radiator cap MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 14 of 1865

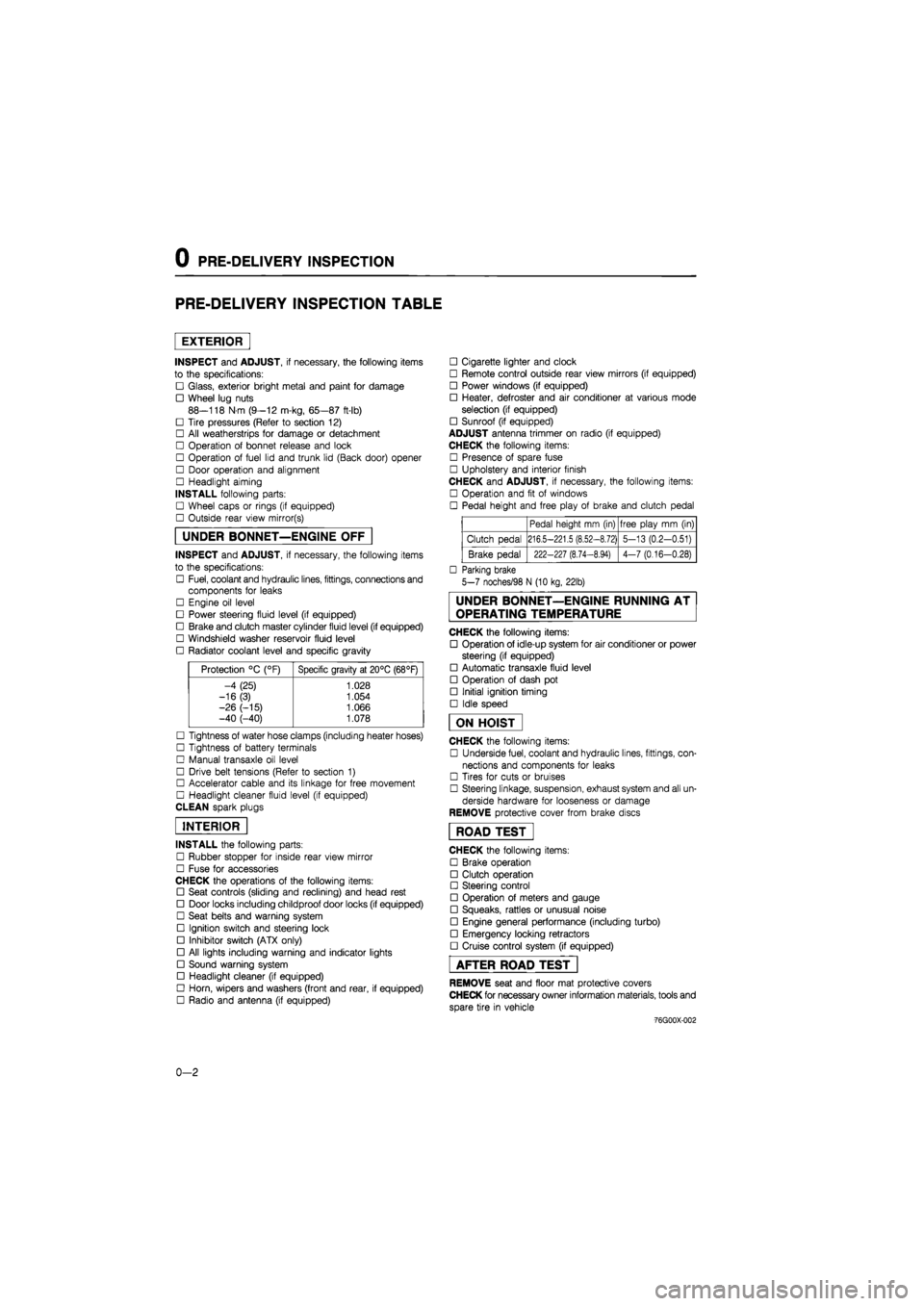

0 PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

EXTERIOR

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Glass, exterior bright metal and paint for damage

• Wheel lug nuts

88—118 N m (9—12 m-kg, 65—87 ft-lb)

• Tire pressures (Refer to section 12)

• All weatherstrips for damage or detachment

• Operation of bonnet release and lock

• Operation of fuel lid and trunk lid (Back door) opener

• Door operation and alignment

• Headlight aiming

INSTALL following parts:

• Wheel caps or rings (if equipped)

• Outside rear view mirror(s)

UNDER BONNET—ENGINE OFF

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

• Engine oil level

• Power steering fluid level (if equipped)

• Brake and clutch master cylinder fluid level (if equipped)

• Windshield washer reservoir fluid level

• Radiator coolant level and specific gravity

Protection °C (°F) Specific gravity at 20°C (68°F)

-4 (25) 1.028

-16(3) 1.054

-26 (-15) 1.066 -40 (-40) 1.078

• Tightness of water hose clamps (including heater hoses)

• Tightness of battery terminals

• Manual transaxle oil level

• Drive belt tensions (Refer to section 1)

• Accelerator cable and its linkage for free movement

• Headlight cleaner fluid level (if equipped)

CLEAN spark plugs

INTERIOR

INSTALL the following parts:

• Rubber stopper for inside rear view mirror

• Fuse for accessories

CHECK the operations of the following items:

• Seat controls (sliding and reclining) and head rest

• Door locks including childproof door locks (if equipped)

• Seat belts and warning system

• Ignition switch and steering lock

• Inhibitor switch (ATX only)

• All lights including warning and indicator lights

• Sound warning system

• Headlight cleaner (if equipped)

• Horn, wipers and washers (front and rear, if equipped)

• Radio and antenna (if equipped)

• Cigarette lighter and clock

• Remote control outside rear view mirrors (if equipped)

• Power windows (if equipped)

• Heater, defroster and air conditioner at various mode

selection (if equipped)

• Sunroof (if equipped)

ADJUST antenna trimmer on radio (if equipped)

CHECK the following items:

• Presence of spare fuse

• Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

• Operation and fit of windows

• Pedal height and free play of brake and clutch pedal

Pedal height mm (in) free play mm (in)

Clutch pedal 216.5-221.5 (8.52-8.72) 5-13 (0.2-0.51)

Brake pedal 222-227 (8.74-8.94) 4-7 (0.16-0.28)

• Parking brake

5-7 noches/98 N (10 kg, 22lb)

UNDER BONNET—ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

• Operation of idle-up system for air conditioner or power

steering (if equipped)

• Automatic transaxle fluid level

• Operation of dash pot

• Initial ignition timing

• Idle speed

ON HOIST

CHECK the following items:

• Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

• Tires for cuts or bruises

• Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

REMOVE protective cover from brake discs

ROAD TEST"

CHECK the following items:

• Brake operation

• Clutch operation

• Steering control

• Operation of meters and gauge

• Squeaks, rattles or unusual noise

• Engine general performance (including turbo)

• Emergency locking retractors

• Cruise control system (if equipped)

AFTER ROAD TEST

REMOVE seat and floor mat protective covers

CHECK for necessary owner information materials, tools and

spare tire in vehicle

-76G00X-002

0-2

Page 39 of 1865

1A TUNE-UP PROCEDURE

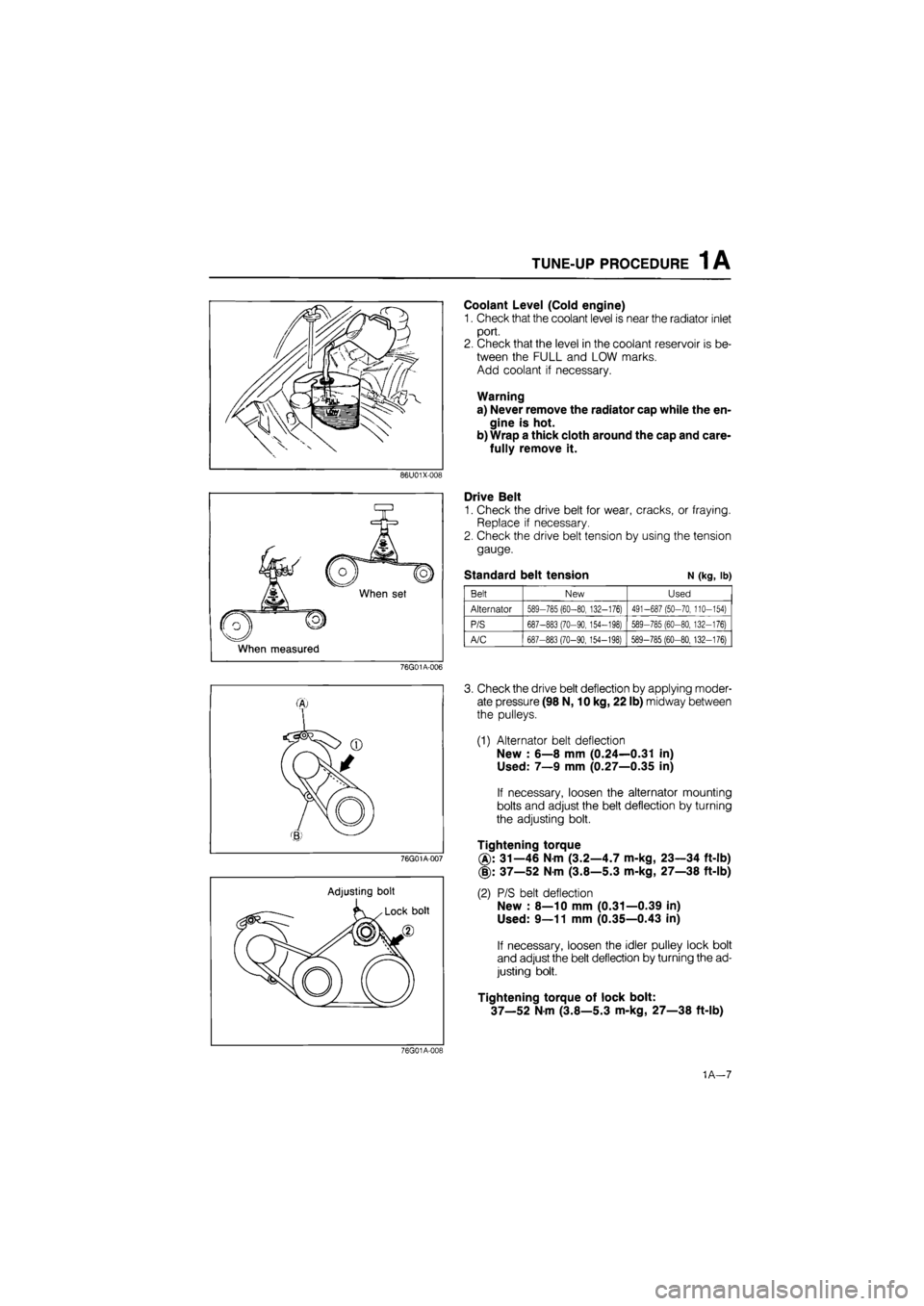

Coolant Level (Cold engine)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the level in the coolant reservoir is be-

tween the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b) Wrap a thick cloth around the cap and care-

fully remove it.

86U01X-008

When set

When measured

Drive Belt

1. Check the drive belt for wear, cracks, or fraying.

Replace if necessary.

2. Check the drive belt tension by using the tension

gauge.

Standard belt tension N (kg, lb)

Belt New Used

Alternator 589-785 (60-80, 132-176) 491-687 (50-70, 110-154)

P/S 687-883 (70-90, 154-198) 589-785 (60-80, 132-176)

A/C 687-883 (70-90,154-198) 589-785 (60-80, 132-176)

76G01A-006

76G01A-007

Adjusting bolt

3. Check the drive belt deflection by applying moder-

ate pressure (98 N, 10 kg, 22 lb) midway between

the pulleys.

(1) Alternator belt deflection

New : 6—8 mm (0.24—0.31 in)

Used: 7—9 mm (0.27—0.35 in)

If necessary, loosen the alternator mounting

bolts and adjust the belt deflection by turning

the adjusting bolt.

Tightening torque

31—46 Nm (3.2—4.7 m-kg, 23—34 ft-lb)

(§): 37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(2) P/S belt deflection

New : 8—10 mm (0.31—0.39 in)

Used: 9—11 mm (0.35—0.43 in)

If necessary, loosen the idler pulley lock bolt

and adjust the belt deflection by turning the ad-

justing bolt.

Tightening torque of lock bolt:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

76G01A-019

1A—7

Page 58 of 1865

1 A ON-VEHICLE MAINTENANCE (VALVE SEAL)

VALVE SEAL

Removal

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01A-114

11. Fuel hose (carb.)

12. Rear housing

13. Rocker arm and shaft assembly

14. Camshaft cap (12-valve)

15. Camshaft

16. Valve keeper

17. Upper valve spring seat

18. Valve spring

19. Lower valve spring seat

20. Valve seal

1. Air cleaner assembly (carb.)

2. Air intake pipe (Fl)

3. High-tension lead and spark plug

4. Upper timing belt cover

5. Timing belt

6. Cylinder head cover

7. Camshaft pulley

8. Front housing

9. Distributor

10. Upper radiator hose

1A—26

Page 137 of 1865

1B TUNE-UP PROCEDURE 1 B

86U01X-008

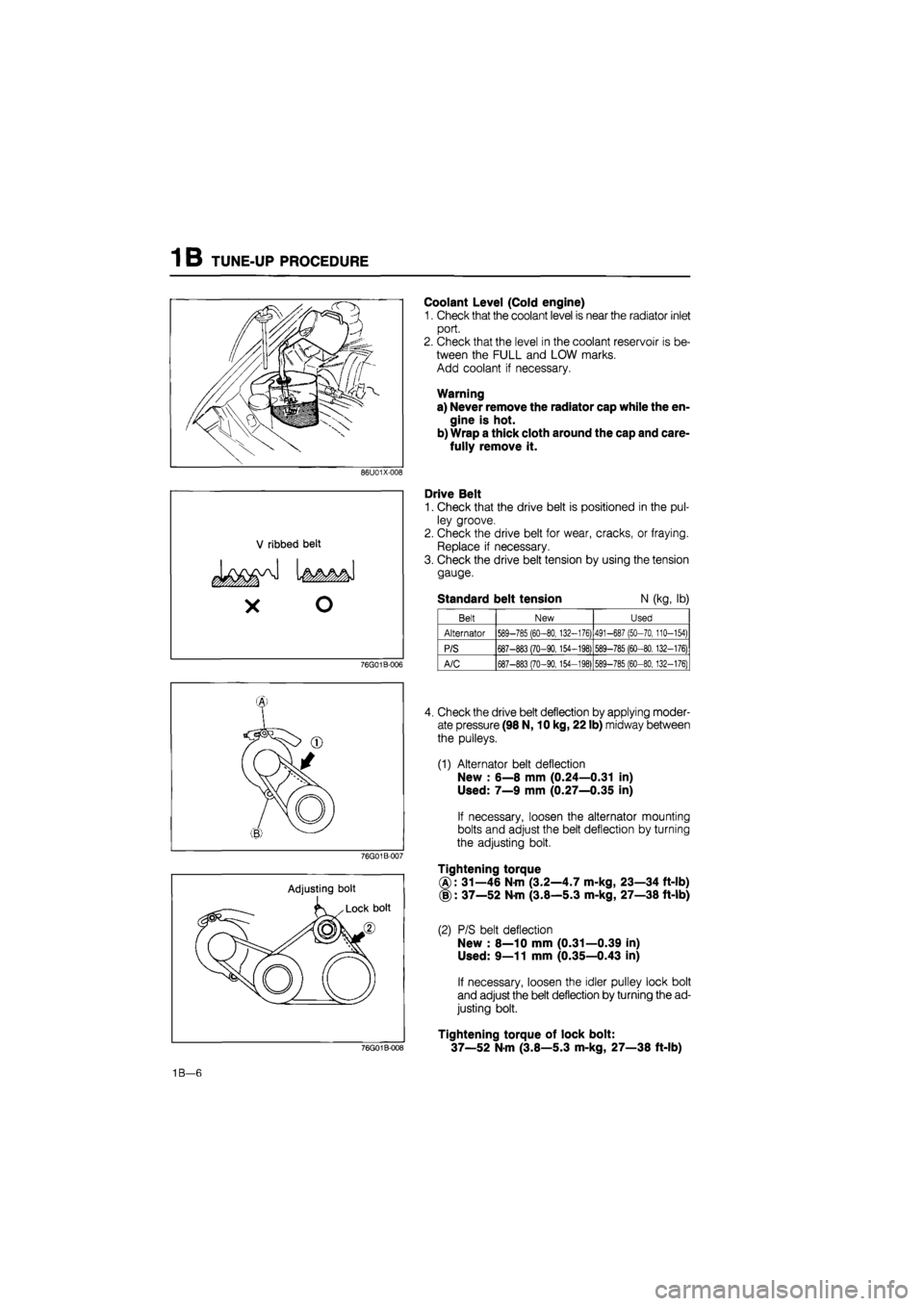

Coolant Level (Cold engine)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the level in the coolant reservoir is be-

tween the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b) Wrap a thick cloth around the cap and care-

fully remove it.

Drive Belt

1. Check that the drive belt is positioned in the pul-

ley groove.

2. Check the drive belt for wear, cracks, or fraying.

Replace if necessary.

3. Check the drive belt tension by using the tension

gauge.

Standard belt tension N (kg, lb)

76G01B-006

Belt New Used

Alternator 589-785 (60-80, 132-176) 491-687 (50-70, 110-154)

P/S 687-883 (70-90,154-198) 589-785 (60-80.132-176)

A/C 687-883 (70-90,154-198) 589-785 (60-80,132-176)

76G01B-007

Adjusting bolt

76G01B-008

4. Check the drive belt deflection by applying moder-

ate pressure (98 N, 10 kg, 22 lb) midway between

the pulleys.

(1) Alternator belt deflection

New : 6—8 mm (0.24—0.31 in)

Used: 7—9 mm (0.27—0.35 in)

If necessary, loosen the alternator mounting

bolts and adjust the belt deflection by turning

the adjusting bolt.

Tightening torque

®: 31—46 Nm (3.2—4.7 m-kg, 23—34 ft-lb)

(§): 37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(2) P/S belt deflection

New : 8—10 mm (0.31—0.39 in)

Used: 9—11 mm (0.35—0.43 in)

If necessary, loosen the idler pulley lock bolt

and adjust the belt deflection by turning the ad-

justing bolt.

Tightening torque of lock bolt:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

1B—6

Page 218 of 1865

1C TUNE-UP PROCEDURE

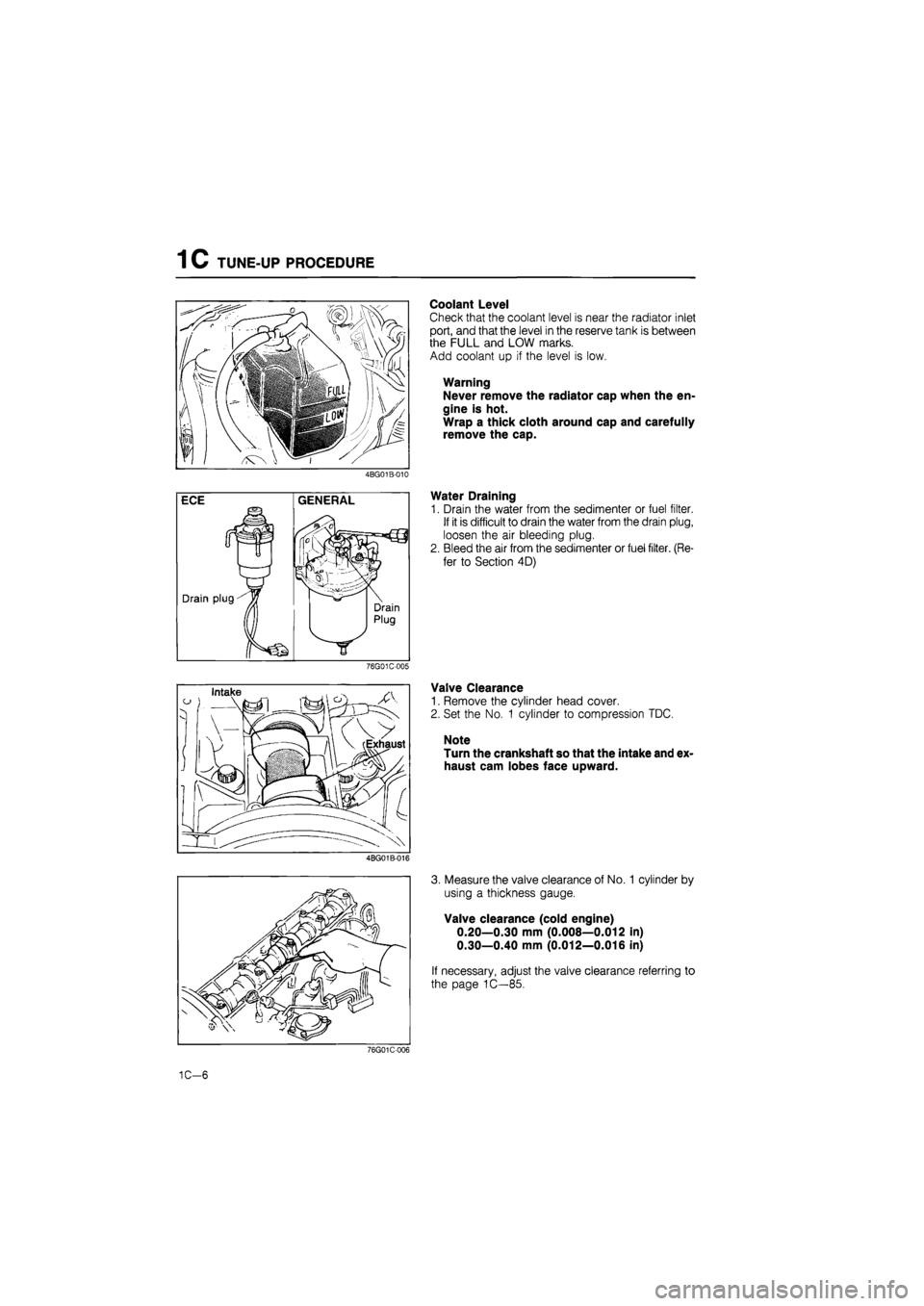

Coolant Level

Check that the coolant level is near the radiator inlet

port, and that the level in the reserve tank is between

the FULL and LOW marks.

Add coolant up if the level is low.

Warning

Never remove the radiator cap when the en-

gine is hot.

Wrap a thick cloth around cap and carefully

remove the cap.

4BG01B-010

Water Draining

1. Drain the water from the sedimenter or fuel filter.

If it is difficult to drain the water from the drain plug,

loosen the air bleeding plug.

2. Bleed the air from the sedimenter or fuel filter. (Re-

fer to Section 4D)

76G01C-005

Valve Clearance

1. Remove the cylinder head cover.

2. Set the No. 1 cylinder to compression TDC.

Note

Turn the crankshaft so that the intake and ex-

haust cam lobes face upward.

4BG01B-016

3. Measure the valve clearance of No. 1 cylinder by

using a thickness gauge.

Valve clearance (cold engine)

0.20—0.30 mm (0.008—0.012 in)

0.30—0.40 mm (0.012—0.016 in)

If necessary, adjust the valve clearance referring to

the page 1C—85.

76G01C-006

1C-6

Page 340 of 1865

COOLING SYSTEM

(GASOLINE ENGINE)

OUTLINE 3A— 2

COOLANT FLOW CHART (DOHC) 3A— 2

COOLANT FLOW CHART (SOHC) 3A— 3

SPECIFICATIONS 3A- 4

TROUBLESHOOTING GUIDE 3A— 4

COOLANT 3A- 5

INSPECTION 3A— 5

REPLACEMENT 3A— 5

RADIATOR CAP 3A— 6

INSPECTION 3A— 6

RADIATOR 3A— 7

REMOVAL AND INSTALLATION 3A— 7

INSPECTION 3A— 7

WATER PUMP 3A— 8

REMOVAL 3A— 8

INSPECTION 3A—10

INSTALLATION 3A—10

THERMOSTAT 3A—11

REMOVAL 3A—11

INSPECTION 3A-11

INSTALLATION 3A—11

COOLING FAN 3A—12

SYSTEM CIRCUIT 3A—12

CIRCUIT INSPECTION 3A—12

FAN MOTOR 3A—13

WATER THERMO SWITCH 3A—14

76G03A-001

Page 343 of 1865

3A TROUBLESHOOTING GUIDE i

SPECIFICATIONS

^Engine model

Item ^__

FE-DOHC

FE 8-valve,

F8, F6...except

Middle East

.General

FE 12-valve

FE 8-valve F8, F6...only Middle East General

Cooling system Water cooled, forced circulation

Coolant capacity liters (US qt, Imp qt)

With heater 7.5 (7.9, 6.6) Coolant capacity liters (US qt, Imp qt) Without heater 7.0 (7.4, 6.2)

Water pump Type Centrifugal, timing belt driven Water pump

Water seal Unified seal

Thermostat

Type Wax, 2-stage Wax

Thermostat

Opening temperature °C(°F) Sub

.

83.5-86.5 (182-188) Main: 86.5-89.5 (188-193) 86.5-89.5 (188-193) 80.5-83.5 (177-182) Thermostat

Full-open temperature °C(°F) 100 (212) 95 (203)

Thermostat

Full-open lift

mm

(in) Sub: 1.5 (0.06) min.

Main: 8.0 (0.31) min. 8.5 (0.33) min.

Radiator

Type Corrugated

Radiator Cap valve opening pressure

kPa (kg/cm2, psi) 74-103 (0.75-1.05, 11-15)

Cooling

fan

Capacity

W

MTX 80

Cooling

fan

Capacity

W

ATX 120

Cooling

fan

Number

of

blade 4 Cooling

fan

Outer diameter

of

blade

mm

(in) MTX 320 (12.6)

Cooling

fan

Outer diameter

of

blade

mm

(in)

ATX 340 (13.4)

76G03A-003

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Overheating

Insufficient coolant Add 3A—

5

Coolant leakage Repair

—

Radiator fins clogged Clean 3A—

7

Radiator cap malfunction Replace 3A-

6

Cooling fan malfunction Repair 3A-12 Thermostat malfunction Replace 3 A-11

Water passage clogged Clean 3A—

5

Water

DumD

malfunction ReDair

or

replace 3A-

8

Corrosion

Impurities

in

coolant Replace 3A-

5

76G03A-004

3A—4

Page 344 of 1865

COOLANT 3A

76G03A-016

69G03A-006

COOLANT

INSPECTION

Coolant Level (Engine cold)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the coolant level in the coolant reser-

voir is between the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

removing it.

Coolant Quality

1. Check that there is no build-up of rust or scales

around the radiator cap or radiator filler neck.

2. Check that coolant is free from oil.

3. Replace the coolant, if necessary.

Coolant Leakage

1. Connect a tester and SST to the radiator inlet port.

2. Apply 103 kPa (1.05 kg/cm2, 15 psi) pressure

to the system.

3. Check that the pressure is held.

If not, check for coolant leakage.

Warning

When removing either the radiator cap or the

tester, loosen it slowly until the pressure in

the radiator is released, and then remove it.

86U03X-005

REPLACEMENT

1. Remove the radiator cap and loosen the drain plug.

2. Drain the coolant into a suitable container.

Warning

a) Never open the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

loosening.

c) Use caution when draining hot coolant.

86U03X-006

3A-5

Page 345 of 1865

3A RADIATOR CAP

J I

V

J* J Q lanana

86U03X-028

86U03X-007

86U03X-008

3. Set the heater control switch to the maximum heat

position.

4. Flush the cooling system with water until all traces

of color are gone, then let the system drain com-

pletely.

5. Fill with the proper mixture and amount of ethy-

lene glycol-based coolant.

Caution

a) Do not use alcohol- or methanol-based

coolant.

b) Use only soft (demineralized) water in the

coolant mixture.

Anti-freeze solution mixture percentage

Protection Volume percentage Gravity

at

20°C (68°F) Protection Solution Water

Gravity

at

20°C (68°F)

Above -16°C (3°F) 35 65 1.054

Above -26°C (-15°F) 45 55 1.066

Above -40°C (-40°F) 55 45 1.078

6. Run the engine at idle with the radiator cap re-

moved. Let any air bleed from the system, and add

more coolant.

7. Install the radiator cap, and inspect all connections

for leakage.

RADIATOR CAP

INSPECTION

Radiator Cap Valve

1. Remove foreign material (such as water residue)

from between the radiator cap valve and the valve

seat.

2. Attach the radiator cap to a tester with the SST.

Apply pressure gradually to 74—103 kPa

(0.75—1.05 kg/cm2, 11—15 psi).

3. Wait about 10 seconds; then check that the pres-

sure has not decreased.

Negative Pressure Valve

1. Pull the negative-pressure valve to open it. Check

that it closes completely when released.

2. Check for damage on the contact surfaces, and

for cracked or deformed seal packing.

3. Replace the radiator cap if necessary.

86U03X-009

3A—6

Page 354 of 1865

3B

COOLING SYSTEM

(DIESEL)

OUTLINE 3B— 2

COOLANT FLOW CHART 3B— 2

SPECIFICATIONS 3B— 3

TROUBLESHOOTING GUIDE 3B— 3

COOLANT 3B— 4

INSPECTION 3B— 4

REPLACEMENT 3B— 4

RADIATOR CAP 3B— 5

INSPECTION 3B— 5

RADIATOR 3B— 6

REMOVAL AND INSTALLATION 3B— 6

INSPECTION 3B— 6

WATER PUMP 3B— 7

REMOVAL 3B— 7

INSPECTION 3B— 8

INSTALLATION 3B— 8

THERMOSTAT 3B— 9

REMOVAL 3B— 9

INSPECTION 3B— 9

INSTALLATION 3B— 9

COOLING FAN 3B—10

SYSTEM CIRCUIT 3B—10

CIRCUIT INSPECTION 3B—10

FAN MOTOR 3B—11

WATER THERMO SWITCH 3B—12

76G03B-001