fuel MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 627 of 1865

4C FUEL SYSTEM

Inspection

1. Check the fuel tank for cracks and corrosion.

2. If any defect is found, repair or replace the tank.

Warning

Before repairing, clean the fuel tank thorough-

ly with steam to remove all explosive fuel and

fumes.

Installation

Install in the reverse order of removal, referring to the installation note.

Torque Specifications

4C-66

76G04C-126

Page 628 of 1865

FUEL SYSTEM 4C

Installation note

Hoses

1. Push the ends of the main fuel hose, fuel return

hose, and evaporation hoses onto the fuel tank fit-

tings at least 25 mm (1.0 in).

2. Push the fuel filler hose onto the fuel tank pipe and

filler pipe at least 35 mm (1.4 in).

Steering angle transfer shaft

(4-wheel steering)

Refer to section 10

4C—67

Page 629 of 1865

4C PRC SYSTEM

PRESSURE REGULATOR CONTROL

(PRC)

SYSTEM

Distributor (Ne signal)

I Fuel

(To fuel tank)

76G04C-128

To prevent percolation of the fuel during idle after the engine is restarted, vacuum is cut to the pres-

sure regulator, increasing the fuel pressure.

Specified time: Approx. 120 sec.

Operating condition: Coolant temperature — above 70°C (158°F)

Intake air temperature — above 30°C (86°F)....Unleaded fuel

above 50°C (122°F)....Leaded fuel

4C-68

Page 630 of 1865

PRC SYSTEM 4C

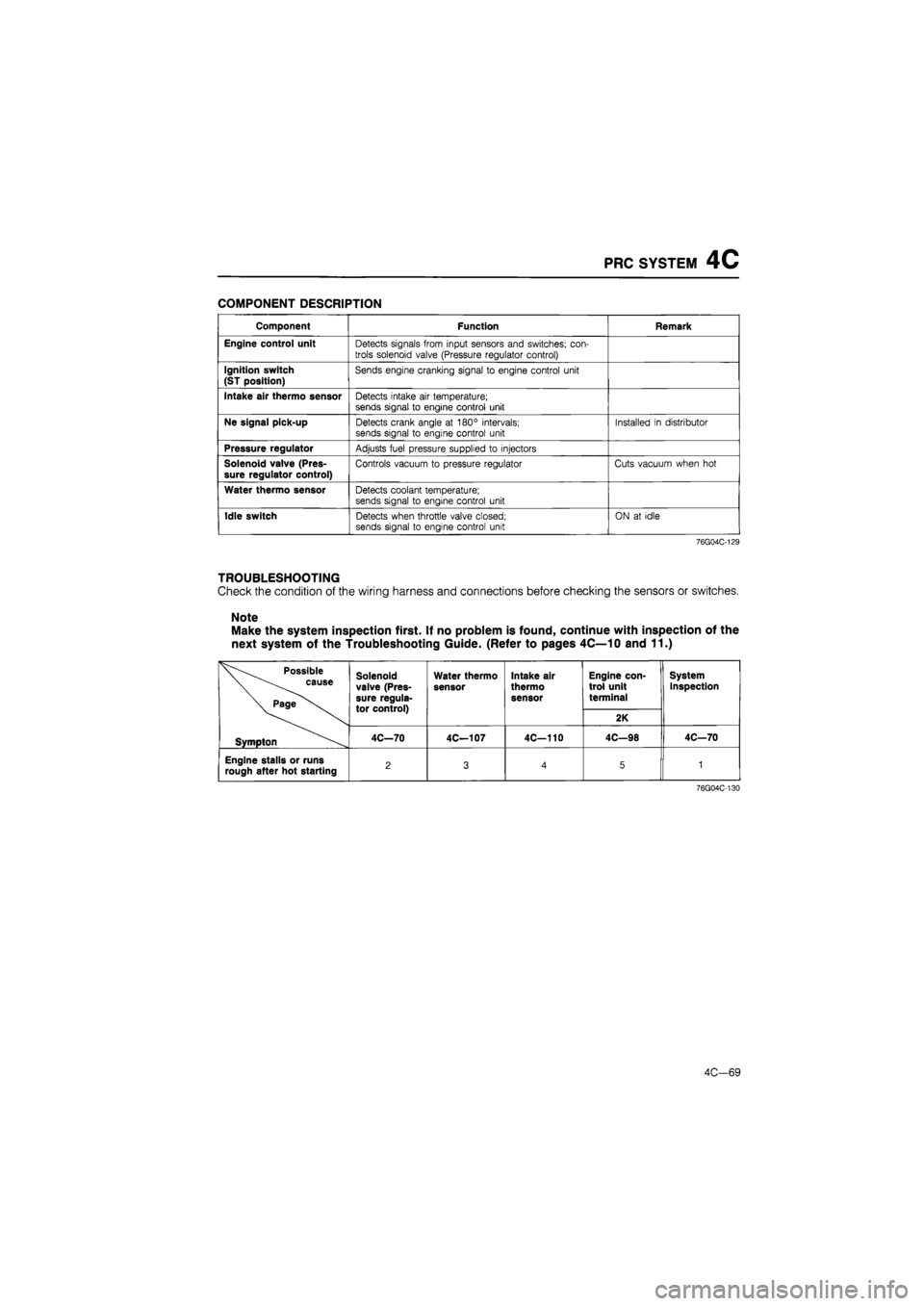

COMPONENT DESCRIPTION

Component Function Remark

Engine control unit Detects signals from input sensors and switches; con-trols solenoid valve (Pressure regulator control)

Ignition switch

(ST position)

Sends engine cranking signal to engine control unit

Intake air thermo sensor Detects intake air temperature; sends signal to engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Pressure regulator Adjusts fuel pressure supplied to injectors

Solenoid valve (Pres-

sure regulator control)

Controls vacuum to pressure regulator Cuts vacuum when hot

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Idle switch Detects when throttle valve closed; sends signal to engine control unit ON at idle

76G04C-129

TROUBLESHOOTING

Check the condition of the wiring harness and connections before checking the sensors or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible

\ cause

\ Page

Solenoid valve (Pres-sure regula-tor control)

Water thermo

sensor

Intake air

thermo

sensor

Engine con-trol unit terminal

System inspection Solenoid valve (Pres-sure regula-tor control) 2K

Symplon 4C—70 4C—107 4C-110 4C—98 4C—70

Engine stalls or runs rough after hot starting 2 3 4 5 1

76G04C-130

4C-69

Page 631 of 1865

4C PRC SYSTEM

System Inspection

1. Connect the SST to the engine. (Refer to page

4C-53.)

2. Start the engine.

76G04C-131

Hi?

Jpll ssil

Water thermo sensor ^^^Tta^e air thermo sensor

76G04C-132

Operating time Fuel line pressure kPa (kg/cm2, psi)

After starting: for 120 sec. 235-275 (2.4-2.8, 34-40)

After 120 sec. 186-226 (1.9-2.3, 27-33)

3. Warm up the engine to normal operating temper-

ature and stop the engine.

Warning

Be careful when disconnecting the water ther-

mo sensor connector because the surround-

ing area is very hot.

4. Disconnect the water thermo sensor connector.

Connect a resistor (200 fl) to the sensor connector.

5. Heat the intake air thermo sensor to above specifi-

cation.

Specification: 30°C (86°F)....unleaded fuel

50°C (122°F)....leaded fuel

6. Restart the engine.

7. Check the fuel line pressure and operating times

as shown in the chart.

76G04C-133

Solenoid Valve (Pressure Regulator Control)

Inspection

1. Disconnect the vacuum hose from the vacuum

pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

76G04C-134

4C—70

Page 633 of 1865

4C DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

Distributor

(Ne signal)

Idle switch

QSO-Water thermo sensor

=5

A/C switch

Engine control unit

Detection of

fuel cut

condition Determi-

nation of

fuel cut

speed

* *

1

T

No.3

I

No.4

No.2

The fuel cut system is provided as a deceleration control system.

This system is to improve fuel consumption.

86U04A-121

4C—72

Page 634 of 1865

DECELERATION CONTROL SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remarks

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit ON at idle

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

76G04C-135

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to page 4C—10 and 11.)

Possible cause Water thermo sensor System inspection

Page 4C—107 4C—74

Checking order 2 1

76G04C-136

4C-73

Page 636 of 1865

ESA CONTROL SYSTEM 4C

ELECTRONIC SPARK ADVANCE

(ESA)

CONTROL SYSTEM

Throttle sensor

76G04C-139

This system electronically controls the ignition timing to obtain better engine performance.

The best ignition timing is determined and set within the engine control unit based on signals from

the various sensors and switches.

The knock control function is used only with leaded fuel engines.

4C-75

Page 637 of 1865

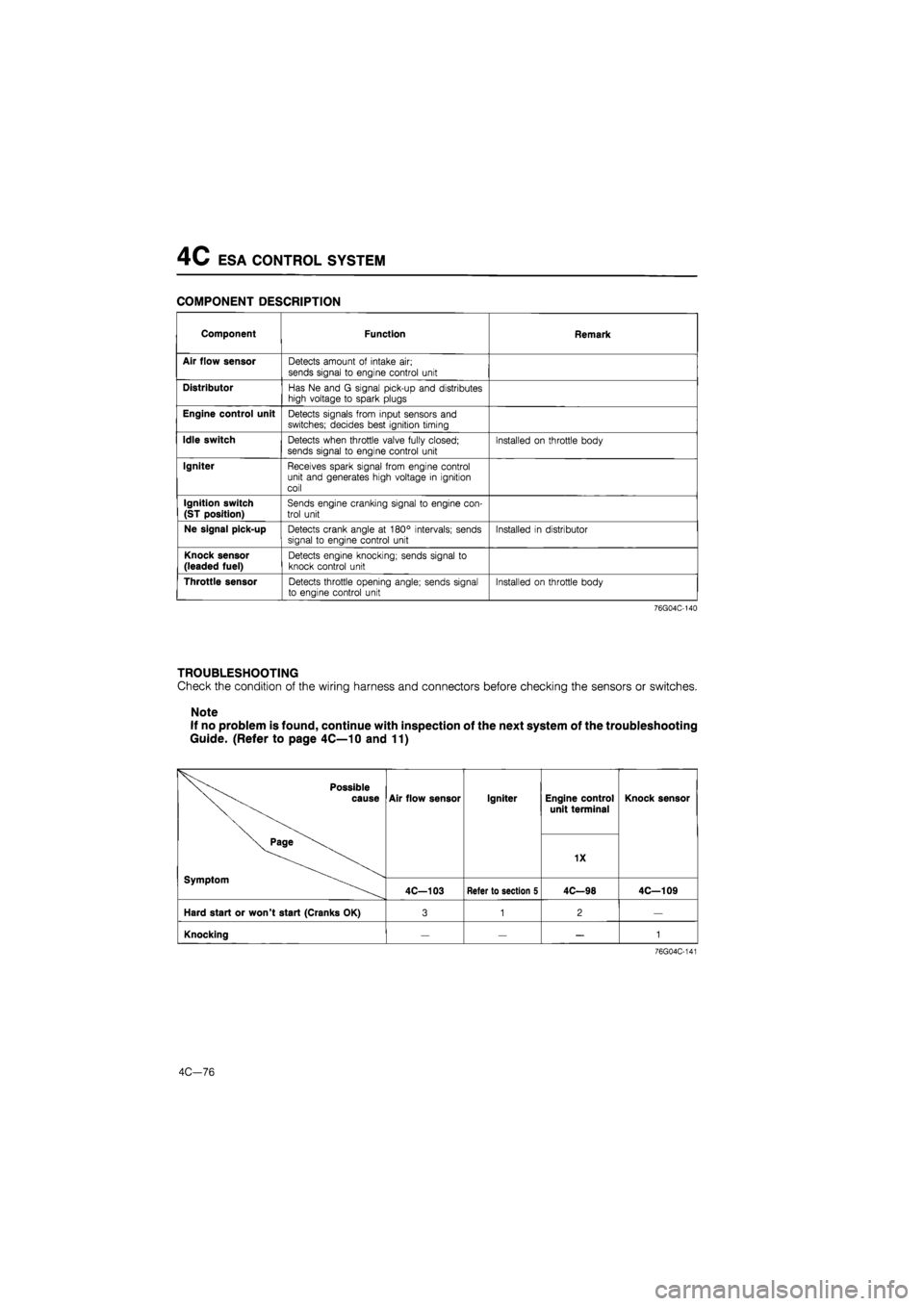

4C ESA CONTROL SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Air flow sensor Detects amount of intake air;

sends signal to engine control unit

Distributor Has Ne and G signal pick-up and distributes high voltage to spark plugs

Engine control unit Detects signals from input sensors and switches; decides best ignition timing

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed on throttle body

Igniter Receives spark signal from engine control unit and generates high voltage in ignition coil

Ignition switch

(ST position) Sends engine cranking signal to engine con-trol unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Knock sensor (leaded fuel) Detects engine knocking; sends signal to knock control unit

Throttle sensor Detects throttle opening angle; sends signal to engine control unit Installed on throttle body

76G04C-140

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches.

Note

If no problem is found, continue with inspection of the next system of the troubleshooting

Guide. (Refer to page 4C—10 and 11)

Possible cause

Page

Symptom

Air flow sensor Igniter Engine control

unit terminal Knock sensor Possible cause

Page

Symptom

Air flow sensor Igniter

1X

Knock sensor Possible cause

Page

Symptom

4C—103 Refer to section 5 4C—98 4C—109

Hard start or won't start (Cranks OK) 3 1 2 —

Knocking — 1

76G04C-141

4C-76

Page 638 of 1865

EGR SYSTEM (UNLEADED FUEL) 4C

EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM (UNLEADED FUEL)

This system introduces exhaust gas into the intake manifold to reduce NOx emissions. It operates de-

pending on the engine load, engine speed (1,500—3,500 rpm), engine coolant temperature (above

70°C, 158°F), and radiator coolant temperature (above 17°C, 63°F).

COMPONENT DESCRIPTION

Component Function Remark

EGR control valve Recirculates portion of exhaust gas

EGR modulator valve Controls vacuum acting on EGR control valve

Engine control unit Detects signals from input sensors and switches; con-trols solenoid valve (EGR)

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit

Solenoid valve (EGR) Controls vacuum to EGR control valve

Throttle sensor Detects throttle valve opening angle; sends signal to en-

gine control unit

Installed on throttle body

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04C-143

AC—17