fuel MAZDA PROTEGE 1992 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 397 of 1164

231JOFX-1

FUEL SYSTEM F

INJECTOR

Inspection

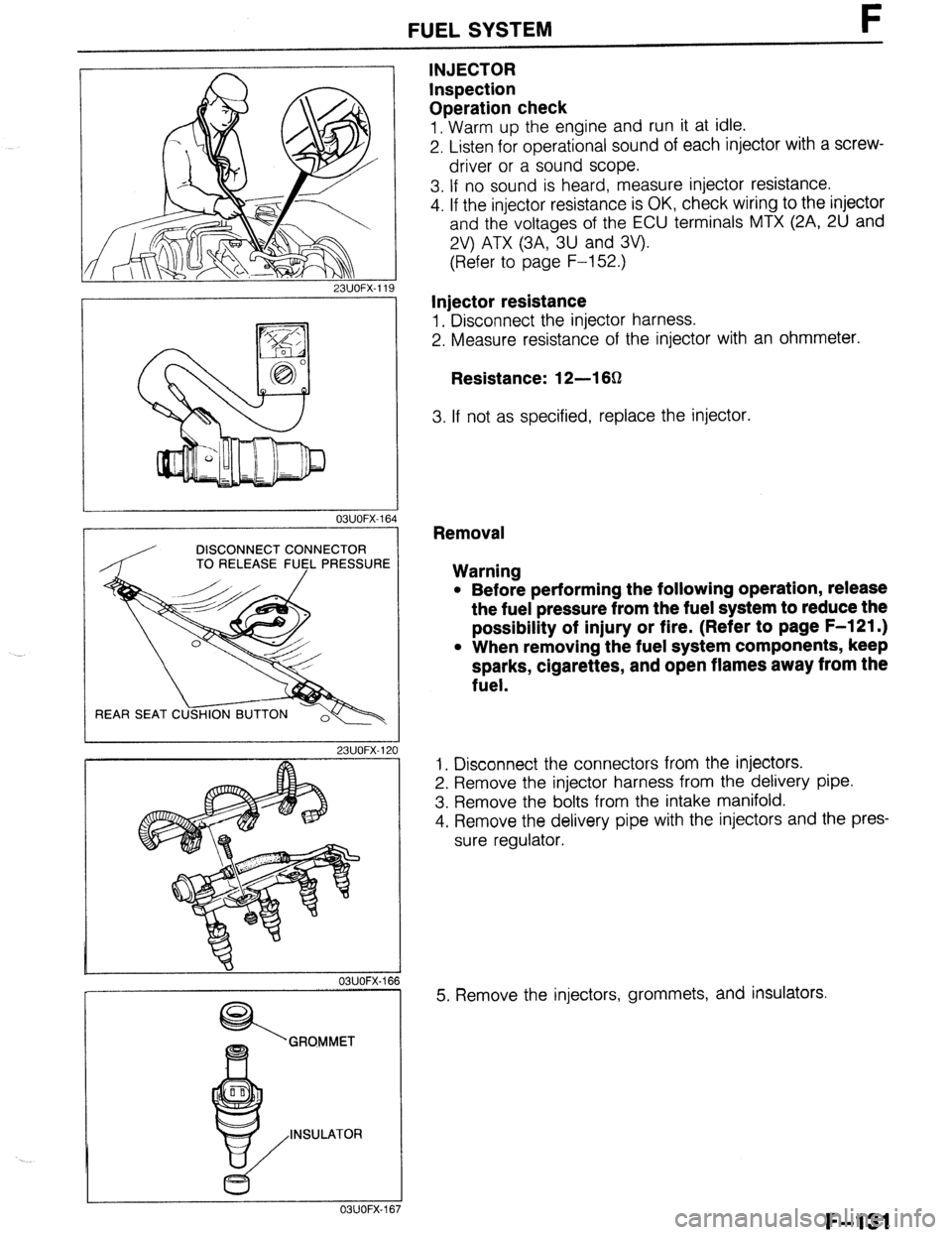

Operation check

1. Warm up the engine and run it at idle.

2. Listen for operational sound of each injector with a screw-

driver or a sound scope.

3. If no sound is heard, measure injector resistance.

4. If the injector resistance is OK, check wiring to the injector

and the voltages of the ECU terminals MTX (2A, 2U and

2V) ATX (3A, 3U and 3V).

(Refer to page F-152.)

Injector resistance

1. Disconnect the injector harness.

2. Measure resistance of the injector with an ohmmeter.

Resistance: 12-l 6Q

3. If not as specified, replace the injector.

03UOFX-1

DISCONNECT CONNECTOR

TO RELEASE FU5L PRESSUR

REAR SEAT C

23UOFX-1

OBUOFX-

GRQMMET

INSULATOR

c5

OSUOFX-

Removal

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121 .)

l When removing the fuel system components, keep

sparks, cigarettes, and open flames away from the

fuel.

1. Disconnect the connectors from the injectors.

2. Remove the injector harness from the delivery pipe.

3. Remove the bolts from the intake manifold.

4. Remove the delivery pipe with the injectors and the pres-

sure regulator.

5. Remove the injectors, grommets, and insulators.

F-131

Page 398 of 1164

l Be extremely careful when working with fuel. I

23UOFX.121 Always work away from sparks or open flames.

3. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

FUEL SYSTEM

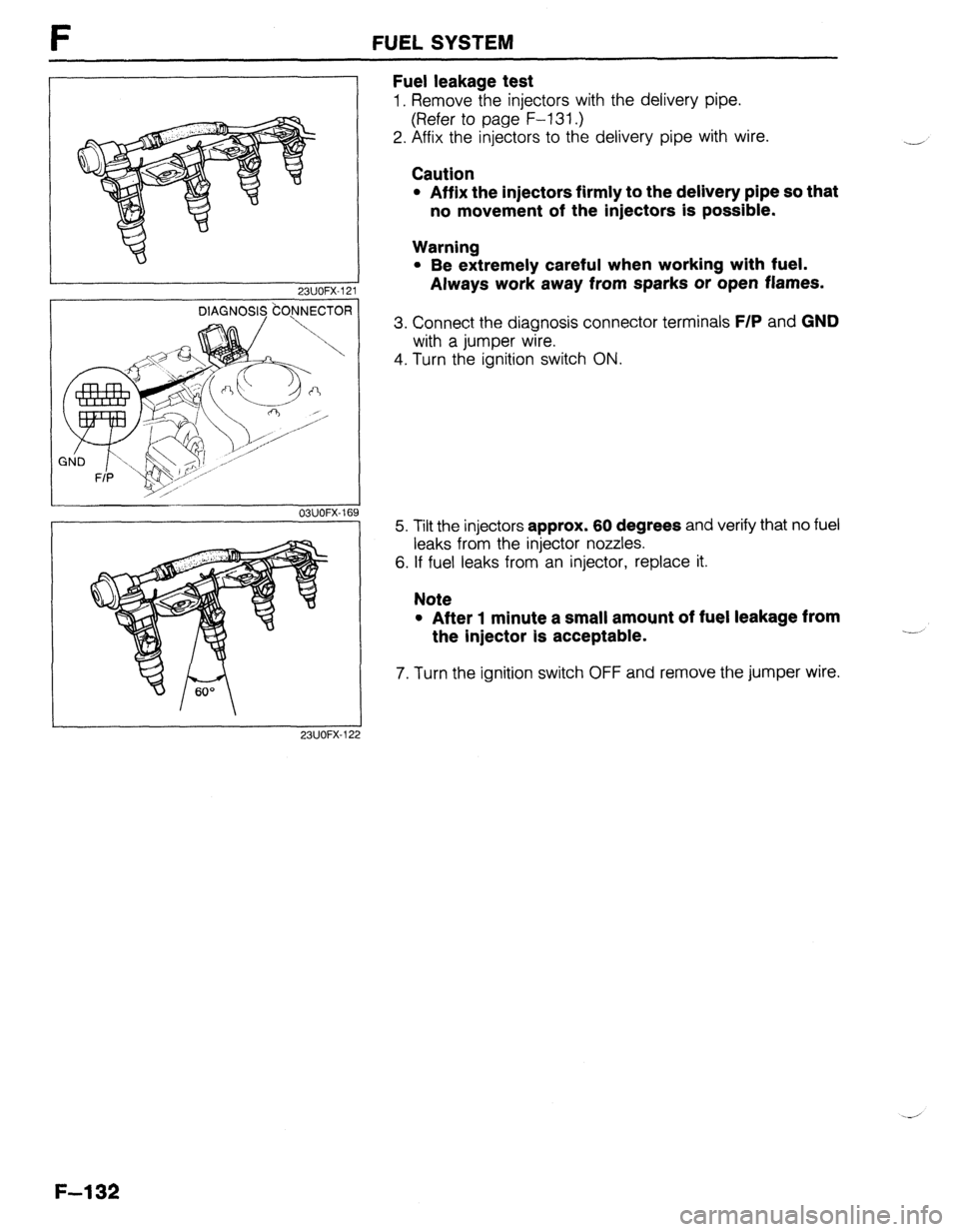

Fuel leakage test

1. Remove the injectors with the delivery pipe.

(Refer to page F-l 31.)

2. Affix the injectors to the delivery pipe with wire.

Caution

l Affix the injectors firmly to the delivery pipe so that

no movement of the injectors is possible.

-

Warning

4. Turn the ignition switch ON.

03UOFX-16’

23UOFX-12 9 5. Tilt the injectors approx. 60 degrees and verify that no fuel

leaks from the injector nozzles.

6. If fuel leaks from an injector, replace it.

Note

l After 1 minute a small amount of fuel leakage from

the injector Is acceptable.

7. Turn the ignition switch OFF and remove the jumper wire.

-i

F-l 32

Page 399 of 1164

FUEL SYSTEM I-

9MUOF2-17

INJEC

GRO

,:.: ‘.L.. :

,;:y :.*‘.

+:: ..y&

..: .:: ,: ,:y>

‘$pID~~ :i

..,..:,:,

,.,i. :)I,

./[::/: :

. ...:;.

/jj,.‘, ;.::,::

.’ .::: ij!/ji..

OSUOFX-17

T MANIFOLD DELIVERY’ PIPE

MUOFX-17

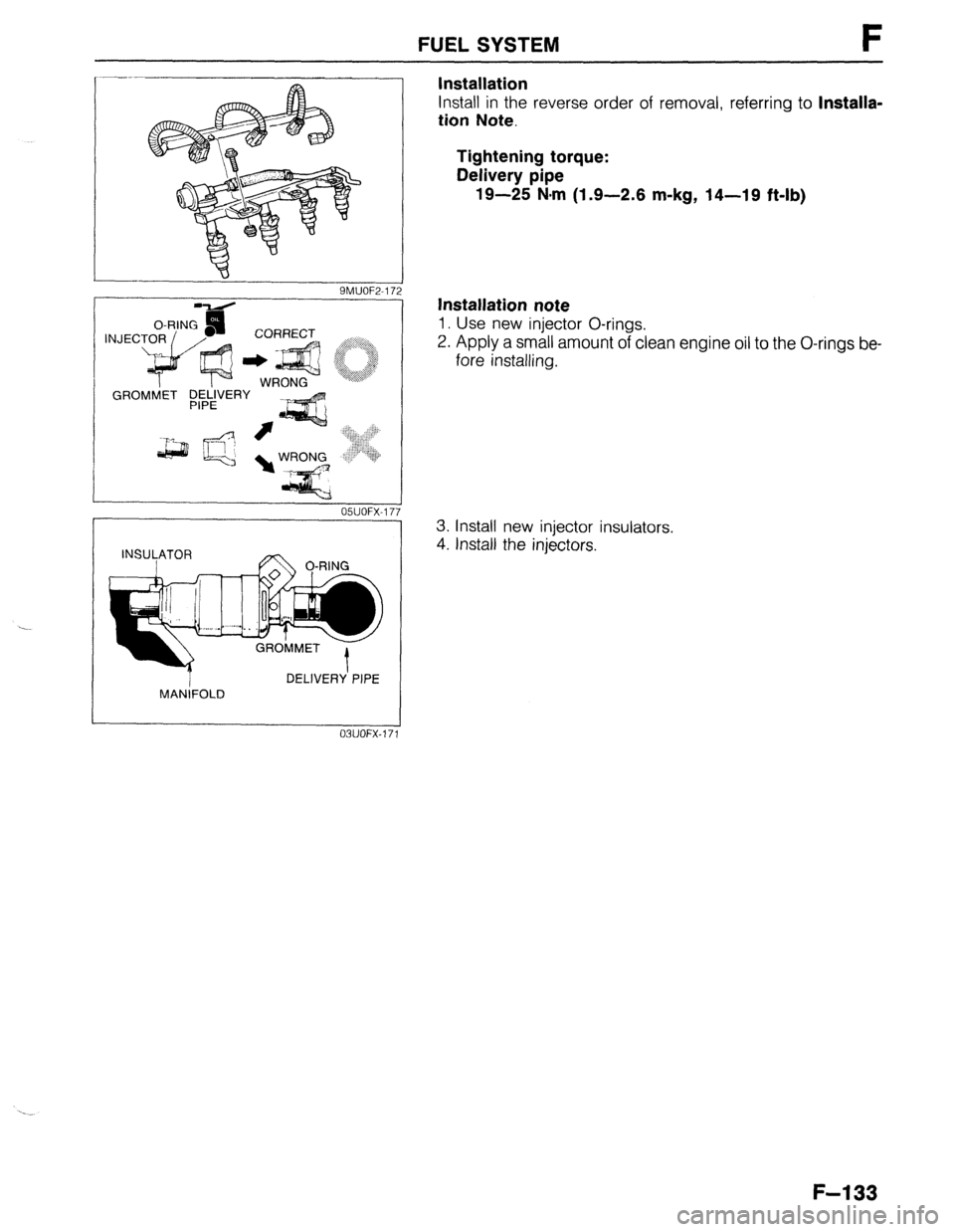

Installation

Install in the reverse order of removal, referring to Installa-

tion Note.

Tightening torque:

Delivery pipe

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

Installation note

1. Use new injector O-rings.

2. Apply a small amount of clean engine oil to the O-rings be-

fore installing.

3. Install new injector insulators.

4. Install the injectors.

F-l 33

Page 400 of 1164

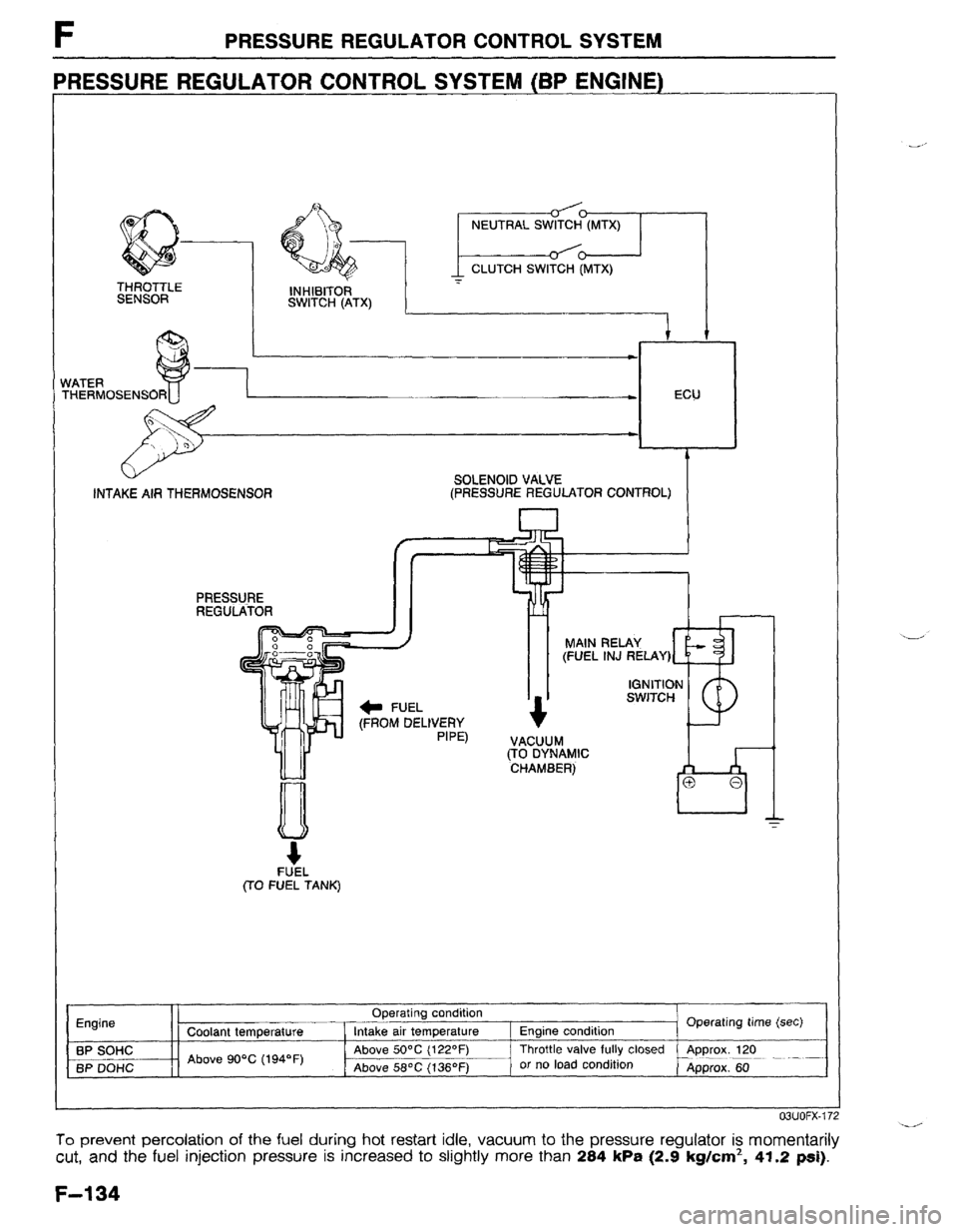

F PRESSURE REGULATOR CONTROL SYSTEM

PRESSURE REGULATOR CONTROL SYSTEM (BP ENGINE)

THERMOSEN

SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

(FROM DELIVERY

FUEL

(TO FUEL TANK)

Engine

BP SOHC

BP DOHC Coolant temperature

Above 90% (194*F) Operating condition

Intake air temperature

Above 50°C (122OF)

Above 58OC (136OF) Engine condition . Operating time (set)

Throttle valve fully closed

Approx. 120

or no load condition

Approx. 60

#.nr IAt-%/ 4 7

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator is momentarily

cut, and the fuel injection pressure is increased to slightly more than 284 kPa (2.9 kg/cm2, 41.2 psi).

F-l 34

Page 407 of 1164

EVAPORATIVE EMISSION CONTROL SYSTEM F

-l CHECK-AND-CUT VALVE

Inspection

1. Remove the check-and-cut valve.

2. Connect a pressure gauge to the passage connected to

the fuel tank.

3. Blow through the valve from port A and verify that the valve

opens at 6.36-6.34

kPa (0.065-0.065 kg/cm2,

0.92-l 2.09 psi).

4. Remove the pressure gauge and connect it to the passage

to atmosphere.

5. Blow through the valve from port B and verifyjhat the valve

opens at

0.96-4.91 kPa (0.01-0.05 kg/cmL, 0.14-0.71

psi). 1 9MUOF2-194

Note

l The test must be performed with the valve held

horizontally. Otherwise, the ball in the valve will

move out of position and close the passage.

CHARCOAL CANISTER

Inspection

1. Visually check for damage and replace the charcoal canis-

ter if necessary.

F-141

Page 409 of 1164

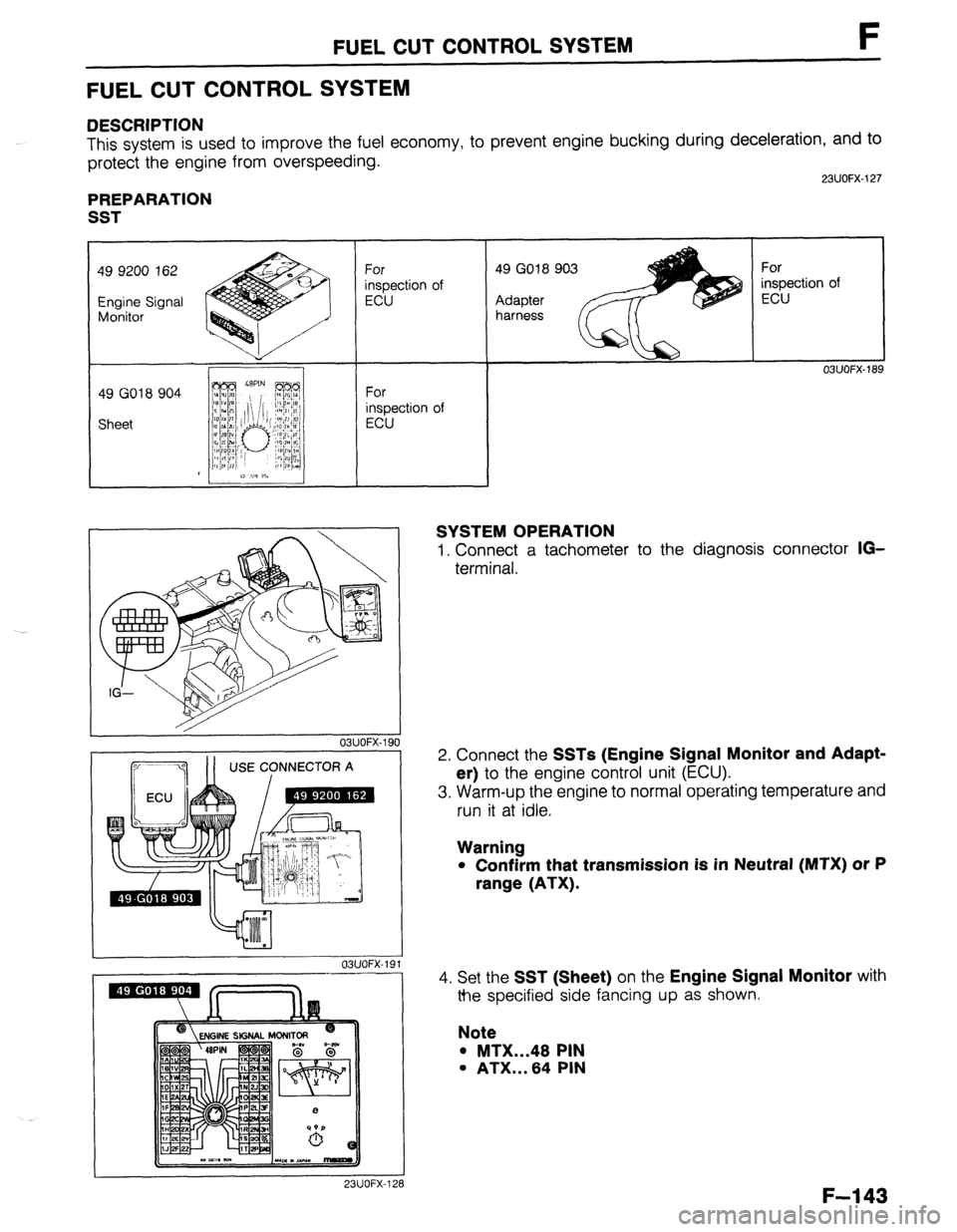

FUEL CUT CONTROL SYSTEM F

FUEL CUT CONTROL SYSTEM

DESCRIPTION

This system is used to improve the fuel economy, to prevent engine bucking during deceleration, and to

protect the engine from overspeeding.

23UOFX-127

PREPARATION

SST

r

49 9200 162

03UOFX.191

l7=---T II USE CPNNECTOR A

03UOFX-19

SYSTEM OPERATION

1. Connect a tachometer to the diagnosis connector IG-

terminal.

2. Connect the

SSTs (Engine Signal Monitor and Adapt-

er)

to the engine control unit (ECU).

3. Warm-up the engine to normal operating temperature and

run it at idle.

Warning

l Confirm that transmission is in Neutral (MTX) or P

range (ATX).

4.

Set the SST (Sheet) on the Engine Signal Monitor with

the specified side fancing up as shown.

Note

l MTX...48 PIN

l ATX...64 PIN

I 23UOFX-128

F-l 43

Page 410 of 1164

F FUEL

23UOFX-12:

0-6V

23UOFX- 131

to the terminal 2U or 2V (MTX), 3U or 3V (ATX)

hat the green and red lamps flash alternately.

nd No,3.....ECU terminal 2U (MTX)

3U (ATX)

. . . ..ECU terminal 2V (MTX)

3V (ATX)

6. Increase the engine speed to 4,000 rpm and then suddenly

release the throttle.

7. Verify that the red indicator lamp illuminates while the en-

gine speed is above approx.

1,900 rpm on deceleration.

t aced maximum rpm over 3 sec.

8. Increase the engine speed and verify that the maximum rpm

does not exceed specification.

.

.

. ..“.*..1”*“.-.“.....*......*...

Approx. 7,300 rpm

. . ..I......m....“.....*........m Approx. 6,300 rpm

F-l 44

Page 411 of 1164

DECHOKE CONTROL SYSTEM t-

DECHOKE CONTROL SYSTEM

DESCRIPTION

To facilitate starting the engine when the spark plugs become fouled, such as when the engine is flooded,

fuel injection is cut if the throttle valve is held wide open while cranking and the engine coolant temperature

is O°C (32OF) or below. This allows the spark oluas to drv and purges excess fuel from the cylinders.

f-- ECU _

. IGNITION SWITCH (START)

l ENGINE SPEED BELOW 500 rpm ’

l THROTTLE VALVE FULLY OPEN

l ENGINE COOLANT TEMPERATURE ;

BELOW

0% (32°F) I FUEL CUT

OBUOFX-19

I / / ‘ I

SYSTEM OPERATION

1.

2. Check if the engine coolant temperature is below O°C

(32OF).

If the engine coolant temperature is above O°C (32OF), dis-

connect the water thermosensor connector and connect an

approx. 10 kB resistor to the connector.

03UOFX.198 3. Turn the ignition switch to START and verify that the injec-

OBUOFX-19! 3

tor operating sound is heard.

4. Depress the accelerator pedal fully and turn the ignition

switch START. Verify that no injector operating sound is

heard.

F-l 45

Page 414 of 1164

F CONTROL SYSTEM

STRUCTURAL VIEW

23UOFX-1:

1. Engine control unit (ECU) 8. Solenoid valve (Pressure regulator control)

- .--

Removal / Installation . . . . . . . . . . . . . . . . page F-149

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-149

2. Circuit opening relay

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 29

Inspection ,...,........................... page F-l 29

3. Clutch switch (MTX)

inspection . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 72

4. Airflow meter (With intake air thermosensor)

Inspection .,..........,...,............... page F-l 68

5. ISC valve

Inspection .,*,........,.,.........,....... page F-116

Removal / Installation . . . . . . . . ,.... page F-l 09

G-Throttle sensor

Inspection . . . . . . . . . . . . , . . . . . . page F- 169

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 09

7. Solenoid valve (VICS) [DOHC]

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 18 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Water thermosensor

Inspection. . . . . . . .

Removal I Installation ....I..........

10. Solenoid valve(Purge control)

Inspection ,............ ,..................

11, Main relay (FUEL INJ relay)

Inspection. ..,............................

12. Neutral switch (MTX)

Inspection ,.,,,,....I.l,,.........I.......

Replacement . . . . . . .

13. Oxygen sensor

Inspection,. . . .

Replacement . , . . . .

14. P/S pressure switch

Inspection . . ..__.._._._........

Replacement . , . . . . . . . . . . . . . page t-135

page F-l 68

page F--l 68

page F-l 40

page F-172

page F-l 73

page F-173

page F-171

page F-172

--

page F-173

page F-173

F-l 48

Page 416 of 1164

CONTROL SYSTEM

Terminal voltage (MTX)

VB: Battery voltage

wminal Input Output Connection to Test condition Correct voltage Remark

1A - - Battery Constant VB For backup

1B 0 Main relay OFF OV

(FUEL INJ relay) Ignition switch ._-

ON VB

1c 0 Ignition switch While cranking Approx. 10V

(START) -

Ignition switch ON ov

10 0 Self-Diagnosis Test switch at “SELF-TEST” With Self-

Checker Lamp illuminated for 3 sec. after ignition 4.5--5.5v Diagnosis Check-

(Monitor lamp) switch OFF+ON er and System

Lamp not illuminated after 3 sec. VEI Selector

Test switch at “02 MONITOR” at idle

Monitor lamp illuminated 4.5-5.5v

Test switch at

“02 MONITOR” at idle

Monitor lamp not illuminated Va

1E 0 Malfunction indica- Lamp illuminated for 3 sec. after ignition

Below 2.5V With System

tor lamp (MIL) switch OFF-ON Selector test

Lamp not illuminated after 3 sec.

VB switch at

“SELF-TEST”

Lamp illuminated Below 2.5V

Lamp not illuminated VR

1F

0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2.5V

l With Self-

Checker switch OFF+ON Diagnosis

(Code Number)

Buzzer not sounded after 3 sec. VE - Checker and

Buzzer sounded Below 2.5V System Selector

l With System

Buzzer not sounded

VB Selector test

switch at

“SELF-TEST”

1G 0 Igniter Ignition switch ON ov

-

Idle Approx. 0.2V

1H - - - - - -

_-

II - - - - - -

1J

0 AIC relay Ignition switch ON

VB

A/C switch ON at idle Below 2.5V

A/C switch OFF at idle VB

-

1K 0 Diagnosis

connector

(TEN terminal) System Selector test switch at

“02 MONITOR”

System Selector test switch at

“SELF-TEST” VB

ov Ignition switch

ON

1L 0 DRL relay

(Canada) Parking brake pulled with ignition switch

Ve

l DRL.: Daytime

ON (DRL OFF) Running Lights

Idle (DRL ON) Below 2.5V

V’

F-l 50