radiator cap MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 76 of 909

E–1

E

ECOOLING SYSTEM

OUTLINE................................................................ E-2

OUTLINE OF CONSTRUCTION.......................... E-2

FEATURES .......................................................... E-2

SPECIFICATIONS ............................................... E-3

COOLING SYSTEM................................................ E-4

STRUCTURAL VIEW ........................................... E-4

COOLING FLOW DIAGRAM ............................... E-5

COOLING FAN .................................................... E-5

OUTLINE................................................................ E-6

SUPPLEMENTAL SERVICE INFORMATION ..... E-6

LOCATION INDEX ............................................... E-6

RADIATOR CAP..................................................... E-7

RADIATOR CAP INSPECTION ........................... E-7

ENGINE COOLANT................................................ E-8

ENGINE COOLANT LEAKAGE INSPECTION .... E-8

THERMOSTAT....................................................... E-9

THERMOSTAT REMOVAL/INSTALLATION ....... E-9

THERMOSTAT INSPECTION ........................... E-10

WATER PUMP...................................................... E-11

WATER PUMP REMOVAL/INSTALLATION...... E-11

FAN MOTOR........................................................ E-12

COOLING FAN MOTOR

REMOVAL/INSTALLATION ............................ E-12

COOLING FAN MOTOR INSPECTION ............. E-13 FEATURES

SERVICE

Page 78 of 909

OUTLINE

E–3

E

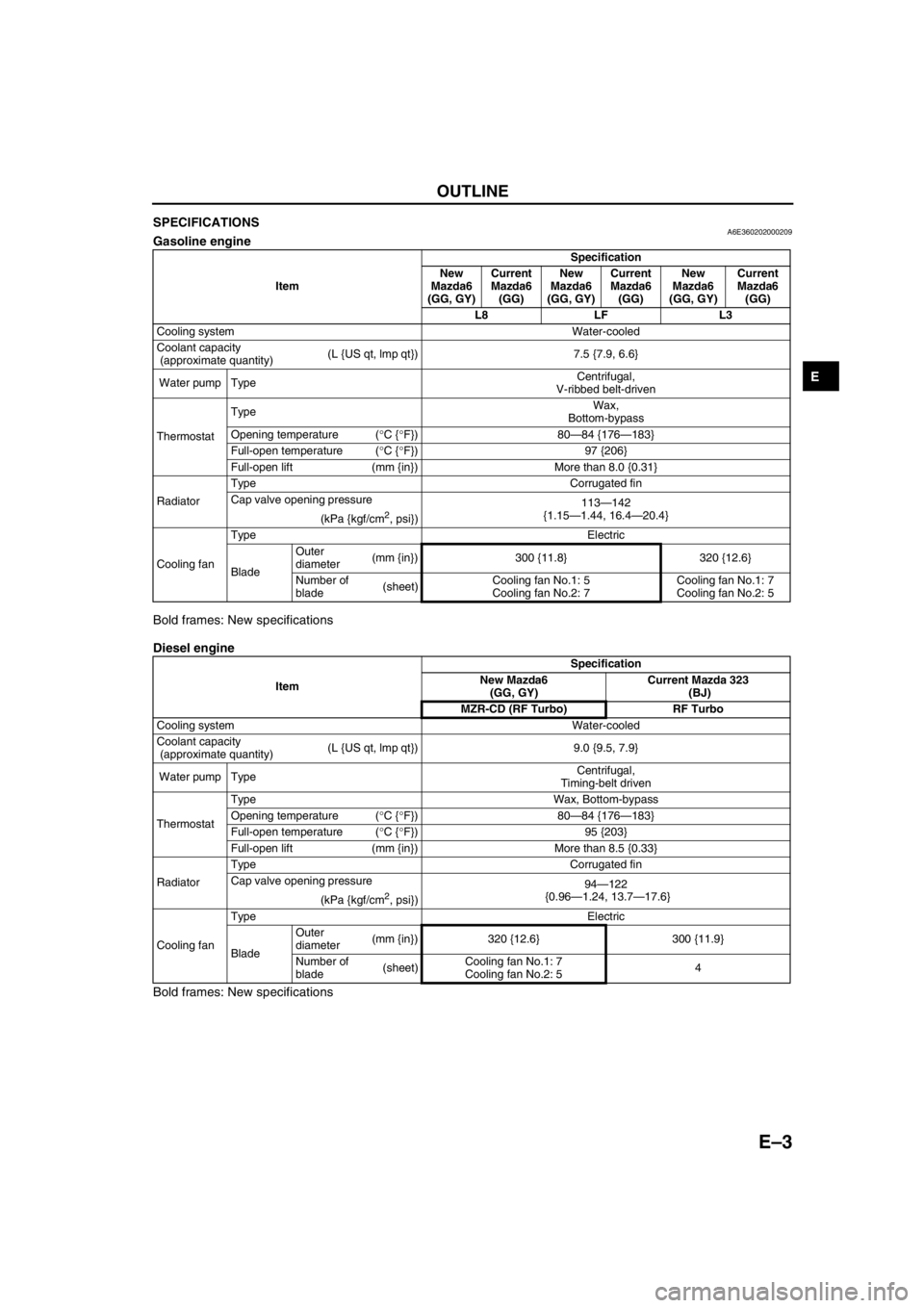

SPECIFICATIONSA6E360202000209Gasoline engine

Bold frames: New specifications

Diesel engine

Bold frames: New specifications

End Of Sie

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 7.5 {7.9, 6.6}

Water pump TypeCentrifugal,

V-ribbed belt-driven

ThermostatTypeWax,

Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 97 {206}

Full-open lift (mm {in}) More than 8.0 {0.31}

RadiatorType Corrugated fin

Cap valve opening pressure

113—142

{1.15—1.44, 16.4—20.4}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 300 {11.8} 320 {12.6}

Number of

blade(sheet)Cooling fan No.1: 5

Cooling fan No.2: 7Cooling fan No.1: 7

Cooling fan No.2: 5

ItemSpecification

New Mazda6

(GG, GY)Current Mazda 323

(BJ)

MZR-CD (RF Turbo) RF Turbo

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 9.0 {9.5, 7.9}

Water pump TypeCentrifugal,

Timing-belt driven

ThermostatType Wax, Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

RadiatorType Corrugated fin

Cap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 320 {12.6} 300 {11.9}

Number of

blade(sheet)Cooling fan No.1: 7

Cooling fan No.2: 54

Page 81 of 909

E–6

OUTLINE

SUPPLEMENTAL SERVICE INFORMATIONA6E360202000208•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Radiator cap

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

Thermostat

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

Water pump

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

Fan motor

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

End Of Sie

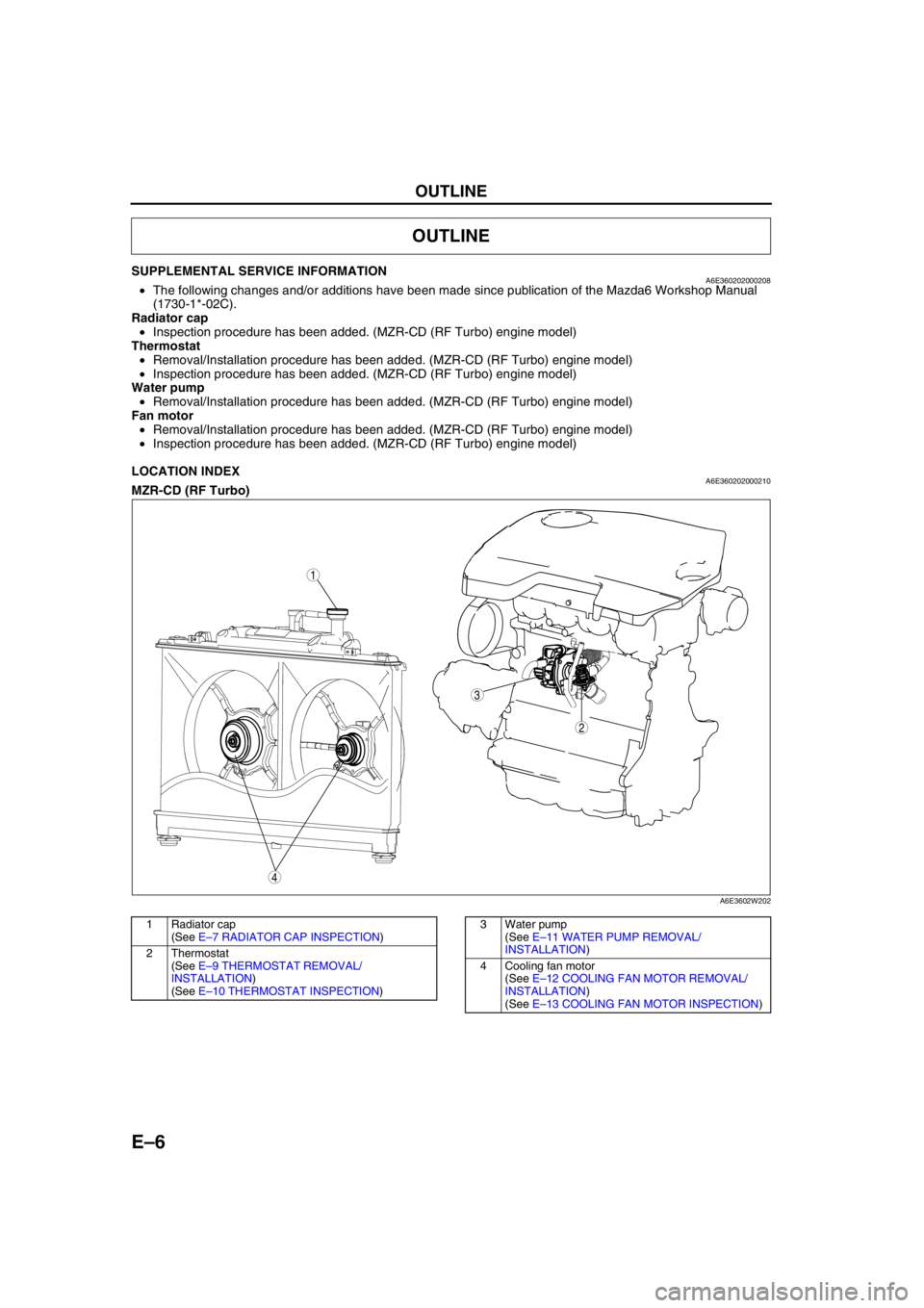

LOCATION INDEXA6E360202000210MZR-CD (RF Turbo)

.

End Of Sie

OUTLINE

4

3

1

2

A6E3602W202

1 Radiator cap

(See E–7 RADIATOR CAP INSPECTION)

2Thermostat

(See E–9 THERMOSTAT REMOVAL/

INSTALLATION)

(See E–10 THERMOSTAT INSPECTION)3 Water pump

(See E–11 WATER PUMP REMOVAL/

INSTALLATION)

4 Cooling fan motor

(See E–12 COOLING FAN MOTOR REMOVAL/

INSTALLATION)

(See E–13 COOLING FAN MOTOR INSPECTION)

Page 82 of 909

RADIATOR CAP

E–7

E

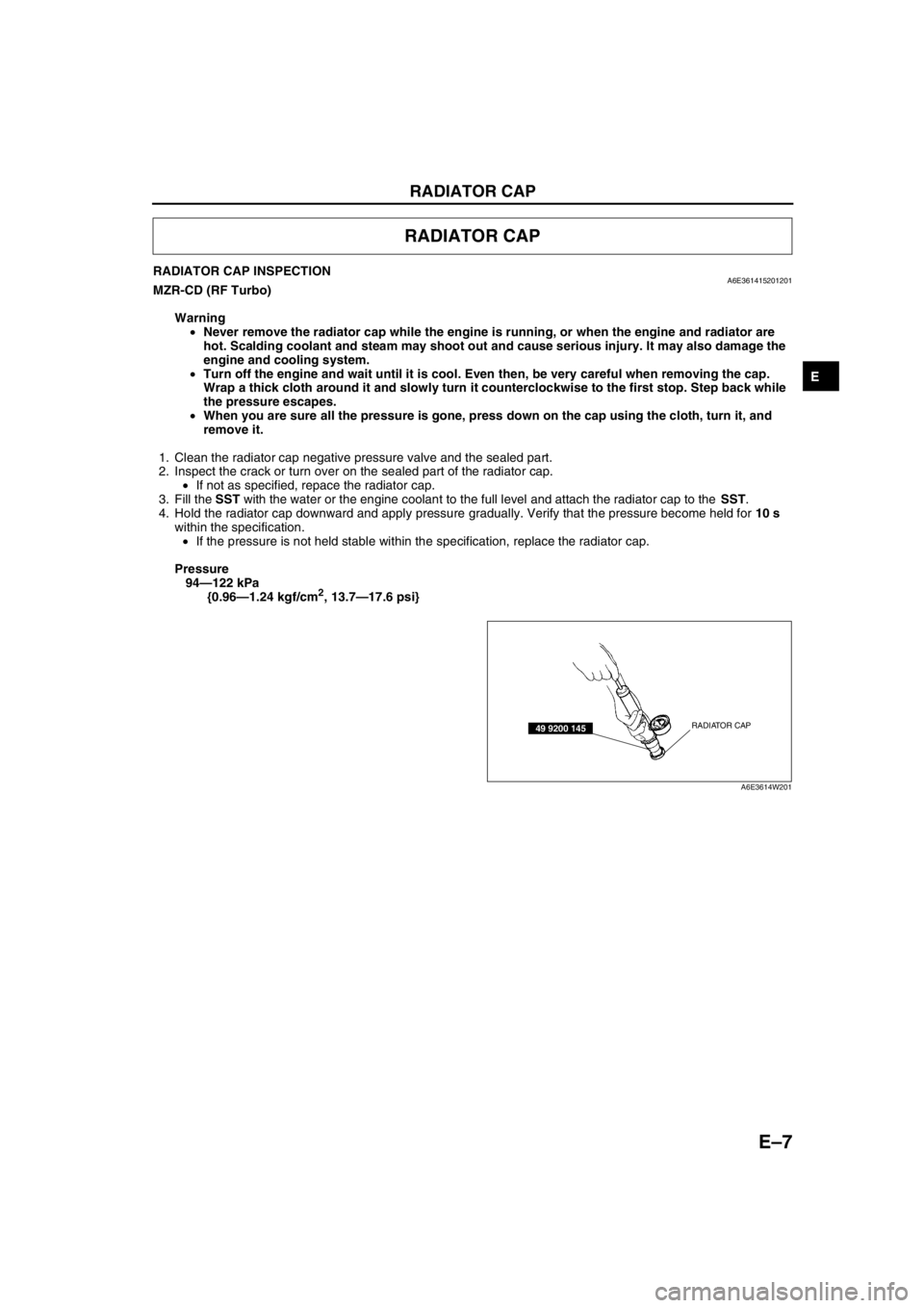

RADIATOR CAP INSPECTIONA6E361415201201MZR-CD (RF Turbo)

Warning

•Never remove the radiator cap while the engine is running, or when the engine and radiator are

hot. Scalding coolant and steam may shoot out and cause serious injury. It may also damage the

engine and cooling system.

•Turn off the engine and wait until it is cool. Even then, be very careful when removing the cap.

Wrap a thick cloth around it and slowly turn it counterclockwise to the first stop. Step back while

the pressure escapes.

•When you are sure all the pressure is gone, press down on the cap using the cloth, turn it, and

remove it.

1. Clean the radiator cap negative pressure valve and the sealed part.

2. Inspect the crack or turn over on the sealed part of the radiator cap.

•If not as specified, repace the radiator cap.

3. Fill the SST with the water or the engine coolant to the full level and attach the radiator cap to the SST.

4. Hold the radiator cap downward and apply pressure gradually. Verify that the pressure become held for 10 s

within the specification.

•If the pressure is not held stable within the specification, replace the radiator cap.

Pressure

94—122 kPa

{0.96—1.24 kgf/cm

2, 13.7—17.6 psi}

End Of Sie

RADIATOR CAP

RADIATOR CAP49 9200 145

A6E3614W201

Page 83 of 909

E–8

ENGINE COOLANT

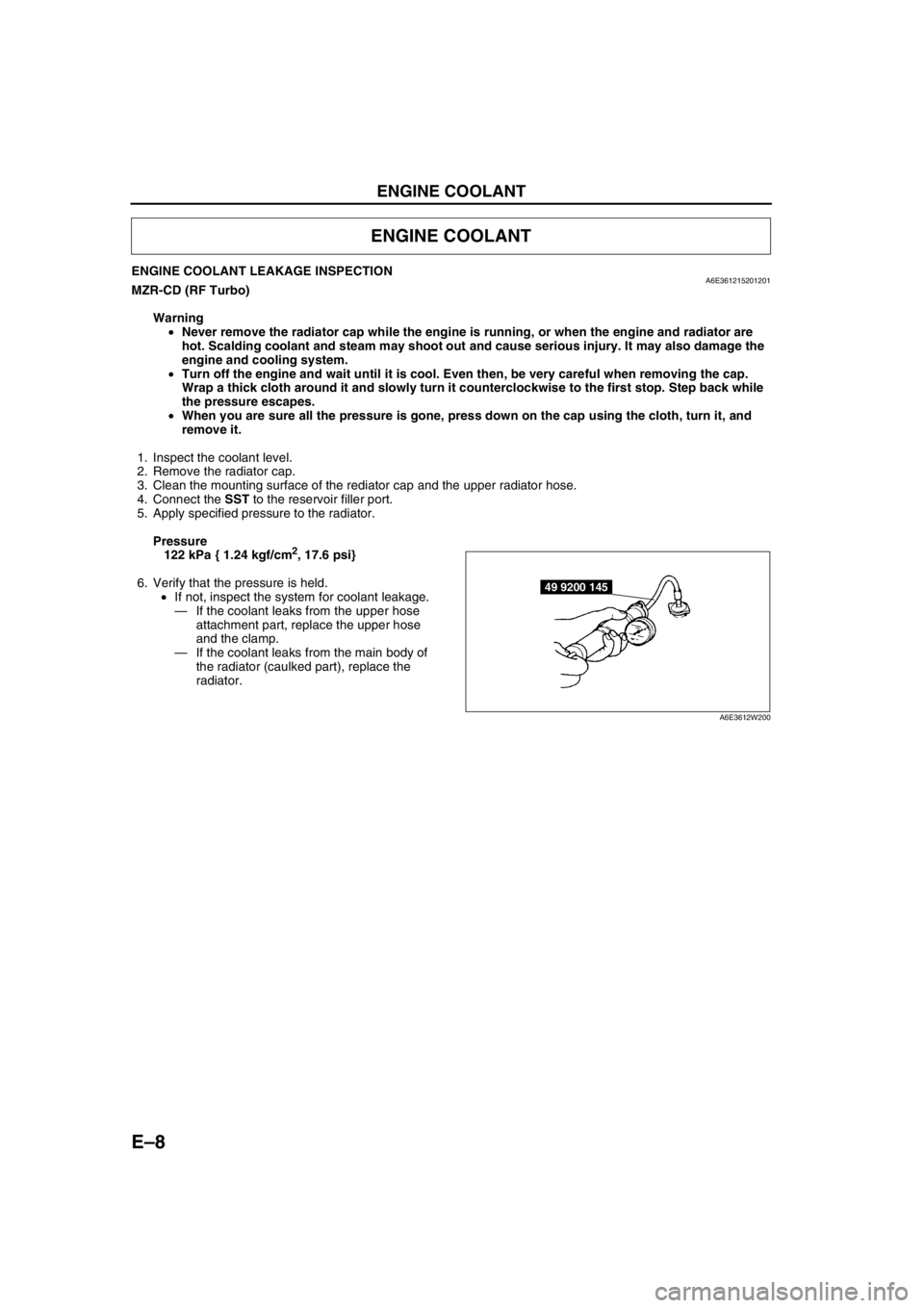

ENGINE COOLANT LEAKAGE INSPECTIONA6E361215201201MZR-CD (RF Turbo)

Warning

•Never remove the radiator cap while the engine is running, or when the engine and radiator are

hot. Scalding coolant and steam may shoot out and cause serious injury. It may also damage the

engine and cooling system.

•Turn off the engine and wait until it is cool. Even then, be very careful when removing the cap.

Wrap a thick cloth around it and slowly turn it counterclockwise to the first stop. Step back while

the pressure escapes.

•When you are sure all the pressure is gone, press down on the cap using the cloth, turn it, and

remove it.

1. Inspect the coolant level.

2. Remove the radiator cap.

3. Clean the mounting surface of the rediator cap and the upper radiator hose.

4. Connect the SST to the reservoir filler port.

5. Apply specified pressure to the radiator.

Pressure

122 kPa { 1.24 kgf/cm

2, 17.6 psi}

6. Verify that the pressure is held.

•If not, inspect the system for coolant leakage.

—If the coolant leaks from the upper hose

attachment part, replace the upper hose

and the clamp.

—If the coolant leaks from the main body of

the radiator (caulked part), replace the

radiator.

End Of Sie

ENGINE COOLANT

49 9200 145

A6E3612W200

Page 362 of 909

F2–210

TROUBLESHOOTING

End Of SieNO.17 COOLING SYSTEM CONCERNS-OVERHEATINGA6E408018881219

Diagnostic Procedure

17

COOLING SYSTEM CONCERNS-OVERHEATING

DESCRIPTION•Engine runs at higher than normal temperature/overheats.

POSSIBLE

CAUSE•Cooling fan No.2 malfunction

•Cooling fan No.1 malfunction

•Low drive belt tension

•Drive belt damage

•Improper coolant level

•Thermostat malfunction

•Radiator clogging

•Improper water/anti-freeze mixture

•Improper or damaged radiator cap

•Radiator hose damage

•Coolant leakage (engine internal, turbocharger, external)

•A/C system malfunction

•EGR system malfunction

•Coolant heater system malfunction

STEP INSPECTION RESULTS ACTION

1 Inspect following:

•Engine coolant level

•Coolant leakage (around heater unit in

passenger compartment, coolant hoses and/

or radiator, and around coolant heater unit.)

•Water and anti-freeze mixture

•Radiator condition

•Collapsed or restricted radiator hoses

•Radiator pressure cap

•Drive belt tension

•Drive belt

•Fan rotational direction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

Page 895 of 909

TECHNICAL DATA

TD–3

TD

Recommended engine oil

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

End Of Sie

COOLING SYSTEMA6E931001001203

End Of Sie

FUEL AND EMISSION CONTROL SYSTEMA6E931001001204

*1: Excludes temporary idle speed drop just after the electrical loads are turned on.

End Of Sie

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3

B3B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Coolant capacity (L {US qt, Imp qt}) 9.0 {9.5, 7.9}

Radiator capCap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

ThermostatType Wax, bottom-bypass

Initial-opening temperature (°C {°F})80—84

{176—183}

Full-opening temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

Cooling fan Motor Current (A)4.4—7.4 (Cooling fan motor No.1)

6.3—9.3 (Cooling fan motor No.2)

ItemEngine

L3 (4WD)

Idle speed

*1(rpm) 650—750 (700±50)

ItemEngine

MZR-CD (RF Turbo)

Idle speed (rpm) 725—825 (775±50)

Idle-up speed (rpm) When A/C is operated 725—825 (775±50)

Boost relief pressure (kPa {mmHg, inHg}) Approx. –14.5 {–108, –4.27}

Page 903 of 909

ST–2

SPECIAL TOOLS

ENGINEA6E941001001205

End Of Sie

LUBRICATION SYSTEMA6E941001001206

End Of Sie

COOLING SYSTEMA6E941001001207

End Of Sie

SPECIAL TOOLS

49 S120 710

Coupling flange

holder 49 G033 107A

Dust cover

installer49 S120 215B

Pulley puller

49 G011 106

Camshaft pulley

puller49 S013 1A1

Compression

gauge set49 B010 002

Oil seal installer

49 G012 0A0

Tappet adjust

wrench set49 G011 105

Crankshaft lock

tool49 U027 003

Oil seal installer

WDS 49 E017 5A0

Engine support

set

—

49 0187 280A

Oil pressure

gauge

——

49 9200 145

Radiator cap

tester adapter

set——