display MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 472 of 1865

4B TROUBLESHOOTING WITH SST

INSPECTION PROCEDURE

1. Connect the SST to the check connector, (Green,

6-pin) and the negative battery terminal.

2. Set the select switch to position A.

Note

The check connector is located at the rear of

the left side wheel housing.

86U04A-011

Test connector: Green (1 pin)

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

Note

The test connector is located near the Self-

Diagnosis Checker check connector.

86U04A-012

OO

uu

SELF-DIAGNOSIS CHECKER

(WPUTOft

SELECT

S*

5

o n==ru

o o o o 49 HO 18 9AI

76G04B-005

4. Turn the ignition switch ON.

5. Verify that 88 flashes on the digital display and that

the buzzer sounds for three seconds after turn-

ing the ignition switch ON.

6. If 88 does not flash, check the main relay (Refer

to page 4B—86), power supply circuit, and check

connector wiring.

7. If 88 flashes and the buzzer sounds continuously

for more than 20 seconds, replace the engine con-

trol unit and perform steps 3 and 4 again.

8. Note the code numbers and check for the causes

by referring to the check sequences shown on

pages from 4B—14 to 4B—24. Repair as

necessary.

Note

Cancel the code numbers by performing the

after-repair procedure after repairing.

AFTER-REPAIR PROCEDURE

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery cable and depressing the

brake pedal for at least 2 seconds; then recon-

nect the negative battery cable.

76G04B-134

4B—10

Page 473 of 1865

TROUBLESHOOTING WITH SST 4B

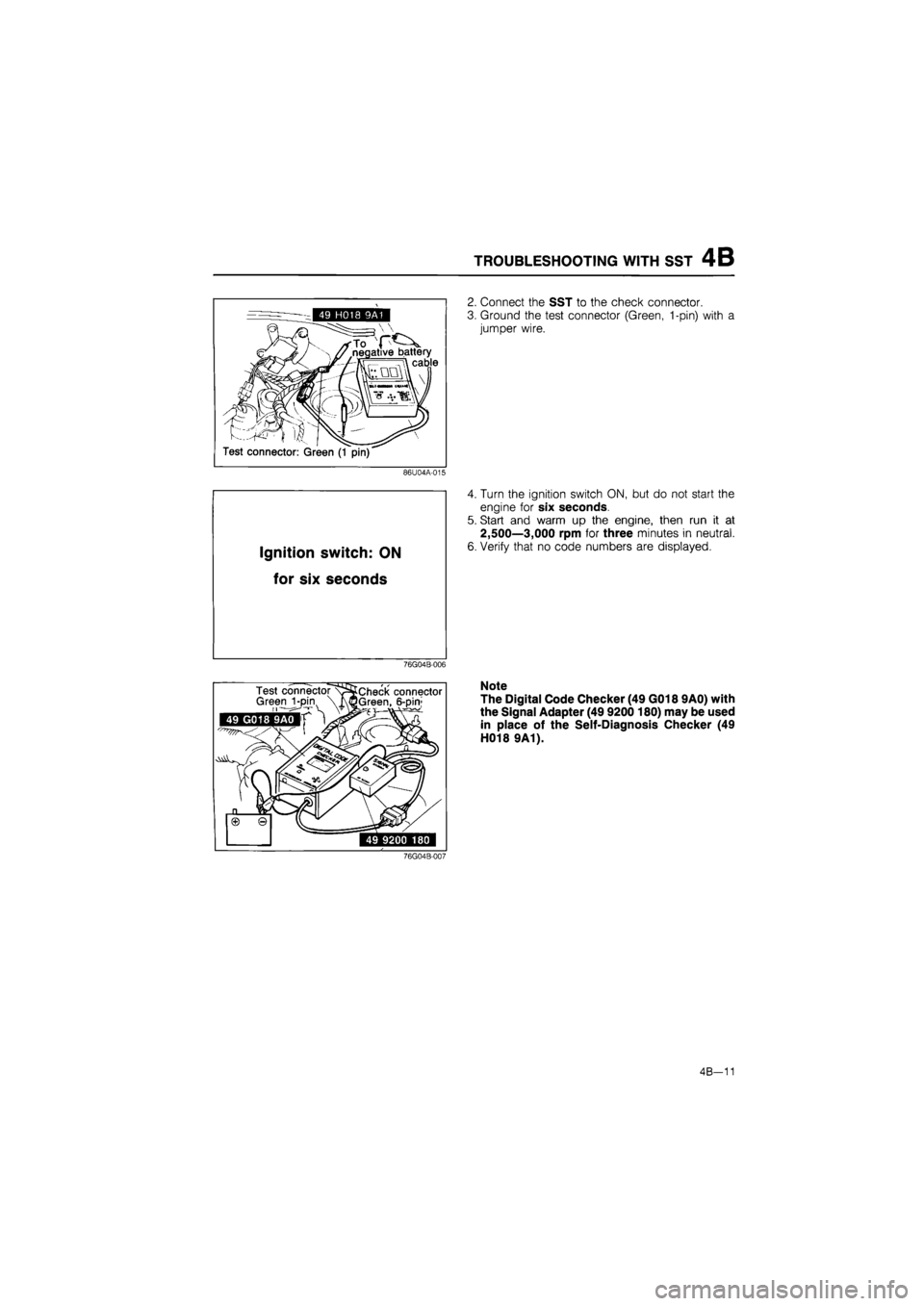

2. Connect the SST to the check connector.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

86U04A-015

Ignition switch:

ON

for six

seconds

4. Turn the ignition switch ON, but do not start the

engine for six seconds.

5. Start and warm up the engine, then run it at

2,500—3,000 rpm for three minutes in neutral.

6. Verify that no code numbers are displayed.

76G04B-006

76G04B-007

Note

The Digital Code Checker (49 G018 9A0) with

the Signal Adapter (49 9200 180) may be used

in place of the Self-Diagnosis Checker (49

H018 9A1).

4B-11

Page 475 of 1865

TROUBLESHOOTING WITH SST 4B

CODE NUMBER

Malfunction display

Self-diagnosis Fail-safe Code

No. Output signal pattern subsystem Self-diagnosis Fail-safe

01

ON

OFF

Ignition pulse

No ignition signal

08

Air flow meter

Open

or

short circuit

Maintains basic sig-

nal

at

preset value

09

1 111

Water thermo sensor

Open

or

short circuit

Maintains constant command 35°C (95 °F)

10

Intake

air

thermo sensor (air flow meter) Open

or

short circuit

Maintains constant 20°C (68°F) command

12

£_IUILJIIL

Throttle sensor

Open

or

short circuit

Maintains constant

command

of

throttle

valve fully open

14

OFF

TL

I I nil

Atmospheric pres-

sure sensor Open

or

short circuit

Maintains constant command

of

sea level pressure

15

oTp m 11 [U

Oxygen sensor Sensor output con-tinues less than 0.55V 120 sec. after engine starts (1,500 rpm)

Cancels EG

I

feed-

back operation

17

SLJlMJl

Feedback system Sensor output

not

changed

20

sec.

af-

ter engine exceeds 1,500 rpm

Cancels EGI feed-back operation

25

^JMLJl

Solenoid valve (pres-

sure regulator)

Open

or

short circuit

26

SUUBUIL

Solenoid valve (purge control)

Open

or

short circuit 28

£ mi in nr

Solenoid valve

(EGR) Open

or

short circuit

34

^jmiUTT

Air bypass solenoid

valve (Idle-up

C)

Open

or

short circuit

35

0Nnnnj OFFU u UUU

"fin nnr

Air bypass solenoid

valve (Idle-up

B)

Open

or

short circuit

76G04B-008

Caution

a) If there is more than one failure present, the lowest number malfunction code is dis-

played first, the remaining codes are displayed sequentially.

b) After repairing a failure, turn off the ignition switch and disconnect the negative battery

cable and depress the brake pedal for at least 2 seconds to erase the memory of a mal-

function code.

4B-13

Page 573 of 1865

4C TROUBLESHOOTING WITH SST

Check connector: (Green, 6 pin)

49 H018 9A1

86U04A-011

Test connector: (Green, 1 pin)'

INSPECTION PROCEDURE

1. Connect the SST to the check connector. (Green,

6-pin) and the negative battery terminal.

2. Set the select switch to position A.

Note

The check connector is located at the rear of

the left side wheel housing.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

Note

The test connector is located near the Self-

Diagnosis Checker check connector.

86U04A-012

OO

uu

SELF-DIAGNOSIS CHECKER

MONITOR LAMP SELECT SW «

o o o

o

76G04C-012

4. Turn the ignition switch ON.

5. Verify that 88 flashes on the digital display and that

the buzzer sounds for three seconds after turn-

ing the ignition switch ON.

6. If 88 does not flash, check the control relay (refer

to page 4C—96), power supply circuit, and check

connector wiring.

7. If 88 flashes and the buzzer sounds continuously

for more than 20 seconds check the check con-

nector wiring, then replace the engine control unit

and perform steps 3 and 4 again.

8. Note the code numbers and check for the causes

by referring to the check sequences shown on

pages 4C—16 to 4C—24. Repair as necessary.

Note

Cancel the code numbers by performing the

after-repair procedure after repairing.

AFTER-REPAIR PROCEDURE

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery cable and depress the

brake pedal for at least five seconds.

76G04C-013

4C-12

Page 574 of 1865

TROUBLESHOOTING WITH SST 4C

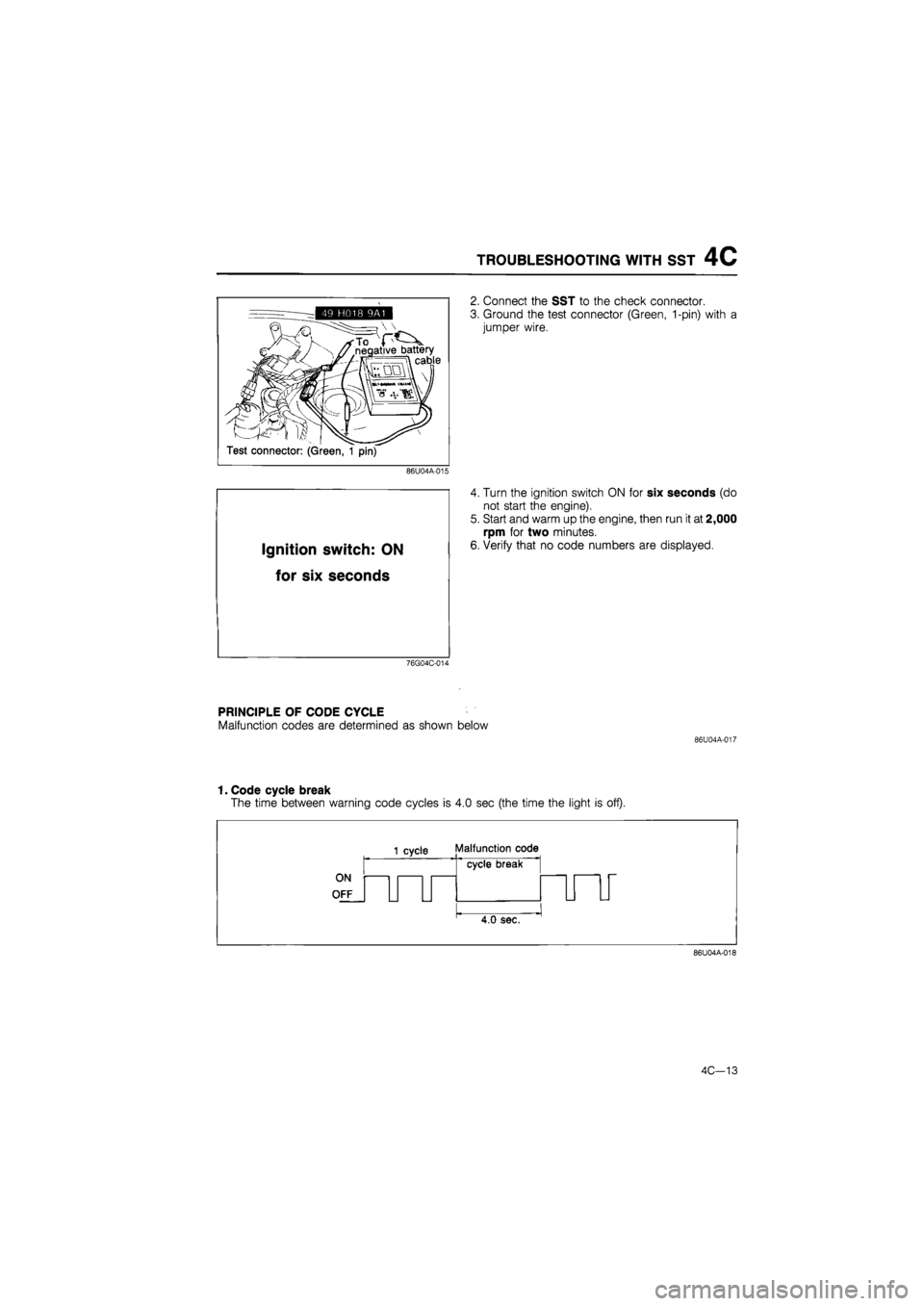

49 H018 9A1

negative battery cable

^ll

Test connector: (Green, 1 pin)

86U04A-015

Ignition switch:

ON

for six

seconds

76G04C-014

2. Connect the SST to the check connector.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

4. Turn the ignition switch ON for six seconds (do

not start the engine).

5. Start and warm up the engine, then run it at 2,000

rpm for two minutes.

6. Verify that no code numbers are displayed.

PRINCIPLE OF CODE CYCLE

Malfunction codes are determined as shown below

86U04A-017

1. Code cycle break

The time between warning code cycles is 4.0 sec (the time the light is off).

ON

OFF

1 cycle Malfunction code

cycle break

4.0 sec.

86U04A-018

4C—13

Page 575 of 1865

4C TROUBLESHOOTING WITH SST

2. Second digit of malfunction code (ones position)

The digit in the ones position of the malfunction code represents the number of times the buzzer

is on 0.4 sec during one cycle.

ON

OFF

1 cycle Malfunction code

1 2 3 cycle break

Malfunction

code: 03

n^j

0.4 0.4 sdc. sec.

4.0 sec.

76G04C-015

3. First digit of malfunction code (tens position)

The digit in the tens position of the malfunction code represents the number of times the buzzer

is on 1.2 sec during one cycle.

It should also be noted that the light goes off for 1.6 sec. between the long and short pulses of

the buzzer.

1 cycle Malfunction code

1 2

~U 0.4

1.2 sec. sec h

1 2|

flfl

First digit

1.6 sec.

cycle break

Malfunction

code: 22

nr

4.0 sec.

Second

digit

76G04C-016

CODE NUMBER

Malfunction display

Sensor or

subsystem Self-diagnosis Fail-safe Malfunction

code no.

Malfunction code output signal pattern

Sensor or

subsystem Self-diagnosis Fail-safe

02 o°nfJLJJL

Ne signal No Ne signal from crank angle sensor during craking

03 oppJUllUl

G signal No G signal Cancels sequencial

injection

05

Knock sensor (only

leaded fuel)

Open or short circuit • Retards ignition timing 4°

76G04C-017

4C—14

Page 576 of 1865

TROUBLESHOOTING WITH SST 4C

Malfunction display

Sensor or subsystem Self-diagnosis Fail-safe Malfunction

code no. Malfunction code output signal pattern

Sensor or subsystem Self-diagnosis Fail-safe

08

Air flow sensor Open or short circuit Maintains basic sig-nal at preset value

09 o°pNp II IIL •

Water thermo sensor Open or short circuit Maintains constant 35°C (95°F) command

11 0°FNFJUUL

Intake air thermo sensor (dynamic chamber)

Short circuit Maintains constant 20°C (68°F) command

12

Throttle sensor Open or short circuit Maintains constant command of throttle valve fully open

15 ON n

OFF •L 01

Oxygen sensor Sensor output con-tinues less than 0.55V 120 sec. after engine starts (1,500 rpm or over)

Cancels

EG I

feed-

back operation

17 ON n

OFF L HI il

Feedback system Sensor output not changed 20 sec. af-ter engine starts (1,500 rpm or over)

Cancels

EG I

feed-

back operation

25 0°nfJU1LJIL

Solenoid valve (pres-sure regulator control)

Open or short circuit

26 2LMJIL

Solenoid valve (No.1 purge control)

Open or short circuit

27 ON nn

OFF | _ •111

-ii-Solenoid valve (No.2

purge control)

Open or short circuit

28 ON nn

OFF L Hi nr

Solenoid valve (EGR)

Open or short circuit

34 ^jmiHum

Solenoid valve (Idle speed control)

Open or short circuit

36 °FFJMI«U

Oxygen sensor relay

Open or short circuit

41 <£jimjiuM

Solenoid valve (Vari-able inertia control)

Open or short circuit

76G04C-018

Caution

a) If there is more than one failure present, the lowest number malfunction code is dis-

played first, the remaining codes are displayed sequentially.

b) After repairing a failure, turn off the ignition switch and disconnect the negative battery

cable and depress the brake pedal for at least 5 seconds to erase the memory of a mal-

function code.

4C—15

Page 883 of 1865

TROUBLESHOOTING (G4A-EL) 7B

06 4 second period

55 4 second period

63

-*•

4 second period

Repeats above

General Note

1. If there is more than one malfunction, the code

numbers will be displayed on the tester one by one

in a numerical order. In the case of malfunctions,

55, 06, and 63, the code numbers are displayed

in an order of 06, 55, then 63. The display is as

shown.

86U07B-018

When the service connector

is not grounded

Malfunctions YES

NO

Hold indicator YES

flashing NQ

YES

NO

Memory in control unit

2. The hold indicator flashes to indicate the same pat-

tern as the buzzer of the EC-AT Tester when the

EC-AT service connector is grounded.

When the EC-AT service connector is not ground-

ed, the indicator flashes in a constant frequency

while a malfunction is occurring and goes out

if

the

malfunction recovers. However, the warning code

is memorized in the EC-AT control unit.

76G07B-015

Sensors-

Solenoid-valve

Fail-safe program Proces--\Out sing -v puts

The EC-AT control unit has a built-in fail-safe func-

tion for the throttle sensor, the pulse generator, and

the 1-2, 2-3, and 3-4 shift solenoid valves.

If a malfunction occurs, the EC-AT control unit will

control operation of the remaining components ac-

cording to a preset fail-safe program.

The vehicle may still be driven, although the driv-

ing performance will be slightly affected.

79G07C-062

4. The memory of warning codes is canceled by dis-

connecting the negative battery terminal for ap-

prox. five seconds.

79G07C-063

7B-17

Page 884 of 1865

7B TROUBLESHOOTING (G4A-EL)

Retrieval Procedure

1. Locate the service connector.

86U07B-019

76G07B-214

11 IDLFC

5» O | || KICK DOWNS* _ If, DEPRESS

|[BRAKE UORRSW

MNMWE STF *

° M CRUISE CONTROL SW

CDS®> *• PI ^ SPEED DROPS

Gf Aft

•

OO ou

I I

w

6019 HI NOW* XIKI

CO , LTQ

MUX

IN

JAP"

76G07B-016

2. Ground the ground connector of the EC-AT

Tester.

3. Connect the 6-pin connector of the EC-AT Tester

to the service connector.

Note

The service connector is blue-colored con-

nector.

4. Ground the 1 pin service connector.

Note

The service connector is blue-colored con-

nector.

5. Turn the ignition switch ON.

6. Check that "88" flashes on the digital display and

the buzzer sounds for three seconds after turning

the ignition switch ON.

7. If "88" does not flash, check the service connec-

tor wiring.

8. If "88" flashes and the buzzer sounds continuously

for more than 20 seconds, check wiring to 2M ter-

minal of the EC-AT control unit for short-circuit then

replace the EC-AT control unit and repeat steps

3 and 4.

9. Note the code numbers and check for the causes

by referring to the Inspection Procedure shown on

pages 7B—19 to 7B—21, repair as necessary.

Note

After repairs are made, recheck for code num-

bers by performing the "After-repair

procedure."

7B—18

Page 885 of 1865

TROUBLESHOOTING (G4A-EL) 7B

79G07C-068

Drive at 50

km/h

(31

mph)

Kick-down

Stop

the

vehicle

79G07C-069

After-repair Procedure

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery terminal for at least five sec-

onds, then reconnect it.

2. Remove the EC-AT tester if it is connected.

3. Drive the vehicle at 50 km/h (31 mph), then de-

press the accelerator pedal fully to activate kick-

down. Stop the vehicle gradually.

KICK goimsv

BRAKE LIGHTS*

CRUISE CONTROL

C V,. DEPRESS FULL*

Ox

azsa

ORUti rpn

"J

i"

•

rm uu

£ZL ofF

4. Reconnect the EC-AT tester to the 6-pin service

connector.

5. Ground the 1 -pin service connector with a jumper

wire.

6. Turn the ignition switch ON.

7. Check that no code numbers are displayed.

79G07C-070

Inspection Procedure

No. 06 code display (Vehicle speed sensor)

76G07B-017

7B-19