light MAZDA MX-5 1994 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 699 of 1708

P PARKING BRAKE SYSTEM PARKING BRAKE SYSTEM TROUBLESHOOTING GUIDE I Problem I Possible cause I Brake fluid or oil on pads -- Brakes do not release Parking brake does not hold well I Hardening of pad surfaces or poor contact Improper return of parking brake cable or improper adjustment Excessive lever stroke Brake cable stuck or damaged Action 1 page 1 d Repair or adjust Adjust Repair or replace Clean or replace Grind or replace 25UOPX-026 PARKING BRAKE LEVER Inspection 1. Depress the brake pedal several times. 2. Verify that the stroke is within specification when the parking brake lever is pulled with a force of 196 N (20 kgf, 44 Ibf). Stroke: 7-9 notches Adjustment 1. On level ground, jack up the rear of the vehicle until the wheels are free to turn, and support it with stands. 2. Depress the brake pedal several times. 3. Remove the cover. 4. Turn the adjusting nut to adjust the lever stroke. --/, 5. Depress the parking brake pedal one notch, and verify that the parking brake warning light comes on. Release the parking brake. 6. Turn the wheels by hand, and verify that the brakes do not drag. 7. Lower the vehicle. Gartner Banana

Page 700 of 1708

PARKING BRAKE SYSTEM P Removal 1 Inspection / lnstallation 1. Block the wheels firmly. 2. Release the parking brake. - 3. Remove in the order shown in the figure. 4. lnspect all parts and repair or replace as necessary. 5. Install in the reverse order of removal, referring to lnstallation Note. 6. After installation, adiust the arki in^ lever stroke. (Refer to page P-34.) 1. Screw 6. Release button 2. Cover 7. Spring 3. Bolt Inspect for weakness 4. Parking brake switch 8. Bolt lnstallation Note . . . . . . . . . . . . . . . . . below 9. Parking brake lever lnspect for damage and cracks 5. Adjusting nut and clip lnstallation note Parking brake switch 1. Install the parking brake switch so that it contacts the parking brake lever when the lever is fully released. 2. Turn the ignition switch ON, and verify that the parking brake warning light illuminates with the lever pulled up one notch. Gartner Banana

Page 702 of 1708

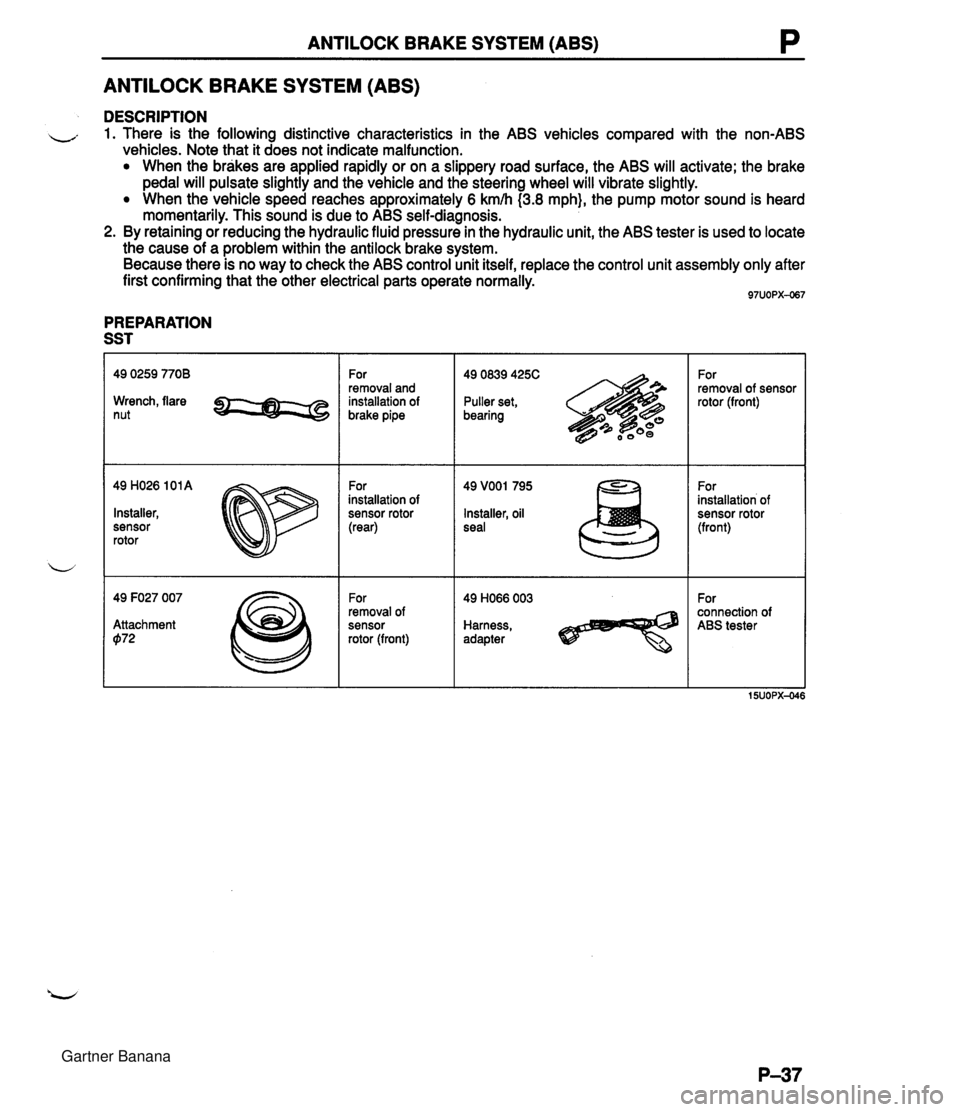

ANTILOCK BRAKE SYSTEM (ABS) P ANTILOCK BRAKE SYSTEM (ABS) DESCRIPTION - 1. There is the following distinctive characteristics in the ABS vehicles compared with the non-ABS vehicles. Note that it does not indicate malfunction. When the brakes are applied rapidly or on a slippery road surface, the ABS will activate; the brake pedal will pulsate slightly and the vehicle and the steering wheel will vibrate slightly. When the vehicle speed reaches approximately 6 kmh (3.8 mph}, the pump motor sound is heard momentarily. This sound is due to ABS self-diagnosis. 2. By retaining or reducing the hydraulic fluid pressure in the hydraulic unit, the ABS tester is used to locate the cause of a problem within the antilock brake system. Because there is no way to check the ABS control unit itself, replace the control unit assembly only after first confirming that the other electrical parts operate normally. PREPARATION SST Wrench, flare nut 49 H026 101 A Installer, sensor rotor 49 F027 007 Attachment 072 For removal and installation of brake pipe For installation of sensor rotor (rear) For removal of sensor rotor (front) 49 0839 425C Puller set, bearing Installer, oil seal Harness, adapter For removal of sensor rotor (front) For installation of sensor rotor (front) For connection of ABS tester Gartner Banana

Page 704 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P LISTED BELOW IS AN EXPLANATION OF THE 5B. BRAKE LIGHT SWITCH TEST PROCEDURE - INDICATES TESTER DISPLAY I u U ,INDlCAlES ( TESTER SWITCHES I PRESS BRAKE PEDAL FIRMLY AND HOLD PRESSURE.. . I IF NO FAULTS A'RE DETECTED. IF A FAULT I; DETECTED. TESTER WILL DISPLAY: TESTER WILL DISPLAY. TESTER WlLL GlVE INST RUCTIONSIINFORMATION. "THEN* INDICATES THE TESTER WlLL ALTERNATE THE TWO DISPLAYS. TESTER "ASKS A OUESTION" WHICH MUST BE ANSWERED BY PRESSING THE SWITCH UNDER THE DESIRED ANSWER. NOTE: IN THIS CASE. PRESS YES - TEST CONTINUES. PRESS NO - T ESTER DISPLAYS: PRESS BRK - - - - HOLD TESTER WlLL PROCESS INFORMATION. 1 IYES CONTINUE? NO[ TESTER WlLL GlVE NEW INStRUCTIONSllNFORMATI~ AND CONTINUE. Gartner Banana

Page 707 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) (Cont .) I THEN YES LIGHT? NO (Is AntlLock Light On?) PRESS: -OR - t CHK ANTILOCK (Check AntlLock Llght) I T HEN I PRESS: PRESS THE BRAKE PEDAL FIRMLY ANDHOLO PRESSURE I THEN + !YES PRESSED? NO! PRESS: Q -0R- IF NO FAULTS ARE DETECTED, TESTER WILL DISPLAY IF A FAULT IS DETECTED TESTER WILL DISPLAY: PRESS: ql Gartner Banana

Page 714 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P Inspection of ABS system Check system ground Caution To prevent damage to the terminals, create a probe by wrapping a thin wire around the tester lead before inserting. Check for an open circuit in (B) wire from terminals 1 Dl 1 S, and 2F of the control unit connector and ground. Check antilock warning light 1. Remove the instrument cluster. 2. Connect 12V to terminal 2K (C-Ol), and ground to termi- nal 1 K ((2-01). 3. Verify that the ABS warning light illuminates. 4. If there is no illumination, check the meter fuse, bulb, and wiring harness. 5. If OK, check the wiring harness (Warning light - Control unit - Hydraulic unit) and repair or replace as necessary. Check ABS diode 1. Check the meter fuse, bulb, and wiring harness. 2. Check the wiring harness (Warning light - Control unit - Hydraulic unit). 3. Disconnect the hydraulic unit 12-pin connector. 4. Using an ohmmeter, check for continuity of the terminals. 5. If continuity is not as specified, replace the hydraulic unit. Check front and rear valves 1. Disconnect the hydraulic unit 12-pin connector. 2. Using an ohmmeter, check for resistance of the termi- nals. -- 3. If resistance is not as specified, replace the hydraulic unit. 4. If resistance is as spe'cified, check the wiring harness (Hydraulic unit - ABS control unit). E (YIG) - H (B) (Rear Valve) C (BR) - H (B) (Right Front Valve) A (B/W) - H (B) (Left Front Valve) Check brake light switch 1. Disconnect the brake light switch connector. 2. Check for continuity between the terminals of the switch. Resistance (n) Approx. 1 .O-1.2 Approx. 1.0-1.2 Approx. 1 .+I .2 M : Indicates continuity Depressed brake pedal 3. If the continuity is not as specified, check the STOP fuse and wiring harness (Brake light switch - Control unit). 0 I 0 Released brake pedal Gartner Banana

Page 763 of 1708

HOOD s HOOD COMPONENTS Removal / Installation 1. Remove in the order shown in the figure. 2. Install in the reverse order of removal. 1. Headlight seal 5. Hinge 2. Side headlight seal 6. Hood stay 3. Washer pipe 7. Hood lock 4. Hood Adjustment .................. page S-6 Adjustment .................. page S-6 8. Release wire Gartner Banana

Page 769 of 1708

WINDOW REGULATOR, GLASS, AND GUIDE s Vertical adjustment of door glass 1. Loosen the upper glass stopper installation bolts. 2. Lower the door glass slightly. 3. Move the upper glass stoppers up or down so that the upper edge of the door glass is in the correct posi- tion. 4. Tighten the installation bolts. Tightening torque: 7.9-10.7 N-m (80-110 kgf-cm, 70-95 imlbf} CORRECT TOO HIGH POSITION TOO LOW GLASS RETAINER SEC. A-A CONVERTIBLE TOP DETACHABLE HARDTOP RETAINER MOUNTING HOLE No.5 RETAINER MOUNTING HOLE No.1 / RETAINER MOUNTING HOLE No.1 /&INER MOUNTING HOLE N0.8 7 RETAINER GLASS % SEC. E-E RETAINER 9.1 2 2.0 I0.36 * 0.08) SEC. F-F mm (in} Gartner Banana

Page 776 of 1708

s TRUNK LID LOCK AND OPENER TRUNK LID LOCK AND OPENER COMPONENTS Removal / Installation 1. Remove in the order shown in the figure. 2. Install in the reverse order of removal. Rear console 6. Rear combination light .................... Removal 1 Installation ....... page S-56 Removal Section T Opener lever 7. Rear finisher ............. Opener cable Removal Note page S-28 4. Trunk end trim 8. Key cylinder 5. Trunk lid lock assembly 9. Striker ..................... Adjustment below Adjustment Trunk lid lock assembly Verify that the trunk lid can be closed easily and that there is no looseness. If necessary, loosen the lock assembly mounting bolts and adjust the lock assembly. Gartner Banana

Page 782 of 1708

s FRONT BUMPER FRONT BUMPER COMPONENTS Removal 1 Installation 1. Raise the headlights. 2. Disconnect the negative battery cable. 3. Remove in the order shown in the figure. 4. Install in the reverse order of removal. Front combination light 6. Set plate Removal .................... Section T 7. Front fascia Front side marker light 8. Retainer Removal .................... Section T 9. Bumper reinforcement 3. Fender bracket 10. Spacer 4. Mud guard 11. Front bumper retainer 5. Grille cover 12. Front bumper bracket Gartner Banana