temperature MAZDA 626 1987 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 936 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

Terminal Connected to Voltage Condition

1J — — —

1K — — —

1L (Input) Idle switch Below 1.5V At idle 1L (Input) Idle switch Approx. 12V Other speeds

1M — — —

1N (Input) Brake light switch Approx. 12V Brake pedal depressed 1N (Input) Brake light switch Below 1.5V Brake pedal released

10 (Input) Throttle sensor

Approx. 5V Ignition switch ON 10 (Input) Throttle sensor Below 1,5V Ignition switch OFF

1P (Input)

Throttle sensor

Approx. 0.5—4.3V Throttle valve fully closed to fully open

1Q (Input) Vehicle speed sensor

Approx. 4.5V During driving

1Q (Input) Vehicle speed sensor Approx. 4.5V or below 1.5V Vehicle stopped

1R (Ground) Throttle sensor Below 1,5V —

1S (Input) Pulse generator Approx. 12V Engine running 1S (Input) Pulse generator Below 1,5V Engine stopped

1S (Ground) Pluse generator Below 1.5V —

2A (Battery power) Battery Approx. 12V Ignition switch ON 2A (Battery power) Battery Below 1,5V Ignition switch OFF

2B (Ground) Body ground Below 1,5V —

2C (Memory power) Battery Approx. 12V —

2D (Ground) Body ground Below 1,5V —

2E (Output) 1-2 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2E (Output) 1-2 shift solenoid valve Below 1.5V Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Below 1,5V

Refer to page 7B—26 of solenoid valve

operation table

2G — — —

2H (Output) 3-4 shift solenoid valve Approx. 12V Refer to page 7B—26 of solenoid valve operation table 2H (Output) 3-4 shift solenoid valve Below 1.5V

Refer to page 7B—26 of solenoid valve operation table

21 — — —

2J (Output) Lock-up solenoid valve Approx. 12V Lock-up 2J (Output) Lock-up solenoid valve Below 1,5V Other

2K (Output) Hold indicator Below 1,5V Hold mode 2K (Output) Hold indicator Approx. 12V Other modes

2L (Output) Mode indicator Approx. 12V Hold mode 2L (Output) Mode indicator Below 1,5V Power or economy mode

2M (Output) EC-AT Tester

(malfunction code)

Approx. 12V Normal

2M (Output) EC-AT Tester

(malfunction code) Below 1,5V If malfunction present 2M (Output) EC-AT Tester

(malfunction code) Code signal Self-diagnosis check connector grounded

2N — — —

20 (Input) Fluid temperature switch Below 1,5V Above 150°C (302°F) 20 (Input) Fluid temperature switch Approx. 10—12V Below 143°C (289°F)

2P (Input) EC-AT check connect Approx. 12V —

76G07B-084

7B-70

Page 937 of 1865

ON-VEHICLE MAINTENANCE 7B

ON-VEHICLE MAINTENANCE

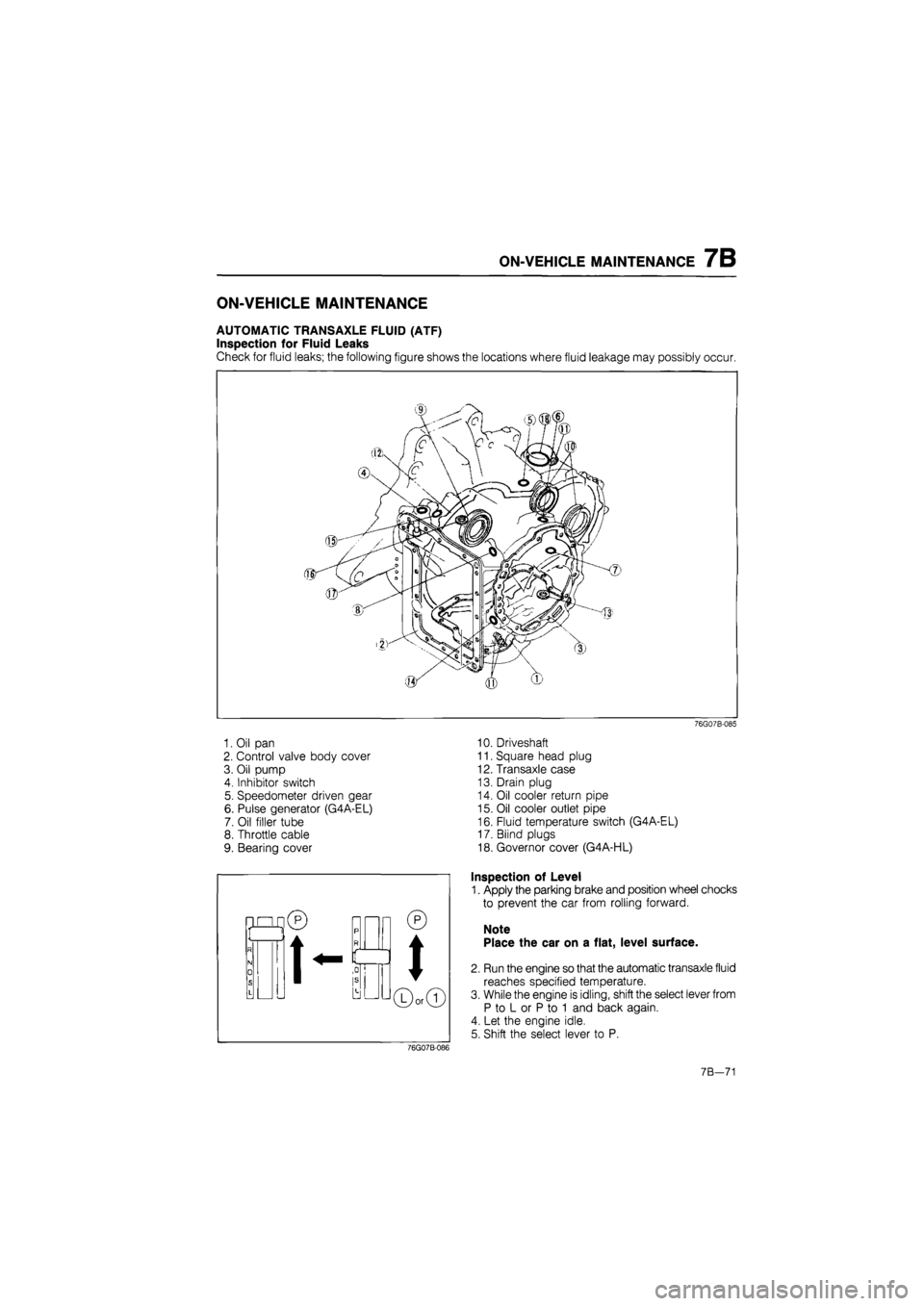

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator (G4A-EL)

7. Oil filler tube

8. Throttle cable

9. Bearing cover

76G07B-085

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch (G4A-EL)

17. Blind plugs

18. Governor cover (G4A-HL)

Inspection of Level

1. Apply the parking brake and position wheel chocks

to prevent the car from rolling forward.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches specified temperature.

3. While the engine is idling, shift the select lever from

P to L or P to 1 and back again.

4. Let the engine idle.

5. Shift the select lever to P.

76G07B-086

7B—71

Page 938 of 1865

![MAZDA 626 1987 Owners Manual

7B ON-VEHICLE MAINTENANCE

86U07B-064

86U07B-065

t «

•A

0 0

0 »

LX] O 9

m

(2)

(1)

Button need not

be depressed

Button must be pressed

76F07B-022

6. Ensure that the ATF level is be MAZDA 626 1987 Owners Manual

7B ON-VEHICLE MAINTENANCE

86U07B-064

86U07B-065

t «

•A

0 0

0 »

LX] O 9

m

(2)

(1)

Button need not

be depressed

Button must be pressed

76F07B-022

6. Ensure that the ATF level is be](/img/28/57059/w960_57059-937.png)

7B ON-VEHICLE MAINTENANCE

86U07B-064

86U07B-065

t «

•A

0 0

0 »

LX] O 9

m

(2)

(1)

Button need not

be depressed

Button must be pressed

76F07B-022

6. Ensure that the ATF level is between the F and L

marks. Add ATF to specification, if necessary.

Low temperature scale:

20°C (68°F)

High temperature scale:

65°C (149°F)

ATF type:

Dexron II or M HI

Inspection of Condition

1. Check the ATF for discoloration.

2. Check the ATF for any unusual smell.

Note

Determine whether or not the automatic trans-

mission should be disassembled by observ-

ing the condition of fluid carefully.

If the fluid is muddy and varnished, it indicates

burned drive plates.

SELECTOR LEVER

Inspection

1. Check that the selector lever can only be shifted

as shown in the figure.

2. Make sure there is a click at each range when shift-

ed from P <-> L or P <-» 1 range.

3. Check that the position of the selector lever and

the indicator are exact.

4. Check that the button returns smoothly when used

to shift the selector.

Adjustment

1. Loosen locknuts A, B, and lockbolt C.

2. Shift the selector lever to P range.

3. Shift the transaxle to P range by moving the man-

ual shaft of the transaxle.

4. While holding the selector lever forward in P range,

tighten lockbolt C to the specified torque.

Tightening torque:

8—11 N-m (80—110 cm-kg, 67—95 in-lb)

76F07B-023

7B—72

Page 941 of 1865

ON-VEHICLE MAINTENANCE 7B

'mfm^i! kfOl iff t—

76G07B-093

76G07B-094

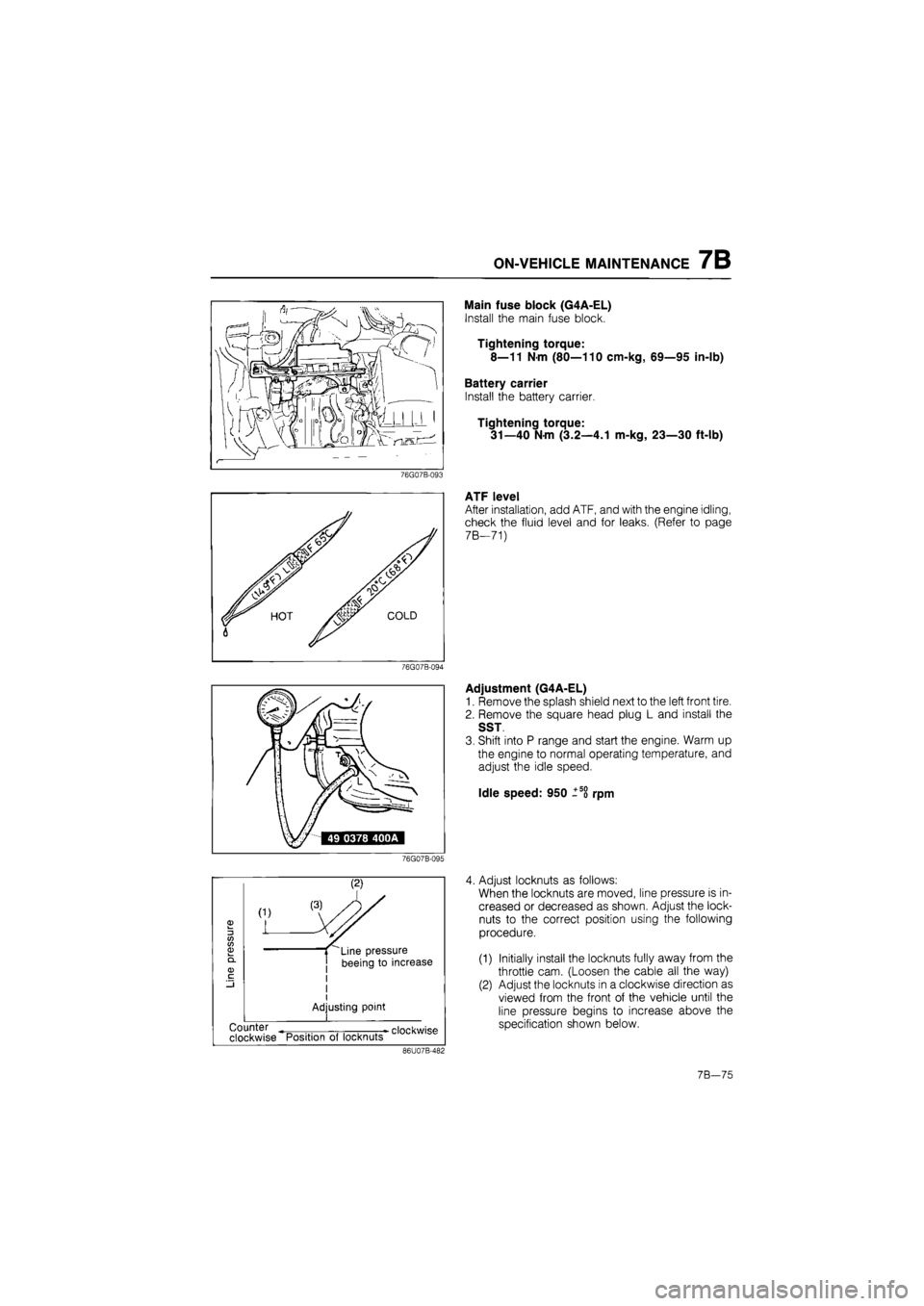

Main fuse block (G4A-EL)

Install the main fuse block.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

Battery carrier

Install the battery carrier.

Tightening torque:

31—40 Nm (3.2—4.1 m-kg, 23—30 ft-lb)

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks. (Refer to page

7 B—71)

Adjustment (G4A-EL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug L and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 950 ±5o rpm

76G07B-095

3 CO CO 03

(1)

L

Line pressure

beeing to increase

I

Adjusting point

•

clockwise Counter

clockwise Position of locknuts

86U07B-482

4. Adjust locknuts as follows:

When the locknuts are moved, line pressure is in-

creased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

line pressure begins to increase above the

specification shown below.

7B—75

Page 942 of 1865

7B ON-VEHICLE MAINTENANCE

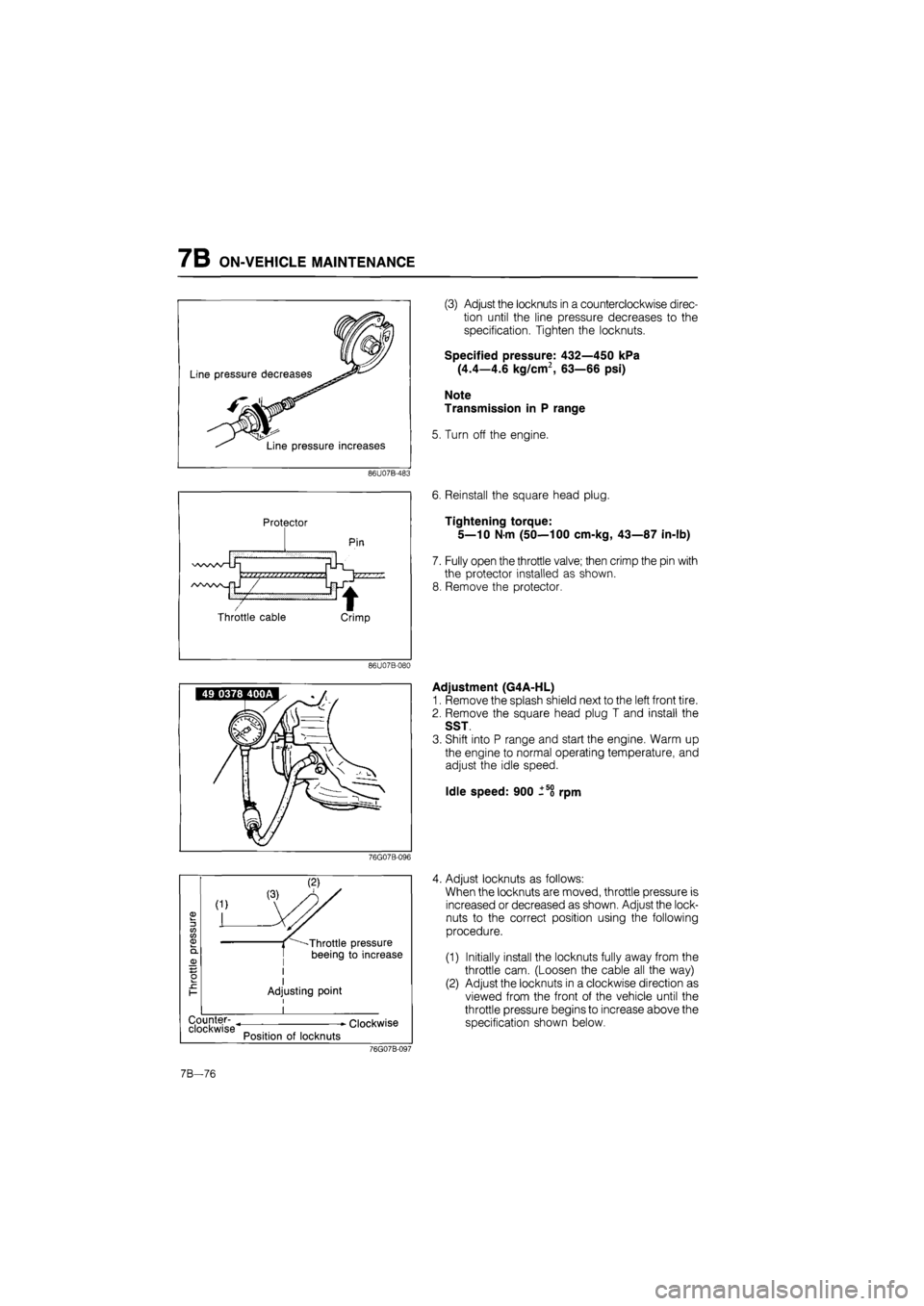

Line pressure decreases

Line pressure increases

86U07B-483

Protector

-7 / Throttle cable

86U07B-080

(3) Adjust the locknuts in a counterclockwise direc-

tion until the line pressure decreases to the

specification. Tighten the locknuts.

Specified pressure: 432—450 kPa

(4.4—4.6 kg/cm2, 63—66 psi)

Note

Transmission in P range

5. Turn off the engine.

6. Reinstall the square head plug.

Tightening torque:

5—10 N m (50—100 cm-kg, 43—87 in-lb)

7. Fully open the throttle valve; then crimp the pin with

the protector installed as shown.

8. Remove the protector.

Adjustment (G4A-HL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug T and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 900 -5o rpm

76G07B-096

3 tn tn

L

Counter- ^ clockwise

Throttle pressure

beeing to increase

I Adjusting point

Position of locknuts

Clockwise

4. Adjust locknuts as follows:

When the locknuts are moved, throttle pressure is

increased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

throttle pressure begins to increase above the

specification shown below.

76G07B-097

7B—76

Page 950 of 1865

7B REMOVAL

76G07B-107

G4A-EL

76G07B-108

76G07B-109

1. Remove the battery and battery carrier.

2. Disconnect the main fuse block.

3. Disconnect the distributor lead.

4. Disconnect the air flow meter connector and re-

move the air cleaner assembly. (G4A-EL)

5. Remove the air cleaner hose. (G4A-EL)

6. Remove the fresh air duct. (G4A-HL)

7. Disconnect the speedometer cable.

8. Disconnect the connectors.

(1) Inhibitor switch

(2) Solenoid valve

(3) Pulse generator (G4A-EL)

(4) Fluid temperature switch (G4A-EL)

9. Disconnect the grounds from the transaxle case.

10. Disconnect the selector cable.

11. Disconnect the throttle cable.

76G07B-110

7B—84

Page 954 of 1865

7B DISASSEMBLY

DISASSEMBLY

DISASSEMBLY-STEP 1

Components

1. Torque converter

2. Oil pump shaft

3. Oil level gauge and oil filler tube

4. Pulse generator, fluid temperature switch,

and inhibitor switch

5. Solenoid connector

6. Wire harnesses

7. Harness clip

86U07B-116

8. Oil pipes, oil hoses, and switch box

9. Oil pan and gasket

10. Oil strainer and O-ring

11. Control valve body cover and gasket

12. Throttle cable

13. Solenoid connector (Valve body side)

14. Control valve body

15. Oil pump and gasket

7B-88

Page 957 of 1865

DISASSEMBLY 7B

6 G4A-EL

Remove the pulse generator, fluid temperature

switch, and inhibitor switch.

G4A-HL

Remove the inhibitor switch.

76GQ7B-123

7. Disconnect the solenoid connector.

8. Remove the harnesses.

76G07B-124

9. G4A-EL

Remove the harness clip, then remove the oil

pipes, oil hoses and switch box as an assembly.

Note

Remove the ball from the case.

76G07B-125

G4A-HL

Remove the oil pipe.

Note Remove the ball from the case.

76G07B-126

7B—91

Page 1079 of 1865

ASSEMBLY 7B

12. Install the pulse generator and fluid temperature

switch.

Tightening torque:

Pulse generator

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Fluid temperature switch

29—39 N-m (3.0—4.0 m-kg, 22—29 in-lb)

76G07B-190

76G07B-191

13. Install the inhibitor switch.

(1) Turn the manual shaft to the "N" position.

(2) Install the inhibitor switch and loosely tighten

the bolts.

(3) Remove the screw and move the inhibitor

switch so that the alignment hole is aligned with

the screw hole.

(4) Insert a 2.0 mm (0.079 in) diameter pin

through the holes.

(5) Install the screw; then tighten the bolts to the

specified torque.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

14. Install the harness with the remaining clip.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

15. Remove the transaxle from the SST.

76G07B-192

16. Install the oil level gauge and tube along with a new

O-ring to the transaxle case.

Tightening torque:

7—10 N-m (70—100 cm-kg, 61—87 in-lb)

76G07B-193

7B-213

Page 1086 of 1865

7B INSTALLATION

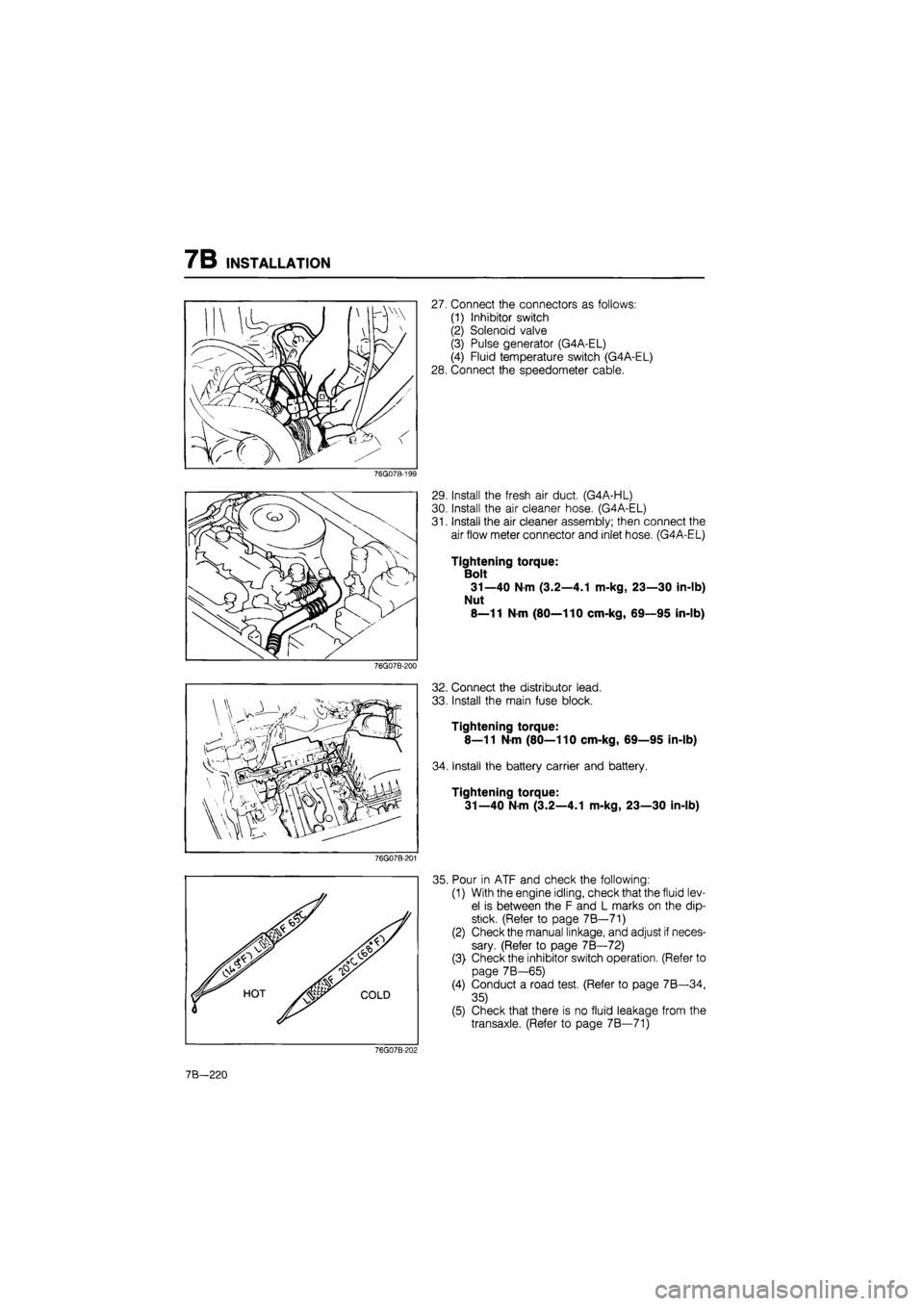

27. Connect the connectors as follows:

(1) Inhibitor switch

(2) Solenoid valve

(3) Pulse generator (G4A-EL)

(4) Fluid temperature switch (G4A-EL)

28. Connect the speedometer cable.

76G07B-199

76G07B-200

76G07B-201

29. Install the fresh air duct. (G4A-HL)

30. Install the air cleaner hose. (G4A-EL)

31. Install the air cleaner assembly; then connect the

air flow meter connector and inlet hose. (G4A-EL)

Tightening torque:

Bolt

31—40 N-m (3.2—4.1 m-kg, 23—30 in-lb)

Nut

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

32. Connect the distributor lead.

33. Install the main fuse block.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

34. Install the battery carrier and battery.

Tightening torque:

31—40 N-m (3.2—4.1 m-kg, 23—30 in-lb)

35. Pour in ATF and check the following:

(1) With the engine idling, check that the fluid lev-

el is between the F and L marks on the dip-

stick. (Refer to page 7B—71)

(2) Check the manual linkage, and adjust if neces-

sary. (Refer to page 7B—72)

(3) Check the inhibitor switch operation. (Refer to

page 7B—65)

(4) Conduct a road test. (Refer to page 7B—34,

35)

(5) Check that there is no fluid leakage from the

transaxle. (Refer to page 7B—71)

76G07B-202

7B—220