service MAZDA 626 1987 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1567 of 1865

1 4 FRONT DOORS

86U14X-060

86U14X-040

86U14X-041

6. Remove the beltline molding. (Refer to page

14-39)

7. Remove the door glass upward.

8. Remove the mounting bolts, and remove the regu-

lator through the service hole.

9. Remove the window motor mounting bolt, and re-

move the motor from the regulator (power window).

Removal of Outer Handle and Key Cylinder

1. Disconnect the rod from the outer handle.

69G14X-036

14—16

Page 1571 of 1865

1 4 REAR DOORS

86U14X-047

86U14X-048

86U14X-049

REMOVAL

Rear Door Glass and Regulator

1. Lower the door glass the way.

2. Remove the clip. (Manual type)

3. Remove the regulator handle. (Manual type)

4. Remove the inner handle cover.

5. Remove the door trim.

Note

For vehicles with power windows, disconnect

the connectors.

6. Remove the door screen.

Caution

Remove the screen carefully so that it may be

reused.

7. Position the door glass so that the mounting bolts

can be removed from the service hole.

8. Remove the mounting bolts.

86U14X-050

14—20

Page 1572 of 1865

REAR DOORS 1 4

9. Remove the door glass upward.

86U14X-051

Remove the mounting bolts, and remove the win-

dow regulator through the service hole.

Remove the window motor mounting bolts, then

remove the motor from the regulator (power

window).

86U14X052

INSTALLATION

Install in the reverse order of removal, noting the fol-

lowing.

Tightening torque:

Nm (m-kg, ft-lb)

Door lock assembly 4.22-6 18 (0 43-0 63, 3,10—4.54)

Outer handle 8.8-13 (0.9-1.3. 6.5-9.4)

Glass Quide 7.8—11 (0.8—1.1, 5.8—8.0)

Regulator Nut 8 8—13 (0.9—1.3, 6.5—9.4) Regulator Bolt 7.8-11 (0.8-1.1. 5.8-8.0)

Door lock striker 18-26 (1.8-2.7, 13-20)

Before installing the motor, connect the leads to a bat-

tery and run regulator down to the position shown.

14—21

Page 1601 of 1865

14 WINDSHIELD GLASS

Repair seal

Dam

_5 mm

.(0.19

11 mm

(0.43 in)

6. Prepare the nozzle of the sealant gun so that it has

a flange that can run along the edge of the glass,

and a V from which the sealant can flow. Once the

primer is dry, apply the sealant around the entire

circumference to fill the gap between the dam and

the edge of the glass with a ridge of sealant 11

mm (0.43 in) high.

Keep the bead of sealant smooth and even,

reshaping it where necessary with a spatula.

86U14X-11E

7BU14X-026

76G14X-044

Replenished section

with sealing agent

— Glass

7. Lift the glass into place. Push it in lightly toward

the vehicle to compress the sealant.

Caution

Open the windows to prevent the glass from

being pushed out by air pressure if a door is

closed.

Hardening time of repair seal

Temperature Surface hardening

time

Time required until car

can be put in service

5°C (41 °F) Approx. 1.5 hrs 12 hrs

20°C (68°F) Approx. 1 hr 4 hrs

35°C (95°F) Approx. 10 min. 2 hrs

8. Use a scraper to smooth away any sealant that

oozes out. Add more sealant to any points of poor

contact.

9. Check for water leaks. If a leak is found, wipe the

water off well and add repair seal (B001 77 739)

where needed.

Spacer

86U14X-120

14-50

Page 1608 of 1865

REAR WINDOW GLASS 1 4

86U14X-135

63U14X-069

Replenished section

with sealing agent

-Glass

Spacer

63U14X-070

7. Attach the back door glass to the body.

Caution

Keep the door glass open until the repair seal

hardens to some degree to prevent pressure

from being exerted on the rear glass, if the

door is closed quickly.

Hardening time of repair seal

Tem-

perature Surface hardening

time

Time required until car

can be put in service

5°C

(41

°F) Approx. 1.5 hrs 12 hrs

20°C (68°F) Approx. 1 hr 4 hrs

35°C (95°F) Approx. 10 min 2 hrs

8. Remove any excess or add repair seal where

necessary.

9. Check for water leaks. If a leak is found, wipe the

water off well and add repair seal (B001 77 739).

10. After checking for water leakage, install the mold-

ing and trim.

11. Connect the defogger connector.

86U14X-136

14—57

Page 1612 of 1865

REAR HATCH GLASS 1 4

8. Keep the door glass open until the repair seal

hardens to some degree to prevent pressure from

being exerted on the rear hatch glass.

If the door is closed quickly etc.

Hardening time of repair seal

Tem-

perature Surface hardening time Time required until car

can be put in service

5°C

(41

°F) Approx. 1.5 hrs 12 hrs

20°C (68°F) Approx. 1 hr 4 hrs

35°C (95°F) Approx. 10 min 2 hrs

86U14X-144

Replenished section

r with sealing agent

^ \ ^Glass

Spacer

10. Check for water leaks. If a leak is found, wipe the

water off well and add repair seal (B001 77 739).

86U14X-146

After checking for water leakage, install the mold.

Install the wiper arm, door trim, and defogger con-

nector.

86U14X-147

14—61

Page 1643 of 1865

1 4 WINDSHIELD WIPER

86U14X-168

86U14X-169

86U14X-170

REMOVAL

1. Disconnect the negative battery cable.

2. Remove the wiper arms.

3. Remove the lower molding.

4. Remove the cover.

5. Disconnect the wiper link from the motor.

Caution

Do not remove the motor arm unless neces-

sary. The motor arm position on the motor

shaft decides the automatic stop position,

(lowest position of the wiper arm)

6. Disconnect the connector.

7. Remove the wiper motor.

8. Remove the wiper link assembly mounting bolts.

9. Lift the wiper link assembly out from the left side

(driver's side) service hole.

86U14X-171

14—92

Page 1749 of 1865

1 5 AUTO ADJUSTING SUSPENSION (AAS)

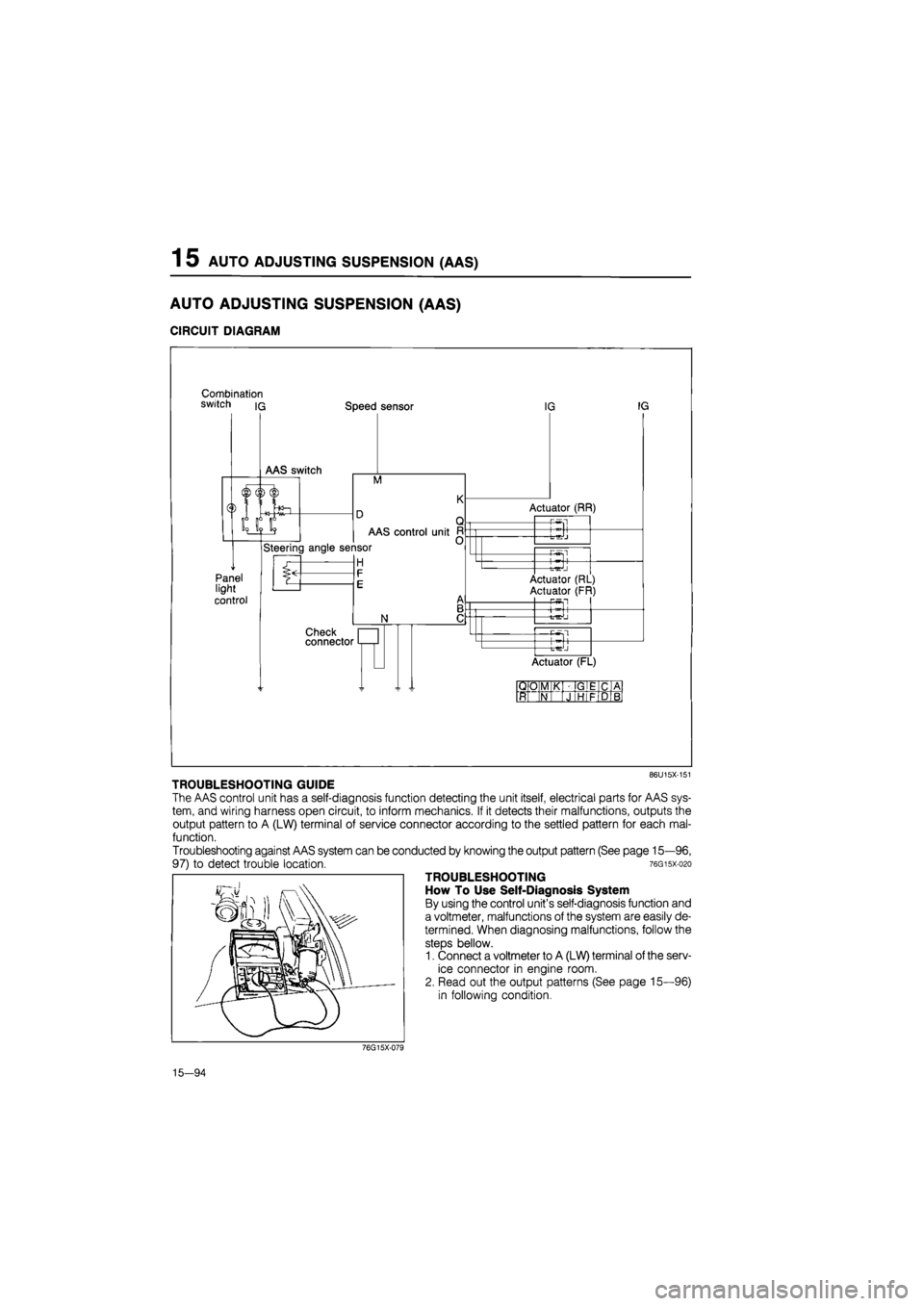

AUTO ADJUSTING SUSPENSION (AAS)

CIRCUIT DIAGRAM

Combination switch iq Speed sensor

M

Panel light

control

AAS control unit

Steering angle sensor

H

N

Check connector

IG IG

Actuator (RR)

-P-Sl

-t-^J

—Pwsl

Actuator (RL)

Actuator (FR) P5fl

+

Actuator (FL)

QO M K GIE C A

ft N J HI F D B

86U15X-151

TROUBLESHOOTING GUIDE

The AAS control unit has a self-diagnosis function detecting the unit itself, electrical parts for AAS sys-

tem, and wiring harness open circuit, to inform mechanics. If it detects their malfunctions, outputs the

output pattern to A (LW) terminal of service connector according to the settled pattern for each mal-

function.

Troubleshooting against AAS system can be conducted by knowing the output pattern (See page 15—96,

97) to detect trouble location. 76gisx-o2o

TROUBLESHOOTING

How To Use Self-Diagnosis System

By using the control unit's self-diagnosis function and

a voltmeter, malfunctions of the system are easily de-

termined. When diagnosing malfunctions, follow the

steps bellow.

1. Connect a voltmeter to A (LW) terminal of the serv-

ice connector in engine room.

2. Read out the output patterns (See page 15—96)

in following condition.

76G15X-079

15—94

Page 1787 of 1865

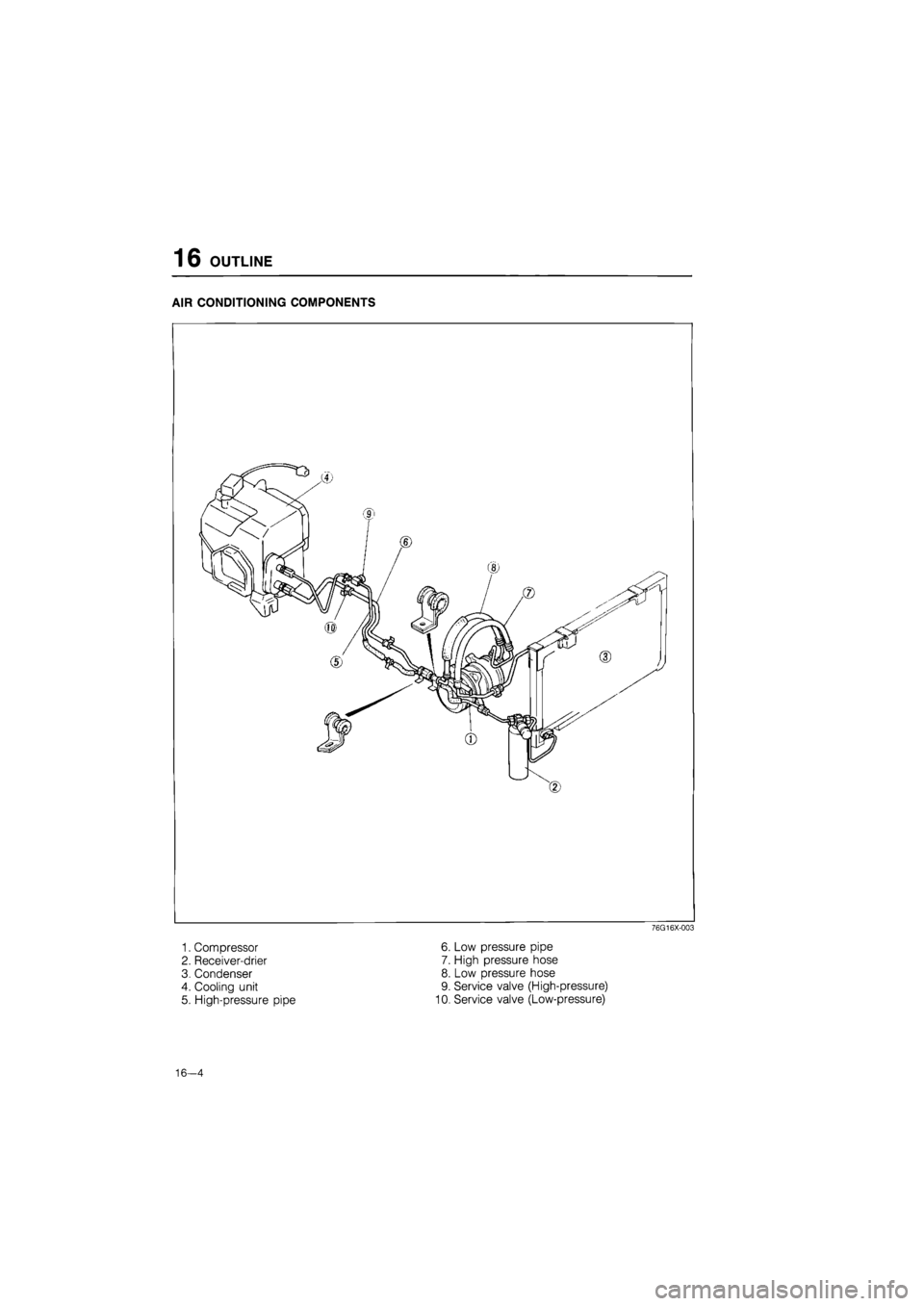

16 OUTLINE

AIR CONDITIONING COMPONENTS

76G16X-003

1. Compressor 6. Low pressure pipe

2. Receiver-drier 7. High pressure hose

3. Condenser 8. Low pressure hose

4. Cooling unit 9. Service valve (High-pressure)

5. High-pressure pipe 10. Service valve (Low-pressure)

16—4

Page 1793 of 1865

16 OUTLINE

Safety Precautions

1. The R-12 liquid refrigerant is highly volatile. A drop

of it on the skin of your hand could result in local-

ized frostbite. When handling the refrigerant, be

sure to wear gloves.

2. If the refrigerant splashes into your eyes, wash

them with clean water immediately. It is standard

practice to wear goggles or glasses to protect your

eyes, and gloves to protect your hands.

3. The R-12 container is a highly pressurized vessel.

Never leave it in a hot place, and check to be sure

that the temperature where it is stored is below

52°C (126°F).

4. A halide leak detector is often used to check the

system for refrigerant leakage. Remember that

R-12, upon coming into contact with flame (this de-

tector burns like propane to produce a small flame),

produces phosgene, a toxic gas.

69G16X020

V/^V

Connection

LZl

jvmi

Refrigerant Container Service Valve

1. Before connecting the valve to the refrigerant con-

tainer, turn the handle fully counterclockwise.

2. Turn the disc counterclockwise until it reaches its

highest position.

3. Connect the center hose to the valve fitting. Turn

the disc fully clockwise by hand.

4. Turn the handle clockwise to make a hole in the

sealed tap.

5. Turn the handle fully counterclockwise to fill the

center hose with air. Do not open the high- and

low-pressure manual valves.

6. Loosen the center hose nut connected to the cen-

ter fitting of the manifold gauge.

Allow air to escape for a few seconds, then tight-

en the nut.

69G16X-021

16-10