temperature MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 611 of 1865

4C FUEL SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Air flow sensor Detects amount of intake air;

sends signal to engine control unit

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

Engine control unit Detects signals from input sensors and switches; controls injector and fuel pump operations

Fuel filter Filters fuel

Fuel pump Provides fuel to injectors • Operates while engine running

• Installed in fuel tank

Fuel pump control unit (4WS) Monitors fuel level in left section; controls transfer pump operation

G signal pick-up Detects No.1 cylinder TDC; sends signal to engine control unit Installed in distributor

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed on throttle body

Ignition switch (ST position) Sends engine cranking signal to engine control unit

Injector Injects fuel into intake port • Controlled by signals from engine control unit • High-ohmic injector

Intake air thermo sensor Detects intake air temperature; send signal to engine control unit

Control relay Supplies electric current to injectors fuel pump and engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

Oxygen sensor (Unleaded fuel) Detects oxygen concentration; sends signal to engine control unit

• Zirconia ceramic and platinum coating • Integrated heater coil

Pressure regulator Adjusts fuel pressure supplied to injectors

Pulsation damper Absorbs fuel pulsation

Throttle sensor Detects throttle valve opening angle;

sends signal to engine control unit

Installed on throttle body

Transfer pump (4WS) Pumps fuel from the left to the right side Controlled by fuel pump control unit

Transfer pump switch (4WS) Detects fuel level in left section;

sends signal to control unit

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch (Unleaded fuel) Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04C-088

4C-50

Page 629 of 1865

4C PRC SYSTEM

PRESSURE REGULATOR CONTROL

(PRC)

SYSTEM

Distributor (Ne signal)

I Fuel

(To fuel tank)

76G04C-128

To prevent percolation of the fuel during idle after the engine is restarted, vacuum is cut to the pres-

sure regulator, increasing the fuel pressure.

Specified time: Approx. 120 sec.

Operating condition: Coolant temperature — above 70°C (158°F)

Intake air temperature — above 30°C (86°F)....Unleaded fuel

above 50°C (122°F)....Leaded fuel

4C-68

Page 630 of 1865

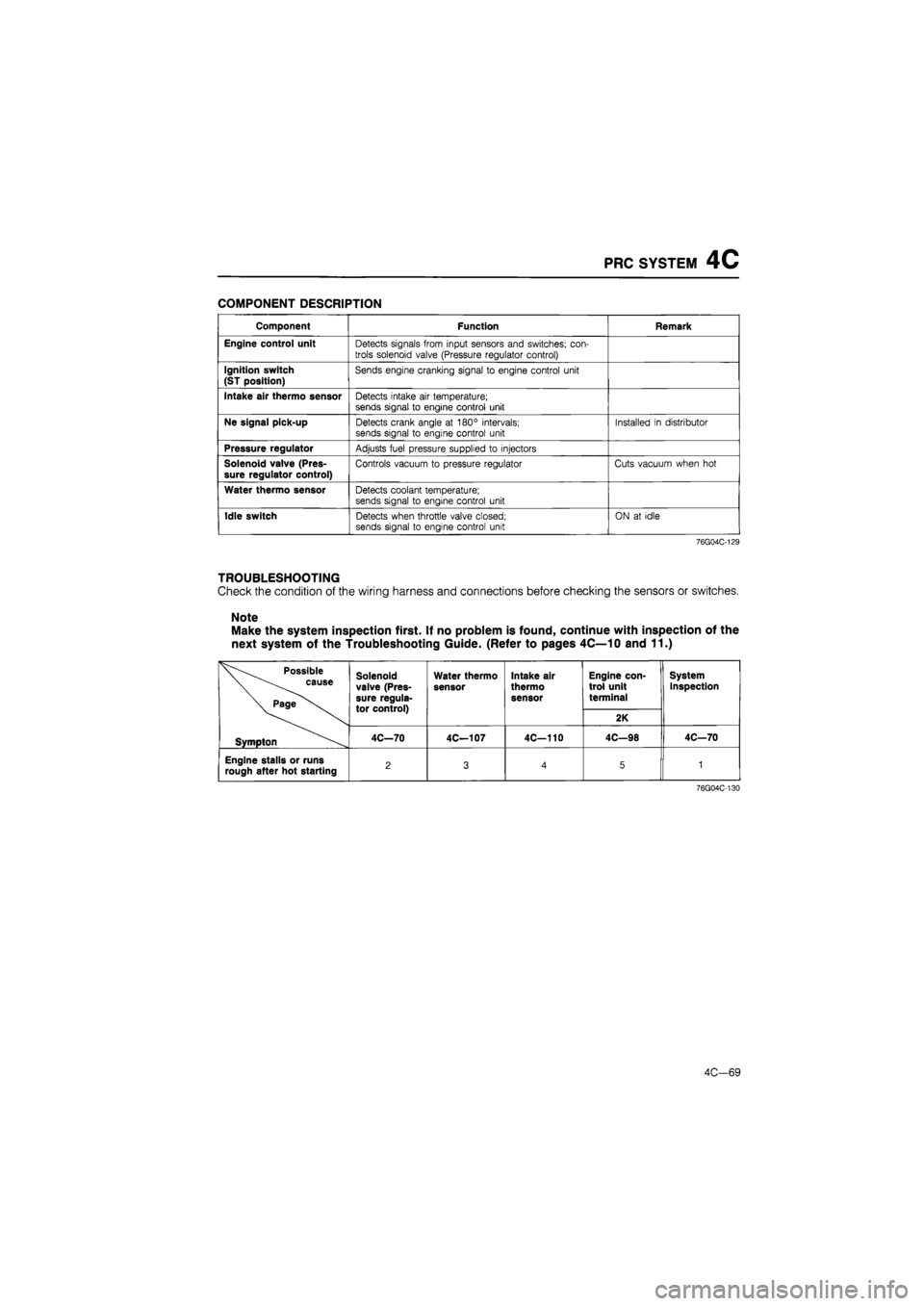

PRC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

Engine control unit Detects signals from input sensors and switches; con-trols solenoid valve (Pressure regulator control)

Ignition switch

(ST position)

Sends engine cranking signal to engine control unit

Intake air thermo sensor Detects intake air temperature; sends signal to engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Pressure regulator Adjusts fuel pressure supplied to injectors

Solenoid valve (Pres-

sure regulator control)

Controls vacuum to pressure regulator Cuts vacuum when hot

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Idle switch Detects when throttle valve closed; sends signal to engine control unit ON at idle

76G04C-129

TROUBLESHOOTING

Check the condition of the wiring harness and connections before checking the sensors or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible

\ cause

\ Page

Solenoid valve (Pres-sure regula-tor control)

Water thermo

sensor

Intake air

thermo

sensor

Engine con-trol unit terminal

System inspection Solenoid valve (Pres-sure regula-tor control) 2K

Symplon 4C—70 4C—107 4C-110 4C—98 4C—70

Engine stalls or runs rough after hot starting 2 3 4 5 1

76G04C-130

4C-69

Page 634 of 1865

DECELERATION CONTROL SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remarks

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit ON at idle

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

76G04C-135

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to page 4C—10 and 11.)

Possible cause Water thermo sensor System inspection

Page 4C—107 4C—74

Checking order 2 1

76G04C-136

4C-73

Page 638 of 1865

EGR SYSTEM (UNLEADED FUEL) 4C

EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM (UNLEADED FUEL)

This system introduces exhaust gas into the intake manifold to reduce NOx emissions. It operates de-

pending on the engine load, engine speed (1,500—3,500 rpm), engine coolant temperature (above

70°C, 158°F), and radiator coolant temperature (above 17°C, 63°F).

COMPONENT DESCRIPTION

Component Function Remark

EGR control valve Recirculates portion of exhaust gas

EGR modulator valve Controls vacuum acting on EGR control valve

Engine control unit Detects signals from input sensors and switches; con-trols solenoid valve (EGR)

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit

Solenoid valve (EGR) Controls vacuum to EGR control valve

Throttle sensor Detects throttle valve opening angle; sends signal to en-

gine control unit

Installed on throttle body

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04C-143

AC—17

Page 641 of 1865

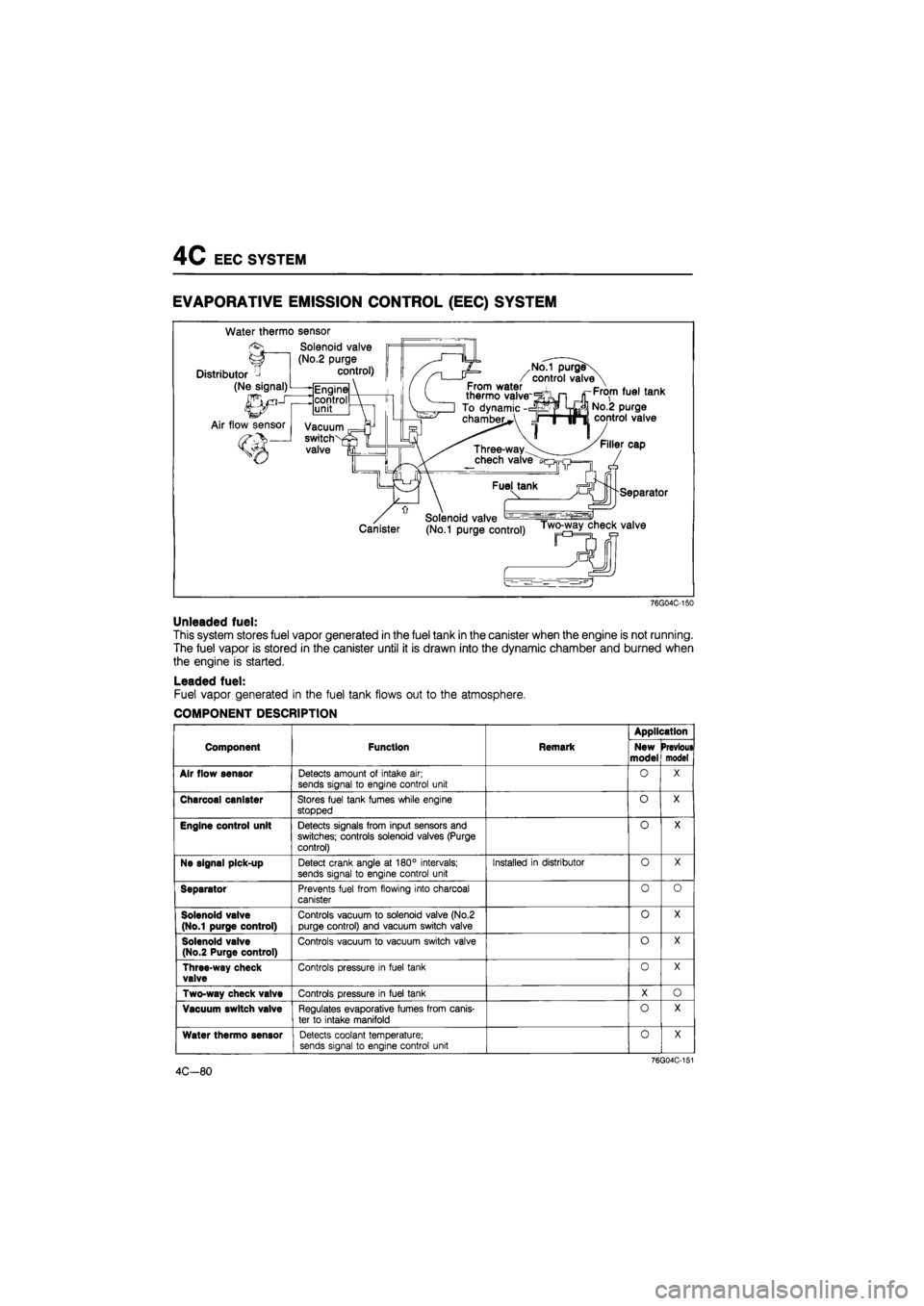

4C EEC SYSTEM

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Water thermo sensor

76G04C-150

Unleaded fuel:

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

Leaded fuel:

Fuel vapor generated in the fuel tank flows out to the atmosphere.

COMPONENT DESCRIPTION

Application

Component Function Remark New

model Prevtoui model

Air flow sensor Detects amount of intake air; sends signal to engine control unit

O X

Charcoal canister Stores fuel tank fumes while engine stopped

o X

Engine control unit Detects signals from input sensors and

switches; controls solenoid valves (Purge

control)

o X

Ne signal pick-up Detect crank angle at 180° intervals; sends signal to engine control unit

Installed in distributor o X

Separator Prevents fuel from flowing into charcoal canister

o o

Solenoid valve

(No.1 purge control)

Controls vacuum to solenoid valve (No.2

purge control) and vacuum switch valve

0 X

Solenoid valve (No.2 Purge control)

Controls vacuum to vacuum switch valve o X

Three-way check valve Controls pressure in fuel tank o X

Two-way check valve Controls pressure in fuel tank X o

Vacuum switch valve Regulates evaporative fumes from canis-ter to intake manifold

o X

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

0 X

76G04C-151

4C-80

Page 671 of 1865

4C CONTROL SYSTEM

76G04C-207

76G04C-208

Replacement

1. Disconnect the knock sensor connector.

2. Lift the vehicle and remove the intake manifold

bracket.

3. Remove the knock sensor with the SST.

4. Install the knock sensor in the reverse order of

removal.

INTAKE AIR THERMO SENSOR (DYNAMIC

CHAMBER)

Inspection

1. Disconnect the intake air thermo sensor connector.

2. Connect an ohmmeter to the sensor terminals.

3. Check the resistance of the sensor.

Temperature Resistance (kQ)

20°C (68°F) 29.7—36.3

50°C (122°F) 8.4-10.2

85 °C (185°F) 2.5-3.1

4. Reconnect the sensor connector.

Replacement

1. Disconnect the intake air thermo sensor connector.

2. Remove the sensor.

3. Install the sensor.

Note

When installing the sensor, tighten to the

specified torque.

Specified torque:

6.9—8.8 N-m (0.7—0.9 m-kg, 72 in-lb)

76G04C-209

4C—110

Page 672 of 1865

4D

FUEL AND EMISSION

CONTROL SYSTEM

(DIESEL)

OUTLINE 4D— 2

SPECIFICATIONS 4D— 2

TROUBLESHOOTING GUIDE 4D— 3

ON-VEHICLE MAINTENANCE 4D— 4

AIR CLEANER ELEMENT 4D— 4

WATER DRAINING 4D— 4

AIR BLEEDING 4D— 4

INJECTION TIMING 4D— 5

IDLE SPEED 4D— 6

EXHAUST SMOKE 4D— 6

INTAKE AIR SYSTEM 4D— 7

STRUCTURAL VIEW 4D— 7

AIR DUCT AND AIR CLEANER 4D— 8

INTAKE MANIFOLD 4D— 9

SUPERCHARGING SYSTEM (RF-CX) 4D-10

TROUBLESHOOTING GUIDE 4D—10

ON-VEHICLE INSPECTION 4D—11

COMPREX SUPERCHARGER 4D—13

STARTING VALVE 4D—15

INTERCOOLER 4D—16

BOOST AIR TEMPERATURE SENSOR 4D—17

EXHAUST SYSTEM 4D—18

STRUCTURAL VIEW 4D—18

EXHAUST MANIFOLD 4D—19

EXHAUST PIPE AND MAIN SILENCER .... 4D—20

FUEL SYSTEM 4D—21

STRUCTURAL VIEW 4D—21

FUEL FILTER 4D—22

SEDIMENTER (GENERAL) 4D—22

WATER LEVEL SENSOR 4D—23

INJECTION PUMP 4D—24

INJECTION NOZZLE 4D—31

FUEL TANK 4D—34

76G04D-001

Page 681 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

SUPERCHARGING SYSTEM (RF-CX)

TROUBLESHOOTING GUIDE

Engine

hard

starting

Poor

acceleration

Excessive

blue

smoke

Excessive

black

smoke

Excessive

compressed

air

temperature

(Buzzser

sounds)

Excessive

noise

Possible Cause Remedy (reference page)

*

*

Comprex supercharger Rotor stuck Casing damaged Rotor bearing damaged

Replace (4D—14)

* * * Drive system

of

Comprex supercharger Drive belt loose

or

worn Repair

or

replace

(4D-12) * Idler pulley damaged

Repair

or

replace

(4D-12) * Pulley bolt loose

or

worn

Repair

or

replace

(4D-12)

* Wastegate

Valve

not

open Clean

or

repace (4D-12) ik * Valve

not

closed

Clean

or

repace (4D-12)

* * Starting valve

Valve

not

open Repair

or

replace (4D-15)

* * Valve

not

closed

Repair

or

replace (4D-15) * Bypass valve

not

open

Repair

or

replace (4D-15)

* * Bypass valve

not

closed

Repair

or

replace (4D-15)

* Intercooler dirty Clean

or

replace (4D-16)

* * * * Intake

air

system Fresh

air

side clogged (Air cleaner

ele-

ment,

etc.)

Repair

or

replace * Compressed

air

side clogged (Intercool-

er,

etc.)

Repair

or

replace

* Fresh

air

side leaks

Repair

or

replace

* * * Compressed

air

side leaks

Repair

or

replace

* Exhaust system

Exhaust

gas

breaked Repair

* * * * * Exhaust pipe clogged

Repair

* Silencer damaged

(in

fender,

in air

clean-er,

in air

funnel, Comprex insulator) Repair

or

replace

* Bolt

and nut

loosend Repair

76G04D-022

4D—10

Page 688 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

BOOST AIR TEMPERATURE SENSOR

Removal

Remove the boost air temperature sensor from the

compressed air funnel.

76G04D-039

Thermometer

Inspection

1. Place the boost air temperature sensor in oil.

2. Heat the oil and check continuity of the sensor with

an ohmmeter. Replace if necessary.

Continuity : over 150°C (302°F)

No continuity: below 143°C (289°F)

76G04D-040

Installation

Install the boost air temperature sensor in the com-

pressed air funnel.

Tightening torque:

29—39 N m (3.0—4.0 m-kg, 22—29 ft-lb)

76G04D-041

4D—17