load capacity MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 29 of 1865

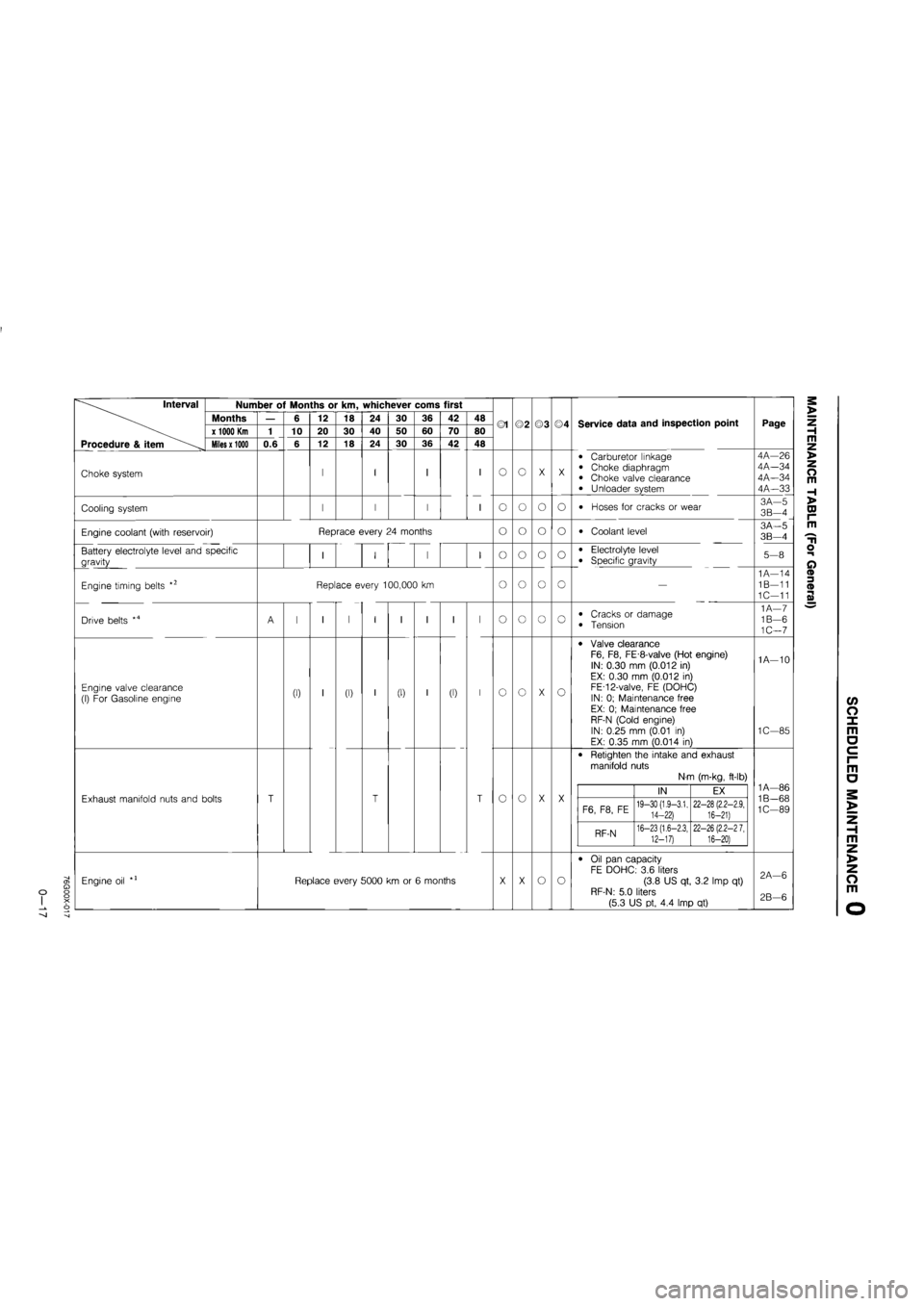

Interval

Procedure & item

Number of Months or km, whichever corns first

©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

Months — 6 12 18 24 30 36 42 48 ©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

x

1000

Km

1 10 20 30 40 50 60 70 80 ©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

Miles x

1000 0.6 6 12 18 24 30 36 42 48

©1 ©2 ©3 ©4 Service data and inspection point Page

Choke system I I I I O O X X

• Carburetor linkage • Choke diaphragm • Choke valve clearance • Unloader system

4A—26

4A-34

4A-34

4A—33

Cooling system I I I I O O o o • Hoses for cracks or wear 3A-5 3B—4

Engine coolant (with reservoir) Reprace every 24 months O O o o • Coolant level 3 A—5 3B—4

Battery electrolyte level and specific gravity I I I I O o o o • Electrolyte level • Specific gravity 5—8

Engine timing belts *2 Replace every 100,000 km O o o o —

1A—14 1B—11 1C—11

Drive belts *4 A I I I I I I I I O o o o • Cracks or damage • Tension

1A—7

1

B—6 1C—7

Engine valve clearance

(1) For Gasoline engine (I) I (I) I (I) I (I) I

T

O o X o

• Valve clearance F6, F8, FE-8-valve (Hot engine) IN: 0.30 mm (0.012 in) EX: 0.30 mm (0.012 in) FE-12-valve, FE (DOHC) IN: 0; Maintenance free EX: 0; Maintenance free RF-N (Cold engine) IN: 0.25 mm (0.01 in) EX: 0.35 mm (0.014 in)

1A—10

1C—85

Exhaust manifold nuts and bolts T T

I

T o o X X

• Retighten the intake and exhaust manifold nuts

N-m (m-kg, ft-lb) 1A—86 1B—68 1C—89 Exhaust manifold nuts and bolts T T

I

T o o X X IN EX 1A—86 1B—68 1C—89 Exhaust manifold nuts and bolts T T

I

T o o X X

F6, F8, FE 19-30 (1.9-3.1, 14-22) 22-28 (2.2-2.9, 16-21)

1A—86 1B—68 1C—89 Exhaust manifold nuts and bolts T T

I

T o o X X

RF-N 16-23 (1.6-2.3,

12-17) 22-26 (2.2-2 7,

16-20)

1A—86 1B—68 1C—89

Engine oil *1 Replace every 5000 km or 6 months X X o o

• Oil pan capacity FE DOHC: 3.6 liters

(3.8 US qt, 3.2 Imp qt) RF-N: 5.0 liters

(5.3 US pt, 4.4 Imp qt)

2A-6

2B—6

m >

o m

H >

00 r~ m

a

Page 713 of 1865

TROUBLESHOOTING GUIDE 5

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Starter does not turn at all, or Its turning speed Is too slow to start the engine.

Battery and related parts Poor contact of battery terminals Poor grounding of negative cable Voltage drop caused by discharged battery Insufficient voltage caused by battery malfunction

Clean and tighten Clean and repair Recharge Replace

5- 8

5- 8 5- 8

Ignition switch and related parts Poor contact of ignition switch Loose ignition switch wiring or connector Broken wire between ignition switch and magnetic switch

Replace Repair Repair or replace 5-38,45,56,66

Magnetic switch and related parts Loose wiring and/or connectors Burnt magnetic switch contact plate or improper contact Broken wire in magnetic switch pull-in coil Broken wire magnetic switch holding coil

Repair Replace

Replace Replace

5-38,45,56,66 5-43,54,64,74

5-43,54,64,74 5-43,54.64,74

Starter Poor contact of brushes

Fatigued brush spring Poor grounding of field coil Poor soldering of field coil Commutator mulfunction Grounded armature Worn parts

Adjust contact or replace Replace Replace Repair Repair or Replace Replace Replace

5-43,54,64,74

Starting problem Gasoline engine Insufficient battery capacity Malfunction of spark plug (s)

Loose positive terminal Damaged distributor cap or rotor Ignition coil malfunction laniter malfunction

Recharge Clean, adjust or replace Tighten Replace Replace Renlane

5— 8 5— 9

5—16 5—10 5-16,20

Diesel engine Insufficient battery capacity QSS svstem malfunction Recharge ReDlace 5— 8 5-76

Starter turns but pinion gear does not mesh with ring gear

Starter Tip of overrunning clutch pinion is worn Weakened overrunning clutch drive spring Worn overrunning clutch Improper sliding of spline

Worn bushing Worn ring gear

Replace Replace Replace Adjust contact and repair, or replace Replace ReDlace

5-40,54,70

Starter turns continuously (does not stop) Magnetic switch Sticking contact place of magnetic switch Layer shorting coil of magnetic switch Ignition switch does not return

Replace Replace Rfinlanfi

5-43,54,64,74 5-43,54,64,74

Misfiring Dirty or damaged spark plug (s) Malfunction of wiring, or open circuit Damaged distributor cap

Clean or replace Repair or Replace Replace

5- 9 5—10 5—16

Discharging of battery Alternator Loose drive belt Grounded or broken stator coil Broken rotor coil Poor contact of brush and slip ring

Malfunction of rectifier Malfunction of IC regulator Battery and related parts Insufficient or unsuitable battery electrolyte Malfunction of battery electrode (internal short-circuit) Poor contact of battery terminal (s) Excessive electric load

Adjust Replace Replace Clean, repair or replace Replace Replace

Adjust Replace

Clean and tighten Check power consump-tion and short circuit

5-37 5-32 5-32 5-32

5-34

5— 8 5- 8

5— 8

Overcharging of battery IC regulator malfunction Operating in extremely high temperature Replace Reoair

Poor acceleration Mis-adjusted ignition timing Distributor malfunction Adjust Repair or replace 5—11 5—11

Knocking Mis-adjusted ignition timing | Distributor malfunction Adjust Repair or replace 5—11 5—11

76G05X-003

5-7

Page 1840 of 1865

30 TECHNICAL DATA

7A. MANUAL TRANSAXLE

Engine model FE DOHC Ffl FE FE

B

valve F8 Item —— Leaded UriBsded Ffl 12 valve Carb. Fl F8 RF-N RF-CX

Transmission

Shift

lever

position Floor shift

Gear ratio

First 3.307

Second 1.833

Third 1.310

Fourth 1.030

Fifth 0.837

1,233

0.970

0.795

0.914

1.161

0.861

0.755 0.680

Reverse 3.166

Oil capacity liters US qt, Imp

qt)

3.35 (3.6, 3.0)

Fluid type

ATF: DEXRON-II

Above 0°F: API GL-4

or

GL-5

SAE80W—90

or

SAE90

Clearance

Clearance

of

lever and reverse idle

gear

mm (in)

Standard 0.1—0.32 (0.004-0.013) Clearance

of

lever and reverse idle

gear

mm (in)

Wear limit 0.5 (0.020)

Clearance

of

shift fork and clutch hub sleeve

mm (in)

Standard 0.2—0.4 (0.008-0.016) Clearance

of

shift fork and clutch hub sleeve

mm (in)

Wear limit 0.5 (0.020)

Clearance

of

synchronizer ring

and

gear

mm

(in)

Standard 1.5 (0.059) Clearance

of

synchronizer ring

and

gear

mm

(in) Wear limit 0.8 (0.021)

Gear thrust clearance

mm (in)

First Standard 0.05—0.28 (0.002-0.011)

Gear thrust clearance

mm (in)

First Limit 0.3 (0.020)

Gear thrust clearance

mm (in)

Second Standard 0.18—0.46 (0.007-0.018)

Gear thrust clearance

mm (in)

Second Limit 0.5 (0.02) Gear thrust clearance

mm (in) Third Standard 0.05-0.20 (0.002-0.008)

Gear thrust clearance

mm (in) Third Limit 0.25 (0.010)

Gear thrust clearance

mm (in)

Fourth Standard 0.17—0.37 (0.0064—0.014)

Gear thrust clearance

mm (in)

Fourth Limit 0.4 (0.016)

Bearing preload

of

primary shaft gear

Primary shaft

0.1-0.25 N-m (1.0-2.5 cm-kg, 0.86-2.18 in-lb) Secondary shaft 0.2-0.4 N-m (2.0—4.0 cm-kg, 1.7-3.4 in-lb)

Bearing preload adjust shim mm (in) 0.25 (0.010), 0.30 (0.012), 0.35 (0.014), 0.40 (0.016), 0.45 (0.018), 0.50 (0.020), 0.55 (0.022), 0.60 (0.024), 0.65 (0.026), 0.70 (0.028), 0.75 (0.030), 0.80 (0.031)

Drive and differential

Final gear

TvDe

Reduction ratio

Side

bearina Dreload

Helical aear

4.1051 3.850 4.1051 3.850

4.150

1.4-2.0 N

m

(14—20 cm-kg, 12-17 in-lb)

Bearing preload adjust shim mm (in)

0.10 (0.004), 0.15 (0.006), 0.20 (0.008), 0.25 (0.010), 0.30 (0.012), 0.35 (0.014), 0.40 (0.016), 0.45 (0.018), 0.50 (0.020), 0.55 (0.022), 0.60 (0.024), 0.65 (0.026), 0.70 (0.028), 0.75 (0.030), 0.80 (0.031), 0.85 (0.033), 0.90 (0.035), 0.95 (0.037), 1.00 (0.039), 1.05 (0.041), 1.10 (0.043), 1.15 (0.045), 1.20 (0.047)

Backlash

of

side aear and

Dinion

aear mm (in) 0-0.1 (0-0.004)

30—26