oil temperature MAZDA MX-5 1994 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 423 of 1708

K MECHANICAL SYSTEM TEST MECHANICAL SYSTEM TEST PREPARATION SST STALL TEST 49 0378 400A Gauge set, oil pressure 49 801 9 901 Gauge, oil pressure For oil pressure test For oil pressure test This test is performed to determine if there is slippage of the friction elements or malfunction of the hy- draulic components. Preparation 1. Check the engine coolant, engine oil, and ATF levels before testing. 2. Warm the engine thoroughly to raise the ATF temperature to operating level (50--80°C, 122-176°F). 3. Engage the parking brake and use wheel chocks at the front and rear of the wheels. ENGAGE PARKING BRAKE WARM UP ENGINE COOLANT LEVEL ENGINE OIL LEVEL TEMPERATURE 60-70°C (1 40-1 58°F) ATF LEVEL Gartner Banana

Page 430 of 1708

ROAD TEST K ROAD TEST A road test is necessary to inspect for problems in the different gear ranges. If a range or function tar- b geted by the road test is found to have any problem, refer to the ELECTRONIC SYSTEM COMPONENT segment or the TRANSMISSION, OIL COOLER, DRIVE PLATE, and SHIFT MECHANISM segments of this section. Do the road test only when the ATF is 50-80°C (1 22-1 76°F). D-RANGE TEST Shift Point, Shift Pattern, and Shift Shock 1. Shift the selector lever to D range and select the Normal mode. 2. Accelerate the vehicle with half-and wide open throttle opening. 3. Verify that 1-2, 2-3, and 3-4 upshifts, downshifts, and lockup are obtained. The shift points must be as shown in the D range (Normal) shift diagram. Note There is fourth gear is any of the following conditions. A The cruise control is operating, and there is an 8kmIh (5 mph} difference between the preset cruise speed and the vehicle speed. B The SET or RESUME switch is ON. There is no lockup when water temperature is below 50°C (1 22°F) or in the throttle valve closed posi- tion. 4. Check the upshifts for shift shock or slippage in the same manner. 5. While driving in overdrive, shift the selector lever to S range and verify that 4-3 downshift immediately occurs, then decelerate and verify that engine braking effect is felt in only third gear and 2nd gears. D-range (Normal) shift diagram p'yJ ..,,*sw.. LOCKUP AVAILABLE WHEN ACCELERATING AND CRUSING LOCKUP AVAILABLE WHEN COASTING 0 20 (1 2) 40 (25) 60 (37) 80 {50) 100 (63) 1 20 (75) 140 (87) 1 60 (99) VEHICLE SPEED kmlh {mph) Gartner Banana

Page 650 of 1708

ENGINE SPEED SENSING POWER STEERING N THERMOMETER GAUGE (50"--60°C (1 22-1 40°F)) / THERMOMETER GAUGE (50"--60°C {I 22-140°F)) / Fluid pressure 1. Assemble the SST as shown in the figure. Tightening torque: 40-49 N-m i4.0-5.0 kgf-m, 2%--36 ft.lbf) 2. Mark both hose connections to ensure that the hose is reinstalled in its original position. 3. Disconnect the pressure hose from the oil pump. Attach the SST. 4. Bleed the air from the system. (Refer to page N-21.) 5. Open the gauge valve fully. Start the engine and turn the steering wheel fully left and right to raise the fluid temper- ature to 50-60°C (122-140°F). Caution Do not let the valve stay closed for more than 5 seconds. The increase in fluid temperature will damage the oil pump. 6. Close the gauge valve completely. Increase the engine speed to 1,000-1,500 rpm and measure the fluid pres- sure generated by the oil pump. If the pressure is not within specification, replace the oil pump assembly. Oil pump fluid pressure: 7,601--8,335 kPa (77.5--85.0 kgf/cm2, 1 ,I 03-1,208 psi) 7. Open the gauge valve fully and increase the engine speed to 1,000-1,500 rpm. Gartner Banana

Page 846 of 1708

BODY ELECTRICAL SYSTEM ................................... INDEX T- 2 ........................... SWITCHES T- 2 FUSES AND RELAYS .................. T- 3 .............................. LIGHTS T- 4 CRUISE CONTROL SYSTEM ........... T- 5 ...................... AUDIO SYSTEM T- 6 SRS AIR BAG SYSTEM ................ T- 7 ............................... OUTLINE T- 8 TROUBLESHOOTING GUIDE ........... T- 8 ELECTRICAL SYMBOLS ............... T- 9 ................................... FUSE T- 10 STRUCTURAL VIEW ................... T- 10 ...................... SPECIFICATIONS T- 11 ........................ DESCRIPTION T- 12 ....................... REPLACEMENT T- 12 ....................... RELAY .. ....... T- 13 STRUCTURAL VIEW ................... T- 13 ........................ DESCRIPTION T- 13 RETRACTABLE HEADLIGHT RELAY .... T- 14 ....................... FLASHER UNIT T- 14 ........................... TNS RELAY T- 15 .......................... HORN RELAY T- 15 COOLANT FAN RELAY ................. T- 15 REAR WINDOW DEFROSTER RELAY ... T- 16 HEADLIGHT RELAY ................... T- 16 ................................ SWITCH T- 17 ................... STRUCTURAL VIEW T- 17 ........................ DESCRIPTION T- 17 .................... IGNITION SWITCH T- 18 COMBINATION SWITCH ............... T- 19 RETRACTOR SWITCH AND HAZARD WARNING ............................. SWITCH T- 21 ................. INSTRUMENT CLUSTER T- 22 ................... STRUCTURAL VIEW T- 22 ........................ DESCRIPTION T- 22 .................... CIRCUIT DIAGRAM T- 23 ................. TROUBLESHOOTING T- 24 ............ REMOVAL / INSTALLATION T- 29 ........... DISASSEMBLY 1 ASSEMBLY T- 29 ...................... SPEEDOMETER T- 30 ........................ TACHOMETER T- 30 WATER TEMPERATURE GAUGE ....... T- 30 ......................... FUEL GAUGE T- 31 OIL PRESSURE GAUGE ............... T- 31 .................... PRINTED CIRCUIT T- 32 VEHICLE SPEED SENSOR ............. T- 32 WATER TEMPERATURE SENDER UNlT . T- 32 FUEL GAUGE SENDER UNlT ...................... (IN FUEL TANK) T- 32 OIL PRESSURE SENSOR .............. T- 33 ............... SPEEDOMETER CABLE T- 33 WARNING LIGHT AND SENDER UNIT ..... T- 34 ................... STRUCTURAL VIEW T- 34 CIRCUIT DIAGRAM .................... T- 35 ................. TROUBLESHOOTING T- 36 BRAKE FLUID LEVEL SENSOR ......... T- 39 PARKING BRAKE SWITCH ............. T- 39 ..................... BUCKLE SWITCH T- 39 ...................... LIGHTING SYSTEM T- 40 ................... STRUCTURAL VIEW T- 40 ......................... HEADLIGHTS T- 41 ......................... STOPLIGHTS T- 53 TURN AND HAZARD WARNING LIGHTS . T- 57 ..................... BACK-UP LIGHTS T- 66 TAILLIGHTS. SIDE MARKER LIGHTS. PARKING LIGHTS AND LICENSE PLATE LIGHTS . T- 69 DAYTIME RUNNING LIGHTS (DRL) .................... (CANADA SPEC.) T- 72 ........... REAR COMBINATION LIGHT T- 76 .................... INTERIOR LIGHTS T- 78 ................ ILLUMINATION LIGHTS T- 82 .................................. HORN T- 84 ................... STRUCTURAL VIEW T- 84 .................... CIRCUIT DIAGRAM T- 85 ................. TROUBLESHOOTING T- 86 ............ REMOVAL 1 INSTALLATION T- 87 ............ REAR WINDOW DEFROSTER T- 89 ................... STRUCTURAL VIEW T- 89 ........................ DESCRIPTION T- 89 ................. TROUBLESHOOTING T- 90 ................ REPAIRING FILAMENT T- 93 ............. CRUISE CONTROL SYSTEM T- 94 ................... STRUCTURAL VIEW T- 94 .................... CIRCUIT DIAGRAM T- 95 ................. TROUBLESHOOTING T- 96 ....... SELF-DIAGNOSTIC INSPECTION T-100 ............... CRUISE CONTROL UNIT T-103 .................... ACTUATOR CABLE T-104 ..................... CLUTCH SWITCH T-105 .......... STOP LIGHTIBRAKE SWITCH T-105 ...... CRUISE CONTROL MAIN SWITCH T-106 ........... CRUISE CONTROL SWITCH T-106 ............. VEHICLE SPEED SENSOR T-106 ........................... ACTUATOR T-107 a .................................. AUDIO T-108 ................... STRUCTURAL VIEW T-108 ................... SYSTEM DIAGRAM T-109 ............................ FEATURES T-110 FUNCTION AND OPERATING ......................... PROCEDURE 1-111 ............. OPERATION DESCRIPTION T-113 .................. ANTITHEFT SYSTEM T-120 ................. TROUBLESHOOTING T-122 ............ REMOVAL I INSTALLATION T-145 .................... POWER ANTENNA T-149 ......................... INSPECTION T-153 CONNECTOR TERMINAL .................... SPECIFICATIONS T-154 SRS AIR BAG SYSTEM .................. T-156 PREPARATION ........................ T-156 ................... STRUCTURAL VIEW T-156 .......... COMPONENT DESCRIPTION T-157 SYSTEM DIAGRAM ................... T-158 ................. SERVICE WARNINGS T-159 GENERAL PROCEDURES ............. T-160 TROUBLESHOOTING ................. T-160 DRIVER-SIDE AIR BAG MODULE ....... T-206 PASSENGER-SIDE AIR BAG MODULE . . T-207 DIAGNOSTIC MODULE ................ T-208 CLOCK SPRING ....................... T-209 CRASH SENSOR (D-SENSOR) ......... T-210 CRASH SENSOR (S-SENSOR) ......... T-213 AIR BAG MODULE DISPOSAL . .. PROCEDURE ........................ T-215 INSPECTION OF SST (DEPLOYMENT TOOL) ............... T-217 Gartner Banana

Page 853 of 1708

T OUTLINE OUTLINE TROUBLESHOOTING GUIDE Symptom a Speedometer does not operate or indication is incorrect a Tachometer does not operate Water temperature gauge does not operate Fuel gauge does not operate a Oil pressure gauge does not operate a Brake system warning light remains illuminated Brake system warning light does not illuminate when parking brake on a Brake system warning light does not illuminate when brake fluid in reservoir is below MIN a OID off indicator light does not illuminate when OID off switch turned on Seat belt warning light remains on six seconds after ignition switch is turned on (Timer function does not operate) Seat belt warning light does not illuminate when ignition switch is first turned on a Headlights do not illuminate Headlight does not illuminate (Right or left) Retractable headlight actuator do not operate (Both sides) Retractable headlight actuator does not operate (One side) Stoplights do not illuminate (All) Stoplight does not illuminate (One only) Turn and hazard warning functions do not operate Turn signals not operate (Hazard warning function operates normally) Hazard warning function does not operate (Turn signals function normally) Back-up lights does not illuminate Taillights, side marker lights, and license plate lights do not illuminate Daytime running lights do not illuminate Daytime running light function does not cancel lnterior lights do not illuminate Interior liahts remains illuminated (Control switch: DOOR ~osition) Horn does not sound Vehicle speed cannot be set (Cruise control unit will not hold vehicle speed) Speakers do not operate (Without headrest speakers) Speakers do not operate (With headrest speakers) Poor sound quality or noise (Radio) Poor sound quality (Cassette tape player) Cassette tape will not load Cassette tape will not play Compact disc will not load Compact disc skips No sound can be heard Some speakers do not operate Bodysonic will not play Service code table (With passenger-side air bag) Service code table (With out ~assenaer-side air baa) Reference page T-24 T-25 T-26 T-27 T-28 T-36 T-37 T-37 Gartner Banana

Page 867 of 1708

T INSTRUMENT CLUSTER INSTRUMENT CLUSTER STRUCTURAL VIEW 1. Speedometer 2. Tachometer 3. Water temperature gauge 4. Fuel gauge 5. Oil pressure gauge 6. Warning and indicator lights 7. Trip meter 8. Odometer DESCRIPTION Speedometer Two scales are shown on the speedometer face. The main scale for U.S. specification vehicles is MPH (0-140 MPH); the main scale for Canada specification vehicles is kmlh (0-220 kmlh). The odometer indication is the same as the main scale. Tachometer The tachometer has a RED STRIPED ZONE (6,500-7,000 rpm) that indicates momentary allowable engine speed. The engine should not be operated in the RED ZONE (7,000-8,000 rpm). Fuel Gauge 2 The fuel gauge continues to indicate the amount of fuel remaining in the fuel tank after the ignition switch has been turned OFF. Gartner Banana

Page 877 of 1708

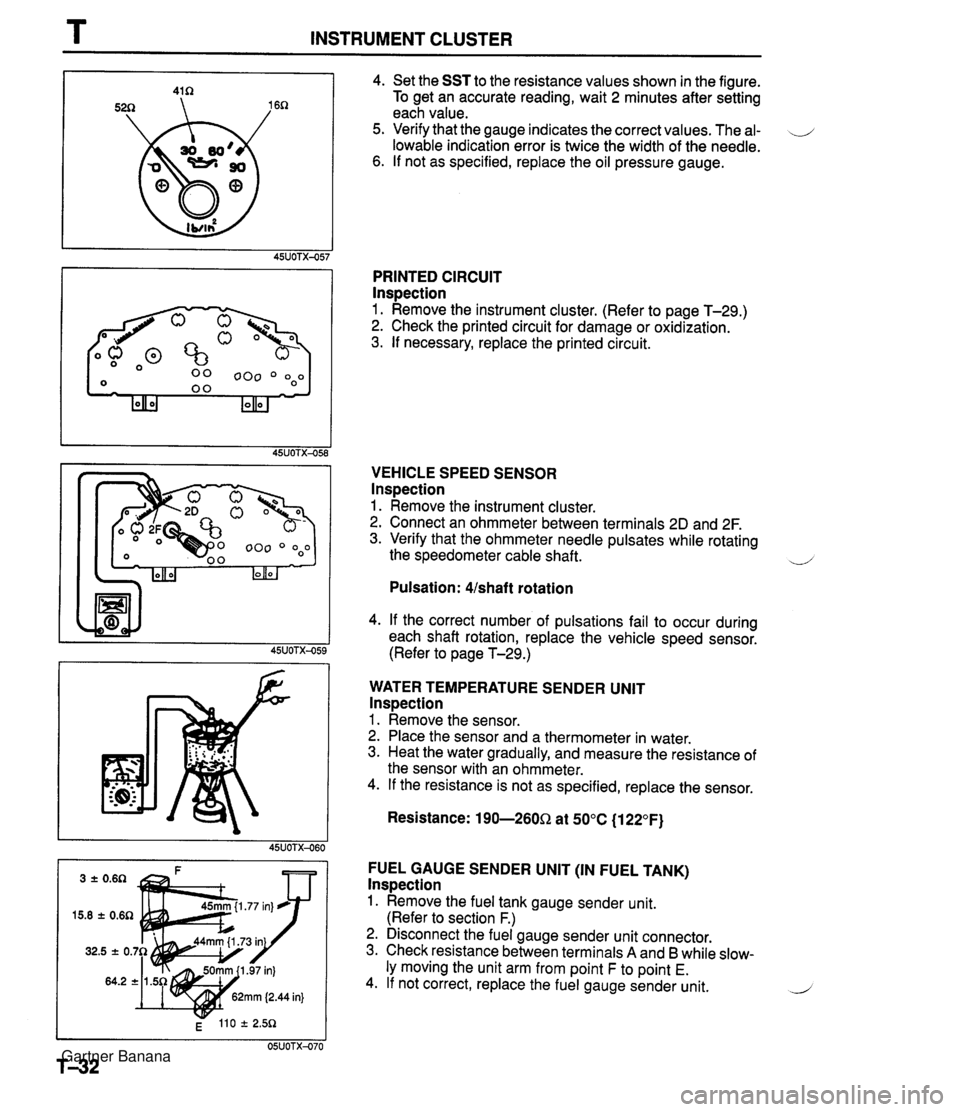

T INSTRUMENT CLUSTER 4. Set the SST to the resistance values shown in the figure. To get an accurate reading, wait 2 minutes after setting each value. 5. Verify that the gauge indicates the correct values. The al- \J lowable indication error is twice the width of the needle. 6. If not as specified, replace the oil pressure gauge. PRINTED CIRCUIT lnspection 1. Remove the instrument cluster. (Refer to page T-29.) 2. Check the printed circuit for damage or oxidization. 3. If necessary, replace the printed circuit. VEHICLE SPEED SENSOR lnspection 1. Remove the instrument cluster. 2. Connect an ohmmeter between terminals 2D and 2F. 3. Verify that the ohmmeter needle pulsates while rotating the speedometer cable shaft. ~ Pulsation: Ushaft rotation 4. If the correct number of pulsations fail to occur during each shaft rotation, replace the vehicle speed sensor. (Refer to page T-29.) WATER TEMPERATURE SENDER UNlT lnspection 1. Remove the sensor. 2. Place the sensor and a thermometer in water. 3. Heat the water gradually, and measure the resistance of the sensor with an ohmmeter. 4. If the resistance is not as specified, replace the sensor. Resistance: 190-260Q at 50°C (1 22°F) FUEL GAUGE SENDER UNlT (IN FUEL TANK) lnspection 1. Remove the fuel tank gauge sender unit. (Refer to section F.) 2. Disconnect the fuel gauge sender unit connector. 3. Check resistance between terminals A and B while slow- ly moving the unit arm from point F to point E. 4. If not correct, replace the fuel gauge sender unit. 2 Gartner Banana

Page 1094 of 1708

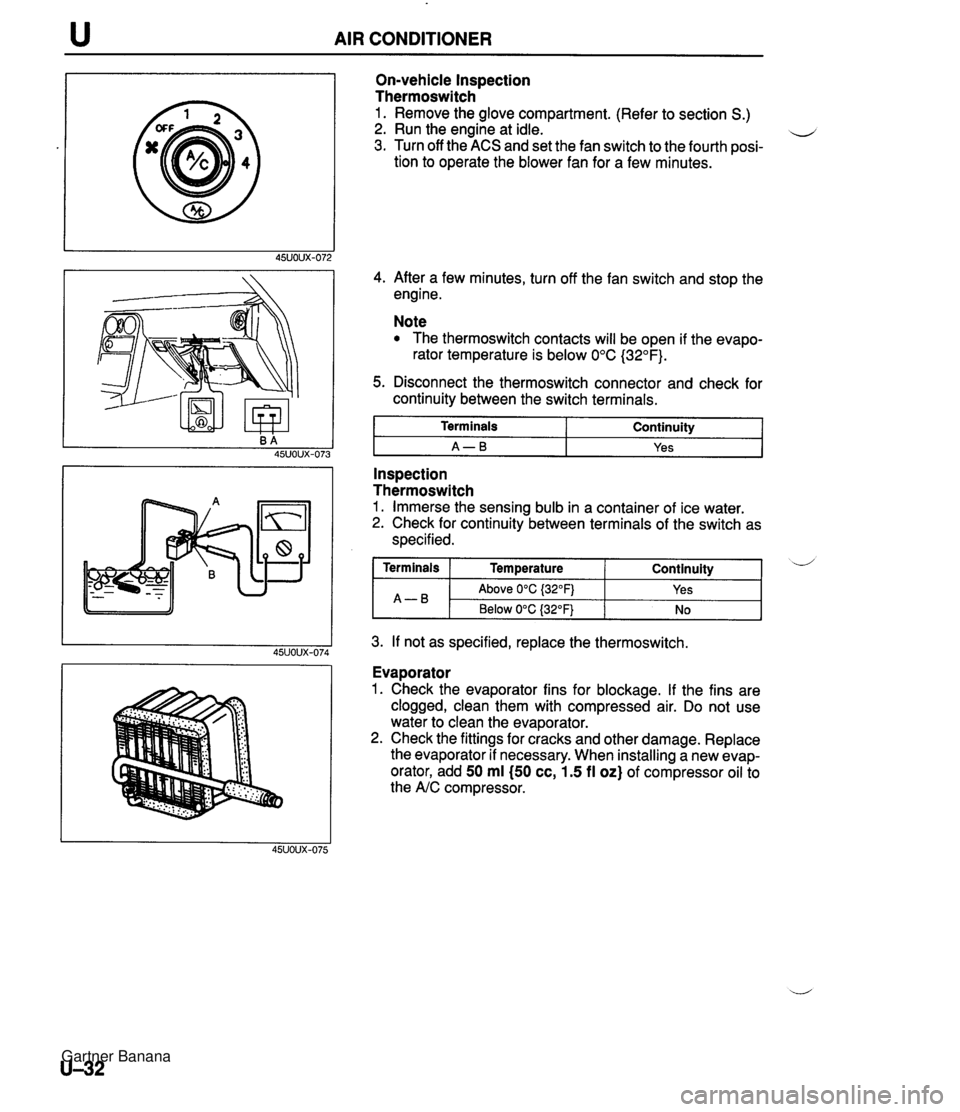

AIR CONDITIONER On-vehicle Inspection Thermoswitch 1. Remove the glove compartment. (Refer to section S.) 2. Run the engine at idle. u 3. Turn off the ACS and set the fan switch to the fourth posi- tion to operate the blower fan for a few minutes. 4. After a few minutes, turn off the fan switch and stop the engine. Note The thermoswitch contacts will be open if the evapo- rator temperature is below 0°C (32°F). 5. Disconnect the thermoswitch connector and check for continuity between the switch terminals. I Terminals I Continuity I I A-B I Yes I - -- Inspection Thermoswitch 1. Immerse the sensing bulb in a container of ice water. 2. Check for continuity between terminals of the switch as specified. 3. If not as specified, replace the thermoswitch. Continuity ( Terminals I Temperature A-B Evaporator 1. Check the evaporator fins for blockage. If the fins are clogged, clean them with compressed air. Do not use water to clean the evaporator. 2. Check the fittings for cracks and other damage. Replace the evaporator if necessary. When installing a new evap- orator, add 50 ml (50 cc, 1.5 fl oz) of compressor oil to the A/C compressor. d Above 0°C {32OFj Below 0°C (32°F) Yes No Gartner Banana

Page 1113 of 1708

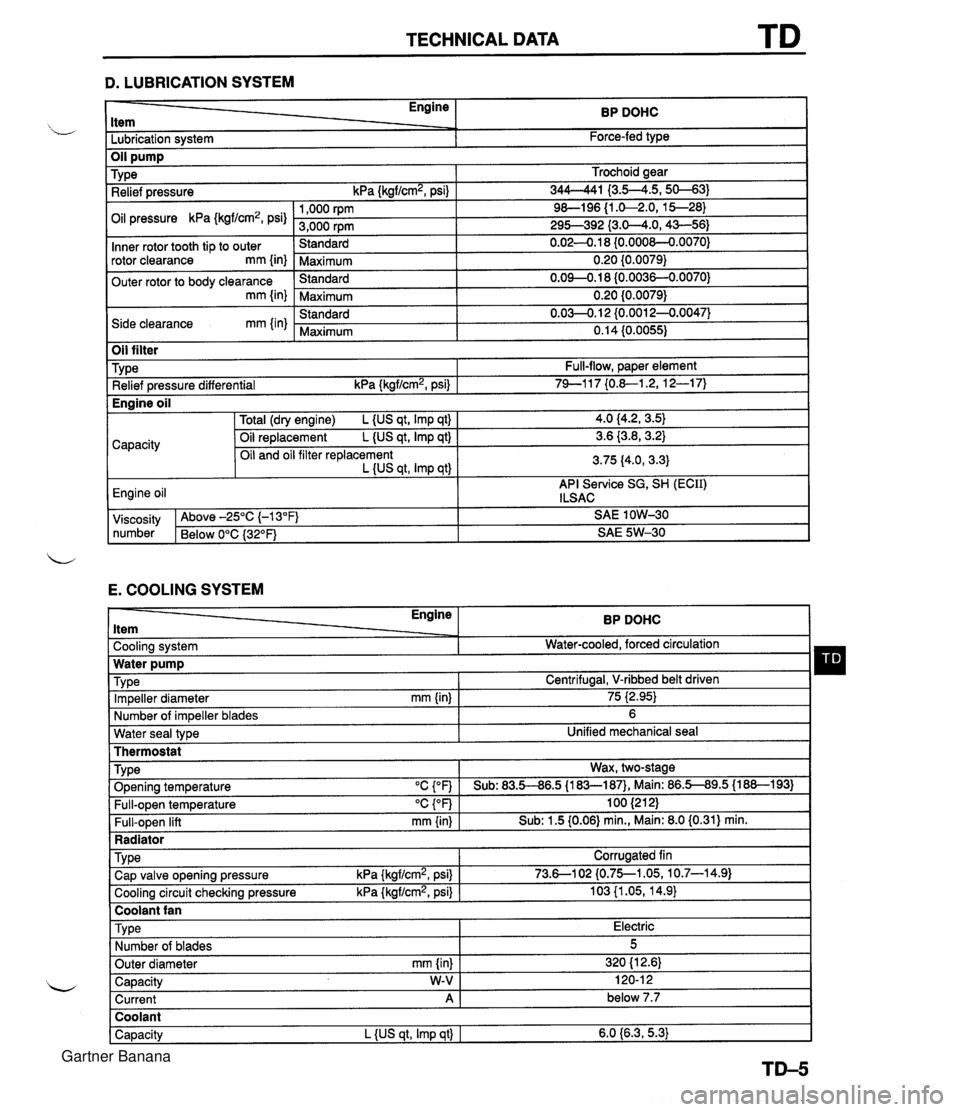

TECHNICAL DATA D. LUBRICATION SYSTEM - Engine ltem BP DOHC - -. Lubrication system Force-fed type E. COOLING SYSTEM Trochoid gear 344-41 I3.5--4.5,s-31 9&l96 {I .&2.0, 15--28) 295-392 {3.0-4.0,43-56) 0.02-0.1 8 {0.000&0.0070) 0.20 {0.0079) 0.09-0.18 (0.0036-0.0070) 0.20 {0.0079) 0.03-0.1 2 {0.0012-0.0047) 0.14 (0.0055) TY pe Relief pressure kPa {kgf/cm2, psi) Oil pressure kPa {kgf/cm2, psi) Inner rotor tooth tip to outer rotor clearance mm {in) Outer rotor to body clearance mm {in) Side clearance mm {in) Water seal type I Unified mechanical seal Thermostat 1,000 rpm 3,000 rpm Standard Maximum Standard Maximum Standard Maximum Oil filter Engine ltem - - Cooling system . . Impeller diameter mm {in) Number of impeller blades Type Relief pressure differential kPa {kgf/cm2, psi) BP DOHC Water-cooled, forced circulation - 75 i2.95) 6 Full-flow, paper element 74-1 17 {0.&1.2, 12-1 7) TY pe . ., . . . - Radiator I Water pump Wax, two-stage v. . . Full-open temperature "c {OF) Full-open lift mm {in) Engine oil TVD~ O~enina tem~erature "C con I Sub: 83.5-86.5 U83-187). Main: 86.5-89.5 (1 88-1 931 100 (21 2) Sub: 1.5 (0.06) min., Main: 8.0 (0.31) min. -. . - . . Cooling circuit checking pressure kPa {kgflcmz, psi) I 103 {I .05, 14.9) I Centrifugal, V-ribbed belt driven TY pe I Coolant fan I 4.0 (4.2, 3.5) 3.6 {3.8,3.2) 3.75 (4.0, 3.3) API Service SG, SH (ECII) ILSAC Capacity Corrugated fin viscosity Above -25°C (-1 3°F) SAE 1 OW-30 number Below 0°C {3Z°F) SAE 5W-30 Total (dry engine) L {US qt, Imp qt) Oil replacement L {US qt, Imp qt) Oil and oil filter replacement L {US qt, Imp qtl Cap valve o~enina pressure kPa {krrf/cm2, psi} 1 73.6--102 {0.75--1.05, 10.7-14.91 Capacity W-V I 120-1 2 Current A 1 below 7.7 Engine oil Type Number of blades Outer diameter mm {in) Coolant Capacity L {US qt, Imp qt) I 6.0 {6.3,5.3) Electric 5 320 (1 2.61 Gartner Banana

Page 1114 of 1708

![MAZDA MX-5 1994 User Guide TD TECHNICAL DATA Idle speed rpm 1 800-900 (850 2 50) [MT], 750-850 (800 f 50) [ATJ lanition timina BTDC I 9"-11 (10 f 1") u F. FUEL AND EMISSION CONTROL SYSTEMS - Engine ltem Item 1 Throat diam MAZDA MX-5 1994 User Guide TD TECHNICAL DATA Idle speed rpm 1 800-900 (850 2 50) [MT], 750-850 (800 f 50) [ATJ lanition timina BTDC I 9"-11 (10 f 1") u F. FUEL AND EMISSION CONTROL SYSTEMS - Engine ltem Item 1 Throat diam](/img/28/57072/w960_57072-1113.png)

TD TECHNICAL DATA Idle speed rpm 1 800-900 (850 2 50) [MT]', 750-850 (800 f 50) [ATJ' lanition timina BTDC I 9"-11' (10' f 1")' u' F. FUEL AND EMISSION CONTROL SYSTEMS - Engine ltem Item 1 Throat diameter mm {in) 1 55 (2.2) 1 Antifreeze solution BP DOHC Specification 1 Throttle body Fuel pump TY pe I Impeller (in-tank) Coolant protection Above -1 6°C (3°F) Above -26°C (-15°F) Above -40°C {-40°n Tv~e -. Output pressure kPa (kgf/cm2, psi) I 294-437 {3.0--6.5,43--92) Fuel filter Specific gravity at 20°C {WF) 1.054 1.066 1.078 Volume percentage % Horizontal draft Water 65 55 45 -. . - Regulating pressure kPa {kgf/cm2, psi) I 280-289 I2.85--2.95, 40.141.9) Fuel iniector Coolant 35 45 55 TY pe IAC valve Solenoid resistance n 1 10.7-1 2.3 (at 20°C (68°F)) Low-pressure side TYP~ Type of drive Resistance n Purge solenoid valve Solenoid resistance n 1 23-27 (at 20°C (68°F)) I Nylon element Pressure regulator TY pe High-ohmic Voltage 13.8 (at 20°C (68"FI) Engine coolant temperature sensor 7 20°C {68"F) I 2.21 -2.69 Resistance kn I 80°C (1 76OF} I 0.287-0.349 High-pressure side Diaphragm i/ Crankshaft position sensor Air valve Openin~l temperature OC {OF) I Below 45 (1 131 Paper element Twe 1 Fuel tank I Hall effect . . . . . . . Capacity L {US gal, Imp gal) I 48 {12.7, 10.5) Air cleaner housing Element type Free play mm (in) I 1-3 {0.039--0.118) I Fuel Oil permeated Specification Accelerator cable Unleaded regular (RON 87 or higher) J +....with system selector (49 B019 9AO) test switch at SELF TEST Gartner Banana