steering wheel adjustment MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 606 of 1865

ISC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

A/C switch Detects air conditioner operation; sends

signal to engine control unit Switch ON when air conditioner

operating

Air valve When cold, supplies bypass air into dy-namic chamber • Engine speed increased to shorten warm-up period • Thermo wax type

• Installed in BAC valve

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

E/L control unit Detects that E/L is being applied; sends

signal to engine control unit

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Idle speed control)

Idle switch Detects when throttle valve fully closed;

sends signal to engine control unit

Installed on throttle body

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

P/S pressure switch Detects P/S operation; sends signal to engine control unit Switch ON when steering wheel turned right or left

Solenoid valve (Idle speed control) Controls bypass air amount • Controlled by duty signal from engine control unit • Installed in BAC valve

• Operates idle-up

Test connector For initial idle speed adjustment • Gerrn, 1-pin

• Idle speed feedback control cancelled when connector grounded

Water thermo sensor Detects coolant temperature; sends

signal to engine control unit

76G04C-078

4C—45

Page 1256 of 1865

TROUBLESHOOTING GUIDE 9

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Faulty operation of

driveshaft

Broken ball joint

Broken tri-pod joint

Worn or seized joint

Replace

Replace

Replace

9—31

9—35

9—31, 35

Abnormal noise from driveshaft Insufficient grease in joint or spline Excessive backlash on spline Worn joint

Add or replace

Replace

Replace

9—33, 36 9—31, 35 9-31, 35

Steering wheel pulls. (Steering wheel pulls toward either right or left side)

Bent steering linkage

Fatigued coil spring

Lower arm bushing worn or damaged Bent knuckle Bent lower arm or loose mounting Incorrect toe-in adjustment Improper tire air pressure Unevenly worn tires (left and right tires) Brake dragging

Refer to Section 10 Refer to Section 13 Refer to Section 13 Replace Refer to Section 13 Refer to Section 13 Refer to Section 12 Refer to Section 12 Refer to Section 11

9-11

Unstable handling Bent steering linkage

Joint in steering system worn or damaged

Incorrect steering pinion preload adjustment Fatigued coil spring

Faulty shock absorber(s) Lower arm bushing worn or damaged Incorrect toe-in adjustment (front or rear) Improper tire air pressure Wheel(s) bent or unbalanced

Refer to Section 10 Refer to Section 10 Refer to Section 10 Refer to Section 13 Refer to Section 13 Refer to Section 13 Refer to Section 13 Refer to Section 12 Refer to Section 12

—

Excessive steering wheel play Faulty front wheel bearing Incorrect steering pinion preload adjustment Rack and pinion worn Joint in steering system worn or damaged Lower arm bushing worn or damaged

Adjust Refer to Section 10 Refer to Section 10 Refer to Section 10 Refer to Section 13

9-11

Tires excessively worn or worn un-evenly

Incorrect toe-in adjustment Improper tire air pressure Unbalanced wheel(s)

Refer to Section 13 Refer to Section 12 Refer to Section 12 —

Abnormal noise

from axle

Faulty wheel bearing Replace 9-11,18,23

86U09X-006

9—7

Page 1289 of 1865

10

STEERING SYSTEM

OUTLINE 10— 2

STRUCTURAL VIEW 10— 2 SPECIFICATIONS 10— 6

TROUBLESHOOTING GUIDE 10— 7

MANUAL STEERING 10— 7

POWER STEERING 10— 8

4WS 10— 9

ON-VEHICLE MAINTENANCE 10— 10

STEERING WHEEL PLAY 10— 10

LOOSENESS OR PLAY OF THE

STEERING WHEEL 10— 10

STEERING WHEEL EFFORT 10— 10

POWER STEERING FLUID LEVEL 1 fl-11

LOOSE OR DAMAGED

OIL PUMP BELT IC— 12

REAR STEERING GEAR OIL 10— 12 LEAKAGE OF POWER STEERING

FLUID 10— 13

INSPECTION AND ADJUSTMENT. 10— 15

BLEEDING OF POWER STEERING

SYSTEM 10— 15

POWER STEERING PRESSURE ... 10— 16

TIE-ROD END BOOTS 10— 18

REMOVAL AND INSTALLATION .. 10— 18

STEERING WHEEL AND COLUMN 10— 21

STRUCTURAL VIEW 10— 21

REMOVAL 10— 22

DISASSEMBLY AND ASSEMBLY.. 10— 24

INSPECTION 10— 25

INSTALLATION 1 fl-27

STEERING GEAR AND LINKAGE .. IC— 28

STRUCTURAL VIEW 10— 28

REMOVAL 10— 29

INSTALLATION 10— 30

4-WHEEL STEERING GEAR AND

LINKAGE 10— 31

STRUCTURAL VIEW 10— 31 4WS PERFORMANCE INSPECTION 10— 32

ADJUSTMENT OF STEERING

ANGLE TRASFER SHAFT 10— 35

REMOVAL AND INSTALLATION .. 10— 37

INSPECTION 10— 44

MANUAL STEERING 10— 48

DISASSEMBLY 10— 48

INSPECTION 10— 51

ASSEMBLY 10— 52

ENGINE SPEED SENSING POWER

STEERING 10— 58

DISASSEMBLY 10— 58

INSPECTION 10— 62

ASSEMBLY 10— 64

ELECTRONICALLY-CONTROLLED

POWER STEERING 10— 75

DISASSEMBLY 10— 75

INSPECTION 10— 78

ASSEMBLY 10— 79

OIL PUMP 10— 83

REMOVAL AND INSTALLATION .. 10— 83

ELECTRICAL COMPONENTS OF

ELECTRONICALLY-CONTROLLED

POWER STEERING 10— 87

CIRCUIT DIAGRAM 10— 87

TROUBLESHOOTING GUIDE 10— 87

TROUBLESHOOTING 10— 87

ELECTRICAL COMPONENTS OF

4 WHEEL STEERING 10— 94

CIRCUIT DIAGRAM 10— 94

TROUBLESHOOTING GUIDE 10— 95

TROUBLESHOOTING 10— 95

4WS WARNING LIGHT 10—102

SPEED SENSOR (IN METER) 10—103

SPEED SENSOR (AT TRANSAXLE) 10—103

REAR-TO-FRONT STEERING

RATIO SENSOR 10—103

OIL LEVEL SWITCH

(IN P/S RESERVOIR) 10—103

RELAY AND TIMER 10—104 76G10X-001

Page 1295 of 1865

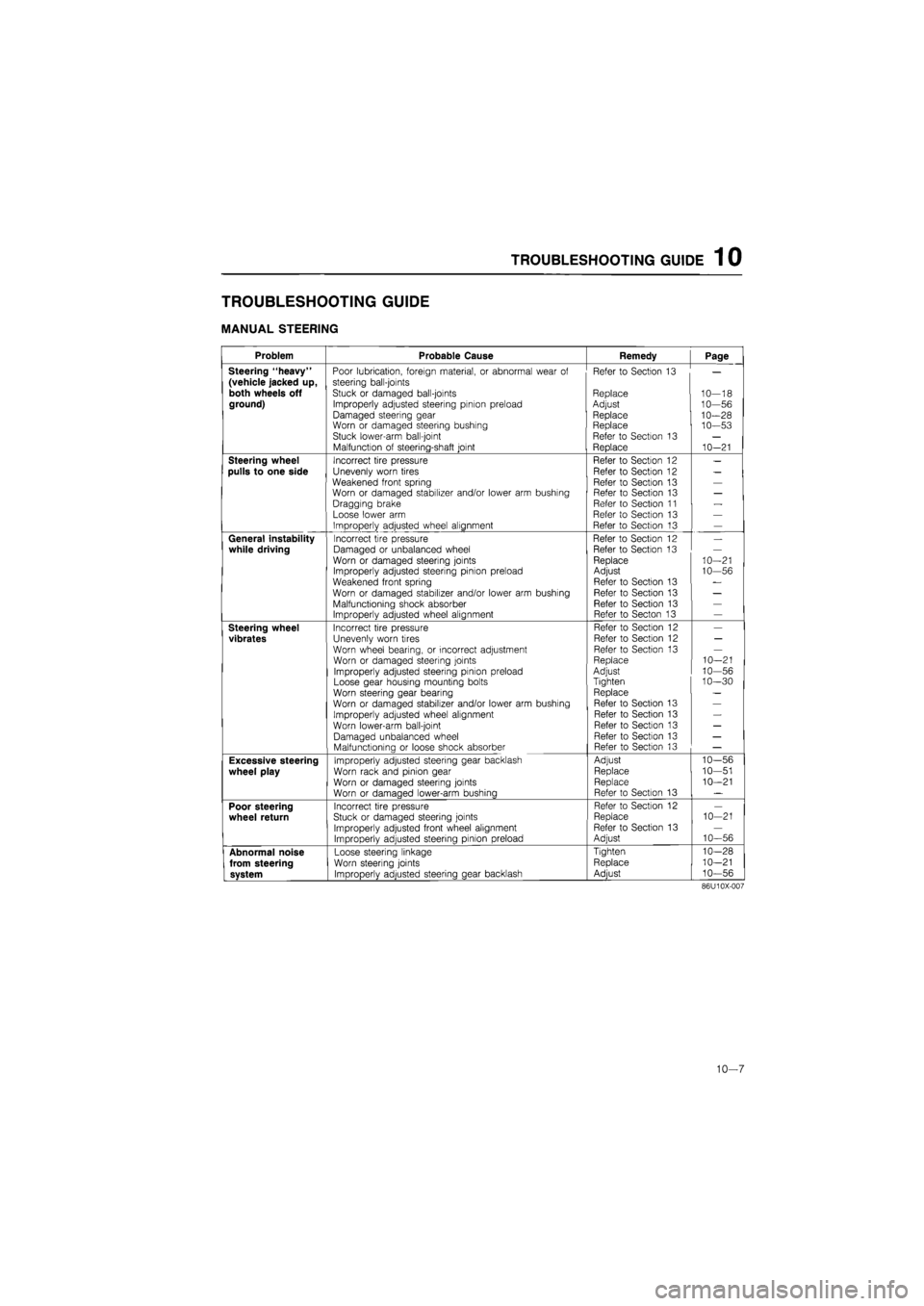

TROUBLESHOOTING GUIDE 1 0

TROUBLESHOOTING GUIDE

MANUAL STEERING

Problem Probable Cause Remedy Page

Steering "heavy" Poor lubrication, foreign material, or abnormal wear of Refer to Section 13

(vehicle jacked up, steering bail-joints

both wheels off Stuck or damaged ball-joints Replace 10--18 ground) Improperly adjusted steering pinion preload Adjust 10--56

Damaged steering gear Replace 10--28 Worn or damaged steering bushing Replace 10--53 Stuck lower-arm ball-joint Refer to Section 13

Malfunction of steering-shaft joint Replace 10--21

Steering wheel Incorrect tire pressure Refer to Section 12

pulls to one side Unevenly worn tires Refer to Section 12

Weakened front spring Refer to Section 13 Worn or damaged stabilizer and/or lower arm bushing Refer to Section 13

Dragging brake Refer to Section 11

Loose lower arm Refer to Section 13

Improperly adjusted wheel alignment Refer to Section 13

General instability Incorrect tire pressure Refer to Section 12

while driving Damaged or unbalanced wheel Refer to Section 13

Worn or damaged steering joints Replace 10--21 Improperly adjusted steering pinion preload Adjust 10--56

Weakened front spring Refer to Section 13

Worn or damaged stabilizer and/or lower arm bushing Refer to Section 13

Malfunctioning shock absorber Refer to Section 13 Improperly adjusted wheel alignment Refer to Secton 13

Steering wheel Incorrect tire pressure Refer to Section 12

vibrates Unevenly worn tires Refer to Section 12

Worn wheel bearing, or incorrect adjustment Refer to Section 13

Worn or damaged steering joints Replace 10--21

Improperly adjusted steering pinion preload Adjust 10--56

Loose gear housing mounting bolts Tighten 10--30

Worn steering gear bearing Replace

Worn or damaged stabilizer and/or lower arm bushing Refer to Section 13

Improperly adjusted wheel alignment Refer to Section 13

Worn lower-arm ball-joint Refer to Section 13

Damaged unbalanced wheel Refer to Section 13

Malfunctionina or loose shock absorber Refer to Section 13

Excessive steering Improperly adjusted steering gear backlash Adjust 10--56

wheel play Worn rack and pinion gear Replace 10--51

Worn or damaged steering joints Replace 10--21

Worn or damaaed lower-arm bushinq Refer to Section 13

Poor steering Incorrect tire pressure Refer to Section 12

wheel return Stuck or damaged steering joints Replace 10 -21

Improperly adjusted front wheel alignment Refer to Section 13

Improperly adjusted steering pinion preload Adjust 10--56

Abnormal noise Loose steering linkage Tighten 10--28

from steering Worn steering joints Replace 10--21

system ImDroDerlv adiusted steerina aear backlash Adiust 10--56

86U10X-007

10—7

Page 1296 of 1865

1 0 TROUBLESHOOTING GUIDE

POWER STEERING

Problem Possible cause Remedy Page

Hard steering

Loose

or

damaged belt Low fluid level,

or air in

fluid Leakage

of

fluid

Malfunctioning electrical system* Insufficient oil pump pressure Improperly adjusted wheel alignment Malfunctioning steering gear Linkage ball joint not operating smoothly

Adjust

or

replace Add fluid

or

bleed

air

Repair

or

replace Repair

or

replace Repair

or

replace Refer

to

Section

13

Repair

or

replace Replace

10—12 10-11 10-13 10-87 10-16

10—28,

37

10-18

Poor return

Insufficient tire pressure

Improperly adjusted wheel alignment

Ball-joint not operating smoothly

Steering shaft contacting something

Refer

to

Section

12

Refer

to

Section

13

Replace

Repair

10-20 10-21

Excessive play

Loose gear box housing mounting bolts Worn linkage

or

tie-rod ball joint Worn lower ball joint Worn

or

damaged steering joint Worn rack and pinion gear

Tighten Replace

Refer

to

Section

13

Replace

Replace

10—30

10—18

10—21

10-58,

75

Steering wheel

vibrates

Insufficient tire pressure Damaged

or

unbalanced wheel Improperly adjusted wheel alignment Loose gear box housing mounting bolts Incorrect pinion preload adjustment Worn ball joints

Loose shock absorber mounting Malfunctioning shock absorber

Refer

to

Section

12

Refer

to

Section

13

Refer

to

Section

13

Tighten Adjust

Replace Refer

to

Section

13

Refer

to

Section

13

10-30 10-72,

81

10—18

Steering wheel

pulls

Unevenly worn tires

Incorrect tire pressure

Dragging brake

Improperly adjusted wheel alignment

Refer

to

Section

12

Refer

to

Section

12

Refer

to

Section

11

Refer

to

Section

13 —

Excessively light

steering at high

speed*

Malfunctioning electrical system Repair

or

replace 10-87

*... Only

for

electronically

-

controlled type

76G10X-002

10—8

Page 1303 of 1865

INSPECTION AND ADJUSTMENT 1 0

INSPECTION AND ADJUSTMENT

BLEEDING OF POWER STEERING SYSTEM

1. Check the fluid level, and add fluid if necessary.

2. Turn the steering wheel fully in both directions 5

times (engine not running).

3. Recheck the fluid level. If the level has lowered,

add fluid, and repeat from step 1.

86U10X-021

4. Start the engine, and run it at idle.

5. Turn the steering wheel fully in both directions 5

times to bleed air from the system.

6. Check that the fluid is not foamy and the fluid lev-

el has not lowered.

If a problem is found, add fluid as necessary and

repeat from step 5.

Note

If bleeding is not done completely, the follow-

ing problems may appear:

• Foamy fluid on level gauge.

• Noise from power steering oil pump.

86U10X-022

10—15

Page 1304 of 1865

![MAZDA 626 1987 Workshop Manual

1 0 INSPECTION AND ADJUSTMENT

86U10X023

2WS

To oil pump

Si£r To gear housing

86U10X-024

86U10X-025

Thermometer [50—60°C (122—140°C)]

ii ^

Gauge

Close valve

completely

POWER STEERIN MAZDA 626 1987 Workshop Manual

1 0 INSPECTION AND ADJUSTMENT

86U10X023

2WS

To oil pump

Si£r To gear housing

86U10X-024

86U10X-025

Thermometer [50—60°C (122—140°C)]

ii ^

Gauge

Close valve

completely

POWER STEERIN](/img/28/57059/w960_57059-1303.png)

1 0 INSPECTION AND ADJUSTMENT

86U10X023

2WS

To oil pump

Si£r To gear housing

86U10X-024

86U10X-025

Thermometer [50—60°C (122—140°C)]

ii ^

Gauge

Close valve

completely

POWER STEERING PRESSURE

1. Disconnect the high-pressure hose of the gear

housing side, and attach the SST.

Tightening torque:

39—49 N-m (4.0—5.0 m-kg, 29—36 ft-lb)

2. Bleed air from the system.

3. Open the gauge valve fully, then start the engine

and turn the steering wheel fully left and right to

raise the fluid temperature to 50—60°C

(122—140°F)

4. To measure the fluid pressure generated by the

oil pump, close the gauge valve completely and

increase the engine speed to 1,000—1,500 rpm.

If the fluid pressure is low, replace the oil pump

assembly.

Warning

If the valve is left closed for more than 15 sec-

onds, the fluid temperature will increase ex-

cessively and adversely affect the oil pump.

Oil pump fluid pressure

2WS

7,355—7,846 kPa

(75—80 kg/cm2, 1,066—1,138 psi)

4WS

Front 8,093—8,829 kPa

(82.5—90.0 kg/cm2, 1,173—1,280 psi)

Rear 7,112—7,848 kPa

(72.5—80.0 kg/cm2, 1,031—1,138 psi)

To measure the fluid pressure generated at the

gear housing, first open the gauge valve complete-

ly, increase the engine speed to 1,000—1,500

rpm, and then turn the steering wheel fully to the

left and right.

Warning

If the steering wheel is kept in the fully turned

position for more than 15 seconds, the fluid

temperature will rise excessively.

80U10X-026

10—16

Page 1305 of 1865

![MAZDA 626 1987 Workshop Manual

INSPECTION AND ADJUSTMENT 1 0

Thermometer [50—60°C (122—140°C)]

Gauge

(Turn steering wheel

completely

left/right)

Valve fully open

76G10X-032

Gear housing fluid pressure

2WS

7,355—7 MAZDA 626 1987 Workshop Manual

INSPECTION AND ADJUSTMENT 1 0

Thermometer [50—60°C (122—140°C)]

Gauge

(Turn steering wheel

completely

left/right)

Valve fully open

76G10X-032

Gear housing fluid pressure

2WS

7,355—7](/img/28/57059/w960_57059-1304.png)

INSPECTION AND ADJUSTMENT 1 0

Thermometer [50—60°C (122—140°C)]

Gauge

(Turn steering wheel

completely

left/right)

Valve fully open

76G10X-032

Gear housing fluid pressure

2WS

7,355—7,846 kPa

(75—80 kg/cm2, 1,066—1,138 psi)

4WS

Front 8,093—8,829 kPa

(82.5—90.0 kg/cm2, 1,173—1,280 psi)

Rear More than 2,943 kPa

(More than 30 kg/cm2, more than 427 psi)

If the fluid pressure is low, repair or replace the gear

box.

6. Remove the gauge set, then tighten the high-

pressure hose to the specified torque.

Tightening torque:

31—36 Nm (3.2—3.7 m-kg, 23—27 ft-lb)

7. Bleed the air from the system. (Refer to page

10-15.)

10—17

Page 1323 of 1865

4-WHEEL STEERING GEAR AND LINKAGE 1 0

Front joint Rear joint

Rear bracket

Front bracket

76G10X-033

86U10X-313

ADJUSTMENT OF STEERING ANGLE

TRANSFER SHAFT

If the steering angle transfter shaft is disconnected

from the front or rear steering gear or after adjusting

the wheel alignement, or if the rear steering angle is

not correct, adjust the rear turning angle as described

below.

Warning

Improper installation of the 4WS steering

transfer shaft may affect control of the vehi-

cle and result in the risk of an accident or per-

sonal injury.

1. Raise the vehicle on a lift or safety stands.

2. Remove cover B and joint bolt A.

3. Slide the shaft out of the joint.

4. Remove the plug from the rear steering gear. Sight

through the hole and turn the steering angle input

shaft to align the notch in the input shaft with the

center of hole.

5. Remove the set bolt attached to the rear steering

gear, and install it in the steering gear to set the

input shaft.

Tightening torque:

4.9—7.8 N-m (50—80 cm-kg, 43—69 in-lb)

86U10X-314

Note

After the input shaft is set, manually turn the rear

joint and chack that the shaft does not move.

86U10X-315

10—35

Page 1330 of 1865

1 0 4-WHEEL STEERING GEAR AND LINKAGE

86U10X-075

86U10X-076

86U10X-077

Front joint Rear joint

Rear bracket

Front bracket

Installation Note

Front steering gear

Tighten the universal joint to the pinion shaft.

Tightening torque:

18—26 N (1.8—2.7 m-kg, 13—20 ft-lb)

Install the subframe.

Tightening torque:

36—54 Nm (3.7—5.5 m-kg, 27—40 ft-lb)

Adjust the rear turning angle. (Refer to page 10—35.)

Rear steering gear

Adjust the rear steering angle after installation of the

rear steering gear. (Refer to page 10—35.)

Note

When the replacement of rear steering gear

or the oil pan gasket owing to the oil leakage,

add fluid to the specified level. (Refer to page

10—12)

Steering angle transfer shaft

Caution

Installation of the steering angle transfer shaft

must be done correctly.

Work carefully, referring to the adjustment of

steering angle transfer shaft (page 10—35).

If not installed correctly, the rear steering an-

gle may be incorrect, causing steering prob-

lems or damage to the rear steering gear

assembly.

86U10X-078

10—42