fuel MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 639 of 1865

4C EGR SYSTEM (UNLEADED FUEL)

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible cause

Throttle

sensor

Solenoid valve

(EGR)

EGR

modula-

tor valve

EGR con-trol valve

Water

thermo

sensor

Water

thermo switch

Engine control unit

terminal

System in-spection

2N

Page 4C—104 4C—78 4C—79 4C—79 4C—107 4C—106 4C—98 4C—78

Checking order 8 2 4 3 6 5 7 1

76G04C-144

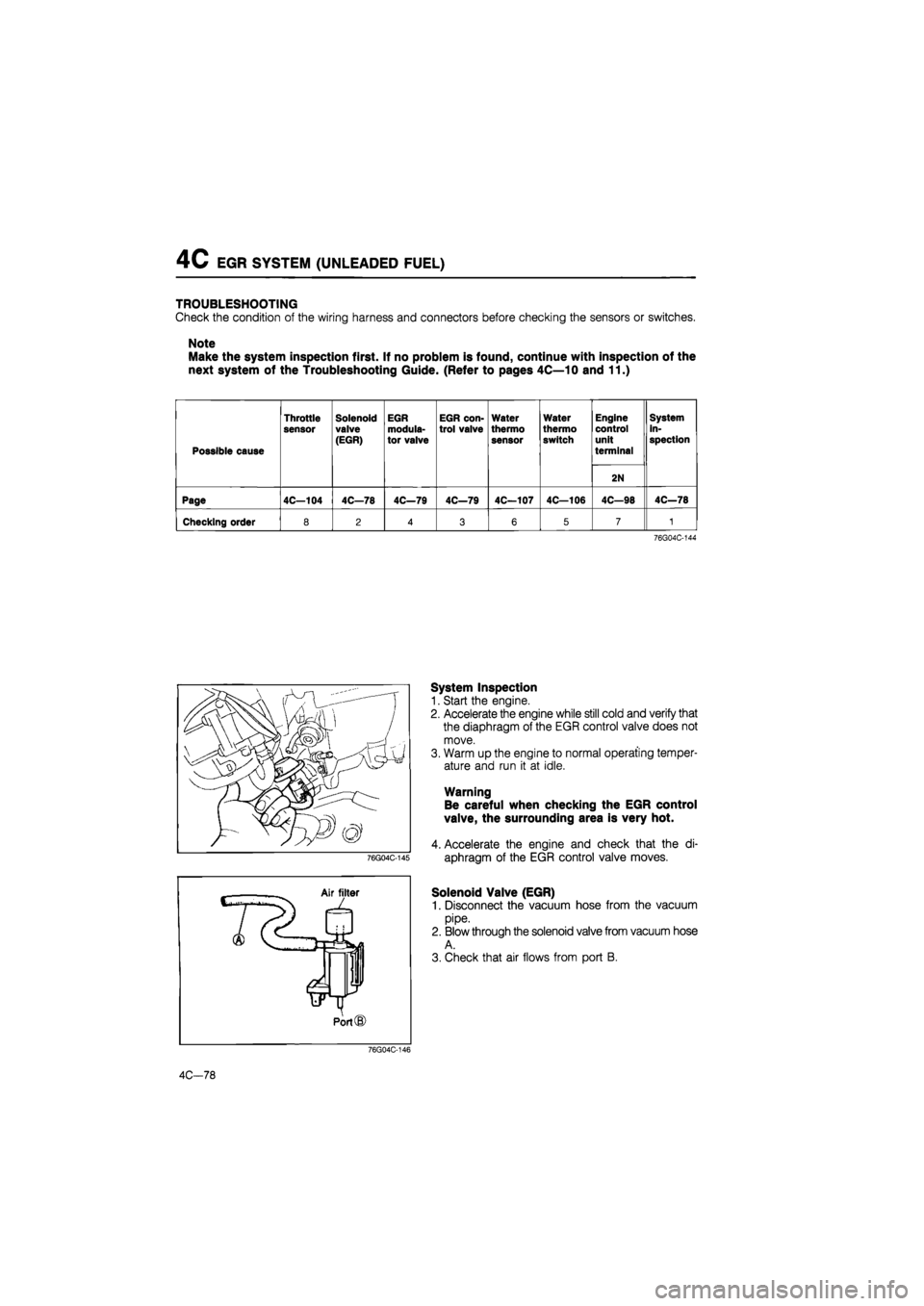

System Inspection

1. Start the engine.

2. Accelerate the engine while still cold and verify that

the diaphragm of the EGR control valve does not

move.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve, the surrounding area is very hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves.

Solenoid Valve (EGR)

1. Disconnect the vacuum hose from the vacuum

pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

76G04C-146

4C-78

Page 640 of 1865

EGR SYSTEM (UNLEADED FUEL) 4C

Apply 12V

J* Port

76G04C-147

86U04A-133

76G04C-148

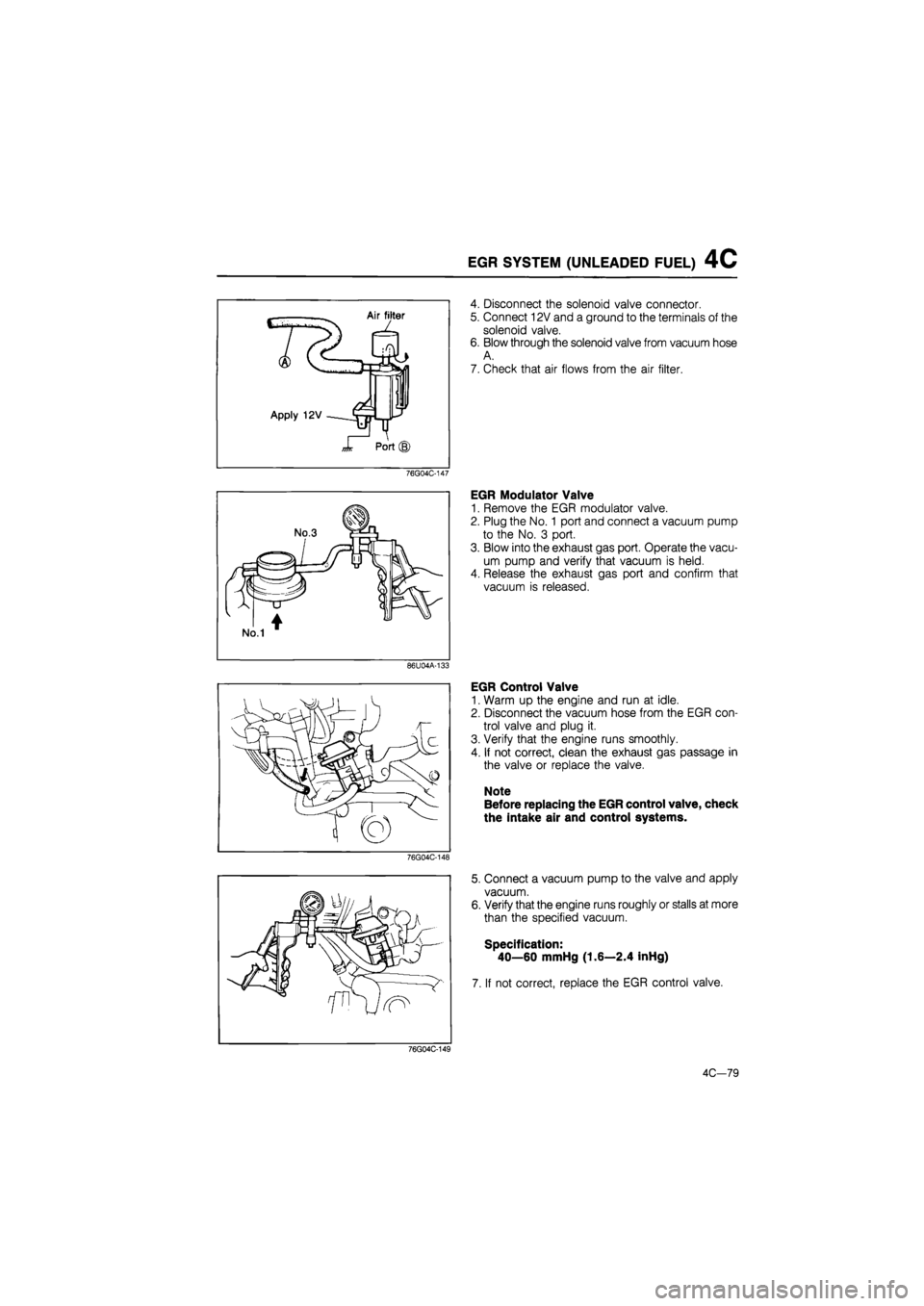

4. Disconnect the solenoid valve connector.

5. Connect 12V and a ground to the terminals of the

solenoid valve.

6. Blow through the solenoid valve from vacuum hose

A.

7. Check that air flows from the air filter.

EGR Modulator Valve

1. Remove the EGR modulator valve.

2. Plug the No. 1 port and connect a vacuum pump

to the No. 3 port.

3. Blow into the exhaust gas port. Operate the vacu-

um pump and verify that vacuum is held.

4. Release the exhaust gas port and confirm that

vacuum is released.

EGR Control Valve

1. Warm up the engine and run at idle.

2. Disconnect the vacuum hose from the EGR con-

trol valve and plug it.

3. Verify that the engine runs smoothly.

4. If not correct, clean the exhaust gas passage in

the valve or replace the valve.

Note

Before replacing the EGR control valve, check

the intake air and control systems.

5. Connect a vacuum pump to the valve and apply

vacuum.

6. Verify that the engine runs roughly or stalls at more

than the specified vacuum.

Specification:

40—60 mmHg (1.6—2.4 inHg)

7. If not correct, replace the EGR control valve.

76G04C-149

4C-79

Page 641 of 1865

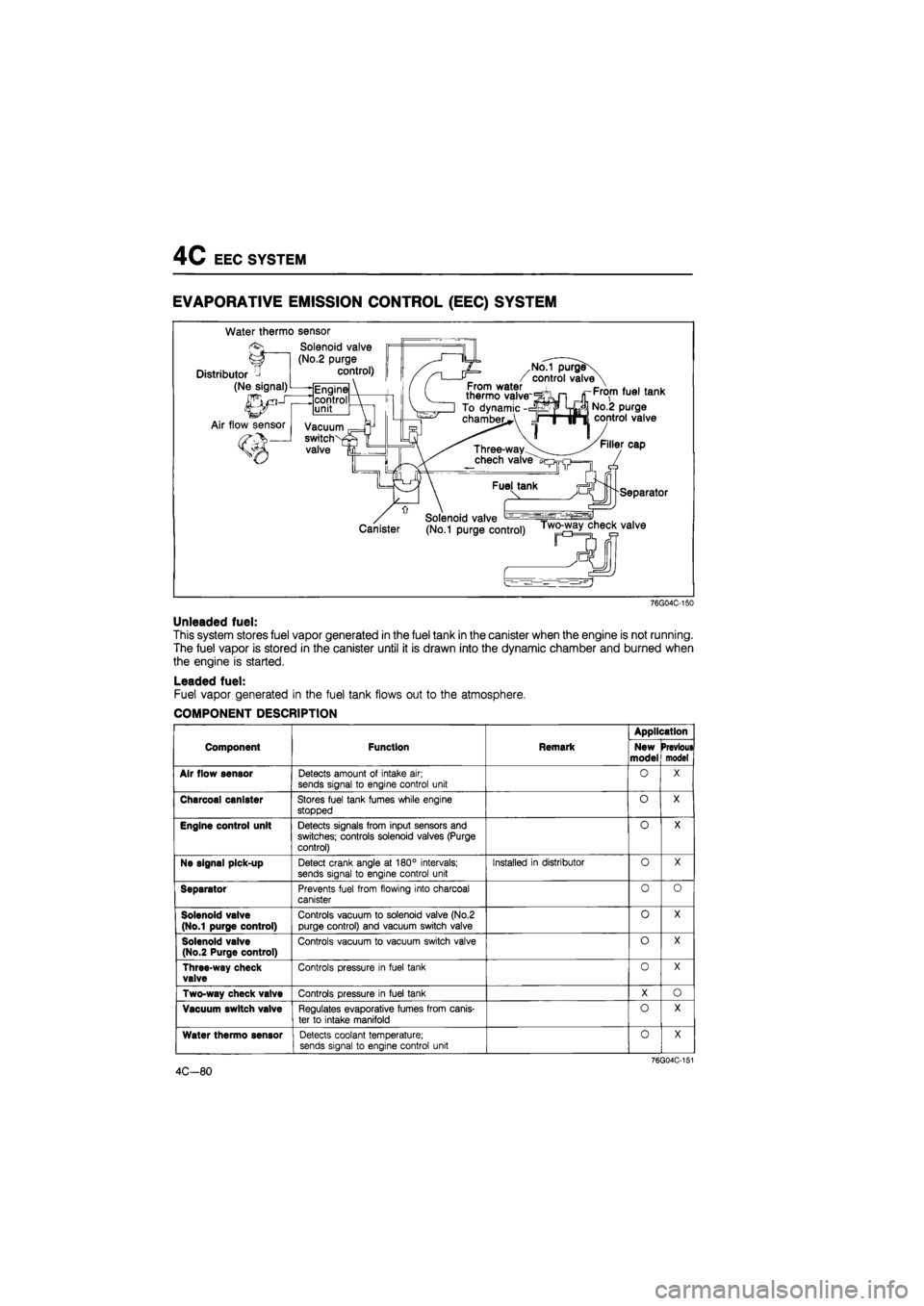

4C EEC SYSTEM

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Water thermo sensor

76G04C-150

Unleaded fuel:

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

Leaded fuel:

Fuel vapor generated in the fuel tank flows out to the atmosphere.

COMPONENT DESCRIPTION

Application

Component Function Remark New

model Prevtoui model

Air flow sensor Detects amount of intake air; sends signal to engine control unit

O X

Charcoal canister Stores fuel tank fumes while engine stopped

o X

Engine control unit Detects signals from input sensors and

switches; controls solenoid valves (Purge

control)

o X

Ne signal pick-up Detect crank angle at 180° intervals; sends signal to engine control unit

Installed in distributor o X

Separator Prevents fuel from flowing into charcoal canister

o o

Solenoid valve

(No.1 purge control)

Controls vacuum to solenoid valve (No.2

purge control) and vacuum switch valve

0 X

Solenoid valve (No.2 Purge control)

Controls vacuum to vacuum switch valve o X

Three-way check valve Controls pressure in fuel tank o X

Two-way check valve Controls pressure in fuel tank X o

Vacuum switch valve Regulates evaporative fumes from canis-ter to intake manifold

o X

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

0 X

76G04C-151

4C-80

Page 642 of 1865

EEC SYSTEM

4C

TROUBLESHOOTING

Check

the

condition

of the

wiring harness

and

connectors before checking

the

sensors

or

switches.

Note

Make

the

system inspection first.

If no

problem

is

found, continue with inspection

of the

next system

of the

Troubleshooting Guide. (Refer

to

pages 4C—10

and 11.)

Possible cause

« > (0 >

£ O

S in

E 3 3

Solenoid

valve

(No.

1 purge

control)

Solenoid

valve

(No.

2 purge

control)

Two-way

check

valve

a>

>. >

i

S

i

^

3>

o

o CO k n

V

*

£

3

_

a

o

k. T-

a>

E»S 3

_

a

o

CM

£

£ O

S in o E tm a> £

w V

o ID C a> in o E k a> £ **

a>

Engine

control

unit

terminal

c o +s o a> a. w c

E a> O <0 >

Solenoid

valve

(No.

1 purge

control)

Solenoid

valve

(No.

2 purge

control)

Two-way

check

valve

>-

0)

£

£

1-

o

Q. d) o

fe

Z

o

ofe Z

O

(0 (0 $ 2P,20

in

(O

Page 4C—83 4C-84 4C-84 4C—84 4C-83 4C-85 4C-82 4C-83 4C-106 4C-107 4C—98 4C-81

Checking order (Unleaded fuel) 4 2 3 — 10 11 5 6 7 8 9 1

Checking order

(Leaded fuel) — — — 1 — 2

76G04C-152

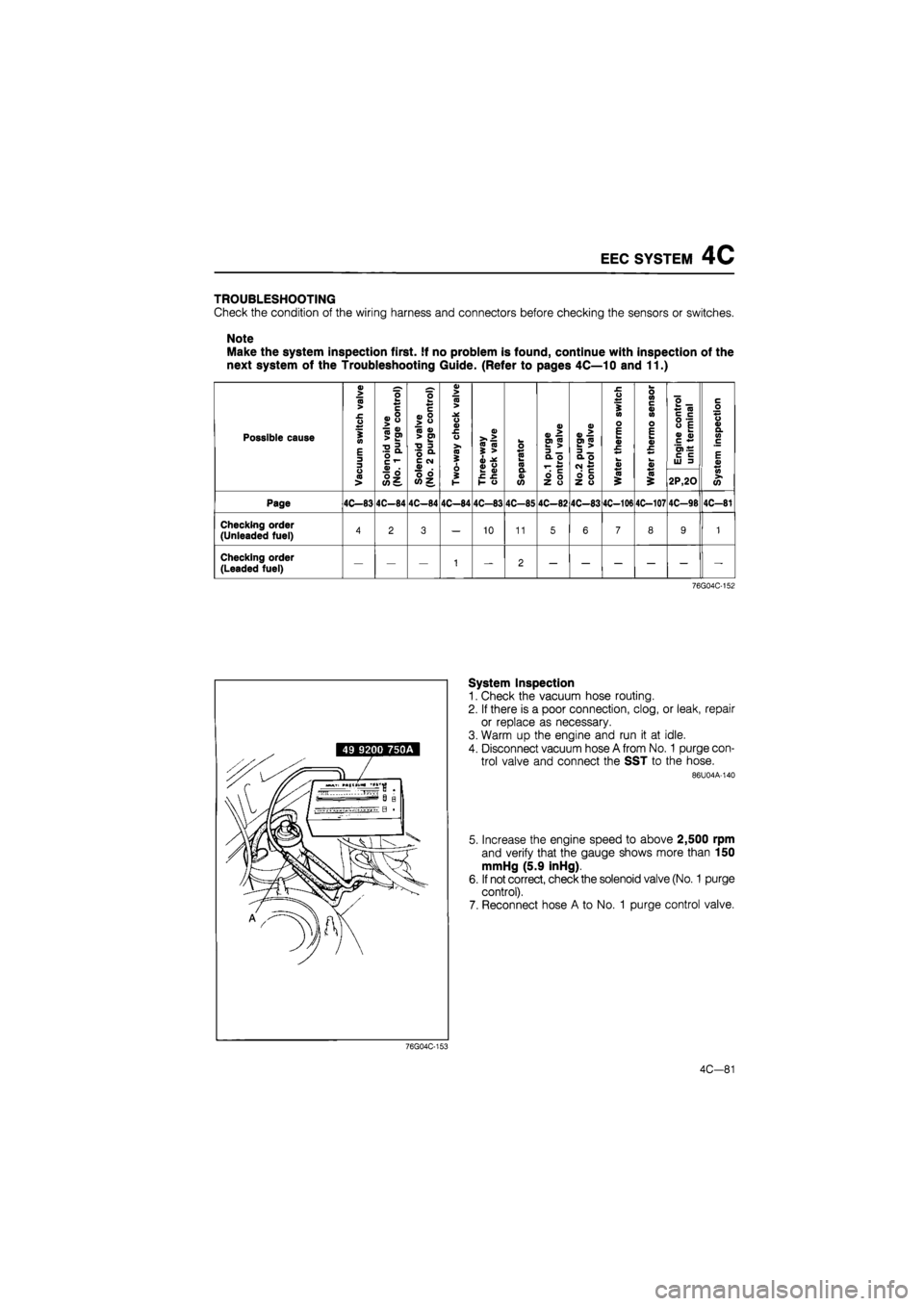

System Inspection

1. Check

the

vacuum hose routing.

2. If there

is a

poor connection, clog,

or

leak, repair

or replace

as

necessary.

3. Warm

up the

engine

and run it at

idle.

4. Disconnect vacuum hose

A

from

No. 1

purge con-

trol valve

and

connect

the SST to the

hose.

86U04A-140

5. Increase

the

engine speed

to

above 2,500

rpm

and verify that

the

gauge shows more than

150

mmHg

(5.9

inHg).

6. If not correct, check the solenoid valve (No.

1

purge

control).

7. Reconnect hose

A to No. 1

purge control valve.

4C-81

76G04C-153

Page 645 of 1865

4C EEC SYSTEM

Solenoid Valve

1. Remove the solenoid valve.

76G04C-159

2. Connect vacuum hoses to the valve as shown in

the figure.

3. Blow air through the valve from hose A and check

that air comes out of the valve air filter.

4. Apply 12V and ground the solenoid valve with jum-

per wires.

5. Blow air through the valve from hose A and check

that the air comes out of port B.

6. Replace, if necessary.

86U04A-151

Two-way check valve

Inspection

1. Remove the two-way check valve.

76G04C-160

4C-84

Connect a pressure gauge to the passage that nor-

mally is connected to the fuel tank.

Blow through the valve from port A. Verify that the

valve opens at 2.94 kPa (0.03 kg/cm2,0.43 psi).

Remove the pressure gauge and connect

it

to the

passage to atmosphere.

Blow through the valve from port B. Verify that the

valve opens at 0.98 kPa (0.01 kg/cm2,0.14 psi).

Page 646 of 1865

EEC SYSTEM 4C

®(

Atomosphere

side Fuel tank side

76G04C-212

Replacement

1. Remove the two-way check valve.

2. Install a new valve so that the arrow on the valve

faces atmosphere side.

— - ...

h§§

IB// i \

1 S LCD \

1

J M

J k

Separator

^ X

IB// i \

1 S LCD \

1

J M

J k ==J/

J——K

1

Separator

1. Remove the separator.

2. Visually check the separator for damage.

3. Replace, if necessary.

86U04A-154

4C—85

Page 648 of 1865

EXHAUST SYSTEM (UNLEADED FUEL) 4C

EXHAUST SYSTEM (UNLEADED FUEL)

Exhaust manifold

Catalytic converter

Main silencer

Middle pipe

76G04C-163

The catalytic converter is used to reduce CO and HC. The converter contains a compound of plati-

num and rhodium. It is a two-way catalyst type with a volume of 2,300 cc (140 cu in).

4C—87

Page 649 of 1865

4C EXHAUST SYSTEM (UNLEADED FUEL)

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

Torque Specifications

86U04A-159

4. Catalytic converter

5. Bracket

6. Front pipe

INSPECTION

1. Check the catalytic converter and exhaust pipe for

deterioration or restriction.

2. Check the insulation covers welded onto the cata-

lytic converter for damage.

Note

If the insulation cover is touching the catalytic

converter housing, excessive heat at the floor

will occur.

19—26 N-m (1.9—2.6 m-kg, 14—19 tt-lb)

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

34—49 N-m (3.5—5.0 m-kg, 26—36 ft-lb)

39—57 N-m (4.0-5.8 m-kg, 29—42 ft-lb)

37—52 N m (3.8—5.3 m-kg, 27—38 ft-lb) 8—11 N-m 8—1.1 m-kg, 69—95 In-lb)

N-m .3 m-kg, 38 ft-lb)

1. Main silencer

2. Middle pipe

3. Pre-silencer

86U04A-160

4C—88

Page 650 of 1865

EXHAUST SYSTEM (LEADED FUEL) 4C

EXHAUST SYSTEM (LEADED FUEL)

Pre silencer (No.1)

Main silencer

Middle pipe

76G04C-164

4C-89

Page 651 of 1865

4C EXHAUST SYSTEM (LEADED FUEL)

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

Torque Specifications

1. Main silencer

2. Middle pipe

3. No. 2 pre-silencer

76G04C-165

4. No. 1 pre-silencer

5. Bracket

6. Front pipe

4C—90