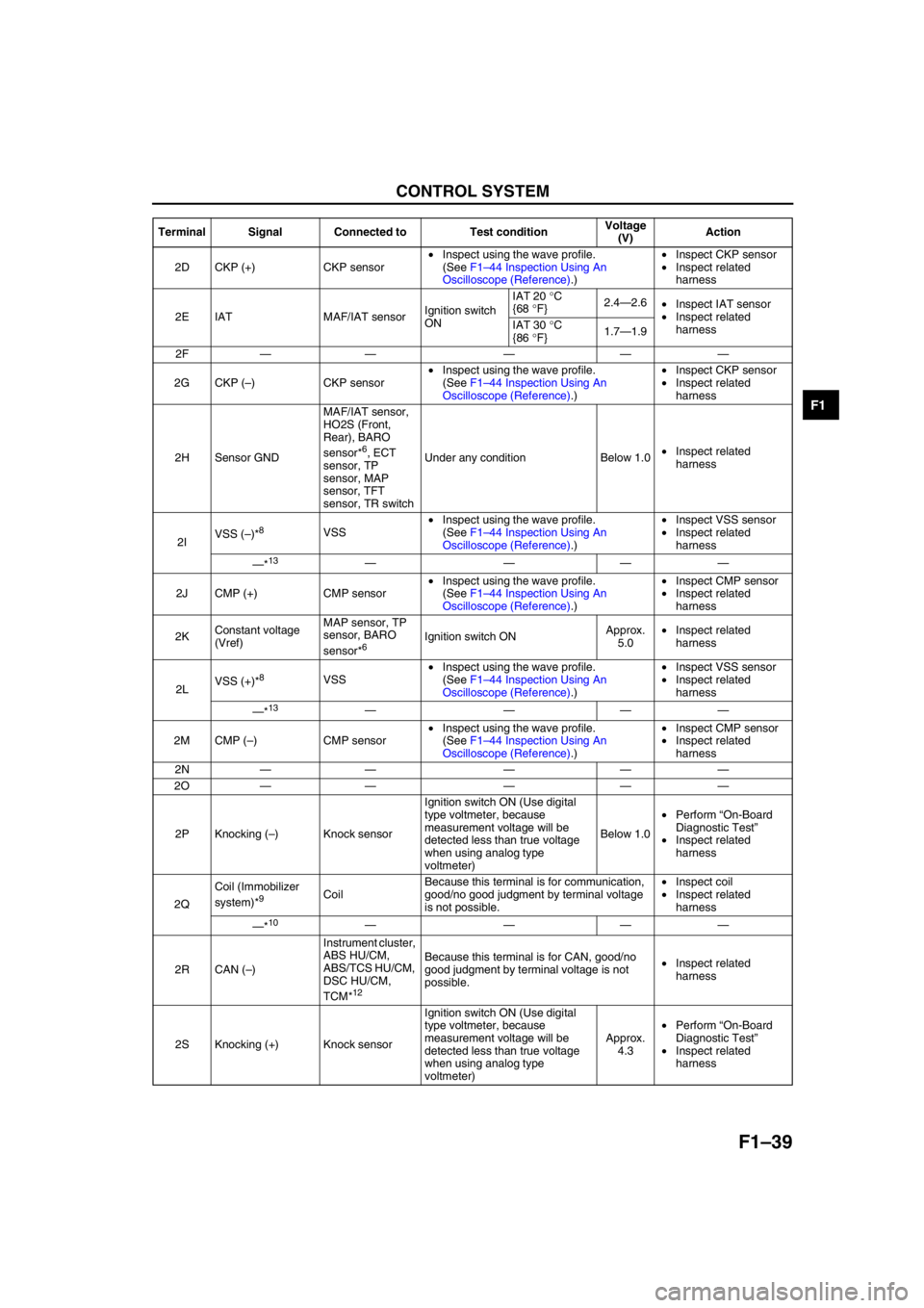

2D CKP (+) CKP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CKP sensor

•Inspect related

harness

2E IAT MAF/IAT sensorIgnition switch

ONIAT 20 °C

{68 °F}2.4—2.6

•Inspect IAT sensor

•Inspect related

harness IAT 30 °C

{86 °F}1.7—1.9

2F—— — ——

2G CKP (–) CKP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CKP sensor

•Inspect related

harness

2H Sensor GNDMAF/IAT sensor,

HO2S (Front,

Rear), BARO

sensor*

6, ECT

sensor, TP

sensor, MAP

sensor, TFT

sensor, TR switchUnder any condition Below 1.0•Inspect related

harness

2IVSS (–)*

8VSS•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect VSS sensor

•Inspect related

harness

—*

13————

2J CMP (+) CMP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CMP sensor

•Inspect related

harness

2KConstant voltage

(Vref)MAP sensor, TP

sensor, BARO

sensor*

6Ignition switch ONApprox.

5.0•Inspect related

harness

2LVSS (+)*

8VSS•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect VSS sensor

•Inspect related

harness

—*

13————

2M CMP (–) CMP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CMP sensor

•Inspect related

harness

2N—— — ——

2O—— — ——

2P Knocking (–) Knock sensorIgnition switch ON (Use digital

type voltmeter, because

measurement voltage will be

detected less than true voltage

when using analog type

voltmeter)Below 1.0•Perform “On-Board

Diagnostic Test”

•Inspect related

harness

2QCoil (Immobilizer

system)*

9CoilBecause this terminal is for communication,

good/no good judgment by terminal voltage

is not possible.•Inspect coil

•Inspect related

harness

—*

10————

2R CAN (–)Instrument cluster,

ABS HU/CM,

ABS/TCS HU/CM,

DSC HU/CM,

TCM*

12

Because this terminal is for CAN, good/no

good judgment by terminal voltage is not

possible.•Inspect related

harness

2S Knocking (+) Knock sensorIgnition switch ON (Use digital

type voltmeter, because

measurement voltage will be

detected less than true voltage

when using analog type

voltmeter)Approx.

4.3•Perform “On-Board

Diagnostic Test”

•Inspect related

harness Terminal Signal Connected to Test conditionVoltage

(V)Action

Page 404 of 909

J2–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E520201025203•The construction and operation of the manual transaxle is the same as those of the current A65M-R type

manual transaxle, except for the following features. (See MPV Workshop Manual supplement 1737-1*-02D.)

End Of Sie

FEATURESA6E520201025201Improved drivability

•The gear ratio has been changed.

End Of Sie

SPECIFICATIONSA6E520201025202

Bold frames:New specifications

End Of Sie

OUTLINE

Item New Mazda6 (GG, GY) Current MPV (LW)

Transaxle typeA65M-R

Transaxle control Floor-shift

Operation system Cable

Shift assistForward

Synchromesh

Reverse

Gear ratio1st 3.416

2nd 1.944 1.789

3rd 1.258 1.193

4th 0.902

5th 0.659

Reverse 3.252

Final gear ratio 3.588 4.133

OilGrade API service GL-4 or GL-5

Viscosity (All season) SAE 75W-90

Capacity (approximate quantity)

(L {US qt, Imp qt})2.30 {2.40, 2.00}

Page 406 of 909

J2–4

MANUAL TRANSAXLE

TRANSAXLE OIL INSPECTIONA6E5212270012011. Park the vehicle on level ground.

2. Remove the filler plug and gasket.

3. Verify that the oil is near the brim of the plug port.

•If the oil level is low, add the specified amount

and type of oil through the filler plug hole.

Specified oil grade

API Service GL-4 or GL-5

Specified oil viscosity

SAE 75W-90

4. Install a new gasket and the filler plug.

Tightening torque

30.0—39.0 N·m

{3.06—3.98 kgf·m, 22.1—28.8 in·lbf}

End Of Sie

TRANSAXLE OIL REPLACEMENTA6E5212270012021. Remove the drain plug with the gasket.

2. Drain the oil into a suitable container.

3. Install a new gasket and the drain plug.

Tightening torque

30.0—39.0 N·m

{3.06—3.98 kgf·m, 22.1—28.8 in·lbf}

4. Remove the filler plug with gasket and add the

specified amount and type of oil through the filler

plug hole until the level reaches the bottom of the

filler plug hole.

Specified oil grade

API Service GL-4 or GL-5

Specified oil viscosity

SAE 75W-90

Capacity (approximate quantity)

2.30 L {2.40 US qt, 2.00 lmp qt}

5. Install a new gasket and the filler plug.

Tightening torque

30.0—39.0 N·m

{3.06—3.98 kgf·m, 22.1—28.8 in·lbf}

End Of Sie

MANUAL TRANSAXLE

DRAIN PLUG FILLER PLUG

A6E5212W010

DRAIN PLUG FILLER PLUG

A6E5212W010

Page 407 of 909

MANUAL TRANSAXLE

J2–5

J2

OIL SEAL (DIFFERENTIAL) REPLACEMENTA6E5212192402011. On level ground, jack up the vehicle and support it evenly on safety stands.

2. Drain the oil from the transaxle.

3. Remove the front wheels and splash shields.

4. Separate the drive shaft and joint shaft from the transaxle. (See Section M.)

5. Remove the oil seals using a screwdriver.

6. Using the SSTs and a hammer, tap each new oil

seal in evenly until the SSTs contact the transaxle

case.

7. Coat the lip of each oil seal with transaxle oil.

8. Insert the drive shaft and joint shaft into the

transaxle. (See Section M.)

9. Install the wheels and splash shields.

10. Add the specified amount and type of oil. (See

J2–4 TRANSAXLE OIL REPLACEMENT.)

End Of SieREVERSE SWITCH INSPECTIONA6E5212190102011. Disconnect the reverse switch connector.

2. Shift the shift lever to each position, and inspect

for continuity between terminals A and B.

•If not as specified, replace the reverse switch.

(See J2–6 REVERSE SWITCH REMOVAL/

INSTALLATION.)

3. Connect the reverse switch connector.

End Of Sie

AME5212W005

49 G030 797

49 U027 003

A6E5212W011

REVERSE SWITCH

A6E5212W012

BA REVERSE SWITCH

PART SIDE CONNENTOR

A6E5212W013

Shift positionConnector terminal

AB:

Continuity

Reverse

Others

A6E5212W014