torque MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 6 of 1865

G FUNDAMENTAL PROCEDURES

DISASSEMBLY

1. Inspection of parts

Each part when removed should be carefully inspect-

ed for malfunctioning, deformation, damage, and

other problems.

2. Arrangement of parts

All disassembled parts should be carefully arranged

for reassembly.

Be sure to separate or otherwise identify the parts to

be replaced from those that will be reused.

3. Cleaning parts for reuse

All parts to be reused should be carefully and

thoroughly cleaned in the appropriate method.

REASSEMBLY

Standard values, such as torques and certain adjust-

ments, must be strictly observed in the reassembly

of all parts.

If removed, these parts should be replaced with new

ones:

1. Oil seals

2. Gasket

3. O-rings

4. Lock washers

5. Cotter pins (split pins)

6. Nylon nuts

G—4

Page 11 of 1865

CHASSIS NUMBER LOCATION/ABBREVIATIONS/UNITS G

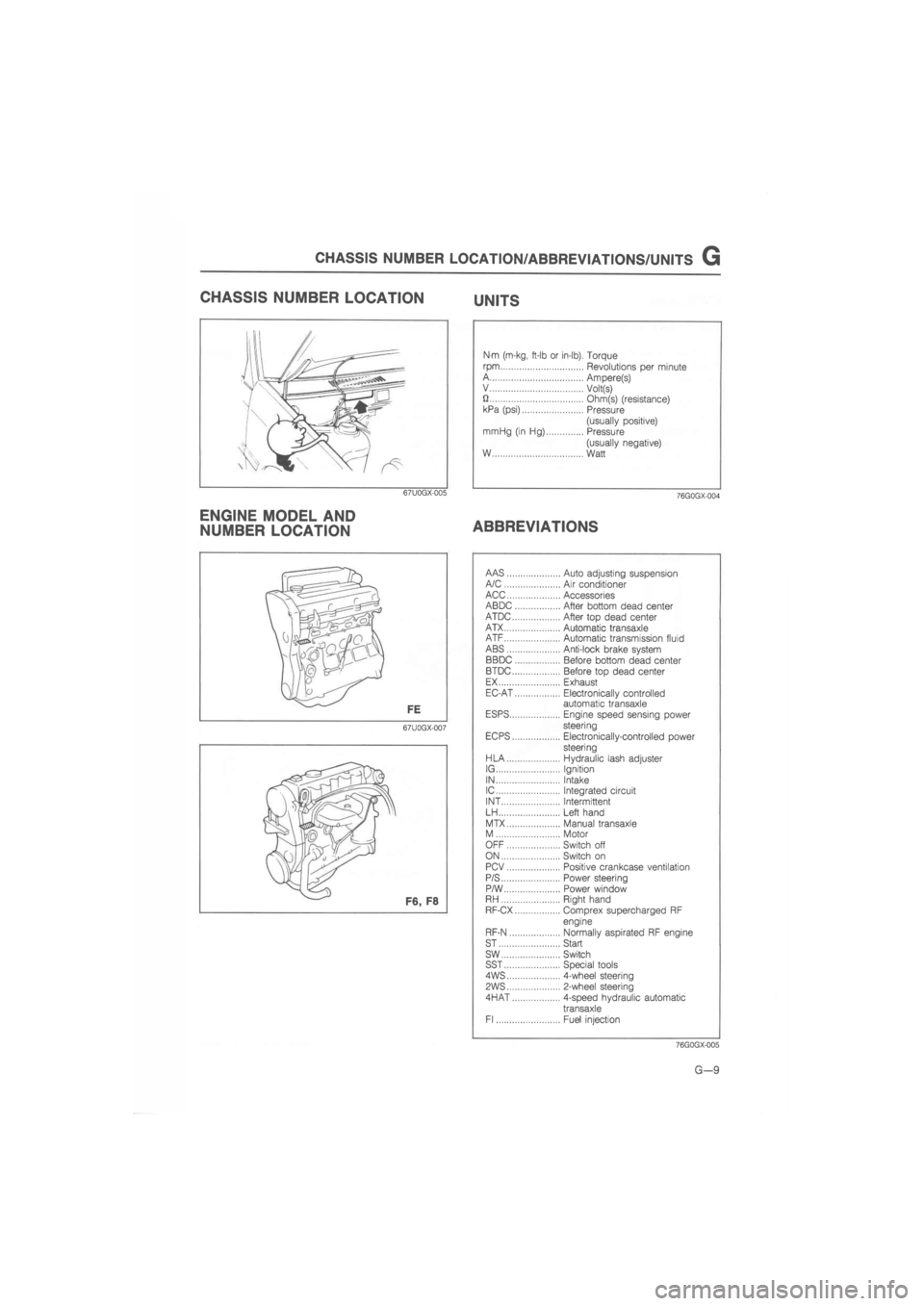

CHASSIS NUMBER LOCATION UNITS

67U0GX-005

ENGINE MODEL AND

NUMBER LOCATION

Nm (m-kg, ft-lb or in-lb). Torque

rpm Revolutions per minute A Ampere(s) V Volt(s) U Ohm(s) (resistance) kPa (psi) Pressure

(usually positive) mrriHg (in Hg) Pressure

(usually negative) W Watt

76G0GX-004

ABBREVIATIONS

67U0GX-007

AAS Auto adjusting suspension A/C Air conditioner ACC Accessories ABDC After bottom dead center ATDC After top dead center ATX Automatic transaxle ATF Automatic transmission fluid ABS Anti-lock brake system BBDC Before bottom dead center BTDC Before top dead center EX Exhaust EC-AT Electronically controlled automatic transaxle ESPS Engine speed sensing power steering EC PS Electronically-controlled power steering HLA Hydraulic lash adjuster IG Ignition IN Intake IC Integrated circuit INT Intermittent LH Left hand

MTX Manual transaxle M Motor OFF Switch off ON Switch on PCV Positive crankcase ventilation P/S Power steering P/W Power window RH Right hand RF-CX Comprex supercharged RF

engine

RF-N Normally aspirated RF engine ST Start sw Switch SST Special tools 4WS 4-wheel steering

PWS 2-wheel steering

4HAT 4-speed hydraulic automatic

transaxle Fl Fuel injection

76GQGX-005

G—9

Page 39 of 1865

1A TUNE-UP PROCEDURE

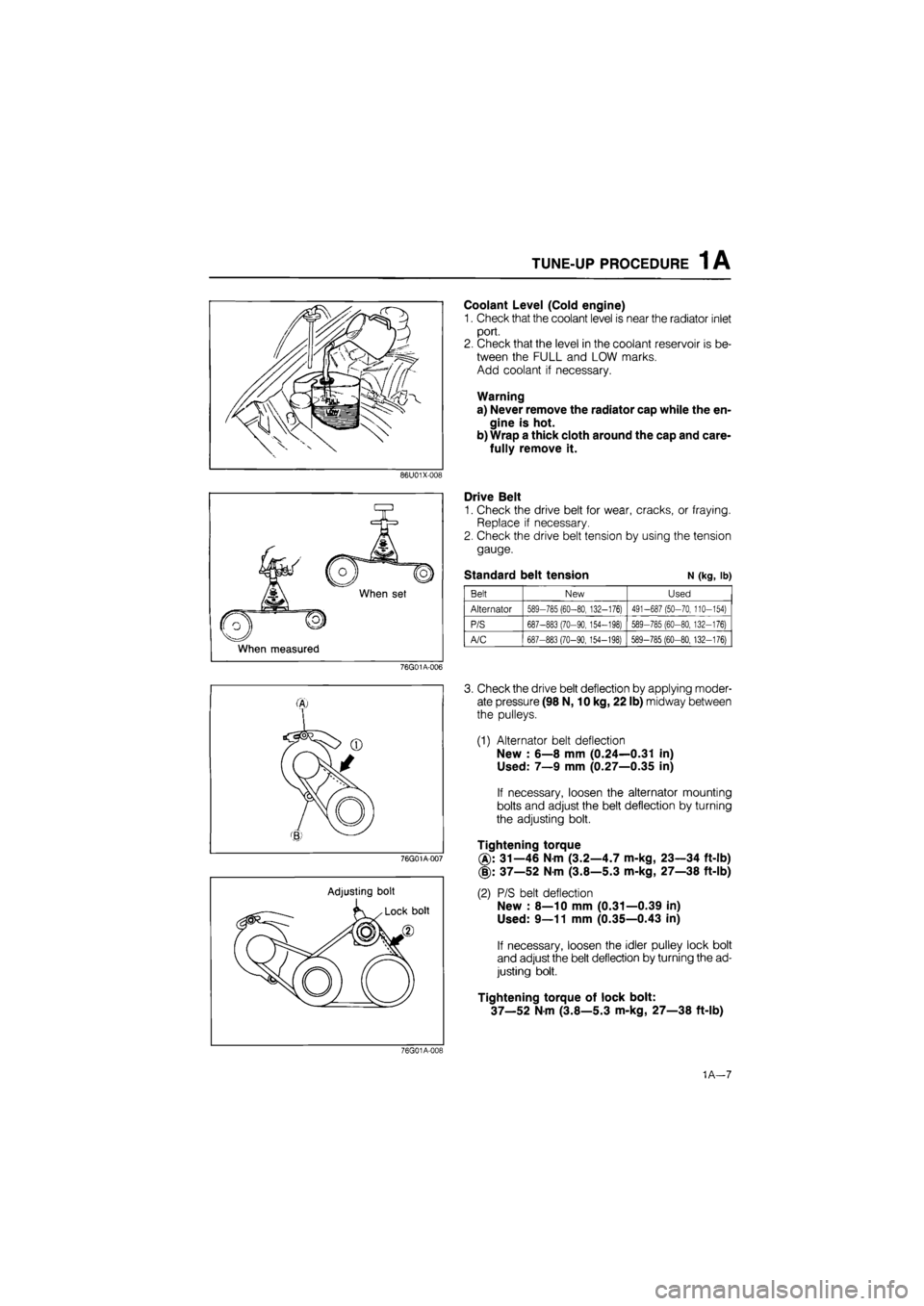

Coolant Level (Cold engine)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the level in the coolant reservoir is be-

tween the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b) Wrap a thick cloth around the cap and care-

fully remove it.

86U01X-008

When set

When measured

Drive Belt

1. Check the drive belt for wear, cracks, or fraying.

Replace if necessary.

2. Check the drive belt tension by using the tension

gauge.

Standard belt tension N (kg, lb)

Belt New Used

Alternator 589-785 (60-80, 132-176) 491-687 (50-70, 110-154)

P/S 687-883 (70-90, 154-198) 589-785 (60-80, 132-176)

A/C 687-883 (70-90,154-198) 589-785 (60-80, 132-176)

76G01A-006

76G01A-007

Adjusting bolt

3. Check the drive belt deflection by applying moder-

ate pressure (98 N, 10 kg, 22 lb) midway between

the pulleys.

(1) Alternator belt deflection

New : 6—8 mm (0.24—0.31 in)

Used: 7—9 mm (0.27—0.35 in)

If necessary, loosen the alternator mounting

bolts and adjust the belt deflection by turning

the adjusting bolt.

Tightening torque

31—46 Nm (3.2—4.7 m-kg, 23—34 ft-lb)

(§): 37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(2) P/S belt deflection

New : 8—10 mm (0.31—0.39 in)

Used: 9—11 mm (0.35—0.43 in)

If necessary, loosen the idler pulley lock bolt

and adjust the belt deflection by turning the ad-

justing bolt.

Tightening torque of lock bolt:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

76G01A-019

1A—7

Page 40 of 1865

1A TUNE-UP PROCEDURE

76G01A-009

76G01A-010

Wear and adhesion of carbon

Burnt

Damage and

deterioration

Damage

76G01A-011

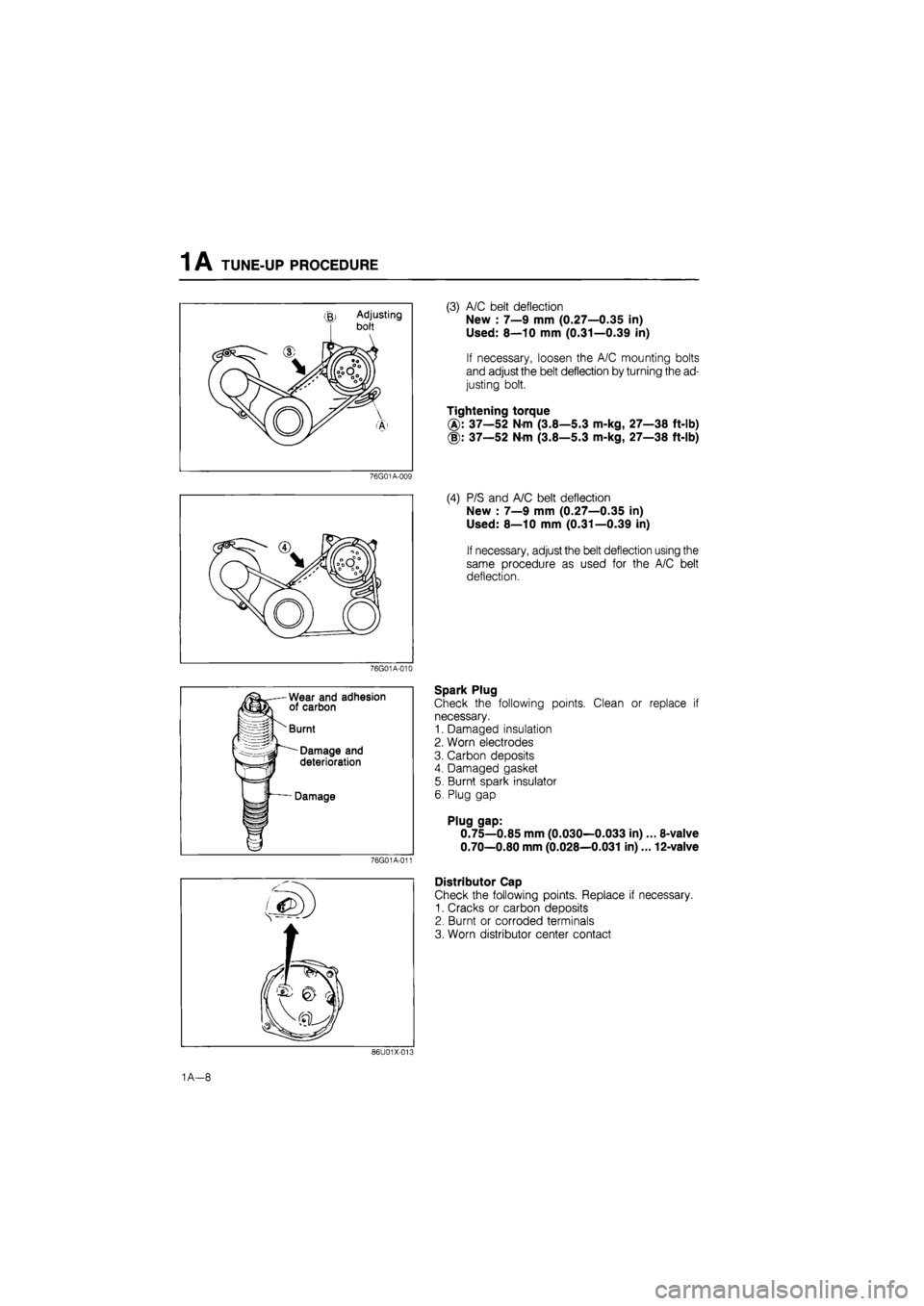

(3) A/C belt deflection

New : 7—9 mm (0.27—0.35 in)

Used: 8—10 mm (0.31—0.39 in)

If necessary, loosen the A/C mounting bolts

and adjust the belt deflection by turning the ad-

justing bolt.

Tightening torque

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(§): 37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(4) P/S and A/C belt deflection

New : 7—9 mm (0.27—0.35 in)

Used: 8—10 mm (0.31—0.39 in)

If necessary, adjust the belt deflection using the

same procedure as used for the A/C belt

deflection.

Spark Plug

Check the following points. Clean or replace if

necessary.

1. Damaged insulation

2. Worn electrodes

3. Carbon deposits

4. Damaged gasket

5. Burnt spark insulator

6. Plug gap

Plug gap:

0.75—0.85 mm (0.030—0.033 in)... 8-valve

0.70—0.80 mm (0.028—0.031 in)... 12-valve

Distributor Cap

Check the following points. Replace if necessary.

1. Cracks or carbon deposits

2. Burnt or corroded terminals

3. Worn distributor center contact

86U01X-013

1A—8

Page 48 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

Installation

Install in the reverse order of removal referring to the installation note.

Torque Specifications

76G01

A-109

7—10

N-m

(70—100 cm-kg, 61—87 in-lb)

7—10 N-m (70—100 em-kg, 61—87 In-lb)

12—17

N-m

(1.25—1.75 m-kg, 109—152 in-lb)

8-11 N-m (80—110 cm-kg,

Installation note

Timing belt

1. Check that the mark on the timing belt pulley is

aligned with the mating mark.

86U01X-220

1A—16

Page 50 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

8. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

69G01B-028

9. Check the timing belt deflection. If the deflection

is not correct, repeat the adjustment from step 5

above.

Timing belt deflection

FE: 5.5—6.5 mm (0.22—0.26 in)

F8, F6: 4.0—5.0 mm (0.16—0.20 in)

/98 N (10 kg, 22 lb)

Caution

Be sure not to apply tension other than that

of the tensioner spring.

76G01A-029

Baffle plate

Install the baffle plate as shown in the figure.

69G01B-030

Drive belt

Install each drive belt, and check the belt deflection.

(Refer to page 1A—7.)

76G01A-030

1A—18

Page 51 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

Spark plug

1. Apply anti-seize compound or molybdenum-based

lubricant to the spark plug threads.

2. Install the spark plugs.

Tightening torque:

15—23 N-m (1.5—2.3 m-kg, 11—17 ft-lb)

79G01C-021

Steps After Installation

Perform the necessary engine adjustment. (Refer to

TUNE-UP PROCEDURE.)

86U01X-029

1A—19

Page 55 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 A

Installation

Install in the reverse order of removal referring to the installation note.

Note a) Position the hose clamp in the original location on the hose.

b) Squeeze the clamp lightly with large pliers to ensure a good fit.

Torque Specifications

19—30

N

m (1.9—3.1 m-kg/' 14—22 ft-lb)

37—63

N m

(3.8—6.4 m-kg 27-46 ft-lb)

37—52 Nm (3.8 27—1

31—46 N-m (3.2—<

Page 56 of 1865

1 A ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

Installation note

Cylinder head

1. Thoroughly remove all dirt and oil from the top of

the cylinder block with a rag.

2. Place a new cylinder head gasket in position.

86U01X-035

®

CD

© (8)

3. Set the cylinder head in place.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80—86 N-m (8.2—8.8 m-kg, 59—64 ft-lb)

86U01X-036

Cylinder head cover

1. Apply silicon sealant to the shaded area shown in

the figure.

2. Install the cylinder head cover.

Tightening torque:

6—8

N

m (60—80 cm-kg, 52—69 in-lb)

86U01X-037

Timing belt

1. Align the mating mark of the camshaft pulley with

the front housing timing mark.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

2. Install the timing belt. (Refer to TIMING BELT of

ON-VEHICLE MAINTENANCE.)

76G01A-034

1A—24

Page 61 of 1865

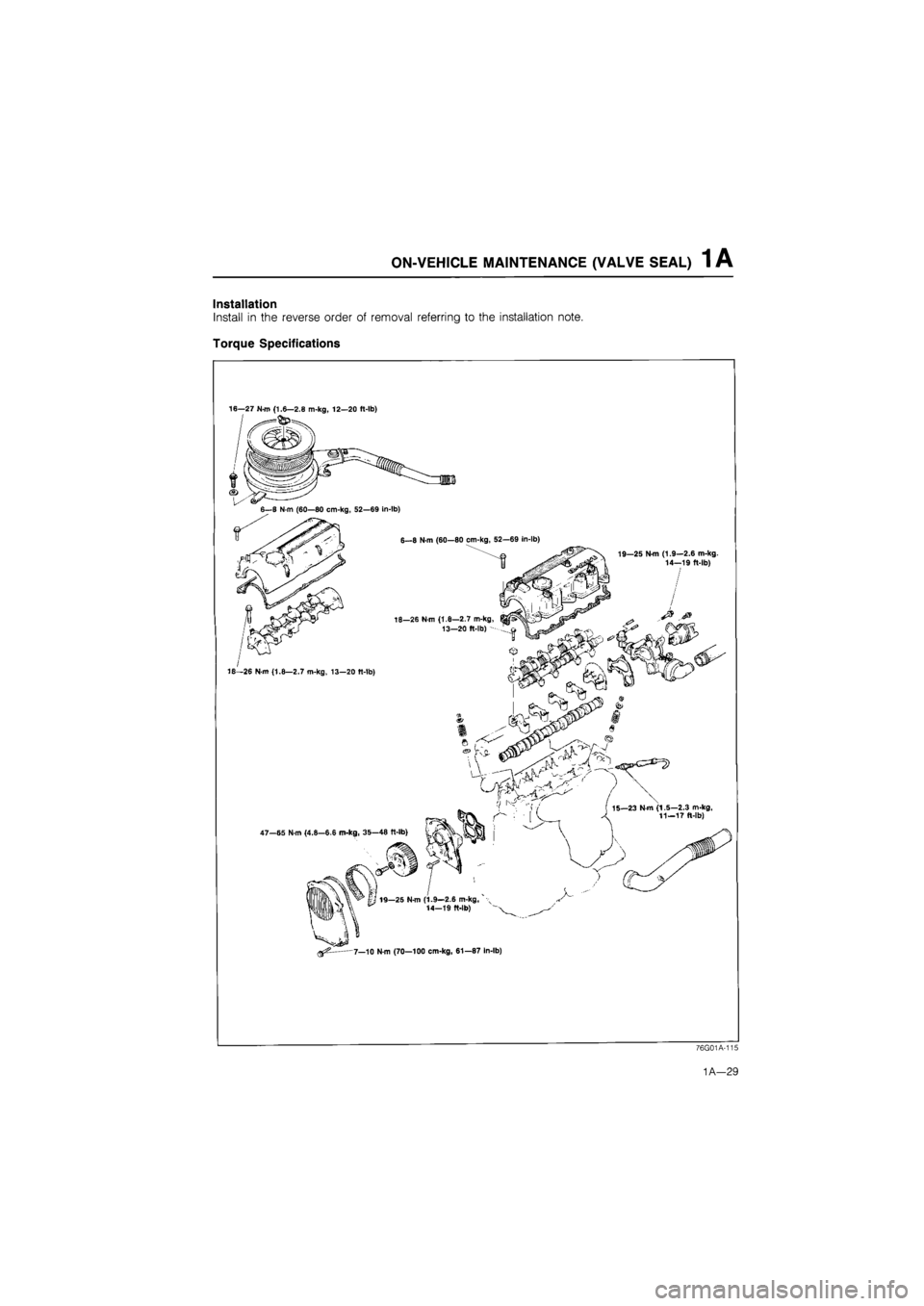

1 A ON-VEHICLE MAINTENANCE (VALVE SEAL)

Installation

Install in the reverse order of removal referring to the installation note.

Torque Specifications

16—27 N-m (1.6—2.8 m-kg, 12—20 ft-lb)

76G01A-115

1A—29