display MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 886 of 1865

7B TROUBLESHOOTING (G4A-EL)

No. 12 code display (Throttle sensor)

76G07B-018

No. 55 code display (Pulse generator)

Is there poor connection at connector? YES Repair or replace.

NO

Does EC-AT Tester display drum speed? (Refer to STEP 3-Signal Inspection)

YES Pulse generator OK.

Cancel memory of code number.

NO

NO Is there 200—400 12 between terminals of pulse generator connector? (Refer to page 7B—68)

NO Replace pulse generator. Is there 200—400 12 between terminals of pulse generator connector? (Refer to page 7B—68)

YES YES Check for open or short-circuit in wiring. Check for open or short-circuit in wiring.

76G07B-019

No. 60, 61, 62, or 64 code display (1-2 shift, 2-3 shift, or 3-4 shift solenoid valve)

7B-20

Page 887 of 1865

TROUBLESHOOTING (G4A-EL) 7B

76G07B-020

No. 63 code display (Lock-up solenoid valve)

76G07B-021

7B—21

Page 890 of 1865

7B TROUBLESHOOTING (G4A-EL)

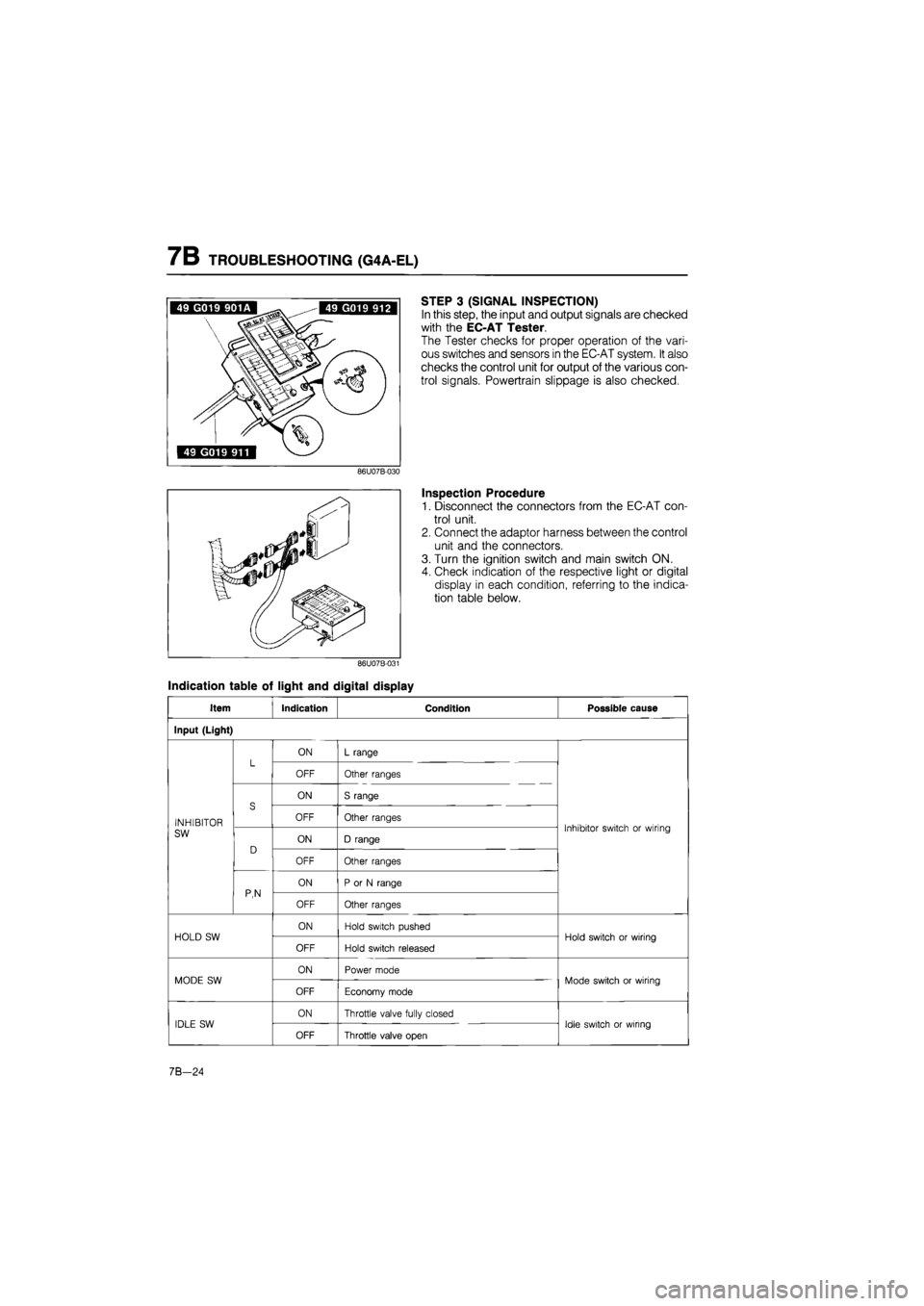

STEP 3 (SIGNAL INSPECTION)

In this step, the input and output signals are checked

with the EC-AT Tester.

The Tester checks for proper operation of the vari-

ous switches and sensors in the EC-AT system. It also

checks the control unit for output of the various con-

trol signals. Powertrain slippage is also checked.

Inspection Procedure

1. Disconnect the connectors from the EC-AT con-

trol unit.

2. Connect the adaptor harness between the control

unit and the connectors.

3. Turn the ignition switch and main switch ON.

4. Check indication of the respective light or digital

display in each condition, referring to the indica-

tion table below.

Indication table of light and digital display

Item Indication Condition Possible cause

Input (Light)

L ON L range L OFF Other ranges

S

ON S range

INHIBITOR

S OFF Other ranges Inhibitor switch or wiring SW

D ON D range

Inhibitor switch or wiring

D

OFF Other ranges

P,N

ON P or N range P,N OFF Other ranges

HOLD SW ON Hold switch pushed Hold switch or wiring HOLD SW

OFF Hold switch released

Hold switch or wiring

MODE SW ON Power mode Mode switch or wiring MODE SW

OFF Economy mode

Mode switch or wiring

IDLE SW ON Throttle valve fully closed Idle switch or wiring IDLE SW

OFF Throttle valve open

Idle switch or wiring

7B-24

Page 891 of 1865

TROUBLESHOOTING (G4A-EL) 7B

Item Indication Condition Possible cause

BRAKE LIGHT SW ON Brake pedal depressed Brake light switch or

wiring BRAKE LIGHT SW

OFF Brake pedal released

Brake light switch or

wiring

WATER TEMP SW ON Coolant temperature 72°C (162°F) or above Water temp switch or wiring WATER TEMP SW

OFF Coolant temperature lower than 65°C (149°F)

Water temp switch or wiring

ATF TEMP SW ON ATF temperature 150°C (302°F) or above Fluid temperature switch or wiring ATF TEMP SW

OFF ATF temperature lower than 143°C (289°F)

Fluid temperature switch or wiring

CRUISE CONTROL SW Not used — —

Input (Digital display)

THROTTLE SENSOR

EC-AT control unit terminal voltage All the time Throttle sensor, idle switch or wirings

VEHICLE SPEED*

Vehicle speed calculated from speed sensor signal

All the time Vehicle speed sensor, speedometer cable, or wiring

DRUM SPEED* Drum speed All the time Pulse generator or wirings

Output (Light)

1-2 SOLENOID VALVE*

ON

Refer to page 7B—26 solenoid valve operation table

Control unit, 1-2 shift sol., or wiring 1-2 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table

Control unit, 1-2 shift sol., or wiring

2-3 SOLENOID VALVE*

ON Refer to page 7B—26 solenoid valve operation table Control unit, 2-3 shift sol., or wiring 2-3 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table Control unit, 2-3 shift sol., or wiring

3-4 SOLENOID VALVE*

ON

Refer to page 7B—26 solenoid valve operation table

Control unit, 3-4 shift sol., or wiring 3-4 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table

Control unit, 3-4 shift sol., or wiring

LOCK-UP SOLE-NOID VALVE*

ON Lock-up condition Control unit, lock-up sol., or wiring LOCK-UP SOLE-NOID VALVE* OFF Non-lock-up condition

Control unit, lock-up sol., or wiring

HOLD INDICATOR ON Hold mode Control unit, Hold switch, or wiring HOLD INDICATOR OFF Other modes

Control unit, Hold switch, or wiring

MODE INDICATOR ON Power or economy mode Control unit, hold switch, mode switch, or wiring MODE INDICATOR

OFF Hold mode

Control unit, hold switch, mode switch, or wiring

NO LOAD SIGNAL Not used — —

76G07B-028

7B-25

Page 892 of 1865

7B TROUBLESHOOTING (G4A-EL)

Item Indication Condition

OUTPUT (Digital display)

1

1

st gear position

GEAR* 2 2nd gear position GEAR*

3 3rd gear position

4 Overdrive (OD) gear position

86U07B-033

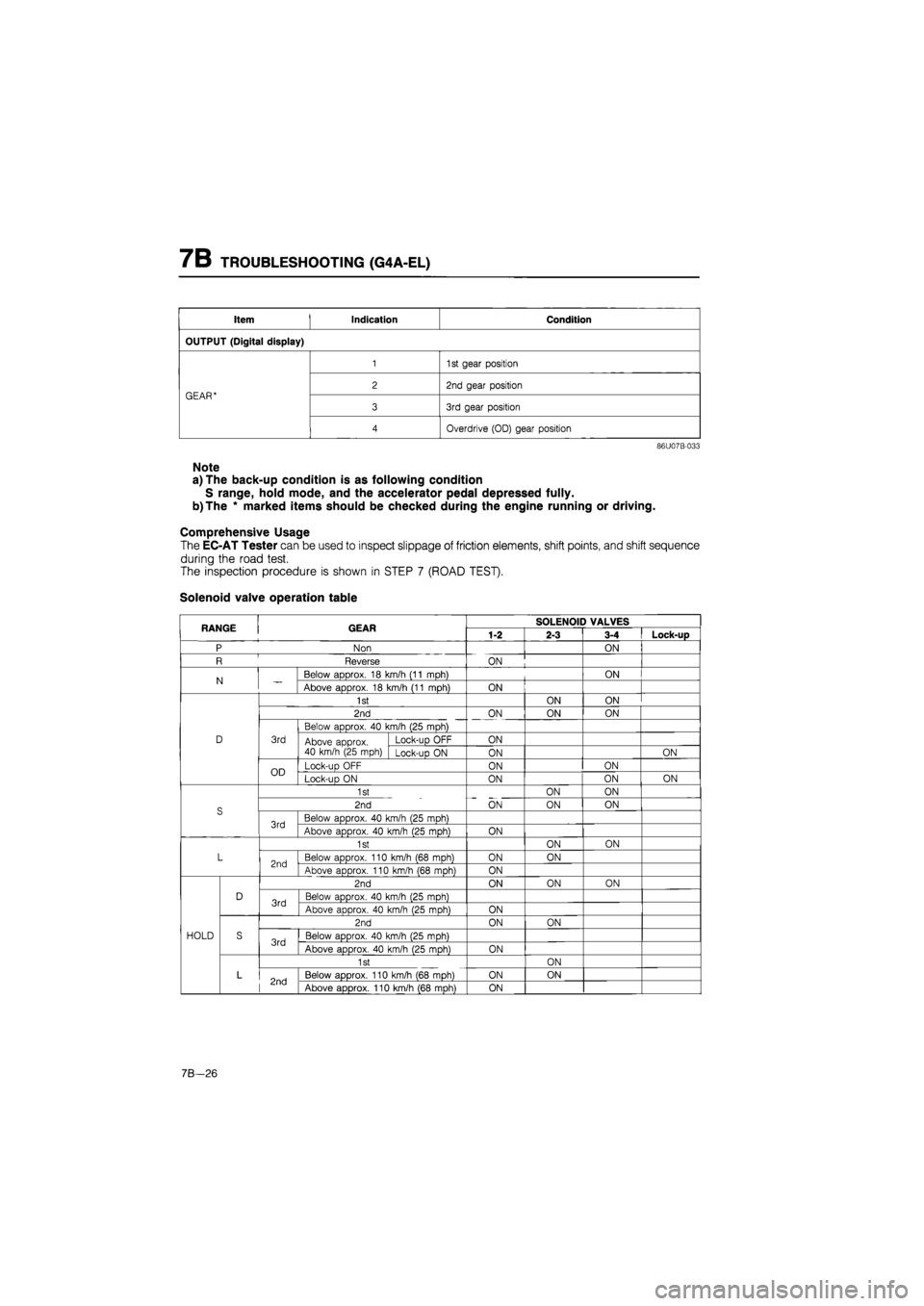

Note

a) The back-up condition is as following condition

S range, hold mode, and the accelerator pedal depressed fully.

b)The * marked items should be checked during the engine running or driving.

Comprehensive Usage

The EC-AT Tester can be used to inspect slippage of friction elements, shift points, and shift sequence

during the road test.

The inspection procedure is shown in STEP 7 (ROAD TEST).

Solenoid valve operation table

RANGE GEAR SOLENOID VALVES RANGE GEAR 1-2 2-3 3-4 Lock-up

P Non ON

R Reverse ON

N Below aDDrox. 18 km/h (11 mDh) ON N Above approx. 18 km/h (11 mph) ON

1st ON ON

2nd ON ON ON

Below approx. 40 km/h (25 mph)

D 3rd Above approx. 40 km/h (25 mph)

Lock-uo OFF ON Above approx. 40 km/h (25 mph) Lock-up ON ON ON

OD Lock-up OFF ON ON OD Lock-uo ON ON ON ON

1st ON ON

S 2nd ON ON ON S

3rd Below approx. 40 km/h (25 mph) 3rd Above approx. 40 km/h (25 mph) ON

1st ON ON

L 2nd Below approx. 110 km/h (68 mph) ON ON 2nd Above approx. 110 km/h (68 moh) ON

2nd ON ON ON

D 3rd Below approx. 40 km/h (25 moh) 3rd Above approx. 40 km/h (25 moh) ON

2nd ON ON

HOLD S 3rd Below approx. 40 km/h (25 mph) 3rd Above approx. 40 km/h (25 mph) ON

1st ON

L 2nd Below approx. 110 km/h (68 mph) ON ON 2nd Above approx. 110 km/h (68 mph) ON

7B—26

Page 1677 of 1865

15 METER

METER

STRUCTURAL VIEW

DIGITAL ELECTRONIC DISPLAY METER

ANALOG DISPLAY METER

76G15X-007

1. Speedometer 5. Warning and indicator lights

2. Tachometer 6. Tripmeter

3. Water temperature gauge 7. Twin tripmeter change switch

4. Fuel gauge 8. Fuel garge scale change switch

15—22

Page 1682 of 1865

![MAZDA 626 1987 User Guide

METER 15

86U15X-033

86U15X-034

104.1t! 21

2330 16.10

a £] U \JEMP j n

JJ

86U15X-035

Standard indication

(km/h)

Allowable range

(km/h)

60 60-63

Standard indication

(mph)

Allowable ran MAZDA 626 1987 User Guide

METER 15

86U15X-033

86U15X-034

104.1t! 21

2330 16.10

a £] U \JEMP j n

JJ

86U15X-035

Standard indication

(km/h)

Allowable range

(km/h)

60 60-63

Standard indication

(mph)

Allowable ran](/img/28/57059/w960_57059-1681.png)

METER 15

86U15X-033

86U15X-034

104.1t! 21

2330 16.10

a £] U \JEMP j n

JJ

86U15X-035

Standard indication

(km/h)

Allowable range

(km/h)

60 60-63

Standard indication

(mph)

Allowable range

(mph)

60 60-63

86U15X-036

3. Set the SST to the resistance values shown in the

figure.

4. Turn the ignition switch ON, and check that the

needle indicator displays the correct values.

If the needle displays correctly, check the gauge

unit. If not, replace the fuel gauge in the meter or

repair the wiring harness.

Caution

a) Continue the above checks for at least two

minutes each to correctly judge the con-

dition.

b)The allowable indication error is twice the

width of the needle.

Water Temperature Gauge

1. Disconnect the connector from the water thermo

sensor.

2. Connect the red lead of the SST to the connec-

tor, and the black lead to a body ground.

3. Set the SST to the resistance values shown in the

figure.

4. Turn the ignition switch ON, and check that the

needle indicator displays the correct values.

If the needle displays the correct values, the trou-

ble is in the gauge unit; if not, the trouble is in the

meter or the wiring harness.

Caution

a) Continue the above checks for at least two

minutes each to correctly judge the con-

dition.

b)The allowable indication error is twice the

width of the needle.

INSPECTION OF DIGITAL METER

Speedometer

1. Using a speedometer tester, check the speedom-

eter for allowable indication error, and check the

operation of the odometer. Replace the meter as-

sembly if necessary.

2. Check the speedometer for fluctuation and/or ab-

normal noise.

Caution

a) If significant fluctuation occurs or the

speedometer does not move at all, remove

the speedometer cable. If normal, replace

the digital meter assembly.

b)Tire wear and improper inflation will in-

crease speedometer error.

15—27

Page 1683 of 1865

15 METER

Standard Indication

(rpm)

Allowable range

(rpm)

1000

900—

950

2000 1900-1950

3000 2900—2950

4000 3900-3950

5000 4900—4950

6000 5900-5950

86U15X-037

86U15X-038

86U15X-039

Standard display Expanded display

E ©FUEL F E © FUEL F

"io — •

QJ1QOOODDOOOD

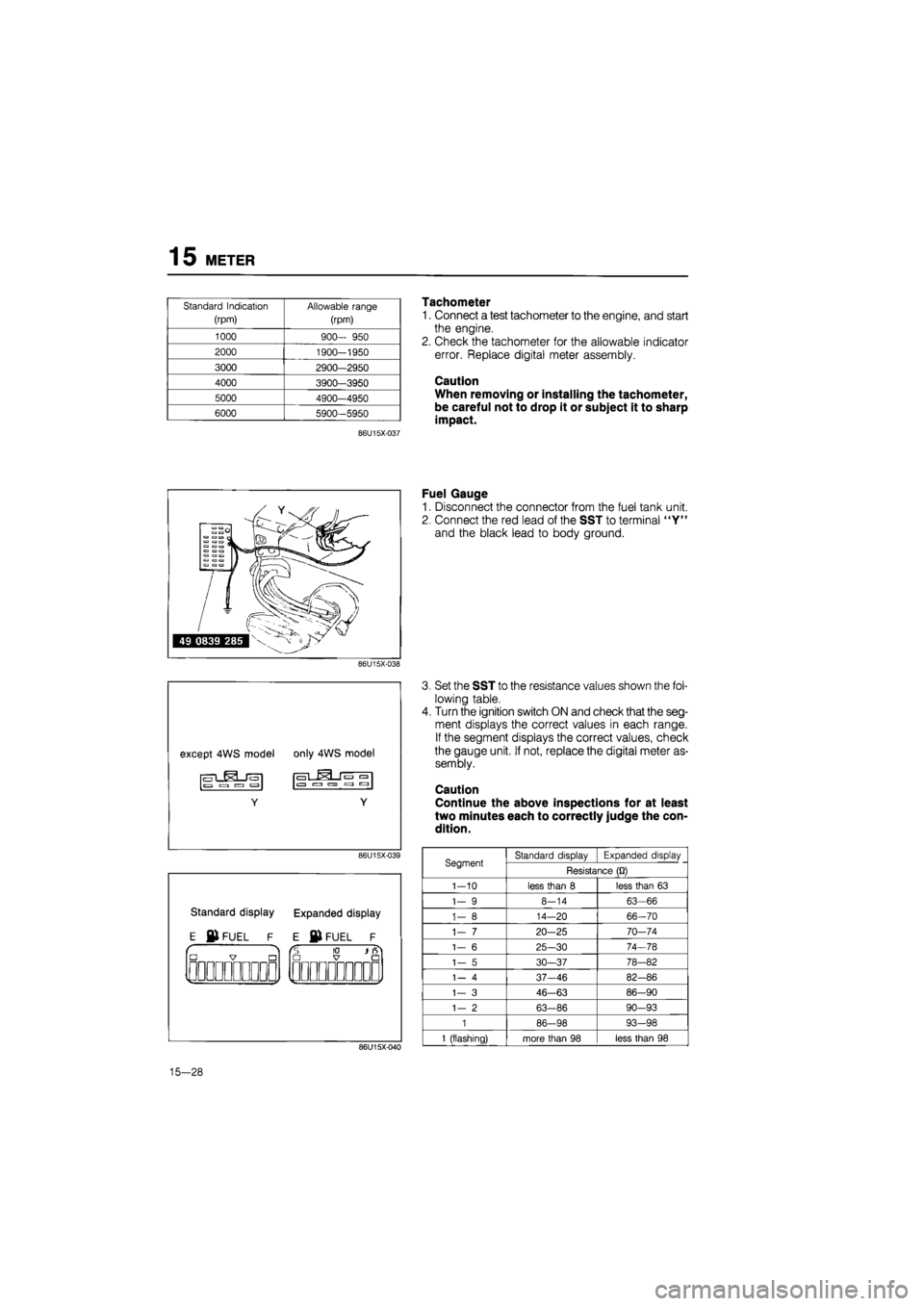

Tachometer

1. Connect a test tachometer to the engine, and start

the engine.

2. Check the tachometer for the allowable indicator

error. Replace digital meter assembly.

Caution

When removing or installing the tachometer,

be careful not to drop it or subject it to sharp

impact.

Fuel Gauge

1. Disconnect the connector from the fuel tank unit.

2. Connect the red lead of the SST to terminal "Y"

and the black lead to body ground.

86U15X-040

Set the SST to the resistance values shown the fol-

lowing table.

Turn the ignition switch ON and check that the seg-

ment displays the correct values in each range.

If the segment displays the correct values, check

the gauge unit. If not, replace the digital meter as-

sembly.

Caution

Continue the above inspections for at least

two minutes each to correctly judge the con-

dition.

Segment Standard display Expanded display Segment Resistance

(Q)

1-10

less than

8

less than

63

1-

9

8-14

63-66

1-

8

14—20 66-70

1-

7

20-25 70-74

1-

6

25-30 74-78

1-

5

30—37 78-82

1-

4

37-46 82-86

1—

3

46-63 86-90

1-

2

63-86 90-93

1

86-98 93-98

1

(flashing) more than

98

less than

98

15-28

Page 1684 of 1865

METER 15

Water Temperature Gauge

1. Remove the connector from the water thermo

sensor.

2. Connect the red lead of the SST to the connec-

tor, and the black lead to a body ground.

86U15X-041

C -&TEMP H

r

•

|

7 •

V i y

86U15X-042

3. Set the SST to the resistance values shown in the

following table.

4. Turn the ignition switch ON and check that the seg-

ment displays the correct values. If the segment

displays the correct values, check the gauge unit.

If not, replace the digital meter assembly or repair

wiring harness.

Caution

Continue the above checks for at least two

minutes each to correctly judge the condition.

Segment Resistance

(Q)

Segment Resistance

(Q)

1-10

less than

17

1-5

33-89

1-

9

17—20

1-4

89-120

1—

8

20—26

1-3

120-145

1—

7

26-28

1-2

145-177

1-

6

28-33

1

more than

177

INSPECTION OF METER SENDER

Fuel tank unit (except 4WS model)

1. Disconnect the connector from the fuel tank unit.

2. Remove the fuel tank unit from the tank.

3. Connect an ohmmeter to terminal "b" of con-

nector.

4. Move the unit arm slowly from point (F) to point

(E), and read the resistance values. If not as speci-

fied, replace the unit.

86U15X-043

15—29