alternator belt MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 247 of 1865

DISASSEMBLY (AUXILIARY PARTS) 1 C

1. A/C compressor bracket 9. Alternator and drive belt

2. Vacuum pump and drive belt 10. Oil filter

3. Air funnel assembly 11. Oil filter cover

4. Comprex supercharger insulator 12. Oil cooler assembly

5. Comprex supercharger and drive belt 13. Exhaust pipe bracket

6. Exhaust manifold insulator 14. Alternator bracket

7. Exhaust manifold 15. Blow-by chamber

8. Intake manifold

Blow-by chamber

76G01C-074

Disassembly Note

Engine hanger

1. Remove the CSD hose.

2. Loosen the vacuum pump oil pipe bolts.

76G01C-075

3. Install the engine on the SST.

76G01C-076

1C—35

Page 300 of 1865

1 C ASSEMBLY (AUXILIARY PARTS)

76G01C-205

76G01C-206

76G01C-207

o e-

Oil Cooler Assembly

1. Clean the contact surfaces of the cylinder block

and oil filter assembly.

2. Install new O-rings, and apply a coat of engine oil.

3. Install the oil cooler assembly.

Tightening torque:

Bolt A: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

4. Connect the water hose.

Oil Filter

1. Install the oil filter cover.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Apply a coat of engine oil to the filter rubber seal.

3. Install the oil filter until the rubber seal contacts the

oil cooler by hand. Then tighten it a 7/6 turn fur-

ther with a band type wrench.

Alternator

1. Install the alternator.

Tightening torque:

Bolt A: 19—26 N m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

2. Install the alternator drive belt, and adjust the belt

deflection. (Refer to page 1C—7)

76G01C-208

1C—88

expert22 ajia http://rutracker.org

Page 360 of 1865

WATER PUMP 3B

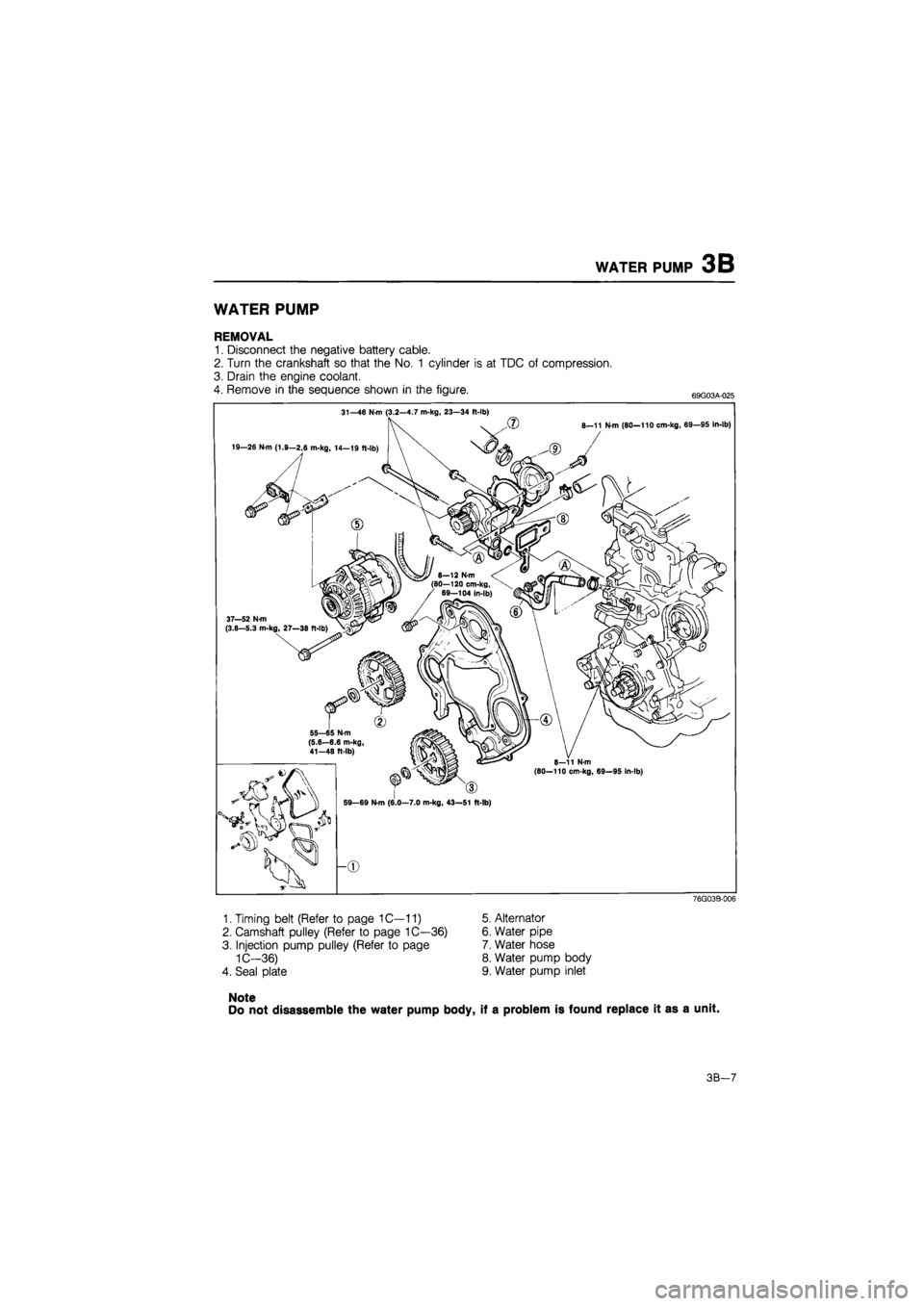

WATER PUMP

REMOVAL

1. Disconnect the negative battery cable.

2. Turn the crankshaft so that the No. 1 cylinder is at TDC of compression.

3. Drain the engine coolant.

4. Remove in the sequence shown in the figure. 69G03A-025

31—46 N m (3.2—4.7 m-kg, 23—34 ft-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

(?) 8—11 N-m (80—110 cm-kg, 69—95 In-lb)

37—52 N-m (3.8—5.3 m-kg, 27—38 ft

55—65 N-m (5.6—6.6 m-kg, 41-48 ft-lb)

(80—110 cm-kg, 69—95 In-lb)

59—69 N-m (6.0—7.0 m-kg, 43—51 ft-lb)

76G03B-006

1. Timing belt (Refer to page 1C—11)

2. Camshaft pulley (Refer to page 1C—36)

3. Injection pump pulley (Refer to page

1C—36)

4. Seal plate

Note

Do not disassemble the water pump body, if a problem is found replace it as a unit.

5. Alternator

6. Water pipe

7. Water hose

8. Water pump body

9. Water pump inlet

3B-7

Page 361 of 1865

3B WATER PUMP

INSPECTION

Check the following. Replace the pump if necessary.

1. Cracks or damage

2. Abnormal noise, bearing sticking or loose

86U03X-014

INSTALLATION

Install in the reverse order of removal referring to the

installation note.

Installation Note

Water pump

1. Remove any gasket fragments, dirt or oil from the

contact surfaces.

2. Install the water pump and new gasket so that the

printed side of the gasket faces the water pump.

Tightening torque:

Bolt A: 31—46 N-m

(3.2—4.7 m-kg, 23—34 ft-lb)

Bolt B: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Water pipe

1. Apply a coat of vegetable oil to the O-ring.

2. Install the water pipe.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

3. Connect the water hose.

76G03B-008

Alternator

1. Install the alternator.

Tightening torque:

Bolt A: 19—26

N

m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

2. Install the alternator drive belt and Comprex su-

percharger drive belt, and adjust the belt deflec-

tion. (Refer to page 1C—7)

76G03B-009

3B—8

Page 707 of 1865

5

ENGINE ELECTRICAL SYSTEM

OUTLINE 5— 2

STRUCTURAL VIEW 5— 2

SPECIFICATIONS 5— 5

TROUBLESHOOTING 5— 7

BATTERY 5— 8

INSPECTION 5— 8

RECHARGE. 5— 8

SPARK PLUG 5— 9

REMOVAL AND INSTALLATION 5— 9

INSPECTION 5— 9

IGNITION COIL 5—10

INSPECTION 5—10

HIGH-TENSION LEAD 5—10

INSPECTION 5—10

DISTRIBUTOR 5—11

SPARK TEST 5—11

IGNITION TIMING 5—11

SPARK CONTROL 5—12

REMOVAL 5—14

DISASSEMBLY 5—15

INSPECTION 5—16

ASSEMBLY 5—17

INSTALLATION 5—18

H.E.I. TROUBLESHOOTING 5—19

IGNITER (FE DOHC) 5—20

INSPECTION 5—20

ALTERNATOR 5—21

CROSS SECTIONAL VIEW 5—21

CHARGING SYSTEM 5—22

TROUBLESHOOTING 5—23

REMOVAL 5—27

DISASSEMBLY 5—28

INSPECTION 5—32

ASSEMBLY 5—35

INSTALLATION 5—36

V-BELT TENSION 5—37

STARTER (GASOLINE ENGINE

0.85, 0.95 KW TYPE) 5—38

STARTING SYSTEM CIRCUIT 5—38

ON-VEHICLE INSPECTION 5—38

REMOVAL AND INSTALLATION 5—39

DISASSEMBLY AND ASSEMBLY 5—39

INSPECTION 5—40

PERFORMANCE INSPECTION 5—43

STARTER

(GASOLINE ENGINE, 1.4 KW TYPE) 5—45

STARTING SYSTEM 5—45

ON-VEHICLE UNSPECTION 5—45

REMOVAL 5—46

DISASSEMBLY 5—46

INSPECTION 5—49

ASSEMBLY 5—53

CHECKING OPERATION 5—54

INSTALLATION 5—55

STARTER

(DIESEL ENGINE, 2.0 kW TYPE) .... 5—56

STARTING SYSTEM CIRCUIT 5—56

ON-VEHICLE INSPECTION 5—56

REMOVAL AND INSTALLATION 5—57

DISASSEMBLY AND ASSEMBLY 5—57

INSPECTION 5—61

PERFORMANCE INSPECTION 5—64

STARTER

(DIESEL ENGINE, 2.2 kW TYPE).... 5—66

STARTING SYSTEM CIRCUIT 5—66

ON-VEHICLE INSPECTION 5—66

REMOVAL AND INSTALLATION 5—67

DISASSEMBLY AND ASSEMBLY 5—67

INSPECTION 5—71

PERFORMANCE INSPECTION 5—74

QUICK START SYSTEM (QSS) 5-76

COMPONENT LOCATION 5—76

CIRCUIT DIAGRAM 5—76

SYSTEM OPERATION 5—77

TROUBLESHOOTING GUIDE 5—78

CONTROL UNIT 5—79

GLOW PLUG RELAY 5—80

BLOW PLUG 5—80

WATER TEMPERATURE SWITCH.... 5—80

76g05x-001

Page 711 of 1865

OUTLINE 5

SPECIFICATIONS

Gasoline Engine

item

Engine

F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE

(DOHC)

Battery

Voltage

Type and capacity

12. Negative ground

(20 hour rate) 34B19L(S) (33 Ah): General 50D20L (50 Ah), 55D23L (60 Ah): ECE

Alternator

Type A.C.

Output V-A 12-70

Regulator type Transistorized (built-in IC regulator)

Regulated voltage 14.1-14.7

Brush length

mm (in) Standard 16.5 (0.650)

Minimum 8.0 (0.315)

Drive belt tension

mm (in)/98 N (10 kg, 22 lb) New: 6-8 (0.24-0.32), Used: 7-9 (0.28-0.35)

Starter

Type Coaxial reduction: Middle East & General (FE • carburetor)

Non-reduction: Others

Output V-kW 12-0.85

Brush length

mm (in)

12-0.95

Standard 17.0 (0.669)

Minimum 11.5 (0.453)

Unleaded fuel

17.0 (0.669)

Others

17.51

Unleaded fuel 11.5(0.453) Others 10,0 (0.394)

12-1.4 12-0.95

17.0 (0.669)

11.5 (0.453)

Ignition timing 6 ± 10 BTDC (Vacuum hose disconnected)

12

±

1° BTDC

(Test connector

grounded)

Distributor

Type Fully transistorized (HEI)

Electronic spark advance

Centrifugal spark advance

(crank angle/engine speed)

degree/rpm

F6

-2-2/1,000 6-10/2,100 14-18/6,100

F8 -2—2/1,000 10-14/2,100 18-22/6,100

FE (8 VALVE)—Carburetor Unleaded fuel

(MTX)-2—2/1,760 12—16/3,360 22—26/5,320 (ATX)-2-2/1,300 12-16/3,360 22-26/5,320

Others

-2—2/1,460 10—14/2,540 22—26/5,540

FE (12 VALVE)—Carburetor -2-2/1,200 10—14/2,400 10—14/4,000 16-20/5,000

FE—Fuel injection (except FE DOHC) -2—2/1,000 10—14/2,600 10—14/4,600 16—20/5,800

Unleaded fuel model 76G05X-503

5-5

Page 712 of 1865

5 OUTLINE

Item

Engine F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE (DOHC)

F6 and F8

-2-2/100 6-10/300

FE (8 VALVE)—Carbu retor Unleaded fuel -2—2/120 8—12/245

Distributor

Vacuum spark advance (Crank angle/Vacuum)

Others (MTX) -2-(ATX) -2--2/100 16-

-2/100 10-

-20/250

-14/200

degree/mmHg (inHg) FE (12 VALVE)—Carburetor

-2-2/120 11-15/300

FE—Fuel injection (except FE DOHC) [A chamber] -2-2/125 18-22/300

[B chamber] -2-2/125 -6 10/200

Spark plug

Type

FE (8 VALVE)*1 NGK: BPR5ES-11, BPR6ES-11 Nippon Denso: W16EXR-U11, W20EXR-U11 Others

NGK: BPR5ES, BPR6ES Nippon Denso: W16EXR-U, W20EXR-U

NGK:

BCPR5E, BCPR6E Nippon

Denso: Q16PR-U, Q20PR-U

Unleaded fuel

NGK: BCPR5E-11 BCPR6E-11 BCPR7E-11

Leaded fuel NGK: BCPR5E BCPR6E

Plug gap mm (in)

0.75-0.85 (0.030-0.033), FE (8 VALVE)*1 1.0-1.1 (0.039-0.043)

0.7-0.8

(0.028-0.031)

1.0-1.1 "

/n noo

n n/9

0.7-0.8 *2 (0.028-0.031)

Firing order 1-3—4-2 76G05X-504

Diesel Engine

——Engine Item RF-N RF-CX

Battery

Voltage V 12, Negative ground Battery Type and capacity

(20 hour rate) 80D26L (65)

50D20L, 50D20R (50)-ECE 80D26L (65)

65D23L, 65D23R (55)

Alternator

Type A.C.

Alternator

Output V-A 12-70 12-75

Alternator

Regulator type Transistorized (built-in IC regulator)

Alternator Regulated voltage V 14.1-14.7 Alternator

Brush length mm (in)

Standard 16.5 (0.650) 21.5 (0.846)

Alternator

Brush length mm (in) Minimum 8.0 (0.315) 8.0 fO.315)

Alternator

Drive belt tension

mm (in)/98 N (10 kg. 92 lb) New: 9-11 (0.35-0.43), Used: 12-14 (0.47-0.55)

Starter

Type Reduction

Starter Output V—kW 12—2.0, 12-2.2 (Cold area) Starter Brush length

mm (in)

Standard 2.0 kW: 17.0 (0.669). 2.2 kW: 18.0 (0.709) Starter Brush length

mm (in) Minimum 2.0 kW: 11.0 (0.453), 2.2 kW: 11.0 (0.453)

Firing order 1-3-4-2

Unleaded fuel model *2 Leaded fuel model

76G05X-505

5-6

Page 713 of 1865

TROUBLESHOOTING GUIDE 5

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Starter does not turn at all, or Its turning speed Is too slow to start the engine.

Battery and related parts Poor contact of battery terminals Poor grounding of negative cable Voltage drop caused by discharged battery Insufficient voltage caused by battery malfunction

Clean and tighten Clean and repair Recharge Replace

5- 8

5- 8 5- 8

Ignition switch and related parts Poor contact of ignition switch Loose ignition switch wiring or connector Broken wire between ignition switch and magnetic switch

Replace Repair Repair or replace 5-38,45,56,66

Magnetic switch and related parts Loose wiring and/or connectors Burnt magnetic switch contact plate or improper contact Broken wire in magnetic switch pull-in coil Broken wire magnetic switch holding coil

Repair Replace

Replace Replace

5-38,45,56,66 5-43,54,64,74

5-43,54,64,74 5-43,54.64,74

Starter Poor contact of brushes

Fatigued brush spring Poor grounding of field coil Poor soldering of field coil Commutator mulfunction Grounded armature Worn parts

Adjust contact or replace Replace Replace Repair Repair or Replace Replace Replace

5-43,54,64,74

Starting problem Gasoline engine Insufficient battery capacity Malfunction of spark plug (s)

Loose positive terminal Damaged distributor cap or rotor Ignition coil malfunction laniter malfunction

Recharge Clean, adjust or replace Tighten Replace Replace Renlane

5— 8 5— 9

5—16 5—10 5-16,20

Diesel engine Insufficient battery capacity QSS svstem malfunction Recharge ReDlace 5— 8 5-76

Starter turns but pinion gear does not mesh with ring gear

Starter Tip of overrunning clutch pinion is worn Weakened overrunning clutch drive spring Worn overrunning clutch Improper sliding of spline

Worn bushing Worn ring gear

Replace Replace Replace Adjust contact and repair, or replace Replace ReDlace

5-40,54,70

Starter turns continuously (does not stop) Magnetic switch Sticking contact place of magnetic switch Layer shorting coil of magnetic switch Ignition switch does not return

Replace Replace Rfinlanfi

5-43,54,64,74 5-43,54,64,74

Misfiring Dirty or damaged spark plug (s) Malfunction of wiring, or open circuit Damaged distributor cap

Clean or replace Repair or Replace Replace

5- 9 5—10 5—16

Discharging of battery Alternator Loose drive belt Grounded or broken stator coil Broken rotor coil Poor contact of brush and slip ring

Malfunction of rectifier Malfunction of IC regulator Battery and related parts Insufficient or unsuitable battery electrolyte Malfunction of battery electrode (internal short-circuit) Poor contact of battery terminal (s) Excessive electric load

Adjust Replace Replace Clean, repair or replace Replace Replace

Adjust Replace

Clean and tighten Check power consump-tion and short circuit

5-37 5-32 5-32 5-32

5-34

5— 8 5- 8

5— 8

Overcharging of battery IC regulator malfunction Operating in extremely high temperature Replace Reoair

Poor acceleration Mis-adjusted ignition timing Distributor malfunction Adjust Repair or replace 5—11 5—11

Knocking Mis-adjusted ignition timing | Distributor malfunction Adjust Repair or replace 5—11 5—11

76G05X-003

5-7

Page 733 of 1865

ALTERNATOR 5

TEST 6

1. Turn the ignition switch ON.

2. Turn all electric loads off and release

the brake pedal.

3. Check that voltage between S terminal

and ground is battery voltage.

S terminal

76G05X-057

76G05X-030

86U05X-074

REMOVAL (GASOLINE)

Remove in the sequence shown in the figure.

1. Disconnect the negative battery terminal.

2. Disconnect the wire and connector from the al-

ternator.

3. Remove the bolts.

4. Remove the V-belt.

-5. Remove the alternator to upper side (LHD) or lower

side (RHD).

REMOVAL (DIESEL)

1. Disconnect the negative battery terminal.

2. Remove the right hand driveshaft (Refer to Sec-

tion 9).

3. Disconnect the wire and connector from the al-

ternator.

4. Loosen the idle pulley nuts and remove the drive

belts.

5. Remove the bolts and remove the alternator from

under the vehicle.

76G05X-031

5-27

Page 743 of 1865

ALTERNATOR 5

Adjusting bar bolt

Mounting bolt

Alternator

drive pulley

Mounting bolt

Drive pulley

76G05X-037

-Adjusting bolt

tidier pulley

v v Ml/v — Locknut

/

Alternator x

V-BELT TENSION (GASOLINE)

Adjustment

1. Loosen the alternator mounting bolt and adjusting

bar bolt.

2. Adjust the alternator belt deflection while pushing

the V-belt with a force of 98 N (10 kg, 22 ft-lb).

Deflection:

New: 6—8 mm (0.24—0.31 in)

Used: 7—9 mm (0.27—0.35 in)

3. Tighten the bolts and recheck the tension.

V-BELT TENSION (DIESEL)

Adjustment

1. Looson the alternator idler pulley locknut.

2. Adjust the alternator belt deflection while pushing

the V-belt with a force of 98 N (10 kg, 22 ft-lb).

Deflection:

Alternator

New: 8—10 mm (0.31—0.39 in)

Used: 9—11 mm (0.35—0.43 in)

76G05X-038

—" , ^Comprex pulley

/ Locknut

/ ^"Wvl If Adjusting bolt^

Idler pulley

Alternator pulley—-V-

(rear) >

Comprex

New: 4.0—5.0 mm (0.16—0.20 in)

Used: 4.5—5.5 mm (0.18—0.21 in)

3. Tighten the bolts and nuts and recheck the tension.

76G05X-058

5—37