engine MAZDA MX-5 1994 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 48 of 1708

ON-VEHICLE MAINTENANCE B ON-VEHICLE MAINTENANCE PREPARATION L SST 49 DO11 102 Lock tool, crankshaft Shaft (Part of 49 E011 1AO) Collar (Part of 49 E011 1 AO) Warninq For removal / installat ion of timing belt pulley For prevention of engine rotation For prevention of engine rotation 49 EOl 1 105 Stopper (Part of 49 EOll 1AO) 49 EOll 1 A0 Ring gear brake set For prevention of engine rotation For prevention of engine rotation ~onhuous exposure with USED engine oil has caused skin cancer in laboratory mice. Protect your skin by washing with soap and water immediately after this work. 49 SEO1 310 A Centering tool, clutch disc For installation of clutch disc Gartner Banana

Page 49 of 1708

B ON-VEHICLE MAINTENANCE TIMING BELT Removal / lnstallation 1. Disconnect the negative battery cable. 2. Drain the engine coolant. 3. Remove the under cover. 4. Remove in the order shown in the figure, referring to Removal Note. 5. Install in the reverse order of removal, referring to lnstallation Note. (80-110 kgfmn, 7.9-10.7 Nm 13-17 Nm (125-175 kgfcm, 109-151 In4bf) Nm (kgfm, ft4bf) 45UOBX425 1. Air intake pipe 12. Spark plug 2. Upper radiator hose Removal / Installation ......... section G 3. Water hoses (Connected to thermostat 13. PCV valve housing) 14. Cylinder head cover 4. PIS andlor A/C drive belt 15. Upper timing belt cover Removal 1 Installation ....... page B- 6 16. Middle timing belt cover 5. Alternator drive belt 17. Lower timing belt cover Removal / Installation ....... page 5 6 18. Timing belt 6. Water pump pulley Removal Note ............. page B-13 7. Plate Installation Note ........... page B-14 8. Crankshaft pulley Inspection ................. page 8-58 9. Pulley lock bolt 19. Tensioner, tensioner spring Removal Note ............. page B-13 Installation Note ........... page B-14 /' Installation Note ........... page 51 5 Inspection ................. page 558 10. Pulley boss 20. Idler 11. Ignition coil and high-tension lead Inspection ................. page 8-58 Gartner Banana

Page 52 of 1708

ON-VEHICLE MAINTENANCE B Stem After Installation 10. Loosen the tensioner lock bolt to apply spring tension to the timing belt. 11. Tighten the tensioner lock bolt. Tightening torque: 38-51 N-m (3.8-5.3 kgf.m, 28--38 ftlbf) 12. Install the pulley boss and pulley lock bolt. 13. Turn the crankshaft 2 and 116 turns clockwise and verify that the timing marks are correctly aligned. 14. Measure the timing belt deflection by applying moderate pressure 98 N (10 kgf, 22 Ibf) midway between the cam- shaft pulleys. If the deflection is not correct, repeat from Step 10 above. Deflection: 9.0-11.5mm (0.36-4.45 in) at 98 N (10 kgf, 22 Ibf) Pulley lock bolt Hold the crankshaft with the SST and tighten the pulley lock bolt. Tightening torque: 157-166 N.m (16-17 kgf.m, 116-122 ftlbf) 1. till the radiator with specified amount and type of engine coolant. (Refer to section E.) 2. Connect the negative battery cable. 3. Start the engine and check, and if necessary, adjust the ignition timing. Gartner Banana

Page 53 of 1708

ON-VEHICLE MAINTENANCE CYLINDER HEAD GASKET Replacement Warning e Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedures" on section F. Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep sparks and flames away from fuel. 1. Disconnect the negative battery cable. 2. Drain the engine coolant. (Refer to section E.) 3. Remove in the order shown in the figure, referring to Removal Note. 4. Install in the reverse order of removal, referring to Installation Note. Gartner Banana

Page 56 of 1708

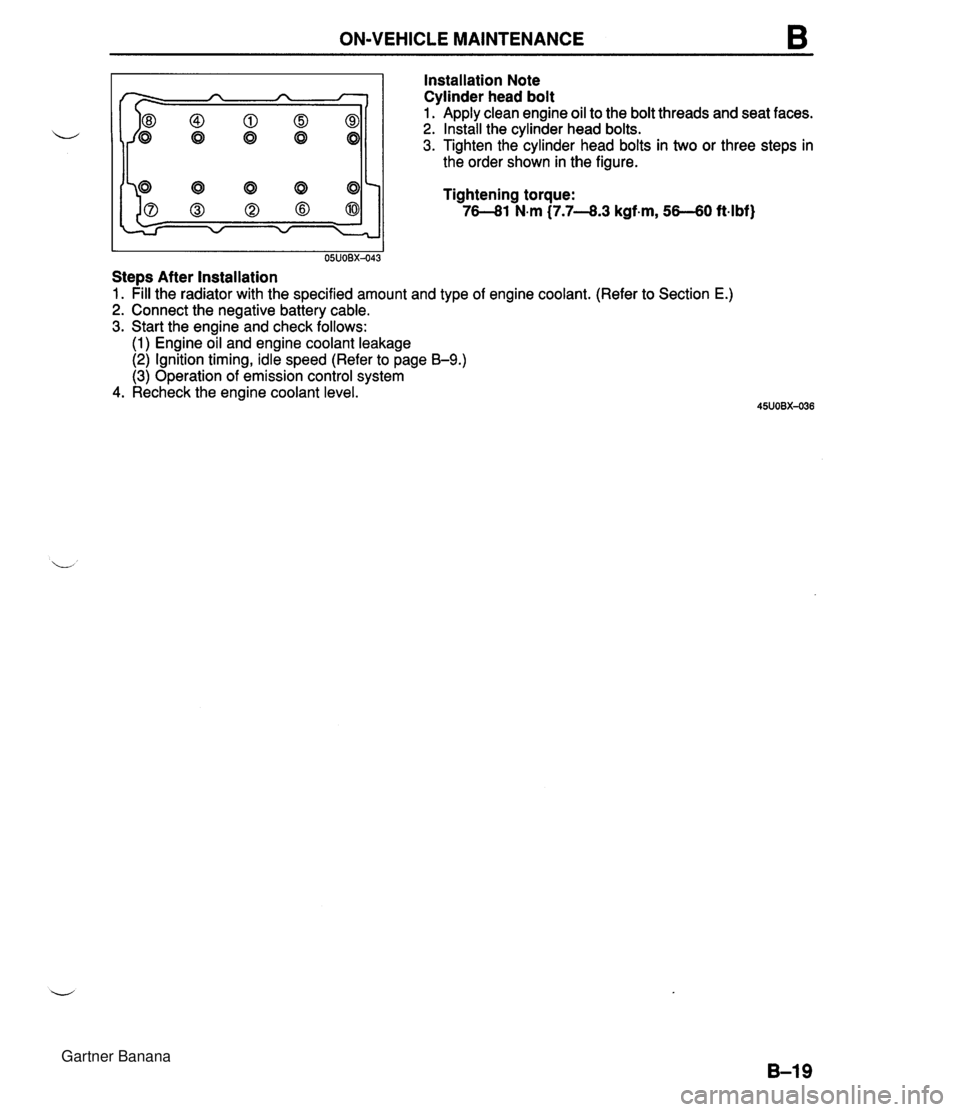

ON-VEHICLE MAINTENANCE B Installation Note Cylinder head bolt I I 05UOBX-043 Stem After Installation Apply clean engine oil to the bolt threads and seat faces. Install the cylinder head bolts. Tighten the cylinder head bolts in two or three steps in the order shown in the figure. Tightening torque: 76-81 N.m (7.7-8.3 kgf-m, 56-60 ft4bf) 1. pill the radiator with the specified amount and type of engine coolant. (Refer to Section E.) 2. Connect the negative battery cable. 3. Start the engine and check follows: (1) Engine oil and engine coolant leakage (2) Ignition timing, idle speed (Refer to page B-9.) (3) Operation of emission control system 4. Recheck the engine coolant level. Gartner Banana

Page 57 of 1708

ON-VEHICLE MAINTENANCE HLA Removal / lnstallation 1. Disconnect the negative battery cable. 2. Drain the engine coolant. (Refer to section E.) 3. Remove in the order shown in the figure, referring to Removal Note. 4. Install in the reverse order of removal, referring to lnstallation Note. 1. Timing belt Removal / Installation ....... page 51 2 2. Crankshaft position sensor Installation Note ............. section G 3. Camshaft pulley Removal Note ............. page 521 Installation Note ........... page 522 4. Camshaft Removal Note ............. page B-21 Installation Note ........... page B-21 5. HLA 1 Removal Note ............. page B-21 Installation Note ........... page B-21 Inspection ................. page B-53 Gartner Banana

Page 58 of 1708

ON-VEHICLE MAINTENANCE B CRANKSHAFT POSITION SENSOR DRIVE GROOVE 45UOBX-04 Removal Note Camshaft pulley 1. Hold the camshaft with a wrench at the cast hexagon. 2. Remove the camshaft pulley lock bolts. 3. Remove the camshaft pulleys. Camshaft 1. Loosen the camshaft cap bolts in two or three steps in the order shown in the figure. 2. Remove the camshaft caps. 3. Remove the camshafts. 4. Remove the camshaft oil seals from the camshafts. HLA Caution The HLA must be reinstalled in the same posi- tions from which they were removed. If they are not, it can cause premature and uneven wear. Note Mark the HLA to show their original positions. Remove the HLA from the cylinder head. Installation Note HLA 1. Apply clean engine oil to the friction surfaces. 2. If the HLA are being reused, install them in the position from which they were removed. 3. Verify that the HLA move smoothly in their bores. Camshaft Note The exhaust camshaft has a groove for the crank- shaft position sensor drive. 1. Apply clean engine oil to the camshaft journals and bear- ings. 2. Install the camshaft in position. Gartner Banana

Page 59 of 1708

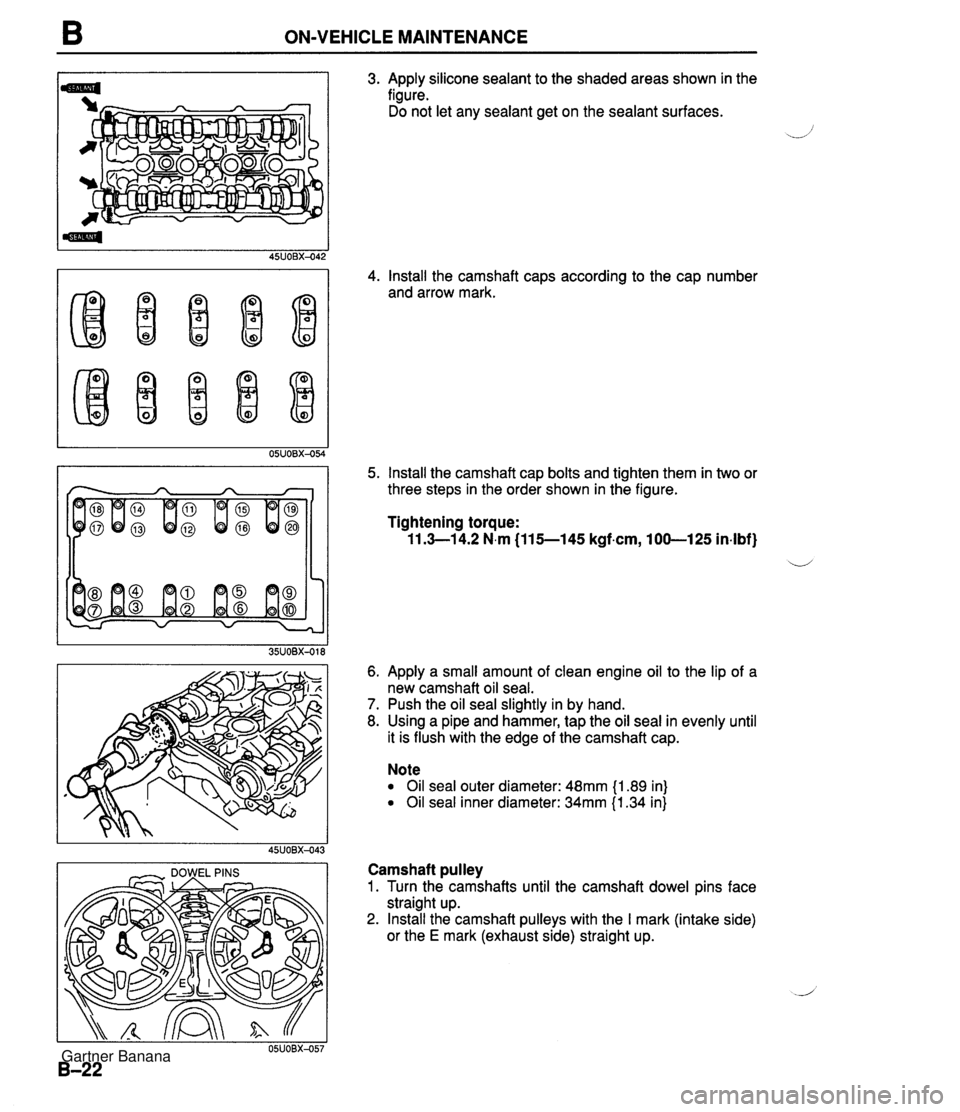

B ON-VEHICLE MAINTENANCE I - DOWEL PINS I 3. Apply silicone sealant to the shaded areas shown in the figure. Do not let any sealant get on the sealant surfaces. 4. Install the camshaft caps according to the cap number and arrow mark. 5. Install the camshaft cap bolts and tighten them in two or three steps in the order shown in the figure. Tightening torque: 11.3-1 4.2 N.m (115--145 kgf.cm, 100-125 in-lbf} ii 6. Apply a small amount of clean engine oil to the lip of a new camshaft oil seal. 7. Push the oil seal slightly in by hand. 8. Using a pipe and hammer, tap the oil seal in evenly until it is flush with the edge of the camshaft cap. Note Oil seal outer diameter: 48mm {I .89 in) Oil seal inner diameter: 34mm {I .34 in} Camshaft pulley 1. Turn the camshafts until the camshaft dowel pins face straight up. 2. Install the camshaft pulleys with the I mark (intake side) or the E mark (exhaust side) straight up. Gartner Banana

Page 60 of 1708

ON-VEHICLE MAINTENANCE B I I 35UOBX-020 Stem After Installation 3. Install the camshaft pulley lock bolts. 4. Hold the camshaft with a wrench at the cast hexagon. 5. Tighten the camshaft pulley lock bolt. Tightening torque: 50-60 Nm C5.0-6.2 kgfm, 3744 ft4bf) 1. pill the radiator with the specified amount and type of engine coolant. (Refer 2. Connect the negative battery cable. 3. Start the engine and check follows: (1) Engine coolant leakage (2) Ignition timing (Refer to page 59.) 4. Recheck the engine coolant levels. to section E.) Gartner Banana

Page 62 of 1708

ON-VEHICLE MAINTENANCE B Steps After Installation 1. Connect the neaative batterv cable. Oil seal 1. Cut the oil seal lip with a razor knife. 2. Remove the oil seal with a screwdriver protected with a rag. Installation Note Oil seal 1. Apply a small amount of clean engine oil to the lip of a new oil seal. 2. Push the oil seal slightly in by hand. 3. Tap the oil seal in evenly with a pipe and a hammer until it is flush with the edge of the oil pump body. Note Oil seal outer diameter: 50.5mm (1.99 in} Oil seal inner diameter: 36.5mm (1.44 in} Timing belt pulley 1. Install the timing belt pulley. 2. Install the pulley woodruff key with the tapered side to- ward the oil pump body. 2. Start the enginsand check, and if necessary, adjust the ignition timing. 3. Connect the negative battery cable. 4. Start the engine and check follows: (1) Engine coolant leakage (2) Ignition timing (Refer to page B-9.) 5. Recheck the engine coolant levels. Gartner Banana