height MAZDA MX-5 1994 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 685 of 1708

P BRAKE SYSTEM k FIRST PEDAL VACUUM GAUG DEPRESSION FORCE GAUGE POWER BRAKE UNIT Quick Inspection, On-vehicle Power brake unit function check (Simple method) ii Step 1 1. With the engine stopped, depress the pedal a few times. 2. With the pedal depressed, start the engine. 3. If immediately after the engine starts the pedal moves down slightly, the unit is operating. Step 2 1. Start the engine and let it run 1 or 2 minutes. 2. Stop the engine. 3. Depress the pedal with the usual force. 4. If the first pedal stroke is long and becomes shorter with subsequent strokes, the unit is operating. 5. If a problem is found, inspect for damage or improper connection of the check valve or vacuum hose. Repair if necessary, and inspect it once again. Step 3 1. Start the engine. 2. Depress the pedal with the usual force. 3. Stop the engine with the pedal depressed. 4. Hold the pedal down for about 30 seconds. 5. If the pedal height does not change, the unit is operating. ,, 6. If there is a problem, check for damage or improper con- nection of the check valve or vacuum hose. Repair if necessary, and check once again. If the nature of the problem is still not clear after following the 3 steps above, follow the more detailed check described in "Method using tester," below. (Method using tester) Connect the SST, vacuum gauge, and pedal depression force gauge as shown in the figure. After bleeding the air from the SST, conduct the test as described in the 3 steps below. Inspection using gauges Connect the SST gauges, a vacuum gauge (A), and a pedal depression gauge (B) as shown. Bleed the air from the SST gauges before performing the following tests. a) Checking for vacuum loss Unloaded condition 1. Start the engine. 2. Stop the engine when the vacuum gauge indicates 66.7 kPa (500 mmHg, 19.7 inHg). 3. Observe the vacuum gauge for 15 seconds. If the gauge indicates 63.4-66.6 kPa (475-500 mmHg, ,, 18.7-19.7 inHg), the unit is operating. Gartner Banana

Page 687 of 1708

P BRAKE SYSTEM Removal / Installation 1. Remove in the order shown in the figure. 2. Install in the reverse order of removal. 3. Take the following steps after installation: (1) Check and adust the push rod and piston clearance. (Standard: refer to page P-12 1 ABS: refer to page P-15.) (2) Add fluid and bleed the air. (Refer to page P-7.) (3) Check all parts for fluid leakage. (4) Check and adjust the brake pedal height and free play. (Refer to page P-9.) (5) Make an on-vehicle check of the unit. (Refer to page P-20.) (6) Check that the vacuum hose does not contact other parts. ABS 1~22 (1.3--2.2,~.&16} STANDARD 35UOPX-01 1. Fluid level sensor connector 5. Clevis tin 2. Brake pipe and proportioning bypass valve 6. Power 'brake unit 3. Master cylinder 7. Gasket 4. Vacuum hose with check valve Apply sealant to the gasket contact surface Gartner Banana

Page 738 of 1708

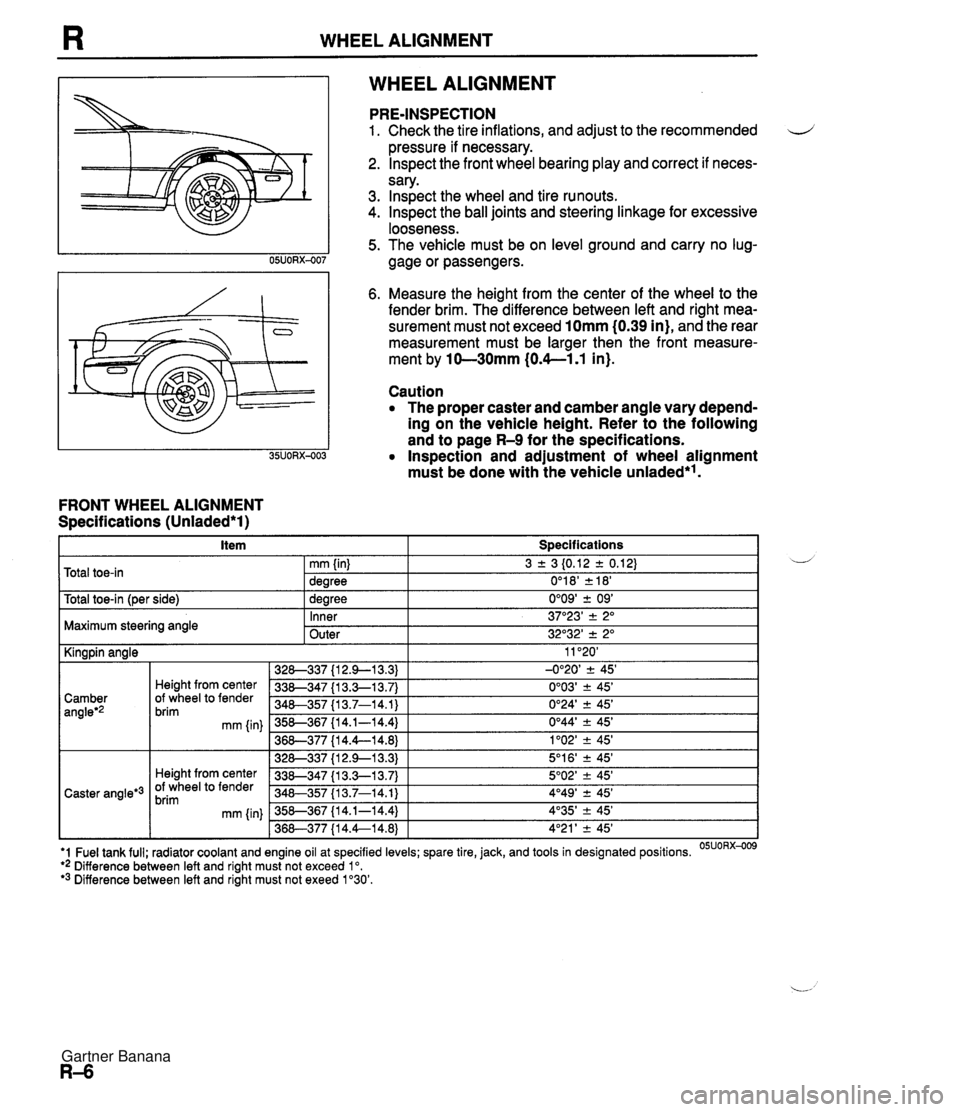

WHEEL ALIGNMENT WHEEL ALIGNMENT FRONT WHEEL ALIGNMENT Specifications (Unladed*l) PRE-INSPECTION 1. Check the tire inflations, and adjust to the recommended d pressure if necessary. 2. lnspect the front wheel bearing play and correct if neces- sary. 3. lnspect the wheel and tire runouts. 4. Inspect the ball joints and steering linkage for excessive looseness. 5. The vehicle must be on level ground and carry no lug- gage or passengers. 6. Measure the height from the center of the wheel to the fender brim. The difference between left and right mea- surement must not exceed 10mm (0.39 in), and the rear measurement must be larger then the front measure- ment by 10-30mm (0.4--1.1 in). Caution The proper caster and camber angle vary depend- ing on the vehicle height. Refer to the following and to page R-9 for the specifications. Inspection and adjustment of wheel alignment must be done with the vehicle unladed*'. . . I Y -- t~otal toe-in l~er side) I 1 dearee 0'09' + 09' I Total toe-in 3 2 3 I0.12 2 0.12) 0'1 8' 2 18' mm (in) dearee Maximum steering angle U - Inner Outer 11 '20' -0°20' 2 45' 0'03' ? 45' 0'24' 2 45' 0°44' -+ 45' 1'02' -+ 45' 5'1 6' ? 45' 5O02' -+ 45' 4O49' 2 45' 4'35' -+ 45' 4'21 ' -+ 45' I Kingpin angle 37"23' -+ 2" 32O32' 2 2" '1 Fuel tank full; radiator coolant and engine oil at specified levels; spare tire, jack, and tools in designated positions. OSUORX-009 ** Difference between left and right must not exceed lo. '3 Difference between left and right must not exeed 1'30'. 328-337 {I 2.9-1 3.3) 338-347 {I 3.3-1 3.7) 340-357 I13.7-14.1) 358-367 {I 4.1-14.4) 36&377 {I 4.4--14.8) 328-337 {I 2.9--13.3) 338-347 {I 3.3-1 3.7) 348-357 113.7-14.1) 358-367 {I 4.1-14.4) 368-377 {I 4.4--14.8) Camber angleg2 Caster angle*3 Height from center Of wheel to fender brim mm {in) Height from center Of wheel to fender brim mm (in) Gartner Banana

Page 741 of 1708

WHEEL ALIGNMENT REAR WHEEL ALIGNMENT Specifications (Unladed*) I Item I Specifications I L *' Fuel tank full; radiator coolant and engine oil at specified levels; spare tire, jack, and tools in designated positions. 05Uo~x-01~ *2 Difference between the leff and right must be exeed lo. 3 + 3 i0.12 * 0.12) 0'18' k18' 0'09' 2 09' -1 "08' +. 30' Total toe-in Total toe-in (per side) Camber angle'' LEFT WHEEL - mm {in) degree degree INCREASE I 1 346-355 (1 3.6-1 4.0) Height from center of wheel to fender brim'2 mm Iin) RIGHT WHEEL C INCREASE 356-3135 {14.0-14.4) 366-375 {I 4.4--14.8) 376-385 {I 4.8-1 5.2) 386--395 {I 5.2-1 5.6) LEFT WHEEL -C -0°54' r 30' -0'43' 2 30' -0°35' r 30' -0'30' +. 30' Toe-in Toe-in is adjusted by turning the front and/or rear adjust- ing cam bolts at the lower arm. Caution Adjust the toe-in before adjusting the camber. 1. Loosen the front and/or rear cam nuts. 2. Turn the front and/or rear adjusting cam bolts to provide the correct toe-in. I Counter- Counter- Decrease Clockwise Clockwise clockwise clockwise Toe-in Note Turning the front cam one graduation changes the toe-in about 2.8mm (0.11 in} and the camber about 15'. Turning the rear cam one graduation changes the toe-in about 2.8mm I0.11 in} and the camber about 6'. 3. 'Adjust the camber. Left wheel Camber Camber is adjusted by turning the front and rear cams at the lower arm. Right wheel Caution Adjust the camber after adjusting the toe-in. Front cam I Rear cam I Front cam I Rear cam 1. Loosen the front and rear cam nuts. 2. Turn the front and rear adjusting cam bolts the same amount in the opposite direction to provide the correct camber angle. Gartner Banana

Page 800 of 1708

s WINDSHIELD WIPER AND WASHER I mm (in) 05UOSX459 I MOLDING EDGE ' C~NTER mm (in) 05UOSx-060 CONNECTOR SHAFT Adjustment Arm height Set the arm height as shown. Washer nozzle Insert a needle or similar object into the nozzle hole and move the nozzle to adjust the spray direction. Installation Note Wiper arm and blade Clean the wiper arm connector shafts with a wire brush before installing the wiper warms. Gartner Banana

Page 812 of 1708

REAR WINDOW INSULATION TAPE RIVET MOUNTING A INSULATION TAPE INSULATION TAPE SEC. A-A THE END OF THE ZIPPER 11. Remove the rivets from the rain rail with a cutter, and remove the rain rail from the convertible top. 12. Remove the rivets from the rear window with a cutter. 13. Peel apart the Velcro. Note Save the zipper stops for reuse. 14. Carefully remove the zipper stops from the rear window ,-- and top fabric, and remove the rear window. Installation Note Rear window 1. Decrease the rain rail with ethyl alcohol. 2. Install insulation tape to the rivet mounting holes of the rain rail. Insulation tape Width : 20 mm (0.79 in) Height : 15 mm 10.59 in) Thickness : 3 mm I0.12 in) 3. Align the ends of the zipper, and install the zipper pull tab. 4. Zip the rear window into place. Gartner Banana

Page 836 of 1708

CONVERTIBLE TOP 26. Install the retainers to the link assembly, aligning the retainer marks with the retainer mounting screws. 27. Install the weatherstri~s to the link assemblv. 28. Install the convertible'to~ to the bodv. (~ef& to paae S-67.) PROTECTOR ADJUSTING NUT WINDSHIELD HEADER CONVERTIBLE TOP I Adjustment Top latch assembly 1. Lift the protector away from the top latch assembly ad- justing nut. 2. Turn the adjusting nut clockwise to decrease clearance A and height B; turn the nut counterclockwise to increase them. 3. Secure the adjusting nut with the protector. Gartner Banana

Page 840 of 1708

DETACHABLE HARDTOP PROTECTOR ADJUSTING NUT DETACHABLE HARDTOl WINDSHIELD HEADER I @ 1 5 r 2 (0.2 f 0.08) @ 1 0 r 2 (0 * 0.08) mm (in) 45UOSX-11 f Adjustment Top latch assembly 1. Lift the protector away from the top latch assembly ad- justing nut. d 2. Turn the adjusting nut clockwise to decrease clearance A and height B; turn the nut counterclockwise to increase them. 3. Secure the adjusting nut with the protector. I I Side latch assembly 1. Lift the protector away from the side latch assembly ad- justing nut. 2. Turn the adjusting nut clockwise to tighten the striker and side latch assembly engagement; turn the nut counter- clockwise to loosen the engagement. - 3. Secure the adjusting nut with the protector. ADJUSTING NUT 45UOSX-117 Rear deck latch assembly 1. Remove the screw and open the latch cover. 2. Loosen the plate mounting bolts. 3. Install the detachable hardtop to the body. 4. Move the plate right, left, fore, or aft until it is tight. 5. Tighten the plate mounting bolts. Tightening torque: 18-26 N.m (1.8-2.7 kgfsm, 14--19 ft-lbf) 6. Close the latch cover and install the screw. Gartner Banana

Page 901 of 1708

T LIGHTING SYSTEM Stoplight Switch Adjustment 1. Adjust the brake pedal height. (Refer to section P.) 2. Disconnect the stoplight switch connector. 4 3. Loosen the stoplight switch locknut. 4. Turn the stoplight switch until it contacts the pedal arm. Turn an additional 112 turn. 5. Tighten the locknut. Locknut tightening torque: 14-18 N.m (1.4-1.8 kgf-m, 120-156 in-lbf) I I I Brake pedal depress I 0 0 1 I Inspection Stoplight switch 1. Disconnect the stoplight switch connector. 2. Check for continuity between terminals of the switch. lnspection condition 3. If not as specified, replace the stoplight switch. Terminal A I B I Brake pedal released I m : Continuity Gartner Banana

Page 950 of 1708

CRUISE CONTROL SYSTEM T BRAKE AND STOPLIGHT SWITCH CLUTCH SWITCH Removal Loosen the locknut and remove the switch. Installation Install in the reverse order of removal. Adjustment Adjust the switch to set the specified pedal height. Pedal height: 175--185mm (6.89-7.82 in) Pedal free play: 0.6-3.lmm (0.02-4.12 in) Inspection 1. Disconnect the clutch switch connector. 2. Check for continuity between terminals of the switch. Pedal position Terminal A B 1 0-a: Continuity Pedal released 3. If not as specified, replace the clutch switch. Pedal de~ressed STOP LIGHTIBRAKE SWITCH Removal Loosen the locknut and remove the switch. 0 I 0 Installation Install in the reverse order of removal. Adjustment Adjust the switch to set the specified pedal height. Pedal height: l7l-l8l mm (6.93--7.13 in) Pedal free play: 4.0-7.0mm (0.16-0.28 in) Inspection 1. Disconnect the brake switch connector. 2. Check for continuity between terminals of the switch. I I I Pedal released I I I Pedal position w: Continuity Terminal Pedal depressed 3. If not as specified, replace the brake switch. 4. If the switch is OK, repair the wiring harness (fuse - brake switch - control unit). A 0 I 0 B Gartner Banana