engine oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 880 of 1865

7B TROUBLESHOOTING (G4A-EL)

ON VEHICLE-

-f-

—OFF VEHICLE

\ Inspection point

and

\ reference page

Condition

•

Electronic control system Prelim-

inary

Hydraulic

control

system

Power train \ Inspection point

and

\ reference page

Condition

•

7B-66

m CO I m r--

7B-63

i

cn to I m

Section

4B

|

Section

4B

|

ID to i m

CO CO 1 CD

7B-68

|

en CO 1 IX)

to 1 00 r-.

cn CD 1 CO

7B-69

|

1 CD r--

cn s-1 m

Section

4B

r*-cn

S-1 CD h-

"=1-

rJ CO

7 CD r-

(XI o

1 m

cn CM 1 CD

7B-107

|

CD

7 CD 7 m

I

7B-113

I

CO CM

7 CO r-.

m cn

7 CO r-.

cn

7 DO r-

CM CM

7 CO

|

7B-126

CO

1*-r*-

7 m r-

\ Inspection point

and

\ reference page

Condition

•

Brake

light

switch

|

Inhibitor

switch

|

Mode

switch

|

1

CO. •o o X

Idle

switch

Throttle

sensor

|

Water

temp,

switch

|

0 tn c 0) cn

s

ffi

Q tn 01 o Hi >

Pulse

generator

|

"a o c 0) a to CM

TJ O CL ID s CO C\l 3-4

solenoid

|

Lock-up

solenoid

I

ATF

level

and

condition

|

Selector

lever

m Xj CO CJ 03

1 sz

Idle

speed

and

Ignition

timing

Control

valves

Accumulators

Oil

pump

Hydraulic

circuit

Torque

converter

Forward

clutch

Coasting

clutch

Reverse

clutch

JT O

u TT ro 2-4

brake

band

and

servo

$ 2

B cn cii > £ "O C CO

o

XI y

o >. CO S cb a O

One-way

clutch

2

s CI Cn tz JC 5 0-

Planetary

gear

Differential

assembly

Accelerating

Vehicle does

not

move

in

D,

S,

L,

or R

range

O O O O O O O O O O 0

Accelerating

Vehicle moves

in N

range -0 0 -—

Accelerating

Excessive creep

-0 O O -—

Accelerating

No creep

at all

O o o o

o

G 0 O O

Shifting

|

No shift

O O o

o

0 O 0 0

o

o O

Shifting

|

Abnormal shift sequence

0 o O O 0

o

o 0 O o o 0 O

Shifting

|

Frequent shifting 0 o 0 0 o 0 O O 0

Shifting

|

Excessively high

or

low

shift point 0 o 0 O 0 0 o 0 O 0 0

Shifting

|

No lock-up

0 o 0 0 o 0 O O o O

Shifting

|

No kick-down o o o o

Slipping

Engine

run

away

or

slip when

starting vehicle 0 o 0 O o O

Slipping

Engine

run

away

or

slip when

up-

or

down-shifting o o o 0 o O 0 0 O

8 n cn 4S SI V)

Excessive

N to D or N to R

shift shock o O o o o O

8 n cn 4S SI V)

Excessive shift shock when

up-

shifting

or

downshifting o o o o 0 0 0 8 n cn 4S SI V) Excessive shift shock when

changing range 0 0 o 0 o

j

Noise

Transaxle noisy

in N or P

range o o 0 O

j

Noise

Transaxle noisy

in D, S, L,

or

R range o 0 0 O

I

Others

j

No engine braking o O o 0 o o

I

Others

j

No mode change o 0 o o o o o o o

O

o

0

I

Others

j

Transaxle overheats

o o

0 o 0 o 0

I

Others

j

Vehicle moves

in

"P",

or

park-ing gear

not

disengaged when

"P"

is

dis-

engaged

0 O

I

Others

j

Hold indicator flashes o

0

o

0

o

O

o — — —

I

Others

j

Engine will

not

start

o

o

O — — —

76G07B-014

7B—14

Page 893 of 1865

TROUBLESHOOTING (G4A-EL) 7B

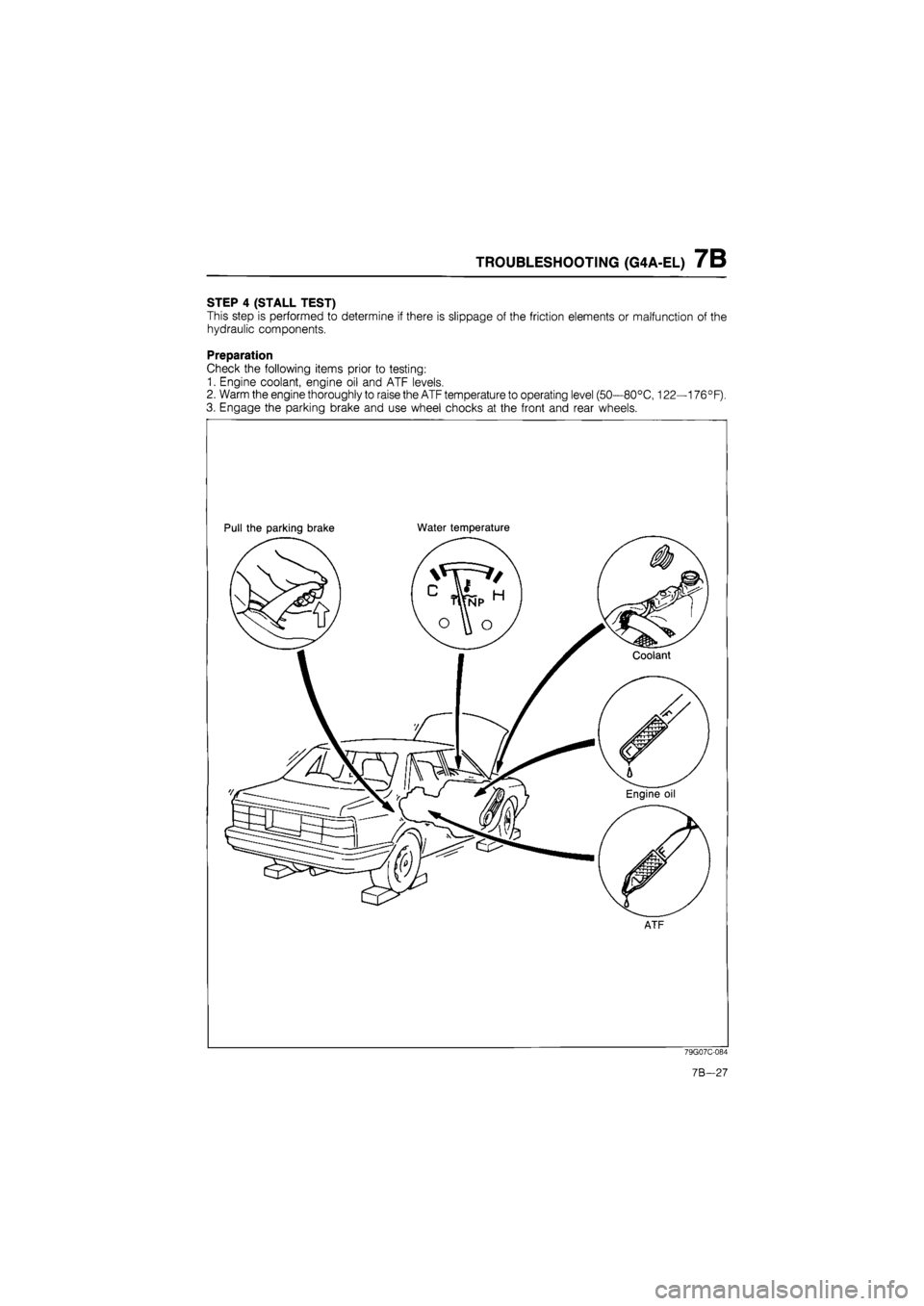

STEP 4 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Engage the parking brake and use wheel chocks at the front and rear wheels.

Pull the parking brake Water temperature

ATF

79G07C-084

7B-27

Page 895 of 1865

TROUBLESHOOTING (G4A-EL) 7B

7. Perform the stall test for the following ranges in the same manner.

(1) D range (4) L range

(2) D range (Hold) (5) L range (Hold)

(3) S range (Hold)

Caution

Be sure to allow sufficient cooling time between each stall test.

Engine stall speed: D.S.L range 2170—2270 rpm

R range 2130—2230 rpm

Note

The stall test can be performed with the EC-AT Tester in place of a tachometer.

Drum stall speed indication: 0 rpm

76G0/B-029

Evaluation

Condition Possible cause

Above specification

In all ranges Insufficient line

pressure

Worn oil pump

Above specification

In all ranges Insufficient line

pressure Oil leakage from oil pump, control valve, and/or transmission case

Stuck pressure regulator valve

Above specification

In forward ranges Forward clutch slipping One-way clutch 1 slipping

Above specification

In D range One-way clutch 2 slipping

Above specification

In S (Hold) and L (Hold) ranges Coasting clutch slipping

Above specification In D (Hold) and S (Hold) ranges 2-4 brake band slipping Above specification

In R, L and L (Hold) ranges Low and reverse brake slipping

Above specification

In R range

Low and reverse brake slipping Reverse cluch slipping Perform road test to determine whether problem is low and reverse brake or reverse clutch

a) Engine brake applied in 1st ...Reverse clutch

b) Engine brake not applied in 1st ...Low and reverse brake

Within specification All shift control elements within transmission are func-

tioning normally.

Below specification

Engine out of tune

Below specification One-way clutch slipping within torque converter

86U07B-036

7B-29

Page 897 of 1865

TROUBLESHOOTING (G4A-EL) 7B

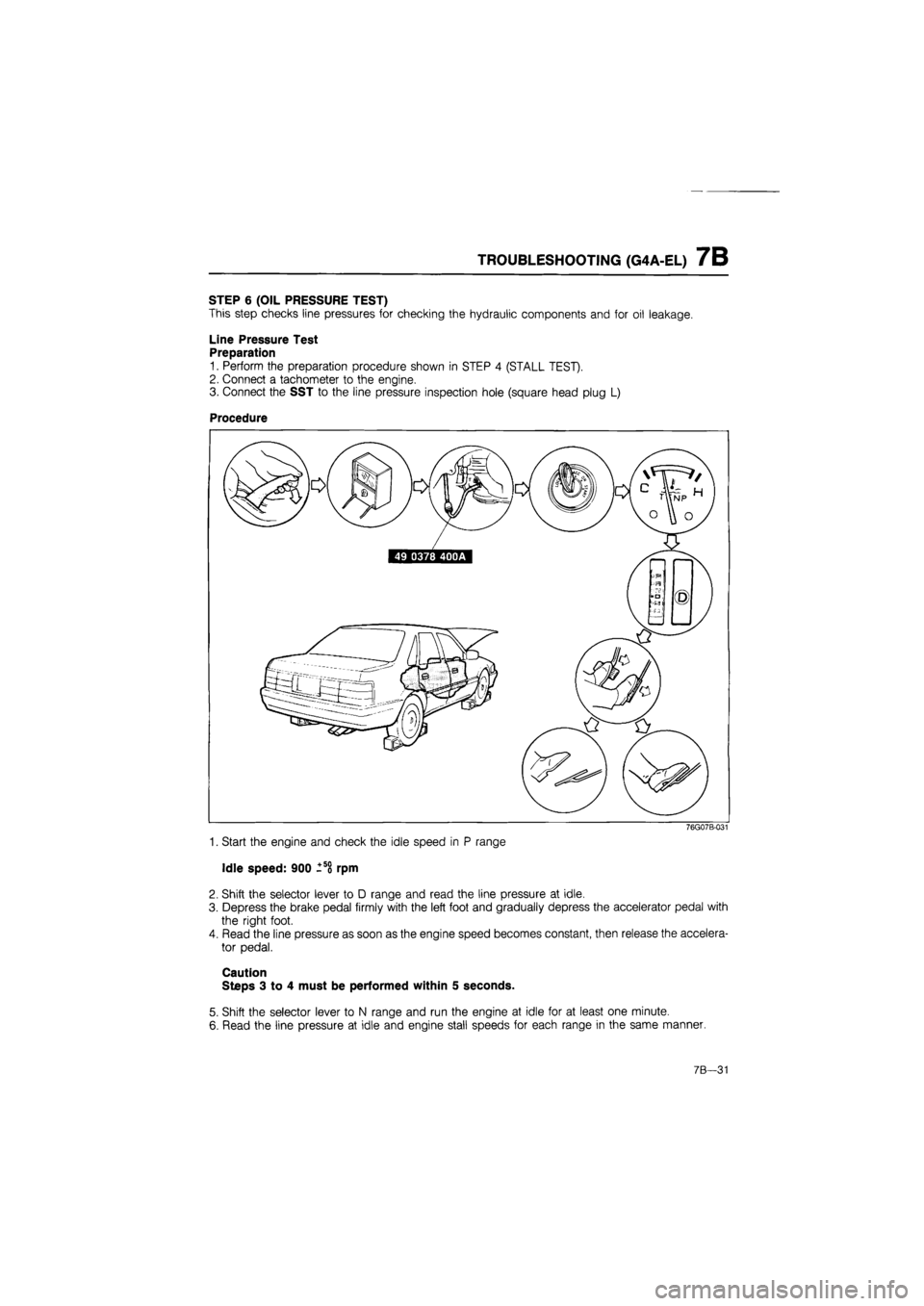

STEP 6 (OIL PRESSURE TEST)

This step checks line pressures for checking the hydraulic components and for oil leakage.

Line Pressure Test

Preparation

1. Perform the preparation procedure shown in STEP 4 (STALL TEST).

2. Connect a tachometer to the engine.

3. Connect the SST to the line pressure inspection hole (square head plug L)

Procedure

76G07B-031

1. Start the engine and check the idle speed in P range

Idle speed: 900 -so rpm

2. Shift the selector lever to D range and read the line pressure at idle.

3. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

4. Read the line pressure as soon as the engine speed becomes constant, then release the accelera-

tor pedal.

Caution

Steps 3 to 4 must be performed within 5 seconds.

5. Shift the selector lever to N range and run the engine at idle for at least one minute.

6. Read the line pressure at idle and engine stall speeds for each range in the same manner.

7B—31

Page 907 of 1865

TROUBLESHOOTING (G4A-HL) 7B

TROUBLESHOOTING (G4A-HL)

GENERAL NOTE

In the event of a problem with the automatic transaxle, the cause may be in the engine, power train,

hydraulic control system, or electrical control system.

When troubleshooting, therefore, it is recommended to begin from those points that can be judged

quickly and easily. The recommended troubleshooting sequence is described below.

STEP 4: TIME LAG TEST

Check time lag of oil pressure supply

STEP 6: OIL PRESSURE TEST Check line, throttle, and governor pressures

This step checks conditions surrounding the automatic

transaxle.

This step checks the electrical control system.

• Function of the electrical control system

• Components

This step checks the power train. • Friction element slipping • Torque converter capacity

This step checks operation of the hydraulic control system. • Accumulators • Friction elements slipping • Regulating valves

This step checks functions of the electric control system and

hydraulic control system.

This step checks major points of the hydraulic control system.

• Oil pump • Line pressure control • Throttle pressure control

• Governer pressure control

STEP 5: ROAD TEST Check items on road test

• Shift point • Shift schedule

• Kick-down • Shift shock • Lock-up and overdrive inhibition

By following the above 6 steps, the cause of the problem should be located.

As another guide to faster location of the causes of problems, the Quick Diagnosis Chart is included

at pages 7B—42, 43.

In this chart, a circle is used to indicate the components that might be the cause of trouble for 20

types of problems. It is only necessary to check those components indicated by circles, at each step

of the troubleshooting process, in order to quickly locate the cause of the problem.

76G07B-040

7B—41

Page 915 of 1865

TROUBLESHOOTING (G4A-HL) 7B

STEP 3 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Engage the parking brake and use wheel chocks at the front and rear wheels.

Pull the parking brake Water temperature

ATF

83U07B-038

7B—49

Page 916 of 1865

7B TROUBLESHOOTING (G4A-HL)

Procedure

76G07B-054

1. Connect a tachometer to the engine.

2. Shift the selector lever to D range.

3. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

4. Read and note the engine speed as soon as it becomes constant, then release the accelerator pedal.

Caution

Steps 3 to 4 must be performed within 5 seconds.

5. Shift the selector to N range and run the engine at idle speed for at least one minutes.

Note This one minute idle period is performed to cool the ATF and prevent oil degradation.

6. Perform stall tests for the following ranges in the same manner.

(1) 2 range

(2) 1 range

(3) R range

Standard stall speed:

FE engine F8 engine

D.S.L range 2430—2530 rpm D.S.L range 2180—2280 rpm

R range 2390—2490 rpm R range 2140—2240 rpm

Caution

Always provide adequate cooling time between individual range stall tests.

7B-50

Page 917 of 1865

TROUBLESHOOTING (G4A-HL) 7B

Evaluation

Condition Possible cause

Above specification

In all ranges Insufficient line pressure

Worn oil pump

Above specification

In all ranges Insufficient line pressure Oil leakage from oil pump, control valve, and/or transaxle case

Stuck pressure regulator valve

Above specification

In D 2, and 1 One-way clutch 1 slipping

Above specification

In D range only One-way clutch 2 slipping

Above specification In 2 range only 2-4 brake slipping Above specification

In R range only

Low and reverse brake slipping

Above specification

In R range only

Reverse clutch slipping

Above specification

In R range only Perform a road test, to determine if this is caused by the low and reverse brake or the reverse clutch, as follows:

a) Effective engine braking in 1 range Front clutch

b) No engine braking in 1 range Low and reverse brake

Within specification All shift control elements within transaxle are functioning

normally.

Below specification

Engine out of tune

Below specification One-way clutch slipping within torque converter

76G07B-055

7B—51

Page 924 of 1865

7B TROUBLESHOOTING (G4A-HL)

Line Pressure Test

Preparation

1. Connect the SST to the line pressure output point

(square head plug L).

2. Connect a tachometer to the engine.

3. Perform the preparation procedure shown in STEP

3 (STALL TEST).

STEP 6 (OIL PRESSURE TEST)

This step checks line, throttle, and governor pressures to check the operation of hydraulic compo-

nents and for oil leakage.

83U07B-047

Procedure

76G07B-062

1. Start the engine and check that the idle speed is 900 rpm.

2. Shift the selector lever to D range.

3. Read the line pressure at idle.

4. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

5. Read the line pressure as soon as the engine speed becomes constant, then release the accelera-

tor pedal.

Caution

Steps 4 to 5 must be performed within 5 seconds.

5. Shift the selector lever to N range and run the engine at idle for at least one minute.

6. Read the line pressure at idle and engine stall speeds for each range in the same manner.

7B—58

Page 937 of 1865

ON-VEHICLE MAINTENANCE 7B

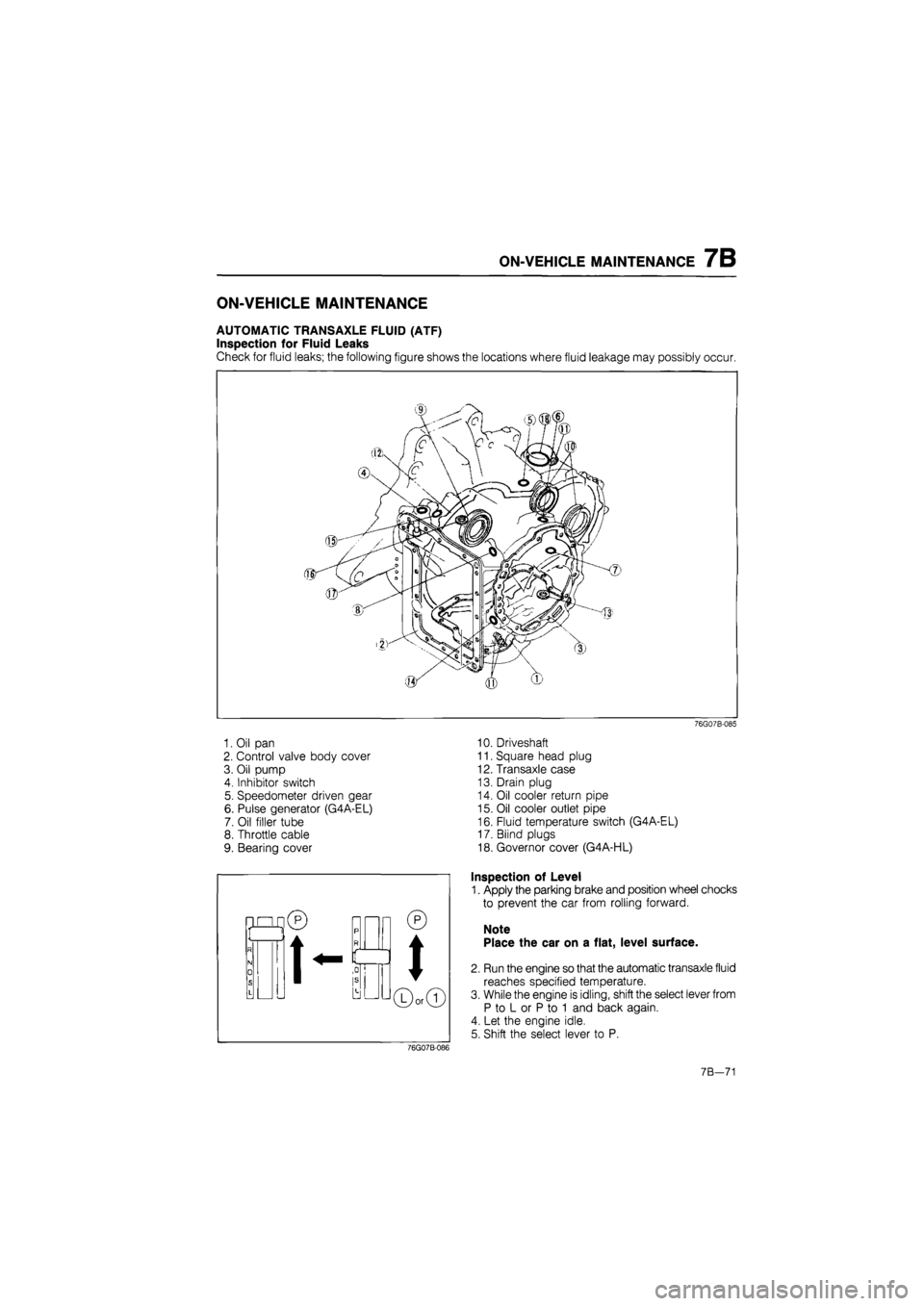

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator (G4A-EL)

7. Oil filler tube

8. Throttle cable

9. Bearing cover

76G07B-085

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch (G4A-EL)

17. Blind plugs

18. Governor cover (G4A-HL)

Inspection of Level

1. Apply the parking brake and position wheel chocks

to prevent the car from rolling forward.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches specified temperature.

3. While the engine is idling, shift the select lever from

P to L or P to 1 and back again.

4. Let the engine idle.

5. Shift the select lever to P.

76G07B-086

7B—71