oil type MAZDA MX-5 1994 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 854 of 1708

OUTLINE T NO type relay I STOP Not in operation (No power supply) ax FLOW I STOP NC type relay NO switch In operation (Power supply) ELECTRICAL SYMBOLS Switches and Relays There is an NC (normally closed) and NO (normally open) indication for switches and relays that shows when no change of operation conditions has occurred. Relay Switch I w FLOW - Other Electrical Symbols - ax STOP FLOW NC switch FLOW STOP I I I I - FUSIBLE LINK e $1 VARIABLE RESISTOR + LIGHT TRANSISTOR HOLDER BOX FUSE 4 RESISTOR 1 T CONDENSER BATTERY 4) MOTOR 8 THERMISTOR SPEAKER I CIGARETTE LIGHTER I HEATER - - BODY GROUND t COIL, SOLENOID + DIODE I 25UOTX-010 Gartner Banana

Page 1113 of 1708

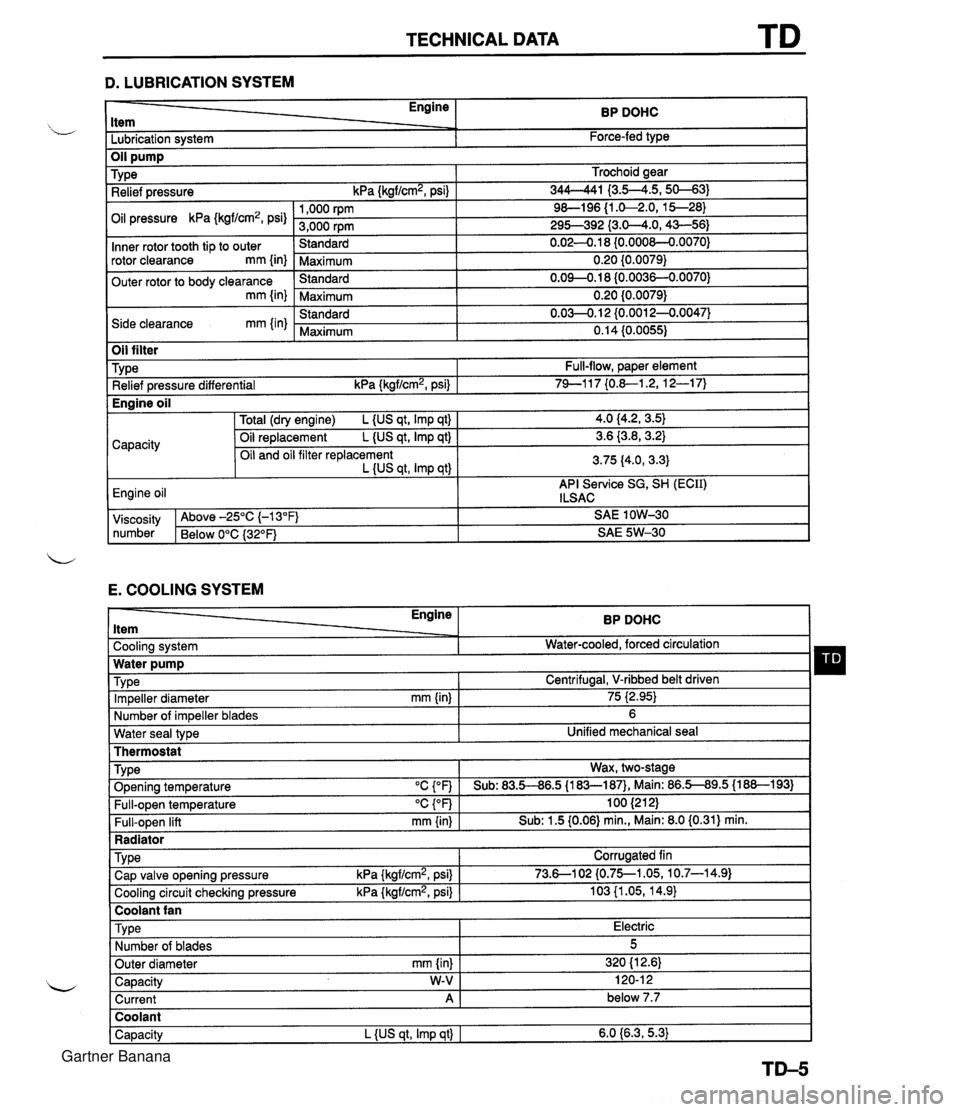

TECHNICAL DATA D. LUBRICATION SYSTEM - Engine ltem BP DOHC - -. Lubrication system Force-fed type E. COOLING SYSTEM Trochoid gear 344-41 I3.5--4.5,s-31 9&l96 {I .&2.0, 15--28) 295-392 {3.0-4.0,43-56) 0.02-0.1 8 {0.000&0.0070) 0.20 {0.0079) 0.09-0.18 (0.0036-0.0070) 0.20 {0.0079) 0.03-0.1 2 {0.0012-0.0047) 0.14 (0.0055) TY pe Relief pressure kPa {kgf/cm2, psi) Oil pressure kPa {kgf/cm2, psi) Inner rotor tooth tip to outer rotor clearance mm {in) Outer rotor to body clearance mm {in) Side clearance mm {in) Water seal type I Unified mechanical seal Thermostat 1,000 rpm 3,000 rpm Standard Maximum Standard Maximum Standard Maximum Oil filter Engine ltem - - Cooling system . . Impeller diameter mm {in) Number of impeller blades Type Relief pressure differential kPa {kgf/cm2, psi) BP DOHC Water-cooled, forced circulation - 75 i2.95) 6 Full-flow, paper element 74-1 17 {0.&1.2, 12-1 7) TY pe . ., . . . - Radiator I Water pump Wax, two-stage v. . . Full-open temperature "c {OF) Full-open lift mm {in) Engine oil TVD~ O~enina tem~erature "C con I Sub: 83.5-86.5 U83-187). Main: 86.5-89.5 (1 88-1 931 100 (21 2) Sub: 1.5 (0.06) min., Main: 8.0 (0.31) min. -. . - . . Cooling circuit checking pressure kPa {kgflcmz, psi) I 103 {I .05, 14.9) I Centrifugal, V-ribbed belt driven TY pe I Coolant fan I 4.0 (4.2, 3.5) 3.6 {3.8,3.2) 3.75 (4.0, 3.3) API Service SG, SH (ECII) ILSAC Capacity Corrugated fin viscosity Above -25°C (-1 3°F) SAE 1 OW-30 number Below 0°C {3Z°F) SAE 5W-30 Total (dry engine) L {US qt, Imp qt) Oil replacement L {US qt, Imp qt) Oil and oil filter replacement L {US qt, Imp qtl Cap valve o~enina pressure kPa {krrf/cm2, psi} 1 73.6--102 {0.75--1.05, 10.7-14.91 Capacity W-V I 120-1 2 Current A 1 below 7.7 Engine oil Type Number of blades Outer diameter mm {in) Coolant Capacity L {US qt, Imp qt) I 6.0 {6.3,5.3) Electric 5 320 (1 2.61 Gartner Banana

Page 1114 of 1708

![MAZDA MX-5 1994 Owners Manual TD TECHNICAL DATA Idle speed rpm 1 800-900 (850 2 50) [MT], 750-850 (800 f 50) [ATJ lanition timina BTDC I 9"-11 (10 f 1") u F. FUEL AND EMISSION CONTROL SYSTEMS - Engine ltem Item 1 Throat diam MAZDA MX-5 1994 Owners Manual TD TECHNICAL DATA Idle speed rpm 1 800-900 (850 2 50) [MT], 750-850 (800 f 50) [ATJ lanition timina BTDC I 9"-11 (10 f 1") u F. FUEL AND EMISSION CONTROL SYSTEMS - Engine ltem Item 1 Throat diam](/img/28/57072/w960_57072-1113.png)

TD TECHNICAL DATA Idle speed rpm 1 800-900 (850 2 50) [MT]', 750-850 (800 f 50) [ATJ' lanition timina BTDC I 9"-11' (10' f 1")' u' F. FUEL AND EMISSION CONTROL SYSTEMS - Engine ltem Item 1 Throat diameter mm {in) 1 55 (2.2) 1 Antifreeze solution BP DOHC Specification 1 Throttle body Fuel pump TY pe I Impeller (in-tank) Coolant protection Above -1 6°C (3°F) Above -26°C (-15°F) Above -40°C {-40°n Tv~e -. Output pressure kPa (kgf/cm2, psi) I 294-437 {3.0--6.5,43--92) Fuel filter Specific gravity at 20°C {WF) 1.054 1.066 1.078 Volume percentage % Horizontal draft Water 65 55 45 -. . - Regulating pressure kPa {kgf/cm2, psi) I 280-289 I2.85--2.95, 40.141.9) Fuel iniector Coolant 35 45 55 TY pe IAC valve Solenoid resistance n 1 10.7-1 2.3 (at 20°C (68°F)) Low-pressure side TYP~ Type of drive Resistance n Purge solenoid valve Solenoid resistance n 1 23-27 (at 20°C (68°F)) I Nylon element Pressure regulator TY pe High-ohmic Voltage 13.8 (at 20°C (68"FI) Engine coolant temperature sensor 7 20°C {68"F) I 2.21 -2.69 Resistance kn I 80°C (1 76OF} I 0.287-0.349 High-pressure side Diaphragm i/ Crankshaft position sensor Air valve Openin~l temperature OC {OF) I Below 45 (1 131 Paper element Twe 1 Fuel tank I Hall effect . . . . . . . Capacity L {US gal, Imp gal) I 48 {12.7, 10.5) Air cleaner housing Element type Free play mm (in) I 1-3 {0.039--0.118) I Fuel Oil permeated Specification Accelerator cable Unleaded regular (RON 87 or higher) J +....with system selector (49 B019 9AO) test switch at SELF TEST Gartner Banana

Page 1115 of 1708

TECHNICAL DATA TI) G. ENGINE ELECTRICAL SYSTEM )ark current*' - Engine tem Voltage V 3attery Type and capacity (5-hour rate) Starter -. . BP DOHC MT mA 1 20.0 AT Tvm Ignition system 12, Negative ground S46A24L(S) (32 Ah) Maintenance-free A.C. ST- Output V-A Regulator type Regulated voltage V 12-65 Brush length mm {in) Drive belt deflection mm {in) 17.5 (0.69) 12.0 (0.471 - -- r-- I I hPe Spark plug 1 2-70 Standard Minimum New Used Brush length mm {in) BKR6E-11 (Standard ... MT) NIPPONDENSO : K16PR-U11 K20PR-U11 (Standard ... MT, AT) TYW OU~DU~ V-kW Standard 1 17.0 I0.67) Minimum 1 11.5 10.451 1 Type Spark advance control Ignition timing*2 BTDC ("CA)/rpm Transistorized (built-in voltage regulator) 14.3-1 4.9 21.5 (0.85) 8 I0.31) 5.5-7.0 {0.22--0.27) 6.0-7.5 {0.24--0.29) . . I . . Electronic spark advance (ESA) Powertrain control module (engine) controls spark advance Ignition coil H. CLUTCH Direct lot850 TY ~e Primary coil winding a Secondary coil winding ks2 . .- - Engine Item BP DOHC 1 Coaxial reduction 10/800 Molded (with igniter) - 8.7-1 2.9 NGK : BKR5E-11 *I Dark current is the.constant flow of current while the ignition switch is OFF. (i.e. powertrain control module (engine), audio, etc.) '2 With System Selector (49 B019 9AO) test switch at SELF TEST. , Plug gap mm (in) Firing order 124.95 1 .O-1.1 {0.040--0.043) 1-342 Clutch control Runout limit mm {in) 1 0.2 (0.008) I 12-1.4 Hydraulic Clutch pedal TYP Suspended A .- 6.13 120 (4.72) 175--185 {6.89--7.28) 0.G3.1 (0.02-0.12) 68 I2.68) Pedal ratio Full stroke mm {in) Height (with carpet) mm (in} Free play mm {in} Distance to carpet when clutch fully disengaged rnm [in Minimum Gartner Banana

Page 1116 of 1708

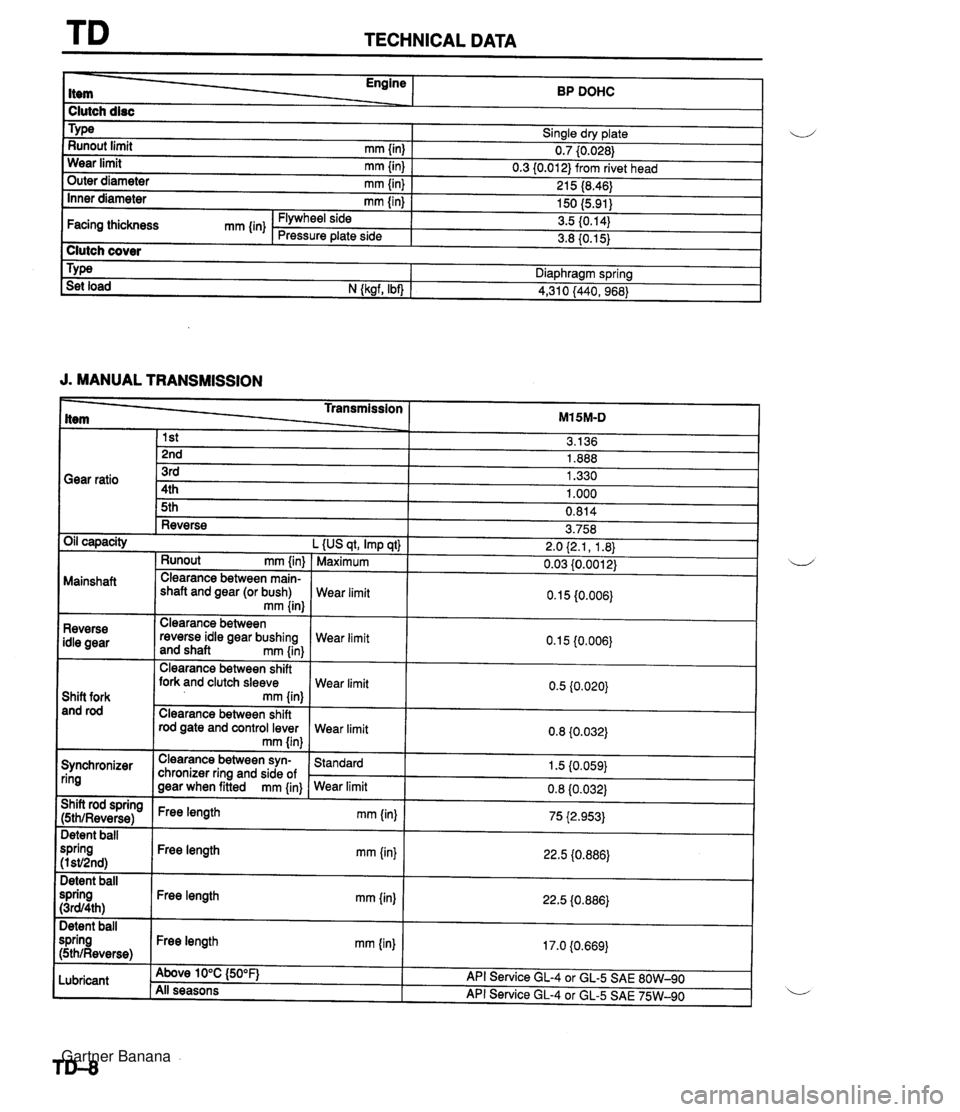

TECHNICAL DATA Engine ------ BP DOHC I Clutch disc I Sinale drv date I u - w- ., Runout limit rnrn {in) 0.7 (0.026) Wear limit rnm linl 0.3 10.01 2) from rivet head . a, 1 outer diameter mm {in) I 215 (8.46) 1 J. MANUAL TRANSMISSION 150 (5.91) 3.5 (0.14) 3.8 (0.15) Inner diameter mm {in) Type _____L- Transmission ___2_ M15M-D Clutch cover Facing thickness mm {in) Diaphragm spring Flywheel side Pressure plate side Set load N {ksrf. Ibn 1 4,310 /440. 968) Gear ratio Runout rnm {in) Mainshaft Clearance between main- shaft and gear (or bush) mm {in} t-- Reverse Oil capacity L {US qt, Imp qt) 1 Maximum 3rd 4th 5th 3.758 2.0 (2.1, 1.8) 0.03 10.001 2) Clearance between shift fork and clutch sleeve Shift fork and rod rod gate and control lever 1.330 1 .OOO 0.814 Reverse idle gear Clearance between reverse idle gear bushing and shaft mrn {in) Synchronizer ring Wear limit Wear limit Clearance between syn- chronizer ring and side of gear when fitted mm {in} Wear limit 0.1 5 {0.006) Wear limit Wear limit I 1 mm {in) ( 75 i2.953) Standard 1.5 (0.059) 22.5 (0.886) 22.5 i0.886) 17.0 (0.669) Detent ball spring (I sV2nd) Detent ball spring (3~94th) Detent ball spring (5thlReverse) Lubricant Free length mm (in) Free length mrn {in) Free length mm {in) Above 10°C {50°F} All seasons API Service GL-4 or GL-5 SAE 80W-90 API Service GL-4 or GL-5 SAE 75W-90 Gartner Banana

Page 1120 of 1708

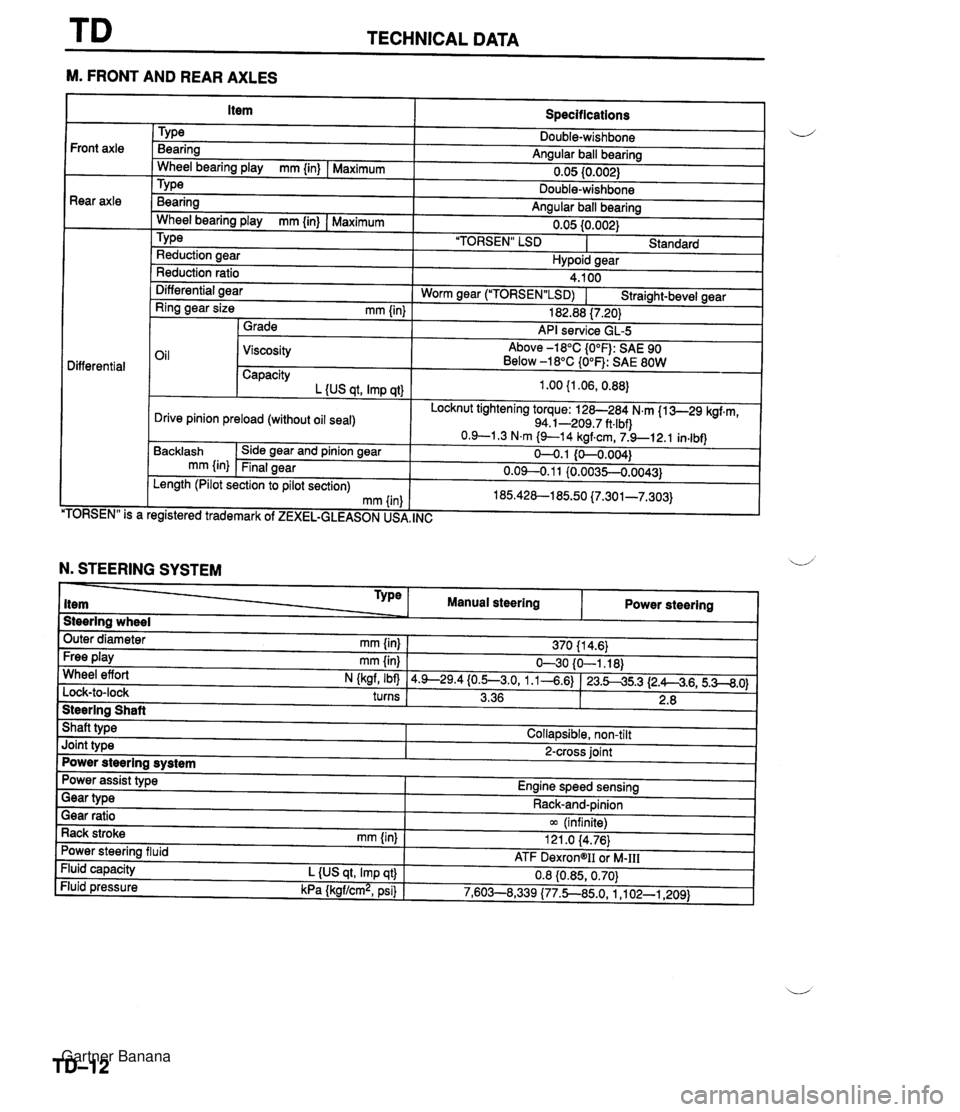

TECHNICAL DATA --- M. FRONT AND REAR AXLES Specifications TY pe Bearing Angular ball bearing 0.05 10.002) Front axle Rear axle - Wheel bearing play mm {in) I Maximum Bearina Anaular ball bearina . .. Wheel bearina plav mm {in) I Maximum " " 0.05 {0.002) 'TORSEN" LSD I Standard TY pe Reduction aear Hvpoid sear Reduction ratio Differential aear 4.100 Worm near ("1ORSEN"LSD) I Straiaht-bevel gear - - Ring gear size mm {in) 1 Grade 182.88 17.201 API service GL-5 Oil 1 Viscosity Above -18°C {O°F): SAE 90 Below -18°C {O°F): SAE 80W Differential Capacity L {US at. Imp at) Locknut tightening torque: 128-284 N.m {I 3-29 kgf.m, 94.1-209.7 ft.lbf) Drive pinion preload (without oil seal) TORSEN" is a Backlash mm {in) . , egistered trademark of ZEXEL-GLEASON US, Side gear and pinion gear Final gear , INC Length (Pilot section to pilot section) mm (in N. STEERING SYSTEM Steering wheel Outer diameter mm {in} 1 370 11 4.6) Type item Free play mm {in) I 630 {O-1.18) Wheel effort N (kaf, Ibfl 14.9--29.4{0.5--3.0, 1.1-4.6) 123.545.3 12.A4.6,5.3--8.0) turns I 3.36 1 2.8 I 1 Manual steering Steering Shaft Shaft type I Collapsible, non-tilt Power steering Joint type I 2-cross joint Power steering system Gear ratio 1 m (infinite) Rack stroke rnm {in) I 121 .O 14.76) Power assist type Engine speed sensing Power steering fluid Fluid capacity L {US qt, Imp qt} Fluid pressure kPa {kgf/cm2, psi) Gear type - - ATF DexrongII oi M-111 0.8 {0.85,0.70) 7,603--8,339 (77.5850, 1 ,I 02-1,209) Rack-and-pinion Gartner Banana

Page 1122 of 1708

TECHNICAL DATA R. SUSPENSION Front sus~ension I i/ Differential - . - ~- Coil springs MT I AT Shock absorbers "TORSEN" LSD TY ~a Cylindrical double-acting, low-pressure gas charged Standard Stabilizer Double-wishbone Torsion bar Wire diameter mm {in) Coil inner diameter mm {in} Rear suspension Tv~e I Double-wishbone TY pe Diameter mm {in) 20.0 (0.79) I Identification color 11 .O {0.43} 83.0 f3.27) . . Free length mm {in) Coil number 19.0 {0.75} . . 292.5 (1 1.52) 1 302.0 {I 1.89) 6.32 I - . I1 . ,I . , I Shock absorbers Cylindrical double-acting, low-pressure gas charged White I I Identification color I Yellow I Green I Blue Torsion bar 12.0 (0.471 1 11 .O 10.43) .a Stabilizer TYPe Diameter mm {in) Coil springs Wheel alignment I Front wheel alignment (Unladen'') I I - Caster angle*3 King pin angle I tun'aoen 'I 1 Camber angle'2 -0°43' 2 30' I I - Wire diameter mm {in) Coil inner diameter mm {in) Free length mm {in} Coil number Maximum steering angle 4O26' -c 45' 11 "20' Rear wheel alignment ,, l-l_A_-*i, *1 Fuel tank full; radiator coolant and engine oil at specified level, and spare tire, jack, and tools in designated position. *2 Difference between left and right must not exceed lo. *3 Difference between left and right must not exceed 1'30'. 10.1 (0.40) Inner Outer 10.2 I0.40) mm (in) Camber ana~e*~ J 3 + 3 10.12 r 0.12) 0°18' 2 18' -. - 3 r 3 {0.12 2 0.12) 0'24' 2 45' 37O23' 2 2" 32O32' 2 2" Total toe-in 83.0 i3.27) U' mm {in} degree 348.5 113.72) Total toe-in 356.5 {I 4.04) dearee 7.68 0'18' & 18' 7.96 Gartner Banana

Page 1323 of 1708

![MAZDA MX-5 1994 Owners Manual UNDERCOATING, PVC PAINTING AND RUST PREVENTIVE WAX TREATMENT Air dry a minimum of 4-6 hours [20°C (68OF)l. L Heat dry a minimum of 30-40 minutes [60°C (140°F)]. Color coat i Apply coating afte MAZDA MX-5 1994 Owners Manual UNDERCOATING, PVC PAINTING AND RUST PREVENTIVE WAX TREATMENT Air dry a minimum of 4-6 hours [20°C (68OF)l. L Heat dry a minimum of 30-40 minutes [60°C (140°F)]. Color coat i Apply coating afte](/img/28/57072/w960_57072-1322.png)

UNDERCOATING, PVC PAINTING AND RUST PREVENTIVE WAX TREATMENT Air dry a minimum of 4-6 hours [20°C (68OF)l. L Heat dry a minimum of 30-40 minutes [60°C (140°F)]. Color coat i Apply coating after PVC paint film is thoroughly dry. Sanding is not necessary if all oil and grease were completely removed. Conditions such as air pressure, paint viscosity, etc. can be same as for ordinary body coating. -1 Done in same way as for ordinary body coating. Nozzle type A Nozzle type B RUST PREVENTIVE WAX TREATMENT WAX APPLICATION PROCEDURE Preparation of equipment 1. Prepare equipment suitable for the wax chosen. 2. Use the correct nozzle, spray pattern, and in- jection pressure based on instructions provided for the wax. 3. If necessary, clean the nozzle with thinner before beginning work. Preparation of vehicle (or parts) 1. Scrape mud, etc. off the wax application area. 2. Dry any water collected at the wax application area. 3. The temperature of the vehicle body should be kept at more than 10°C (50°F) during the opera- tion. 4. Close all windows of the vehicle. Caution When repairing a damaged part, complete painting first, then apply the wax. The reasons are: a) The wax is sometimes dissolved by heat [more than 120°C (248OF)I during the drying process, resulting in deteriorated anticor- rosion effects. b)lf the wax applied before painting is smeared over the paint application surface, poor painting will result because the wax repels the paint. Gartner Banana