suspension MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 23 of 1708

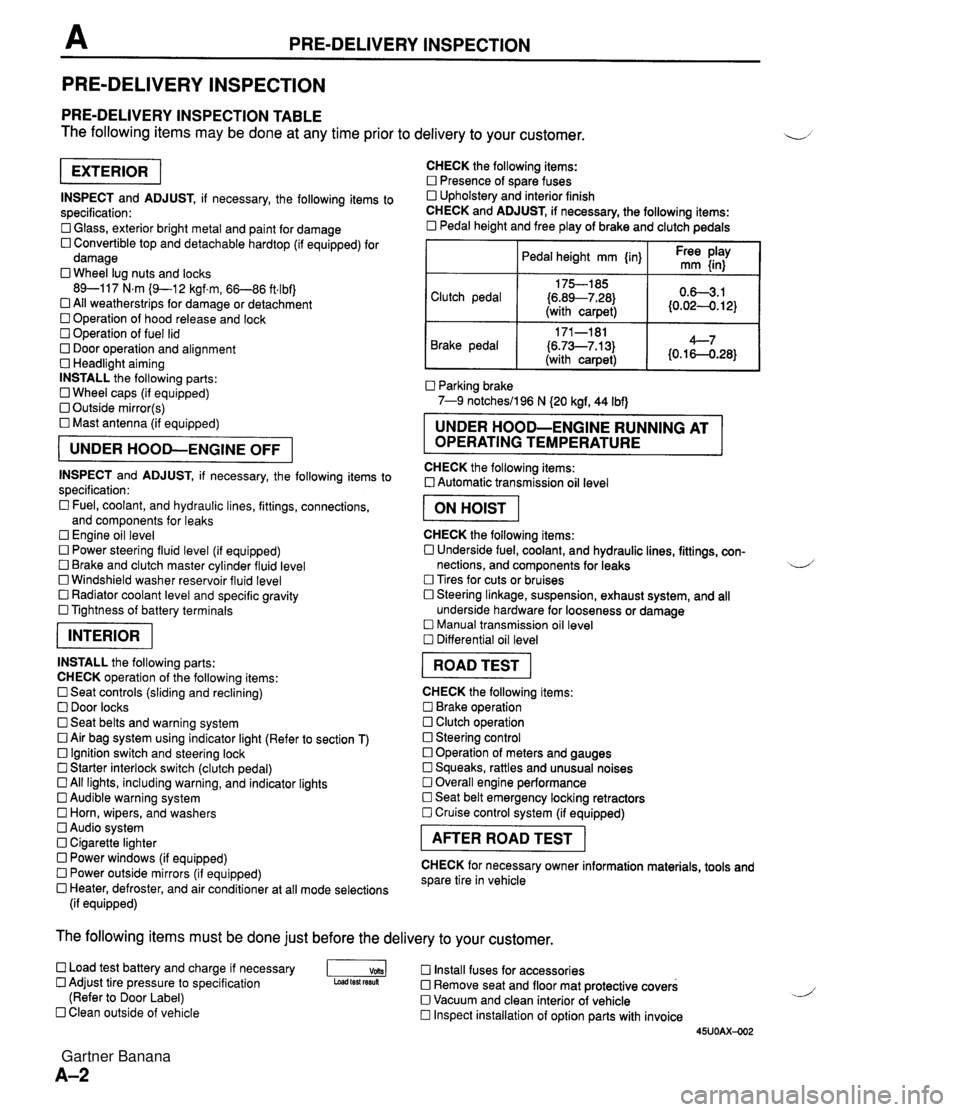

PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION TABLE The following items may be done at any time prior to delivery to your customer. INSPECT and ADJUST, if necessary, the following items to specification: 0 Glass, exterior bright metal and paint for damage 0 Convertible top and detachable hardtop (if equipped) for damage 0 Wheel lug nuts and locks 89-117 N.m (9-1 2 kgf.m, 66-86 ft4bf) 0 All weatherstrips for damage or detachment Operation of hood release and lock Operation of fuel lid 0 Door operation and alignment Headlight aiming INSTALL the following parts: Wheel caps (if equipped) 0 Outside mirror(s) 0 Mast antenna (if equipped) UNDER HOOD-ENGINE OFF INSPECT and ADJUST, if necessary, the following items to specification : Fuel, coolant, and hydraulic lines, fittings, connections, and components for leaks Engine oil level 0 Power steering fluid level (if equipped) Brake and clutch master cylinder fluid level 0 Windshield washer reservoir fluid level 0 Radiator coolant level and specific gravity 0 Tightness of battery terminals pKiq INSTALL the following parts: CHECK operation of the following items: 0 Seat controls (sliding and reclining) 0 Door locks 0 Seat belts and warning system 0 Air bag system using indicator light (Refer to section T) Ignition switch and steering lock 0 Starter interlock switch (clutch pedal) All lights, including warning, and indicator lights 0 Audible warning system 0 Horn, wipers, and washers Audio system 0 Cigarette lighter Power windows (if equipped) 0 Power outside mirrors (if equipped) 0 Heater, defroster, and air conditioner at all mode selections (if equipped) CHECK the following items: Presence of spare fuses 0 Upholstery and interior finish CHECK and ADJUST, if necessary, the following items: 0 Pedal height and free play of brake and clutch pedals I Pedal height mm {in} I Ft: $iy I Clutch pedal {6.89--7.28) (with carpet) Parking brake 7-9 notchesil96 N (20 kgf, 44 Ibf) 0.63.1 (0.024. 12) Brake pedal RUNNING AT OPERATING TEMPERATURE CHECK the following items: 0 Automatic transmission oil level 171-181 (6.73--7.13) (with carpet) I ON HOIST I 4--7 {0.16-0.28} CHECK the following items: 0 Underside fuel, coolant, and hydraulic lines, fittings, con- nections, and components for leaks 4 Tires for cuts or bruises 0 Steering linkage, suspension, exhaust system, and all underside hardware for looseness or damage Manual transmission oil level Differential oil level I ROAD TEST I CHECK the following items: Brake operation Clutch operation 0 Steering control 0 Operation of meters and gauges Squeaks, rattles and unusual noises 0 Overall engine performance Seat belt emergency locking retractors 0 Cruise control system (if equipped) I AFTER ROAD TEST I CHECK for necessary owner information materials, tools and spare tire in vehicle The following items must be done just before the delivery to your customer. 0 Load test battery and charge if necessary -1 Install fuses for accessories Adjust tire pressure to specification Load test fesuk 0 Remove seat and floor mat protective covers (Refer to Door Label) 0 Vacuum and clean interior of vehicle Clean outside of vehicle Inspect installation of option parts with invoice 45UOAX-002 Gartner Banana

Page 26 of 1708

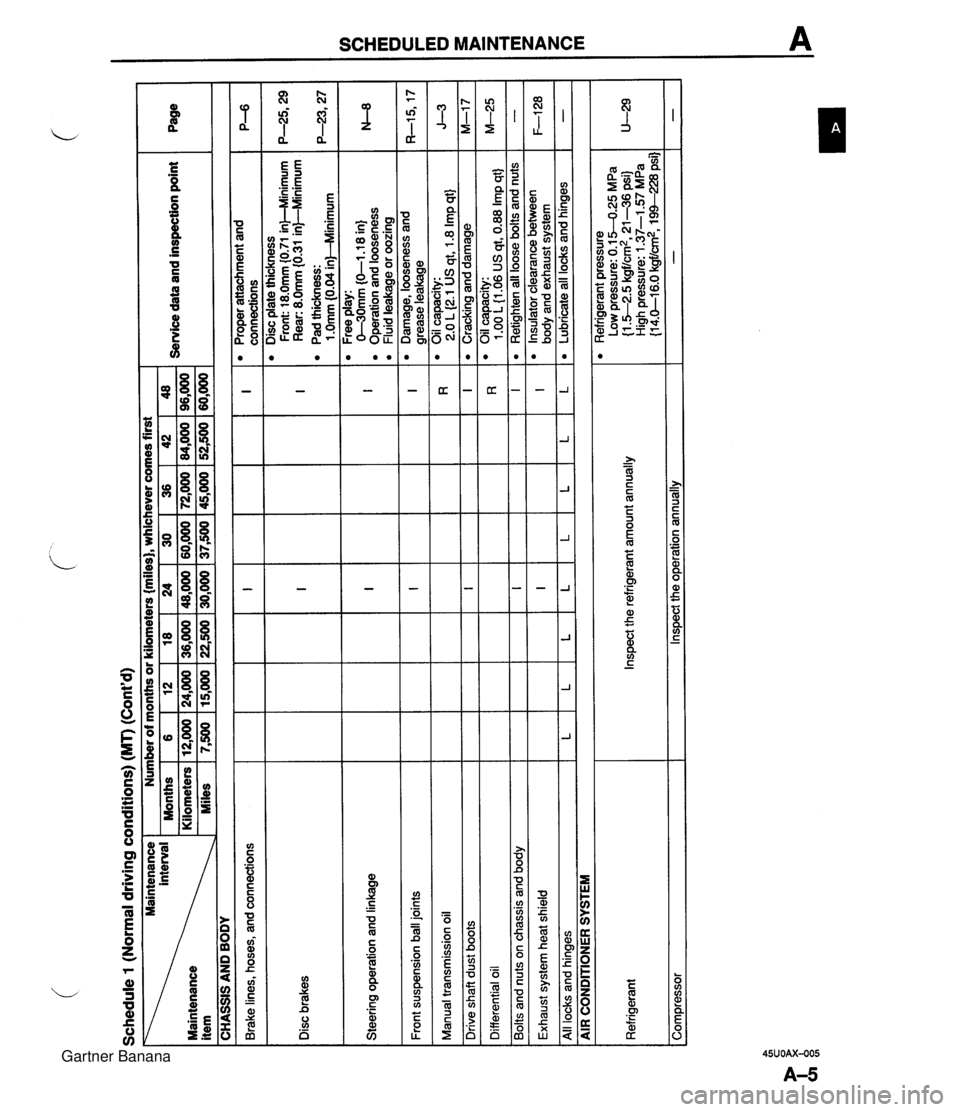

Schedule 1 (Normal driving conditions) (MT) (Cont'd) Maintenance 1 Number of months or kilometers {miles), whichever comes first I I 1 Months 1 6 18 124 130 136 142148 Service data and inspection point 36,000 1 48,000 1 60,000 1 72,000 1 84,000 1 96,000 Maintenance item I CHASSIS AND BODY Brake lines, hoses, and connections Disc plate thickness Front: 18.0mm (0.71 in)--Minimum I I 1 near: 8.0mm {o31 inFMnimum P-6 I Disc brakes I Pad thickness: I I I I I ~10mrn~0.04inMlinimum I Proper attachment and connections Steering operation and linkage I I I I I I I 0-3'0mm (0-1.1 8 in) Operation and looseness Fluid leakaae or oozina I I Front suspension ball joints I I Free play: I I I I I I I - - Manual transmission oil I I I I I , I Damage, looseness and I grease leakage Oil capacity: 2.0 L (2.1 US at. 1.8 Imp qtJ Ill I I I I I Cracking and damage I , I Oil capacity: I I I Differential oil I Drive shaft dust boots I Bolts and nuts on chassis and body I I I n I 1 .OO L {I .06 US qt, 0.88 Imp qt} Ill Exhaust system heat shield I I I I 1 Retiahten all loose bolts and nuts L All locks and hinges lLlLl - AIR CONDITIONER SYSTEM I L Refrigerant pressure Low pressure: 0.1 5-0.25 MPa {I -52.5 kgf/cm2, 21-36 psi) High pressure: 1.37-1 -57 MPa {I 4.0-1 6.0 kgf/cm2, 1 XI-228 psi] - L Corn~ressor I lnswct the o~eration annuallv Refrigerant L Inspect the refrigerant amount annually L I L " Insulator clearance between body and exhaust system Lubricate all locks and hinges F-128 - Gartner Banana

Page 28 of 1708

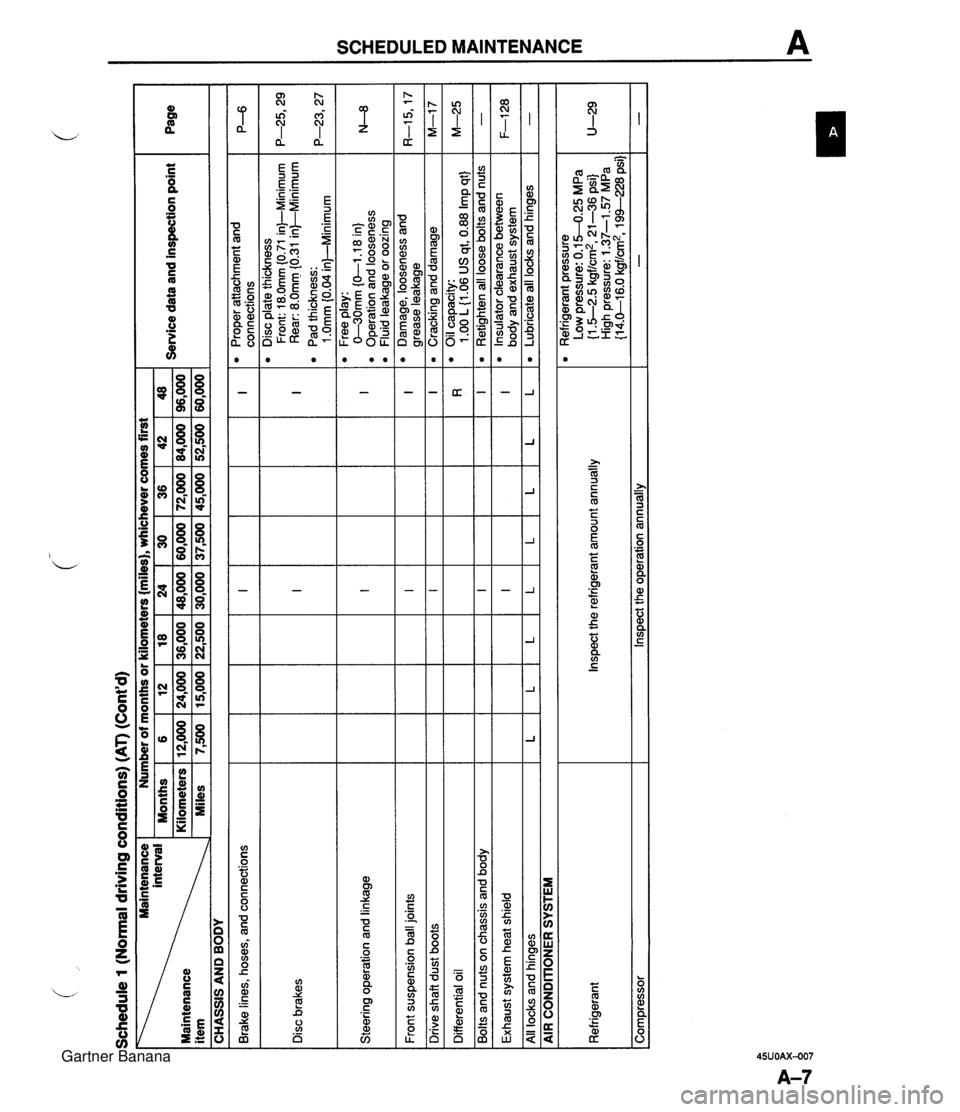

Schedule 1 (Normal driving conditions) (AT) (Cont'd) - .. .. Brake lines, hoses, and connections -- Front suspension ball joints Page I Disc brakes Steering operation and linkage I I 1 I I I I Drive shaft dust boots Ill CHASSIS AND BODY Service data and inspection point Maintenance Number of months or kilometers {miles), whichever comes first I I Differential oil I interval Months Maintenance Kilometers item Miles Exhaust system heat shield I 36 72,000 45,000 I I I I I I I I I 1 I I I I All locks and hinaes lLlLlLlLlLlLlL 6 12,000 7,500 Bolts and nuts on chassis and body - AIR CONDIIONER SYSTEM 42 84,000 52,500 I Ill 12 24,000 15,000 96,000 60,000 Proper attachment and connections Disc plate thickness Front: 18.0mm (0.71 in)-Minimum Rear: 8.0mm f0.31 in)--Minimum Pad thickness: 1 .Omm 10.04 inl-Minimum .-- Free play: C-30mm (0-1 .I 8 in) Operation and looseness Fluid leakage or oozing 18 36,000 22,500 Refrigerant Compressor Damage, looseness and arease leakaae Inspect the refrigerant amount annually Inspect the operation annually 24 48,000 30,000 30 60,000 37,500 Cracking and damage Oil capacity: 1 .OO L 11.06 US at. 0.88 Irn~ at} M-17 M-25 Retighten all loose bolts and nuts Insulator clearance between bodv and exhaust system Refrigerant pressure Low pressure: 0.1 5-0.25 MPa (1 .5-2.5 kgf/:, 21-36 psi) 1 LJ: High pressure: 1.37-1.57 MPa {I 4.0-1 6.0 kgf/cm2, 194--228 psi) - F-128 Lubricate all locks and hinges - Gartner Banana

Page 31 of 1708

2 (Unique driving conditions) (MT) (Cont'd) Number of months or kilometers miles), whichever comes first 24 28 32 36 40 44 48 48 56 64 72 80 88 96 Service data and inspection point Page Maintenance interval Maintenance item .# CHASSIS AND BODY Proper attachment and connections Brake lines, hoses, and connections IIII Disc brakes I Steering operation and linkage Disc plate thickness Front: 18.0mm (0.71 inkMinimum Rear: 8.0mm I0.31 in)--Minimum Pad thickness: 1 .Omm 10.04 inbMinimum Free play: O-30mm {0-1.18 in) Operation and looseness Fluid leakage or oozing Front suspension ball joints 1111 Damage, looseness and arease leakaae I I I I Drive shaft dust boots Cracking and damage Manual transmission oil Oil capacity: 2.0 L (2.1 US at, 1.8 I~D at1 Differential oil Oil capacity: 1 .OO L(1.06 US qt, 0.88 Imp qt} Retighten all loose bolts and nuts I I I Bolts and nuts on chassis and body Exhaust system heat shield Insulator clearance between bodv and exhaust svstem I I I I All locks and hinges ILlLlLlL Lubricate all locks and hinges - I AIR CONDITIONER SYSTEM ~p - ~-~p- Refrigerant Inspect the refrigerant amount annually Refrigerant pressure Low pressure: 0.1 5-0.25 MPa {I S-2.5 kgf/cm2, 21 -36 psi} High pressure: 1.37-1 57 MPa (1 4.0-1 6.0 kgf/cm2, 194-228 psi) Comoressor I lnsoect the ooeration annuallv I I - Gartner Banana

Page 33 of 1708

I Brake lines. hoses, and connections Ill Schedule 2 (Unique driving conditions) (AT) (Cont'd) Disc brakes Steering operation and linkage I Front suspension ball joints 111 Page I Drive shaft dust boots I I I CHASSIS AND BODY Service data and inspection point Maintenance Number of months or kilometers {miles}, whichever comes first I Differential oil 111 I Bolts and nuts on chassis and body 111 48 96 60 I Exhaust system heat shield Ill interval Months Kilometers Maintenance (x1,OOO) Miles(x1,OOO) All locks and hinges AIR CONDIVONER SYSTEM 12 24 15 4 8 5 Disc plate thickness Front: 18.0mm (0.71 in)-Minimum Rear: 8.0mm i0.31 in)-Minimum Pad thickness: 1 .Omm (0.04 in)--Minimum Free play: 0-30mm {O-1 .I 8 in} Operation and looseness Fluid leakage or oozing 16 32 20 8 16 10 P--6 I l Oil capacity: I I I I 1 I 1.00 L 11-06 US at. 0.88 lm~ at I M-25 l Proper attachment and connections I I I I I I I I 7, .' , Ill I 1 I I Retighten all loose bolts and nuts I - 20 40 25 l Damage, looseness and grease leakage Cracking and damage Insulator clearance between I I I I I1Iob odv and exhaust svstem 28 56 35 24 48 30 L 1 L I L I L 1 L 1 L 1 Lubricatealllocksandhinges I - Refrigerant 32 64 40 Inspect the refrigerant amount annually 36 72 45 l Refrigerant pressure Low pressure: 0.1 5-0.25 MPa (1.5-2.5 kgf/cm2, 21-36 psi} High pressure: 1.37-1 57 MPa {I 4.0-1 6.0 kgfld, 19%-228 psi] - I 40 80 50 Compressor 44 88 55 Inspect the operation annually Gartner Banana

Page 589 of 1708

TROUBLESHOOTING GUIDE TROUBLESHOOTING GUIDE FRONT AXLE I Problem Posslbk Cause Worn or damaged wheel bearing Worn or damaged wheel bearing Steering wheel vibration braking Action Replace Replace REAR AXLE Page M- 6 M-6 I Problem Possible Cause Bent drive shaft Page Action Replace I Abnormal nolse Worn or damaged wheel bearing Worn drive shaft spline Worn or deteriorated upper arm bushing M-13 Replace I M-17 Body "rolls" I Replace section R Body leans Weak upper arm bushing Abnormal nolse from suspension system Worn or deteriorated upper arm bushing DIFFERENTIAL Problem Posrlble Cause lnsufficient differential oil Incorrect differential oil lmproperly adjusted ring gear backlash Poor contact of ring gear teeth Worn or damaged side bearing Worn or damaged ring gear Worn or damaged drive pinion bearing Worn or damaged pinion and side gear (STANDARD) Worn or damaged gear in LSD assembly ("TORSEN" LSD) Seized side gear and case Worn side gear spline Worn pinion shaft Worn thrust washer Worn or damaged needle bearing ("TORSEN" LSD) lmproperly adjusted side gear backlash lmproperly adjusted drive pinion gear preload Action Add oil Replace Adjust Adjust Replace Replace Replace Replace Replace Page M-25 M-25 M40 M4l M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-40 M-39 Abnormal nolse Replace Replace Replace Replace Replace Adjust Adjust Heat buildup lnsufficient differential oil lnsufficient drive pinion gear backlash Excessive bearing preload Add oil Adjust Adjust Oil leakage Excessive differential oil Loose differential carrier Worn or damaged oil seal Remove oil Tighten or repair Replace I - No dlfferentlal operation I Misassembled or damaged Repair Gartner Banana

Page 632 of 1708

MANUAL STEERING TROUBLESHOOTING GUIDE Problem Steering heavy Posslble Cause Poor lubrication, foreign material, or abnormal wear of steering ball joint Stuck or damaged lower arm ball joints lmproper steering pinion preload Damaged steering gear Malfunction of steering shaft joint lmproperly adjusted wheel alignment Malfunctioning steering gear Replace Replace gear Replace Replace Adjust Replace ~ction- Lubricate or replace section R N-12 N-12 N- 9 section R N-12 ~i&d~ection N-13 General instability while driving Steering wheel pulls to one side Shake (Steering wheel vibrates upidown) Worn or damaged stabilizer and/or suspension arm bushings Dragging brake Loose lower arm lmproperly adjusted wheel alignment lncorrect tire pressure Damaged or unbalanced wheel Worn or damaged steering joints lmproper steering pinion preload Weak front coil spring Worn or damaged stabilizer andlor suspension arm bushings Malfunctioning shock absorber lmproperly adjusted wheel alignment Excessive tire and/or wheel runout Loose lug nuts Unbalanced wheel(s) Incorrect tire pressure Incorrect tire pressure Unevenly worn tires Weak front spring Replace Repair Tighten Adjust Adjust Adjust or replace Replace Replace gear Replace Replace Replace Adjust Replace Tighten Adjust or replace section R section P section R section R section Q section Q N- 9 N-12 section R section R section R section R section Q section Q section Q Adjust Adjust Replace Replace section Q section Q section Q section R I Cracked or worn transmission mount I Cracked or worn engine mount 1 ~e~lace I section B lncorrect tire pressure Unevenly worn tires Malfunction of shock absorber Shimmy (Steering wheel vibrates circumferentially) Excessive steering wheel play Cracked or worn steering gear mount Loose steering gear mounting bolts Stuck or damaged steering ball joint Excessive tire and/or wheel runout Loose lug nuts Unbalanced wheel(s) Adjust Replace Replace Replace Replace Tighten Replace Replace Tighten Adjust or replace section Q section Q section R section J N-12 N-12 N-13 section Q section Q section Q I Loose shock absorber mounting bolts 1 Tighten I section R Stuck or damaged lower arm ball joint Cracked or worn suspension bushings Damaged or worn front wheel bearing lmproperly adjusted front wheel alignment Worn steering gear Worn or damaged steering joints Worn or damaged suspension arm bushings Loose steering gear mounting bolts I lmproperly adjusted front wheel alignment Poor steering wheel return Replace Replace Replace Adjust Replace Replace Replace Tighten Replace Adjust Replace Adjust Worn linkage &-tie-rod ball joint lncorrect tire pressure Stuck or damaged steering joints section R section R section M section R N-12 N- 9 section R N-12 N-12 section Q N- 9 section R Abnormal noise from steering system 25UONX-00! Improper steering pinion preload Ball joint not operating smoothly Steering shaft contacting something Loose steering gear Malfunctioning steering gear Obstruction near steering column Loose steering linkage Worn steering joints Replace gear Replace Repair Tighten Replace Repair or replace Tighten or replace Replace N-12 N-13 N- 9 N-12 N-12 N- 9 N-12 N- 9 Gartner Banana

Page 647 of 1708

N ENGINE SPEED SENSING POWER STEERING TROUBLESHOOTING GUIDE Steering feels heavy - - Poor lubrication, foreign material, or abnormal wear of steering ball joint Stuck or damaged lower arm ball joints lmproper steering pinion preload Damaged steering gear Malfunctioning steering shaft joint Problem I lmproperly adjusted wheel alignment Possible Cause 1 Malfunctioning steering gear lncorrect tire pressure Loose or damaged oil pump drive belt Low fluid level or air in fluid I Leakage of fluid I Insufficient oil pump pressure Steering wheel pulls lncorrect tire pressure to one side Unevenly worn tires ( Weak front spring General instability while driving Worn or damaged stabilizer and/or upper or lower arm bushing Dragging brake Loose lower arm lmproperly adjusted wheel alignment lncorrect tire pressure Damaged or unbalanced wheel Worn or damaged steering joint(s) lmproper steering pinion preload Weak front coil spring Worn or damaged stabilizer and/or upper or lower arm bushing Malfunctioning shock absorber Cracked or worn engine mount Cracked or worn transmission mount Shake (Steering wheel vibrates up/ down) Shimmy (Steering wheel vibrates left1 right) lmproperly adjusted wheel alignment Excessive tire and/or wheel runout Loose lug nuts Unbalanced wheel(s) Excessive steering wheel play Poor steering wheel return Cracked or worn steering gear mount Loose steering gear mounting bolts Stuck or damaged steering ball joint Excessive tire and/or wheel runout Loose lug nuts Unbalanced wheel@) lncorrect tire pressure Unevenly worn tires Malfunctioning shock absorber Loose shock absorber mounting bolts Stuck or damaged lower arm ball joint Cracked or worn suspension bushings Damaged or worn front wheel bearing lmproperly adjusted front wheel alignment Worn steering gear Worn or damaged steering joints Worn or damaged lower arm bushing Loose steering gear mounting bolts Worn linkage or tie-rod ball joint lncorrect tire pressure Stuck or damaged steering joints lmproperly adjusted front wheel alignment lmproper steering pinion preload Ball joint not operating smoothly Steering shaft contacting something Action Lubricate or replace Replace Adjust Replace Replace Adjust Replace Adjust Adjust or replace Add fluid or bleed air Repair or replace Replace Adjust Replace Replace Replace Repair Tighten or replace Adjust Adjust Adjust or replace Replace Adjust Replace Replace Replace Adjust Replace Tighten Adjust or replace Replace Replace Replace Tighten Replace Replace Tighten Adjust or replace Adjust Replace Replace Tighten Replace Replace Replace Adjust Replace Replace Replace Tighten Replace Adjust Replace Adjust Adjust Replace Repair Pagelsection N-25 section R N-32 N-25 N- 9 section R N-25 section Q N-37 N-21,22 - N-34 section Q section Q section R section R section P section R section R section Q section Q N- 9 N-32 section R section R section R section R section Q section Q section Q section B section J N-26 N-25 N-25 section Q section Q section Q section Q section Q section R section R section R section R section M section R N-25 N- 9 section R N-25 N-25 section Q N- 9 section R N-32 N-25 N- 9 Gartner Banana

Page 729 of 1708

Q OUTLINE, TROUBLESHOOTING GUIDE OUTLINE Wheels SPECIFICATIONS Tires -2 TROUBLESHOOTING GUIDE Temporary spare 14x4T - - TY Pe Item Size Offset mm {in) Pitch circle diameter mm {in) Material Size Air pressure kPa {kgf/cm2, psi} Standard 14x5 112-JJ 45 11.77) 1 00 (3.94) Aluminum Alloy 185160R14 82H 177 {I .8, 26) Page Excessive or irregu- tar tire wear Premature tire wear Tire squeal body vibration I Unbalanced wheel@) 1 Adjust I Q-5 Steel T1 l5/7ODl4 41 2 {4.2,60) Action Problem 1 Tre deterioration 1 Replace I - I Deformed wheel(s) or tire(s) I Repair or replace I - Possible Cause Refer to page Q-4 for details. Road noise or I Insufficient tire pressure [ Adjust Incorrect tire pressure ( Adjust Incorrect tire pressure 1 Adjust Q-3 Q-3 0-3 Shake [Steering wheel "Ibrates Excessive tire and wheel runout Loose lug nuts Unbalanced wheel(s) Insufficient tire pressure Unevenly worn tires Malfunction of shock absorber Loose shock absorber mounting bolts Stuck or damaged lower arm ball joint Cracked or worn suspension bushings Shimmy (Steering wheel vibrates lefiIright) Replace Tighten Adjust or replace Adjust Replace Replace Tighten Replace Replace Irregular tire wear Excessive tire and wheel runout Loose lug nuts Unbalanced wheel(s) - Q4 Q-5 Q-3 - section R section R section R section R Cracked or worn engine mount Cracked or worn steering gear mount Loose steering gear mounting bolts Stuck or damaged steering ball joint I Damaged or worn front wheel bearing ( Replace ( section M Replace Replace Tighten Adjust or replace I Improperly adjusted front wheel alignment 1 Adjust I section R Uneven (one-sided) I Unequal tire pressures 1 Adjust 1 Q-3 - - Q-4 Q-5 Replace Replace Tighten Replace section B section N section N section N braking Steering wheel I Incorrect tire pressure 1 Adjust doesn't return properly or pulls to either left or right . General driving Instability Excessive steering (2-3 wheel play Irregular tire wear (lefthight) Unequal tire pressures Different types or brands of tires mixed (leftlright) Loose lug nuts Unequal tire pressures Damaged or unbalanced wheel(s) Loose lug nuts Loose lug nuts I 15UOQX-00 Replace Adjust Replace Tighten Adjust Replace or adjust Tighten Tighten - Q-3 - Q-4 Q-3 Q-5 Q-4 Q-4 Gartner Banana

Page 731 of 1708

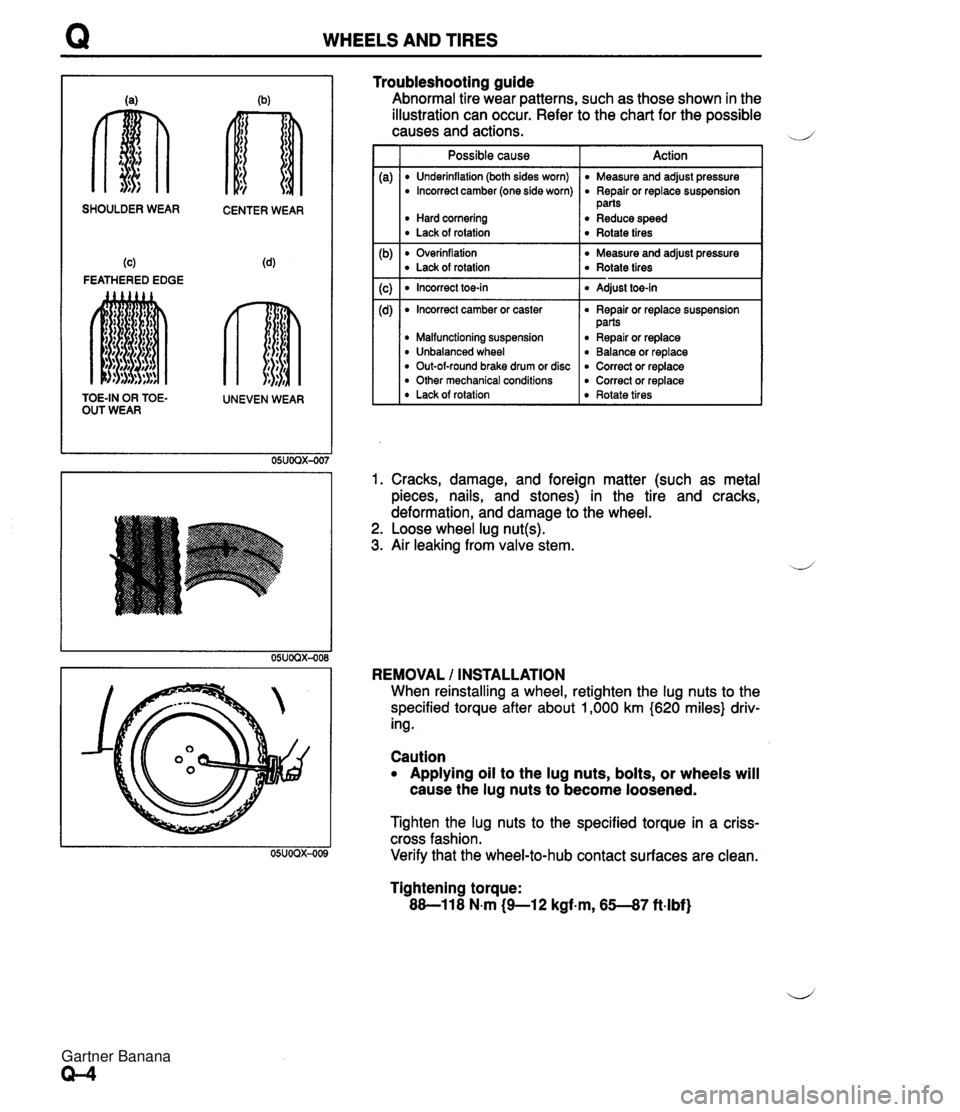

WHEELS AND TIRES SHOULDER WEAR CENTER WEAR (c) (4 FEATHERED EDGE TOE-IN OR TOE- UNEVEN WEAR OUT WEAR Troubleshooting guide Abnormal tire wear patterns, such as those shown in the illustration can occur. Refer to the chart for the possible causes and actions. d' Possible cause I Action I I Underinflation (both sides worn) I Measure and adjust pressure Overinflation Measure and adjust pressure Lack of rotation Rotate tires I Incorrect camber (one side worn) Hard cornering Lack of rotation Incorrect toe-in I Adjust toe-in I Repair or replace suspension parts Reduce speed Rotate tires 1. Cracks, damage, and foreign matter (such as metal pieces, nails, and stones) in the tire and cracks, deformation, and damage to the wheel. 2. Loose wheel lug nut(s). 3. Air leaking from valve stem. Incorrect camber or caster Malfunctioning suspension Unbalanced wheel Out-of-round brake drum or disc Other mechanical conditions Lack of rotation REMOVAL / INSTALLATION When reinstalling a wheel, retighten the lug nuts to the specified torque after about 1,000 km (620 miles} driv- ing. Repair or replace suspension parts Repair or replace Balance or replace Correct or replace Correct or replace Rotate tires Caution Applying oil to the lug nuts, bolts, or wheels will cause the lug nuts to become loosened. Tighten the lug nuts to the specified torque in a criss- cross fashion. Verify that the wheel-to-hub contact surfaces are clean. Tightening torque: 88-11 8 N.m (9-1 2 kgf.m, 65--87 ft-lbf) Gartner Banana