AUX MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 300 of 1865

1 C ASSEMBLY (AUXILIARY PARTS)

76G01C-205

76G01C-206

76G01C-207

o e-

Oil Cooler Assembly

1. Clean the contact surfaces of the cylinder block

and oil filter assembly.

2. Install new O-rings, and apply a coat of engine oil.

3. Install the oil cooler assembly.

Tightening torque:

Bolt A: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

4. Connect the water hose.

Oil Filter

1. Install the oil filter cover.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Apply a coat of engine oil to the filter rubber seal.

3. Install the oil filter until the rubber seal contacts the

oil cooler by hand. Then tighten it a 7/6 turn fur-

ther with a band type wrench.

Alternator

1. Install the alternator.

Tightening torque:

Bolt A: 19—26 N m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

2. Install the alternator drive belt, and adjust the belt

deflection. (Refer to page 1C—7)

76G01C-208

1C—88

expert22 ajia http://rutracker.org

Page 301 of 1865

ASSEMBLY (AUXILIARY PARTS) 1 C

.JfTjQi

76G01C-209

76G01C-210

76G01C-211

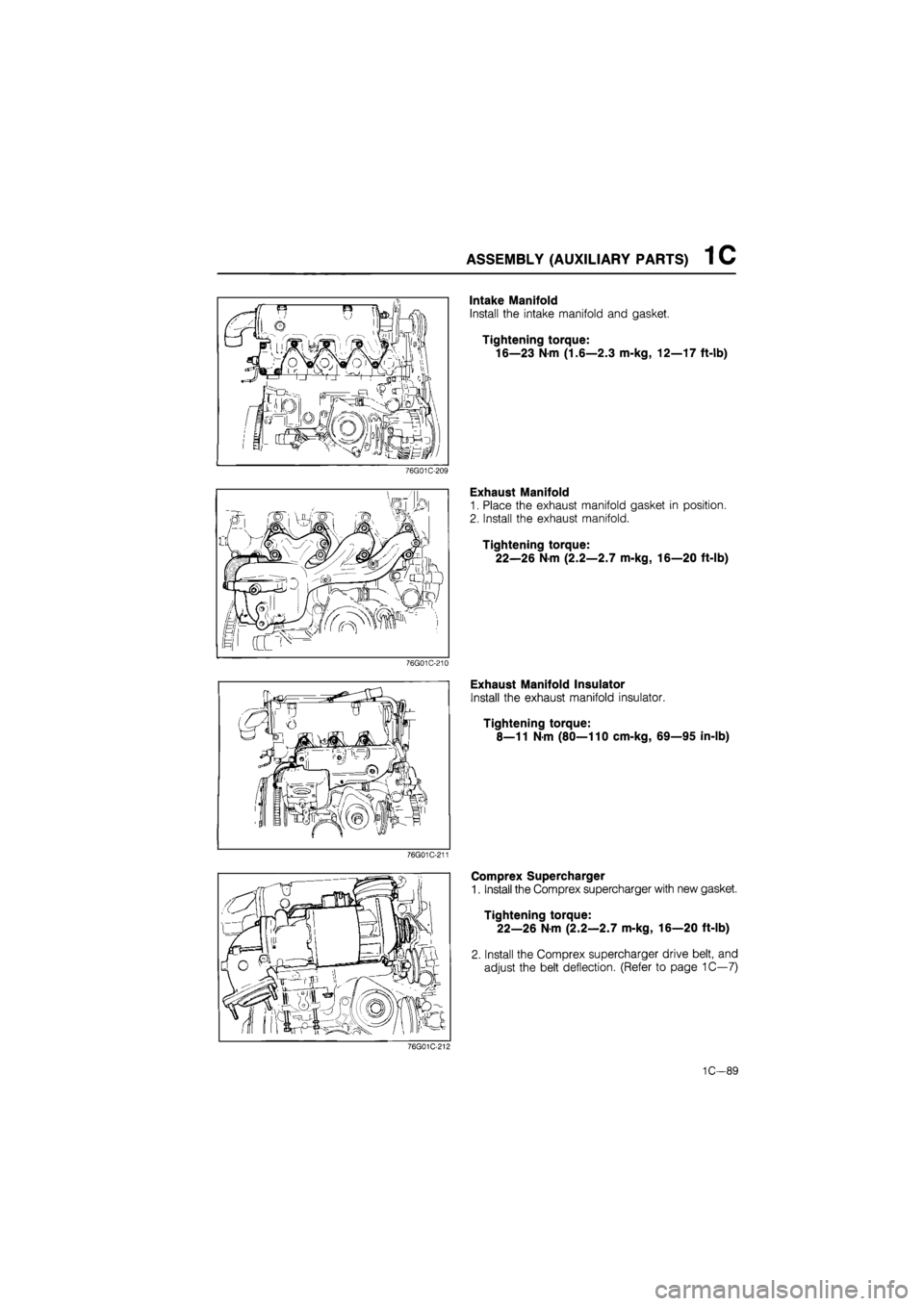

Intake Manifold

Install the intake manifold and gasket.

Tightening torque:

16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

Exhaust Manifold

1. Place the exhaust manifold gasket in position.

2. Install the exhaust manifold.

Tightening torque:

22—26 N-m (2.2—2.7 m-kg, 16—20 ft-lb)

Exhaust Manifold Insulator

Install the exhaust manifold insulator.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Comprex Supercharger

1. Install the Comprex supercharger with new gasket.

Tightening torque:

22—26 N-m (2.2—2.7 m-kg, 16—20 ft-lb)

2. Install the Comprex supercharger drive belt, and

adjust the belt deflection. (Refer to page 1C—7)

76G01C-212

1C—89

Page 302 of 1865

1 C ASSEMBLY (AUXILIARY PARTS)

76G01C-213

76G01C-214

Comprex Supercharger Insulator

Install the comprex supercharger insulator.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Air Funnel Assembly

1. Install the air funnel assembly.

Tightening torque:

Bolt A: 19—26

N

m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 3—4

N

m

(35—45 cm-kg, 30—39 ft-lb)

2. Connect the actuator vacuum tube.

76G01C-215

Vacuum Pump

1. Install the vacuum pump with bracket.

Tightening torque:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

2. Connect the oil pipe and hose.

Tightening torque:

12—18 N-m (1.2—1.8 m-kg, 104—156 ft-lb)

3. Install the drive belt, and adjust the belt deflection.

(Refer to page 1C—7)

PCV Hose

Install the PCV hose.

I! Jfc)' j

.CSD water hose

ilJJM: !

76G01C-216

CSD Water Hose

1. Remove the engine from the engine hanger.

2. Tighten the oil pipe mounting bolts.

Bolt A: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Bolt B: 12—18 N-m

(1.2—1.8 m-kg, 104—156 ft-lb)

3. Install the CSD water hose.

Tightening torque:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

1C-90

Page 1239 of 1865

HYDRAULIC CIRCUIT 7C

HYDRAULIC CIRCUIT

OUTLINE

The flow of the individual hydraulic circuits are identified as listed below.

(Numbers indicate individual circuits)

Line pressure source 7

Control element operation system line pressure.... 1,2,3,4,5,6,7,8,9,10,11,12

Auxiliary line pressure 13

Throttle system pressure 16,17,18,19

Governor system pressure 15

Torque converter system pressure 14

1. Line pressure

The line pressure is the hydraulic pressure of the oil emitted from the oil pump after adjustment

by the pressure regulator valve.

2. Throttle pressure

Derived from the line pressure, the throttle pressure is the hydraulic pressure generated by the throttle

valve which operates in conjunction with the intake manifold vacuum.

3. Governor pressure

Also derived from the line pressure, the governor pressure is the hydraulic pressure which varies

in conjuction with the vehicle's speed. It is controlled by the governor rotating together with the out-

put shaft.

Note

Schematic symbols

X : Drain

Orifice

76G07C-338

7C-125