wheel MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 806 of 1865

6 CLUTCH AND FLYWHEEL

86U06X-042

86U06X-043

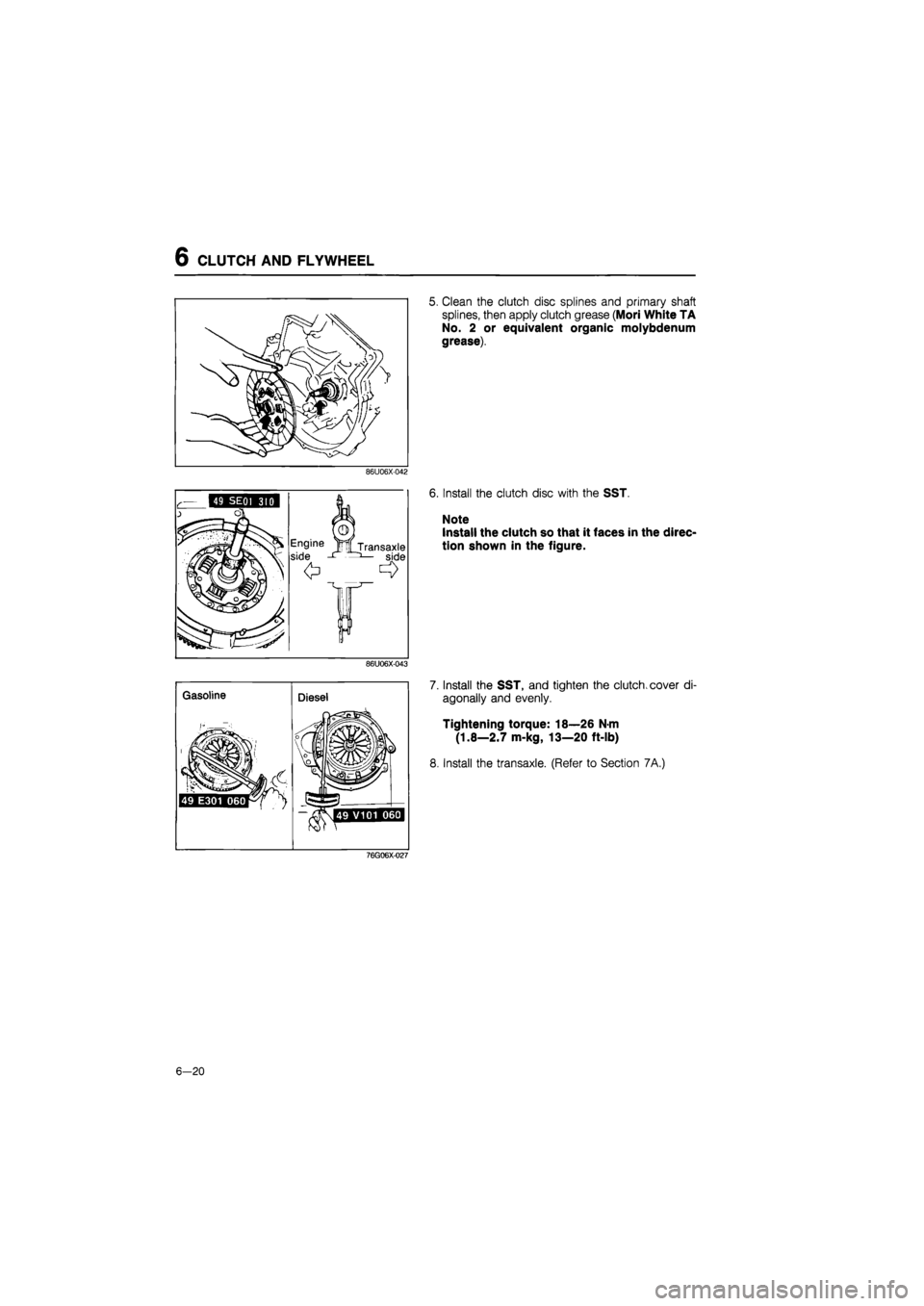

5. Clean the clutch disc splines and primary shaft

splines, then apply clutch grease (Mori White TA

No. 2 or equivalent organic molybdenum

grease).

6. Install the clutch disc with the SST.

Note

Install the clutch so that it faces in the direc-

tion shown in the figure.

7. Install the SST, and tighten the clutch, cover di-

agonally and evenly.

Tightening torque: 18—26 N-m

(1.8—2.7 m-kg, 13—20 ft-lb)

8. Install the transaxle. (Refer to Section 7A.)

76G06X-027

6-20

Page 813 of 1865

ON-VEHICLE MAINTENANCE 7A

DRIVESHAFT OIL SEALS

Replacement

Jack up the vehicle, support it on safety stands, and

then drain the transaxle oil. Next, use the following

procedure to replace the driveshaft oil seals:

1. Remove the front wheel(s).

2. Remove the splash shield(s).

3. Separate the front stabilizer from the lower arm.

61G07X-170

4 Remove the bolt and pull the lower arm downward.

Separate the knuckle from the lower arm ball-joint.

Note

Be careful not to damage the ball-joint dust

boot.

Remove the cotter pin then disconnect the tie-rod

end with the SST.

86U07A-009

6. Separate the driveshaft by pulling the front hub out-

ward. Do not use too much force at once, increase

the force gradually.

Note

a) Do not to allow the driveshaft ball-joint to

be bent to its maximum extent.

b) Support the driveshaft using string, wire,

etc.

86U07A-010

7. Remove the oil seal with a flat-tipped screwdriver.

86U07A-011

7A-7

Page 814 of 1865

7A ON-VEHICLE MAINTENANCE

86U07A-012

86U07A-013

86U07A-014

8. Tap the new oil seal into the transaxle case with

the SST.

Note

a) Tap in until the oil seal installer contacts the

case.

b)Coat the oil seal lip with transaxle oil.

9. Replace the driveshaft end clip with a new one.

Insert the clip with the gap at the top of the groove.

10. Install the driveshaft as follows:

(1) Pull the front hub outward, then

fit

the driveshaft

into the transaxle.

(2) Insert the driveshaft into the transaxle by push-

ing on the wheel hub assembly.

Note

a) Be careful not to damage the oil seal.

b) After installation is finished, pull the front

hub slowly outward to check that the

driveshaft is held securely by the clip.

11. Install the lower arm ball-joint to the knuckle, and

tighten the clinch bolt.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

12. Install the tie-rod end and new cotter pin.

Tightening torque:

29—44 N m (3.0—4.5 m-kg, 22—33 ft-lb)

86U07A-015

7 A—8

Page 815 of 1865

ON-VEHICLE MAINTENANCE 7A

13. Adjust and tighten the stabilizer.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

Dimension: 20.1 mm (0.79 in)

86U07A-016

76G07A-007

14. Install the drain plug.

Tightening torque:

39—59 Nm (4.0—6.0 m-kg, 29—43 ft-lb)

15. Install the wheel.

Tightening torque:

88—118 Nm (9.0—12.0 m-kg, 65—87 ft-lb)

16. Add the correct quantity of the specified oil.

Type: A.T.F.: DEXRON II

Above -18°C (0°F):

API: GL-4 or GL-5

SAE 80W-90 or SAE 90

Capacity: 3.35 liters (3.6 US qt, 3.0 Imp qt)

7A—9

Page 816 of 1865

7A REMOVAL

REMOVAL

Fl except DOHC

76G07A-008

1. Battery

2. Main fuse block

3. Air cleaner assembly

4. Ventilation hose

5. Air hose

6. Ground(s)

7. Speedometer cable

8. Clutch release cylinder

9. Canister hose

10. Wheel

11. Splash sheild

12. Extension bar

13. Control rod

14. Stabilizer

15. Joint shaft

16. Gusset plate (rear)

17. Gusset plate (front)

18. Surge tank bracket

19. Starter

20. Under cover

21. Engine mount No.4

22. Engine mount No.2

23. Hunger rubber

24. Crossmember

7 A—10

Page 817 of 1865

REMOVAL 7A

DOHC

76G07A-009

1. Battery

2. Main fuse block

3. Air cleaner assembly

4. Ventilation hose

5. Air hose

6. Ground(s)

7. Speedometer cable

8. Clutch release cylinder

9. Canister hose

10. Wheel

11. Splash sheild

12. Extension bar

13. Control rod

14. Stabilizer

15. Joint shaft

16. Surge tank bracket

17. Starter

18. Engine mount No.4

19. Engine mount No.2

20. Rear member (4WS)

21. Hunger rubber

22. Crossmember

7A—11

Page 818 of 1865

7A REMOVAL

Carburator

76G07A-010

15. Starter

16. Engine mount No.4

17. Engine mount No.2

18. Under cover

19. Hunger rubber

20. Crossmember

1. Battery

2. Air cleaner assembly

3. Ground

4. Speedometer cable

5. Clutch release cylinder

6. Canister hose

7. Wheel

8. Splash sheild

9. Extension bar

10. Control rod

11. Stabilizer

12. Joint shaft

13. Gusset plate (rear)

14. Gusset plate (front)

7 A-12

Page 819 of 1865

REMOVAL 7A

RF-N and RF-CX

1. Battery

2. Air cleaner assembly

3. Vacuum hose

4. Intercooler pipe and hose

(RF-CX)

5. Electric fan

6. Speedometer cable

7. Ground(s)

8. Clutch release cylinder

9. Pressure and return hoses

(power steering)

10. Starter

11. Wheel

12. Splash shield

13. Stabilizer

14. Joint shaft

15. Extension bar

16. Control rod

76G07A-011

17. Exhaust pipe bracket

18. Water pipe

19. Gusset plate (rear)

20. Gusset plate (front)

21. Under cover

22. Engine mount No.4

23. Engine mount No.2

24. Crossmember

7 A—13

Page 820 of 1865

7A REMOVAL

1. Remove the battery and battery carrier.

2. Disconnect the main fuse block. (Fl)

3. Disconnect the distributor lead.

4. Remove the air cleaner assembly.

76G07A-012

5. Remove the vacuum hose, the intercooler hose

(RF-CX) and the electric fan. (RF-N and RF-CX)

86U07A-021

8. Remove the front wheels.

9. Remove the splash shields.

10. Drain the transaxle oil.

86U07A-022

7A—14

Page 862 of 1865

7A INSTALLATION

76G07A-063

76G07A-064

18. Install the left driveshaft as follows:

(1) Pull the front hub outward and insert the

driveshaft into the transaxle.

(2) Push the joint at the differential side to connect

the driveshaft to the differential side gear.

Note

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to confirm that the driveshaft doesn't come

out.

19. Install the lower arm ball joints to the knuckles and

tighten the bolts and nuts.

Tightening torque: 43—54 N-m

(4.4—5.5 m-kg, 32—40 ft-lb)

20. Install the under cover, (except DOHC)

Note

Before installation, fill the notches with sili-

con as shown in the figure.

Tightening torque: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

21. Install the stabilizer bar control links as follows.

(1) Install the stabilizer bar control link.

(2) Adjust protrusion to 20.1 mm (0.79 in)

(3) Tighten bolt to specified torque.

Tightening torque: 16—23 N-m

(1.6—2.3 m-kg , 12—17 ft-lb)

76G07A-065

76G07A-066

22. Install the tie-rod ends and new cotter pine.

Tightening torque: 29—44 N-m

(3.0—4.5 m-kg, 22—33 ft-lb)

23. Install the splash shields.

Tightening torque: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

24. Install the front wheels.

Tightening torque: 88—118 N-m

(9.0—12.0 m-kg, 65—87 ft-lb)

—56