charging MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 688 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

BOOST AIR TEMPERATURE SENSOR

Removal

Remove the boost air temperature sensor from the

compressed air funnel.

76G04D-039

Thermometer

Inspection

1. Place the boost air temperature sensor in oil.

2. Heat the oil and check continuity of the sensor with

an ohmmeter. Replace if necessary.

Continuity : over 150°C (302°F)

No continuity: below 143°C (289°F)

76G04D-040

Installation

Install the boost air temperature sensor in the com-

pressed air funnel.

Tightening torque:

29—39 N m (3.0—4.0 m-kg, 22—29 ft-lb)

76G04D-041

4D—17

Page 707 of 1865

5

ENGINE ELECTRICAL SYSTEM

OUTLINE 5— 2

STRUCTURAL VIEW 5— 2

SPECIFICATIONS 5— 5

TROUBLESHOOTING 5— 7

BATTERY 5— 8

INSPECTION 5— 8

RECHARGE. 5— 8

SPARK PLUG 5— 9

REMOVAL AND INSTALLATION 5— 9

INSPECTION 5— 9

IGNITION COIL 5—10

INSPECTION 5—10

HIGH-TENSION LEAD 5—10

INSPECTION 5—10

DISTRIBUTOR 5—11

SPARK TEST 5—11

IGNITION TIMING 5—11

SPARK CONTROL 5—12

REMOVAL 5—14

DISASSEMBLY 5—15

INSPECTION 5—16

ASSEMBLY 5—17

INSTALLATION 5—18

H.E.I. TROUBLESHOOTING 5—19

IGNITER (FE DOHC) 5—20

INSPECTION 5—20

ALTERNATOR 5—21

CROSS SECTIONAL VIEW 5—21

CHARGING SYSTEM 5—22

TROUBLESHOOTING 5—23

REMOVAL 5—27

DISASSEMBLY 5—28

INSPECTION 5—32

ASSEMBLY 5—35

INSTALLATION 5—36

V-BELT TENSION 5—37

STARTER (GASOLINE ENGINE

0.85, 0.95 KW TYPE) 5—38

STARTING SYSTEM CIRCUIT 5—38

ON-VEHICLE INSPECTION 5—38

REMOVAL AND INSTALLATION 5—39

DISASSEMBLY AND ASSEMBLY 5—39

INSPECTION 5—40

PERFORMANCE INSPECTION 5—43

STARTER

(GASOLINE ENGINE, 1.4 KW TYPE) 5—45

STARTING SYSTEM 5—45

ON-VEHICLE UNSPECTION 5—45

REMOVAL 5—46

DISASSEMBLY 5—46

INSPECTION 5—49

ASSEMBLY 5—53

CHECKING OPERATION 5—54

INSTALLATION 5—55

STARTER

(DIESEL ENGINE, 2.0 kW TYPE) .... 5—56

STARTING SYSTEM CIRCUIT 5—56

ON-VEHICLE INSPECTION 5—56

REMOVAL AND INSTALLATION 5—57

DISASSEMBLY AND ASSEMBLY 5—57

INSPECTION 5—61

PERFORMANCE INSPECTION 5—64

STARTER

(DIESEL ENGINE, 2.2 kW TYPE).... 5—66

STARTING SYSTEM CIRCUIT 5—66

ON-VEHICLE INSPECTION 5—66

REMOVAL AND INSTALLATION 5—67

DISASSEMBLY AND ASSEMBLY 5—67

INSPECTION 5—71

PERFORMANCE INSPECTION 5—74

QUICK START SYSTEM (QSS) 5-76

COMPONENT LOCATION 5—76

CIRCUIT DIAGRAM 5—76

SYSTEM OPERATION 5—77

TROUBLESHOOTING GUIDE 5—78

CONTROL UNIT 5—79

GLOW PLUG RELAY 5—80

BLOW PLUG 5—80

WATER TEMPERATURE SWITCH.... 5—80

76g05x-001

Page 713 of 1865

TROUBLESHOOTING GUIDE 5

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Starter does not turn at all, or Its turning speed Is too slow to start the engine.

Battery and related parts Poor contact of battery terminals Poor grounding of negative cable Voltage drop caused by discharged battery Insufficient voltage caused by battery malfunction

Clean and tighten Clean and repair Recharge Replace

5- 8

5- 8 5- 8

Ignition switch and related parts Poor contact of ignition switch Loose ignition switch wiring or connector Broken wire between ignition switch and magnetic switch

Replace Repair Repair or replace 5-38,45,56,66

Magnetic switch and related parts Loose wiring and/or connectors Burnt magnetic switch contact plate or improper contact Broken wire in magnetic switch pull-in coil Broken wire magnetic switch holding coil

Repair Replace

Replace Replace

5-38,45,56,66 5-43,54,64,74

5-43,54,64,74 5-43,54.64,74

Starter Poor contact of brushes

Fatigued brush spring Poor grounding of field coil Poor soldering of field coil Commutator mulfunction Grounded armature Worn parts

Adjust contact or replace Replace Replace Repair Repair or Replace Replace Replace

5-43,54,64,74

Starting problem Gasoline engine Insufficient battery capacity Malfunction of spark plug (s)

Loose positive terminal Damaged distributor cap or rotor Ignition coil malfunction laniter malfunction

Recharge Clean, adjust or replace Tighten Replace Replace Renlane

5— 8 5— 9

5—16 5—10 5-16,20

Diesel engine Insufficient battery capacity QSS svstem malfunction Recharge ReDlace 5— 8 5-76

Starter turns but pinion gear does not mesh with ring gear

Starter Tip of overrunning clutch pinion is worn Weakened overrunning clutch drive spring Worn overrunning clutch Improper sliding of spline

Worn bushing Worn ring gear

Replace Replace Replace Adjust contact and repair, or replace Replace ReDlace

5-40,54,70

Starter turns continuously (does not stop) Magnetic switch Sticking contact place of magnetic switch Layer shorting coil of magnetic switch Ignition switch does not return

Replace Replace Rfinlanfi

5-43,54,64,74 5-43,54,64,74

Misfiring Dirty or damaged spark plug (s) Malfunction of wiring, or open circuit Damaged distributor cap

Clean or replace Repair or Replace Replace

5- 9 5—10 5—16

Discharging of battery Alternator Loose drive belt Grounded or broken stator coil Broken rotor coil Poor contact of brush and slip ring

Malfunction of rectifier Malfunction of IC regulator Battery and related parts Insufficient or unsuitable battery electrolyte Malfunction of battery electrode (internal short-circuit) Poor contact of battery terminal (s) Excessive electric load

Adjust Replace Replace Clean, repair or replace Replace Replace

Adjust Replace

Clean and tighten Check power consump-tion and short circuit

5-37 5-32 5-32 5-32

5-34

5— 8 5- 8

5— 8

Overcharging of battery IC regulator malfunction Operating in extremely high temperature Replace Reoair

Poor acceleration Mis-adjusted ignition timing Distributor malfunction Adjust Repair or replace 5—11 5—11

Knocking Mis-adjusted ignition timing | Distributor malfunction Adjust Repair or replace 5—11 5—11

76G05X-003

5-7

Page 714 of 1865

5 BATTERY

BATTERY

INSPECTION

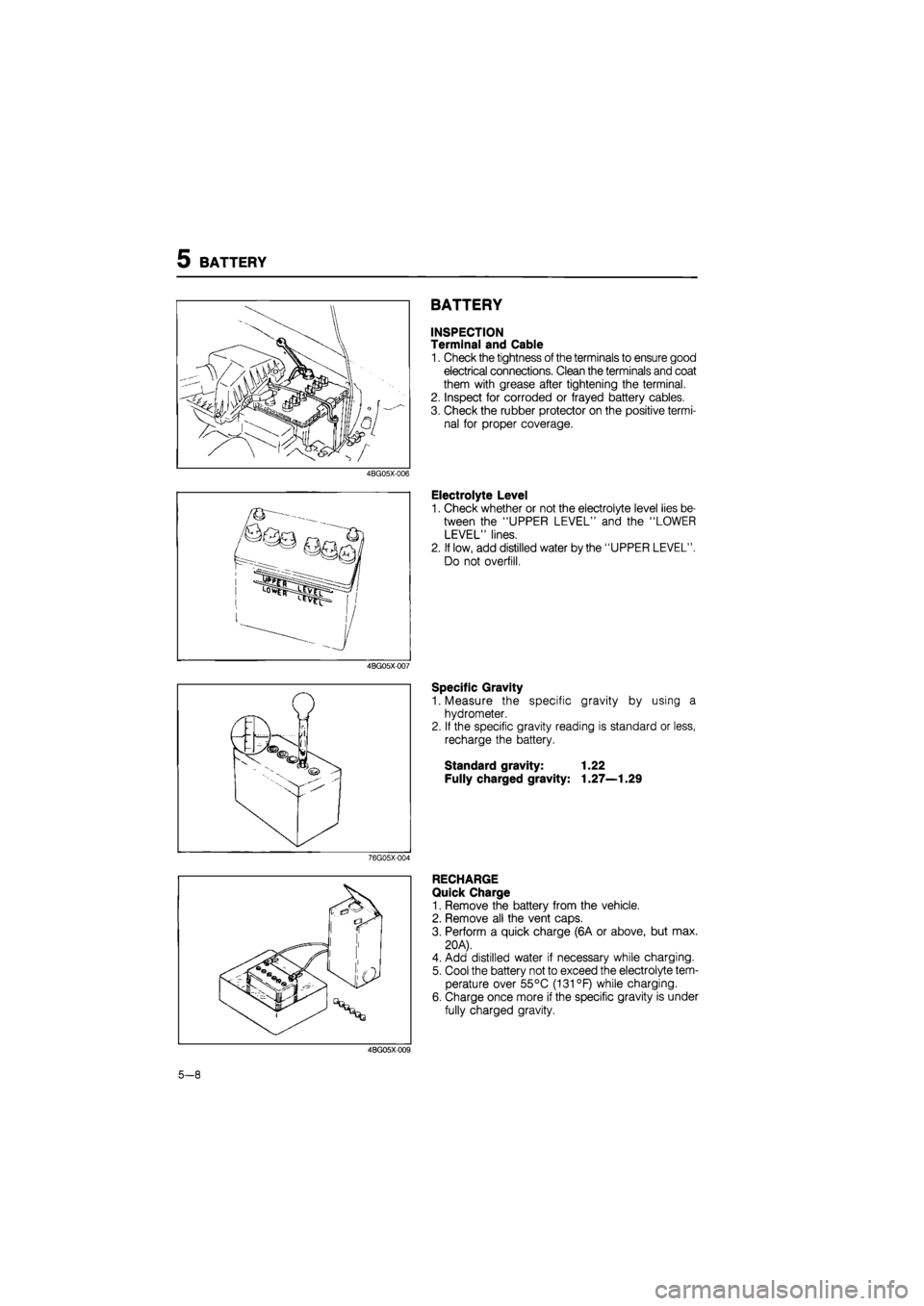

Terminal and Cable

1. Check the tightness of the terminals to ensure good

electrical connections. Clean the terminals and coat

them with grease after tightening the terminal.

2. Inspect for corroded or frayed battery cables.

3. Check the rubber protector on the positive termi-

nal for proper coverage.

4BG05X-006

Electrolyte Level

1. Check whether or not the electrolyte level lies be-

tween the "UPPER LEVEL" and the "LOWER

LEVEL" lines.

2. If low, add distilled water by the "UPPER LEVEL".

Do not overfill.

4BG05X-007

Specific Gravity

1. Measure the specific gravity by using a

hydrometer.

2. If the specific gravity reading is standard or less,

recharge the battery.

Standard gravity: 1.22

Fully charged gravity: 1.27—1.29

76G05X-004

RECHARGE

Quick Charge

1. Remove the battery from the vehicle.

2. Remove all the vent caps.

3. Perform a quick charge (6A or above, but max.

20 A).

4. Add distilled water if necessary while charging.

5. Cool the battery not to exceed the electrolyte tem-

perature over 55°C (131 °F) while charging.

6. Charge once more if the specific gravity is under

fully charged gravity.

4BG05X-009

5-8

Page 715 of 1865

SPARK PLUG 5

Slow Charge

1. Stop the engine

2. Turn all the accessories off.

3. Remove the negative battery cable.

4. Perform a slow charge (3.5A to 4.5A).

5. Add distilled water if necessary while charging.

6. Charge once more if the specific gravity is under

fully charged gravity.

4BG05X-010

SPARK PLUG

REMOVAL AND INSTALLATION

Note the following points:

1. When the high-tension lead is to be pulled off, be

sure to pull the boot itself, and not the wire.

2. Tighten the spark plugs to the specified torque.

Tightening torque: 15—23 N-m

(1.5—2.3 m-kg, 10.8—16.6 ft-lb)

76G05X-054

Wear and adhesion or cabon

INSPECTION

Check the following points. If a problem is found, re-

place the spark plug.

1. Damaged insulation

2. Worn electrodes

3. Carbon deposits

If cleaning is necessary, use a plug cleaner or a

wire brush. Clean the upper insulator also.

4. Damaged gasket

5. Burnt condition of spark insulator

6. If it is black with carbon deposits, either misfiring

due to improper proportions of gas and air or over-

heating of the plug may have occurred.

Plug gap:

FE (12VALVE) and FE DOHC Leaded fuel

model:

0.70—0.80 mm (0.028—0.031 in)

FE (8VALVE) and FE DOHC Unleaded fuel

model:

1.0—1.10 mm (0.039—0.043 in)

Others:

0.75—0.85 mm (0.030—0.034 in)

76G05X-005

5-9

Page 728 of 1865

5 ALTERNATOR

CHARGING SYSTEM

76G05X-023

86U05X-008

Caution

a) Be sure the battery connections are not

reversed, because this will damage the rec-

tifier.

b) Do not use high-voltage testers such as a

megger, because they will damage the rec-

tifier.

c) Remember that battery voltage is always

applied to the alternator B terminal.

d) Do not ground the L terminal while the en-

gine is running.

e) Do not start the engine while the connec-

tor is disconnected from the L and S ter-

minals.

5—22

Page 1791 of 1865

16 OUTLINE

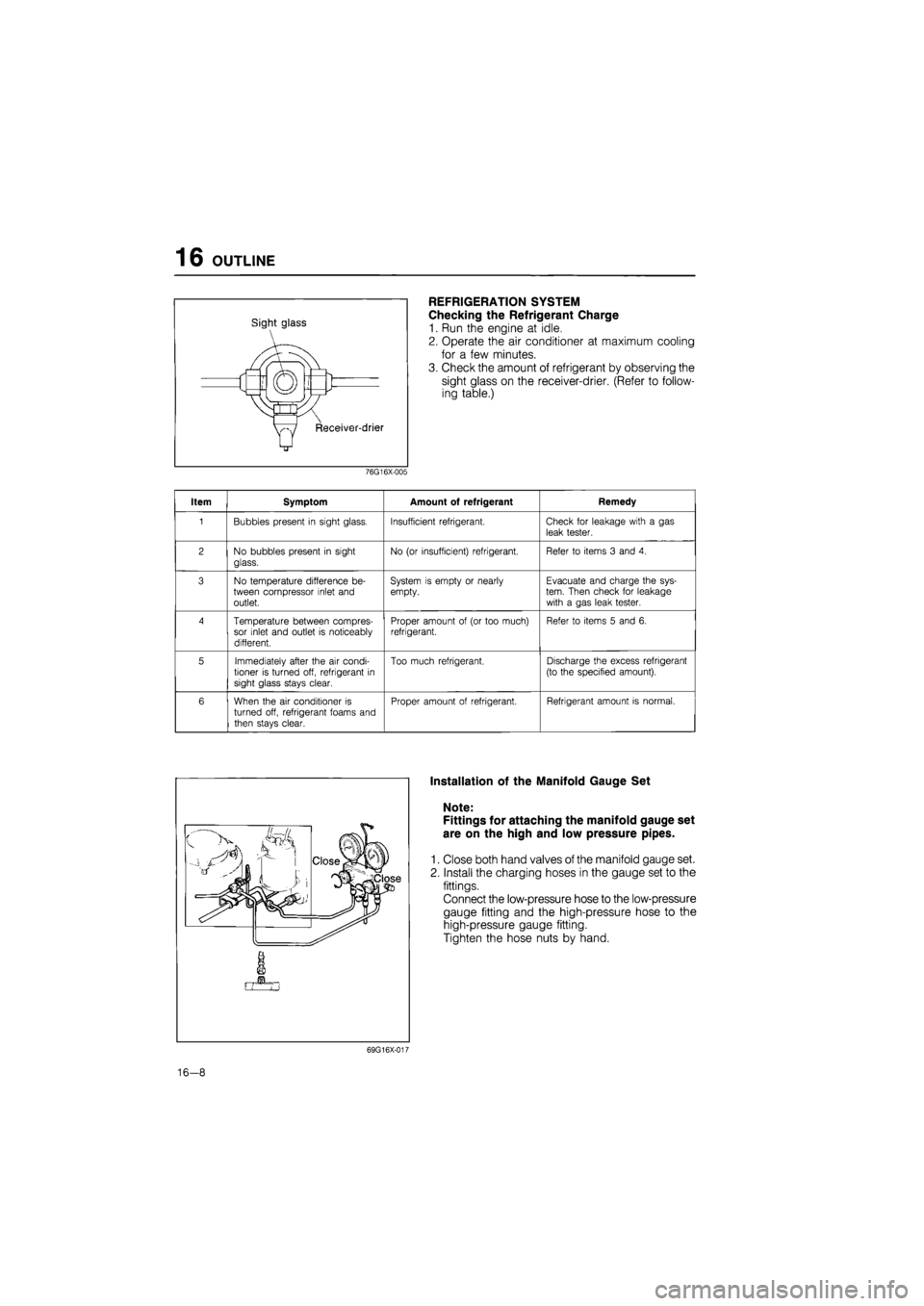

Sight glass

REFRIGERATION SYSTEM

Checking the Refrigerant Charge

1. Run the engine at idle.

2. Operate the air conditioner at maximum cooling

for a few minutes.

3. Check the amount of refrigerant by observing the

sight glass on the receiver-drier. (Refer to follow-

ing table.)

76G16X-005

Item Symptom Amount of refrigerant Remedy

1 Bubbles present

in

sight glass. Insufficient refrigerant. Check

for

leakage with

a gas

leak tester.

2 No bubbles present

in

sight

glass.

No

(or

insufficient) refrigerant. Refer

to

items

3

and

4.

3 No temperature difference

be-

tween compressor inlet and outlet.

System

is

empty

or

nearly empty. Evacuate and charge the sys-tem. Then check

for

leakage with

a

gas leak tester.

4 Temperature between compres-sor inlet and outlet

is

noticeably different.

Proper amount

of (or

too much) refrigerant. Refer

to

items

5

and

6.

5 Immediately after the

air

condi-tioner

is

turned off, refrigerant

in

sight glass stays clear.

Too much refrigerant. Discharge the excess refrigerant

(to the specified amount).

6 When the

air

conditioner

is

turned off, refrigerant foams and

then stays clear.

Proper amount

of

refrigerant. Refrigerant amount

is

normal.

Installation of the Manifold Gauge Set

Note:

Fittings for attaching the manifold gauge set

are on the high and low pressure pipes.

1. Close both hand valves of the manifold gauge set.

2. Install the charging hoses in the gauge set to the

fittings.

Connect the low-pressure hose to the low-pressure

gauge fitting and the high-pressure hose to the

high-pressure gauge fitting.

Tighten the hose nuts by hand.

69G16X-017

16-8

Page 1792 of 1865

OUTLINE 16

Discharging the Refrigeration System

1. Connect the manifold gauge set to the system.

2. Place the free end of the center hose on a shop

towel.

3. Slowly open the high pressure manual valve to ad-

just the refrigerant flow. Open the valve only slightly.

Caution

If refrigerant is allowed to escape too fast, the

compressor oil will be drawn out of the

system.

4. Check the shop towel to make sure no oil is being

discharged.

If oil is present, partially close the manual valve.

5. After the manifold gauge reading drops below 343

kPa (3.5 kg/cm2, 50 psi), slowly open the low

pressure manual valve.

6. As the system pressure drops, gradually open both

the high- and low-pressure manual valves until both

gauges read 0 kPa (0 kg/cm2, 0 psi).

76G16X-631

Evacuation of the Refrigeration System

Whenever the air-conditioning system has been ex-

posed to the atmosphere, it must be evacuated.

1. Connect the manifold gauge set.

2. Connect the center hose of the gauge set to the

vacuum pump inlet.

3. Operate the vacuum pump, then open both man-

ual valves.

4. When the low pressure gauge indicates approxi-

mately 710 mmHg (28 inHg), close both manual

valves and stop the vacuum pump.

5. Check to be sure that the degree of pressure does

not change after 10 minutes or more in this condi-

tion.

If

the pressure changes, check the system for

leaks, and repair if necessary.

6. If no leaks are found, once again operate the vacu-

um pump and open both manual valves to obtain

760 mmHg (30 inHg).

7. Close both manual valves, and stop the vacuum

pump.

Disconnect the hose from the vacuum pump.

69G16X-019

16-9

Page 1794 of 1865

OUTLINE 16

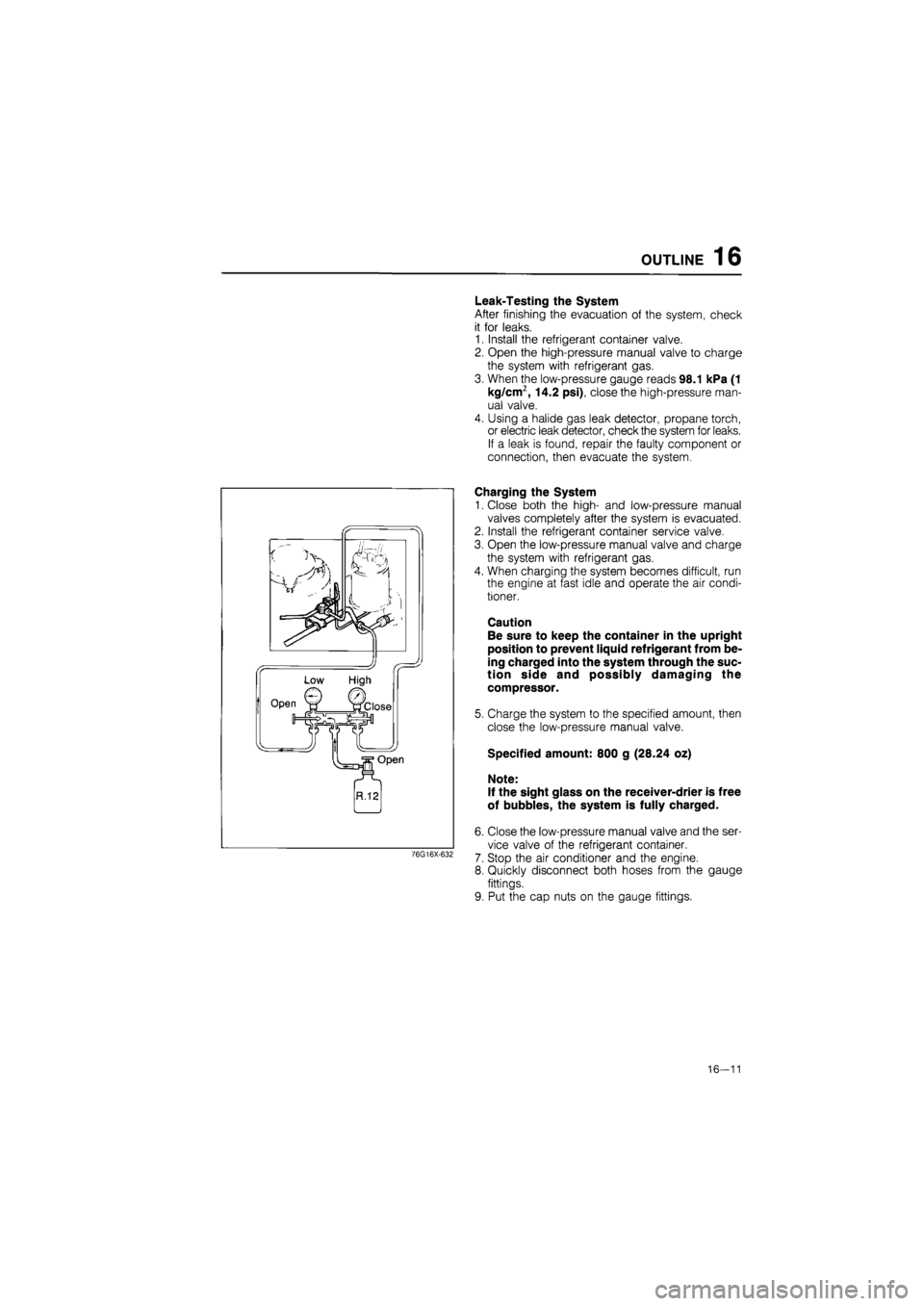

Leak-Testing the System

After finishing the evacuation of the system, check

it for leaks.

1. Install the refrigerant container valve.

2. Open the high-pressure manual valve to charge

the system with refrigerant gas.

3. When the low-pressure gauge reads 98.1 kPa (1

kg/cm2, 14.2 psi), close the high-pressure man-

ual valve.

4. Using a halide gas leak detector, propane torch,

or electric leak detector, check the system for leaks.

If a leak is found, repair the faulty component or

connection, then evacuate the system.

76G16X-632

Charging the System

1. Close both the high- and low-pressure manual

valves completely after the system is evacuated.

2. Install the refrigerant container service valve.

3. Open the low-pressure manual valve and charge

the system with refrigerant gas.

4. When charging the system becomes difficult, run

the engine at fast idle and operate the air condi-

tioner.

Caution

Be sure to keep the container in the upright

position to prevent liquid refrigerant from be-

ing charged into the system through the suc-

tion side and possibly damaging the

compressor.

5. Charge the system to the specified amount, then

close the low-pressure manual valve.

Specified amount: 800 g (28.24 oz)

Note:

If the sight glass on the receiver-drier is free

of bubbles, the system is fully charged.

6. Close the low-pressure manual valve and the ser-

vice valve of the refrigerant container.

7. Stop the air conditioner and the engine.

8. Quickly disconnect both hoses from the gauge

fittings.

9. Put the cap nuts on the gauge fittings.

16—11

Page 1803 of 1865

16 COMPRESSOR

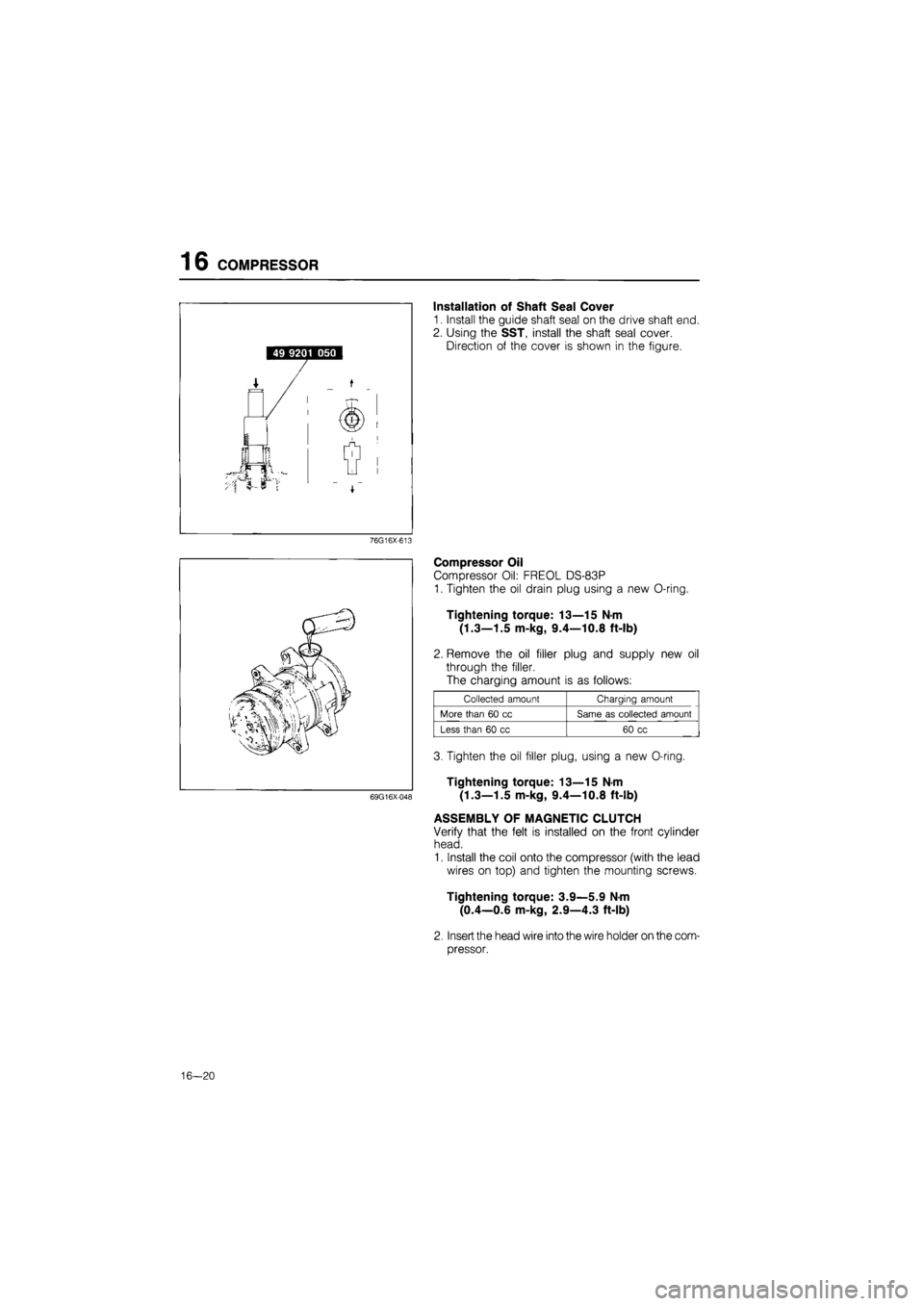

Installation of Shaft Seal Cover

1. Install the guide shaft seal on the drive shaft end.

2. Using the SST, install the shaft seal cover.

Direction of the cover is shown in the figure.

76G16X-613

69G16X-048

Compressor Oil

Compressor Oil: FREOL DS-83P

1. Tighten the oil drain plug using a new O-ring.

Tightening torque: 13—15 N-m

(1.3—1.5 m-kg, 9.4—10.8 ft-lb)

2. Remove the oil filler plug and supply new oil

through the filler.

The charging amount is as follows:

Collected amount Charging amount

More than

60 cc

Same

as

collected amount

Less than

60 cc

60

cc

3. Tighten the oil filler plug, using a new O-ring.

Tightening torque: 13—15 N-m

(1.3—1.5 m-kg, 9.4—10.8 ft-lb)

ASSEMBLY OF MAGNETIC CLUTCH

Verify that the felt is installed on the front cylinder

head.

1. Install the coil onto the compressor (with the lead

wires on top) and tighten the mounting screws.

Tightening torque: 3.9—5.9 N-m

(0.4—0.6 m-kg, 2.9—4.3 ft-lb)

2. Insert the head wire into the wire holder on the com-

pressor.

16—20