display MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 323 of 1164

![MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

17 HESITATES/STUMBLES ON ACCELERATION

bESCRIP-

*Flat spot occurs just after accelerator depressed or mild jerking occurs during acceleration

‘ION TROUBLESHOOTING HINTS]

0 MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

17 HESITATES/STUMBLES ON ACCELERATION

bESCRIP-

*Flat spot occurs just after accelerator depressed or mild jerking occurs during acceleration

‘ION TROUBLESHOOTING HINTS]

0](/img/28/57077/w960_57077-322.png)

TROUBLESHOOTING GUIDE

17 HESITATES/STUMBLES ON ACCELERATION

bESCRIP-

*Flat spot occurs just after accelerator depressed or mild jerking occurs during acceleration

‘ION TROUBLESHOOTING HINTS]

0 Air/Fuel mixture becomes lean when depressing accelerator l Fuel injection control malfunction

(Correction for accelerating condition)

*Air leakage

l Fuel line pressure decreases l Spark advance control malfunction TEP INSPECTION ACTION

1 Check if “00” is displayed on Self-Diagnosis Yes Go to next step

Checker with ignition switch ON W page F-82 ’ No

Service Code No. displayed

SYSTEM SELECT: 1 Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

W: SELF TEST Check ECU terminal IF voltage CT= page F-150

Specification: Battery voltage

(Ignition switch ON) c3 If OK, replace ECU c? page F-149 * If not OK, check wiring between

ECU and Self-Diagnosis Checker Vacuum: More than 450 mmHg (17.7 InHg)

tern components

Replace air cleaner element 4

Check if ECU terminal voltages are OK

Yes Go to next step

MTX...Especiaily 2L

ATX... Especially lT, 2F, and 21 w page F-150

No Check for cause cp page F-151

5

Check if throttle linkage is correctly installed and

Yes Go to next step

operates freely w page F-l 14 ~~

Correct, clean, or replace as required

any binding or damaged linkage and

adjust cable deflection at throttle body w page F-l 14

6

Check continuity between throttle sensor termi- Yes Go to next step

nals IDL and E w page F-189

MTX

A-I-X 1

J E

IDL

Clearance between throttle

lever and stopper Continuity

MTX 0.1 mm (0.004 in) Yes

1 .Omm (0.039 in) No

ATX 0.1 mm (0.004 in)

Yes

0.6mm (0.024 in) No

No Adjust w page F-189

F-57

Page 337 of 1164

![MAZDA PROTEGE 1992 User Guide 22 KNOCKING

DESCRIP- *Abnormal combustion accompanied by audible “pinging” noise

I-ION

[TROUBLESHOOTING HINTS]

3 Incorrect ignition timing (Too advanced)

@ Air/Fuel mixture too lean

3 Carbon MAZDA PROTEGE 1992 User Guide 22 KNOCKING

DESCRIP- *Abnormal combustion accompanied by audible “pinging” noise

I-ION

[TROUBLESHOOTING HINTS]

3 Incorrect ignition timing (Too advanced)

@ Air/Fuel mixture too lean

3 Carbon](/img/28/57077/w960_57077-336.png)

22 KNOCKING

DESCRIP- *Abnormal combustion accompanied by audible “pinging” noise

I-ION

[TROUBLESHOOTING HINTS]

3 Incorrect ignition timing (Too advanced)

@ Air/Fuel mixture too lean

3 Carbon deposits in cylinder

*Fuel injection amount not correct

3 Overheating

l Fuel line pressure decreases while accelerating

TEP INSPECTION

ACTION

1 Connect System Selector to diagnosis connector

Yes Go to next step

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up

CT page F-79

Ignition timing (BTDC)

l BP DOHC : go-1 1 o l BP SOHC : 4”-6O

’ B6 No

Adjust a page F-79

2 Check if “00” is displayed on Self-Diagnosis

Yes Go to next step

Checker with ignition switch ON

W page F-62

No

Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-63

“88” flashes

Check ECU terminal 1F voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

c3 If OK, replace ECU w page F-149

W: SELF TEST c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

3 Check for correct intake manifold vacuum at idle

Yes Go to next step

VaCUUm: More than 450 mmHg (17.7 inHg) No

Check for air leakage of intake air sys-

tem components

4

Check for correct engine compression

Yes Go to next step

w page Bl-10

B2-10

Engine compression (Minimum):

l BP DOHC

883 kPa (9.0 kg/cm’, 128 psi)-300 rpm

l BP SOHC

834 kPa (8.5 kg/cm*, 121 psi)300 rpm

l B6

932 kPa (9.5 kg/cm’, 135 psi)300 rpm No High compression

Check engine condition CI page 81-10

62-l 0 l Carbon deposits

F-71

Page 341 of 1164

![MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati](/img/28/57077/w960_57077-340.png)

TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operation, stop and go driving, extended winter

warm-up periods, etc., as opposed to “trip” mileage, an attempt should be made to determine these factors when con-

fronted with “poor mileage” conditions. However, since the operator is not always at fault, the following is offered.

@II Operator depressing accelerator more than usual due to

@ Air/Fuel mixture too rich

low engine power

l Poor ignition *High fuel line pressure

@ Alcohol blended fuel used

*Low intake air amount

l Electronic spark advance control system malfunction @ High vehicle load l Low tire pressure

*Clutch slipping/ATX slipping l Incorrect tire size l Exhaust component restricted l Brake dragging ;TEP

INSPECTION ACTION

1

Check factors other than engine Yes

Go to next step

l Low tire pressure = Section Q 9 Unrecommended tire srze v Section Q l Clutch slipping w Section H l Brake dragging No

0 Section P Repair

l Exhaust component restricted cz= page F-136

2

Check if air hoses are connected correctly - Yes

Go to next step CI page F-109

No

Repair 3

Check if “00” IS displayed on Self-Diagnosis

Yes

Checker with ignition switch ON Go to next step W page F-82 No

SYSTEM SELECT: 1 Service Code No. displayed Check for cause (Refer to specified

check sequence) w page F-63

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU CT= page F-149 e If not OK, check wiring between

ECU and Self-Diagnosis Checker 4

Check for correct intake manifold vacuum at idle

Yes Go to next step Vacuum: More than 450 mmHg (17.7 inHg) No

Check for air leakage at intake air sys-

tem components 5

Check if air cleaner element is clean Yes

Go to next step CT= page F-79

No

Replace air cleaner element

F-75

Page 349 of 1164

SELF-DIAGNOSIS FUNCTION F

PREPARATION

SST

49 6019 9AO

System Selector For

diagnosis 49 HO18 9Al

Self-Diagnosis

Checker For

diagnosis

SERVICE CODE NUMBER

Inspection Procedure

1. Connect the SST to the diagnosis connector.

2. Set switch @to position 1.

3. Set TEST SW to SELF-TEST position.

23UOFX-048

03UOFX.059

I

4. Connect the SST to the System Selector and a ground

5. Set the select switch to position A.

6. Turn the ignition switch to ON.

7. Verify that 88 flashes on the digital display and the buzzer

sounds for 3 sec. after turning the ignition switch ON.

8. If 88 does not flash, check the main relay (FUEL INJ relay)

(Refer to page F-172) power supply circuit, and diagno-

sis connector wiring.

9. If 88 flashes and the buzzer sounds continuously for more

than 20 sec., check for a short circuit between the engine

control unit terminal 1 F and the diagnosis connector. Re-

place the engine control unit if necessary and perform Steps

3 and 7 again.

23UOFX-049 IO. Note any code numbers and check for the causes by refer-

ring to the check sequences shown on pages F-88

through F-103. Repair as necessary.

Note

l Cancel the code numbers by performing the after-

repair procedure following repairs.

(Refer to page F-104.)

I 23UOFX-050

F--83

Page 370 of 1164

F SELF-DIAGNOSIS FUNCTION

23UOFX-08: 3

03UOFX.086

i:a pj

MONITOR

SELECT El

03UOFX-:6

7

I

7

After-repair Procedure

1. Cancel the memory of malfunctions by disconnecting the

negative battery cable for

at least 20 seconds. Reconnect

the negative battery cable.

2. Connect the

SST (System Selector) to the diagnosis con-

nector.

3. Set the switch @to position 1.

4. Set TEST SW to SELF-TEST.

5. Connect the

SST (Self-Diagnosis Checker) to the System

Selector and a ground.

6. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

7. Turn the ignition switch ON.

8. Start and warm up the engine, then run it at

2,000 rpm for

three minutes.

9. Verity that no code numbers are displayed.

F-l 04

Page 417 of 1164

CONTROL SYSTEM F

VB: Battery voltage

incorrect voltage POBSible cause

Alwvs OV’ l ROOM IOA fuse burned l Open circuit in wiring from ROOM IOA fuse to ECU terminal 1A

Always OV

l Main relay malfunction (Refer to page F-171) l Open or short circuit in wiring from main relay to ECU terminal 1B

I

Always OV (Starter turns) l Open or short circuit in wiring from starter interlock switch (USA), ignition

switch (CANADA), to ECU terminal 1C

I

Always OV

Always Vs

Always approx. 5V

l Main relay (FUEL IWJ relay) malfunction (Refer to page F-171) l Open circuit in wiring from main relay to diagnosis connector terminal +B l Open or short circuit in wiring from diagnosis connector terminal MEN to

ECU terminal 1D

l Poor connection at ECU connector l ECU malfunction

l ECU malfunction

Always below

23 MIL always ON

MIL never ON

l Short circuit in wiring from combination meter to ECU terminal 1E l ECU malfunction

l Open circuit in wiring from combination meter to ECU terminal 1E

I

Always Ve l Poor connection at ECU connector l ECU malfunction

Always below

2.5V

Always

VB

No display on Self- * Main relay (FUEL INJ relay) malfunction (Refer to page F-171)

Diagnosis Checker l Open circuit in wiring from main relay to diagnosis connector terminal +B

“88” displayed and

l Open or short circuit in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal 1F

tinuously

l Poor connectron at ECU connector l ECU malfunction

Always OV

l Short circuit in wiring from igniter to ECU terminal 1G

I -

I -

I

I -

I -

I

Always below

2.5V

Always VB AIC does not operate l A/C relay malfunction (Refer to page U-55) l Open circurt in wiring from ignition switch to A/C relay l Open circuit in wiring from A/C relay to ECU terminal 1J

A/C switch OFF but

l Short circuit in wiring from A/C relay to ECU terminal IJ

AIC operates l ECU malfunction

l Poor connection at ECU connector l ECU malfunction

Always below l.OV

l Short circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

Always Vs

l Open circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

l Open circuit in wiring from diaonosis connector terminal GND to ground

Always below

2.W

Always Va DRL ON when ignition

l Short circuit in wiring from DRL relay to ECU terminal IL

switch ON l Short circuit in wiring from DRL relay to DRL unit

DRL never ON

l Open circuit in wiring from DRL relay to ignition switch

l Parking brake switch always ON l DRL unit malfunction (Refer to page T-33)

23UOFX- 134

F-l 51

Page 425 of 1164

CONTROL SYSTEM F

VB: Battery voltage

Incorrect voltage Possible cause

Always OV l ROOM 10A fuse burned l Open circuit in wiring from ROOM 10A fuse to ECU terminal 1A

Always OV

l Main relay malfunction (Refer to page F-171) l Open or short circuit in wiring from main relay to ECU terminal 1B

Always OV (Starter turns)

l Open or short circuit in wiring from or inhibitor switch (ATX) to ECU termi-

nal 1C

Always OV

Always Ve

Always 4.5~5.5U

l Main relay (FUEL INJ relay) malfunction (Refer to page F-171) l Open circuit in wiring from main relay to diagnosis connector terminal +B l Open or short circuit in wiring from diagnosis connector terminal MEN to

ECU terminal 1D

l Poor connection at ECU connector l ECU malfunction

l ECU malfunction

Always below

25v

Always Va MIL always ON

MIL never ON

l Short circuit in wiring from combination meter to ECU terminal 1E l ECU malfunction

l Open circuit in wiring from combination meter to ECU terminal 1E

l Poor connection at ECU connector l ECU malfunction

Always below

2.5V

Always VB No display on Self- * Main relay (FUEL INJ relay) malfunction (Refer to page F-171)

Diagnosis Checker

l Open circuit in wiring from main relay to diagnosis connector terminal +B

“88” displayed and

l Open or short circuit in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal 1F

tinuously

l Poor connection at ECU connector l ECU malfunction

Always OV

l Short circuit in wiring from igniter to ECU terminal 1G

Always below 1 .OV (Headlights OK)

l Open or short circuit in wiring from headlight relay to ECU terminal 1H

(Refer to page F-171)

Always OV

Always VB

Always OV Illumination lamp

ON when rear

window defroster

switch ON

Illumination lamp

never ON

Approx. 5V (California)

Always OV (Canada)

l Short circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal II

l Open circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal II

l Open circuit in wiring from diagnosis connector terminal GND to ground

l Open or short circuit in wiring from rear window defroster switch to ECU

terminal 1 J

l Open circuit in wiring from ignition switch to rear window defroster switch l Rear window defroster switch malfunction (Refer to page T-21)

l Open circuit in wiring from ECU terminal 1K to ground

l Short circuit in wiring from ECU terminal 1K to main relay (FUEL INJ relay)

23UOFX-14: 2

f-1 59

Page 923 of 1164

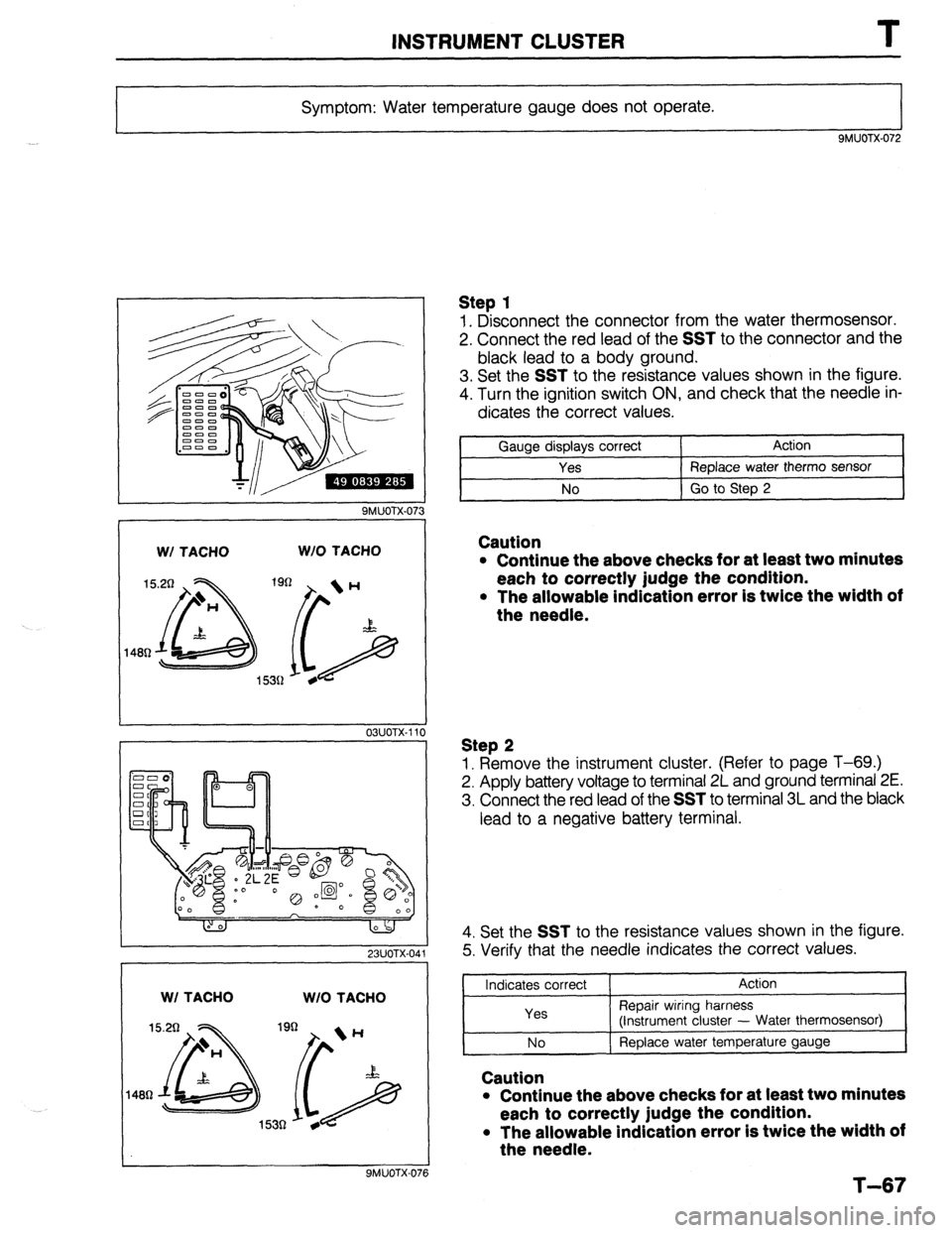

INSTRUMENT CLUSTER T

Symptom: Water temperature gauge does not operate.

9MUOTX-072

W/ TACHO W/O TACHO

OSUOTX-111

0

23UOTX-041

WI TACHO

W/O TACHO

9MUOTX-076

Step 1

1. Disconnect the connector from the water thermosensor.

2. Connect the red lead of the

SST to the connector and the

black lead to a body ground.

3. Set the

SST to the resistance values shown in the figure.

4. Turn the ignition switch ON, and check that the needle in-

dicates the correct values.

Gauge displays correct Action

Yes Replace water therm0 sensor

No Go to Step 2

Caution

l Continue the above checks for at least two minutes

each to correctly judge the condition.

l The allowable indication error is twice the width of

the needle.

Step 2

1. Remove the instrument cluster. (Refer to page T-69.)

2. Apply battery voltage to terminal 2L and ground terminal 2E.

3. Connect the red lead of the

SST to terminal 3L and the black

lead to a negative battery terminal.

4. Set the

SST to the resistance values shown in the figure.

5. Verify that the needle indicates the correct values.

Indicates correct

Yes Action

Repair wiring harness

(instrument cluster - Water thermosensor)

I--~ No I ReDlace water temperature gauge

I

Caution

l Continue the above checks for at least two minutes

each to correctly judge the condition.

l The allowable indication error is twice the width of

the needle.

T-67

Page 1066 of 1164

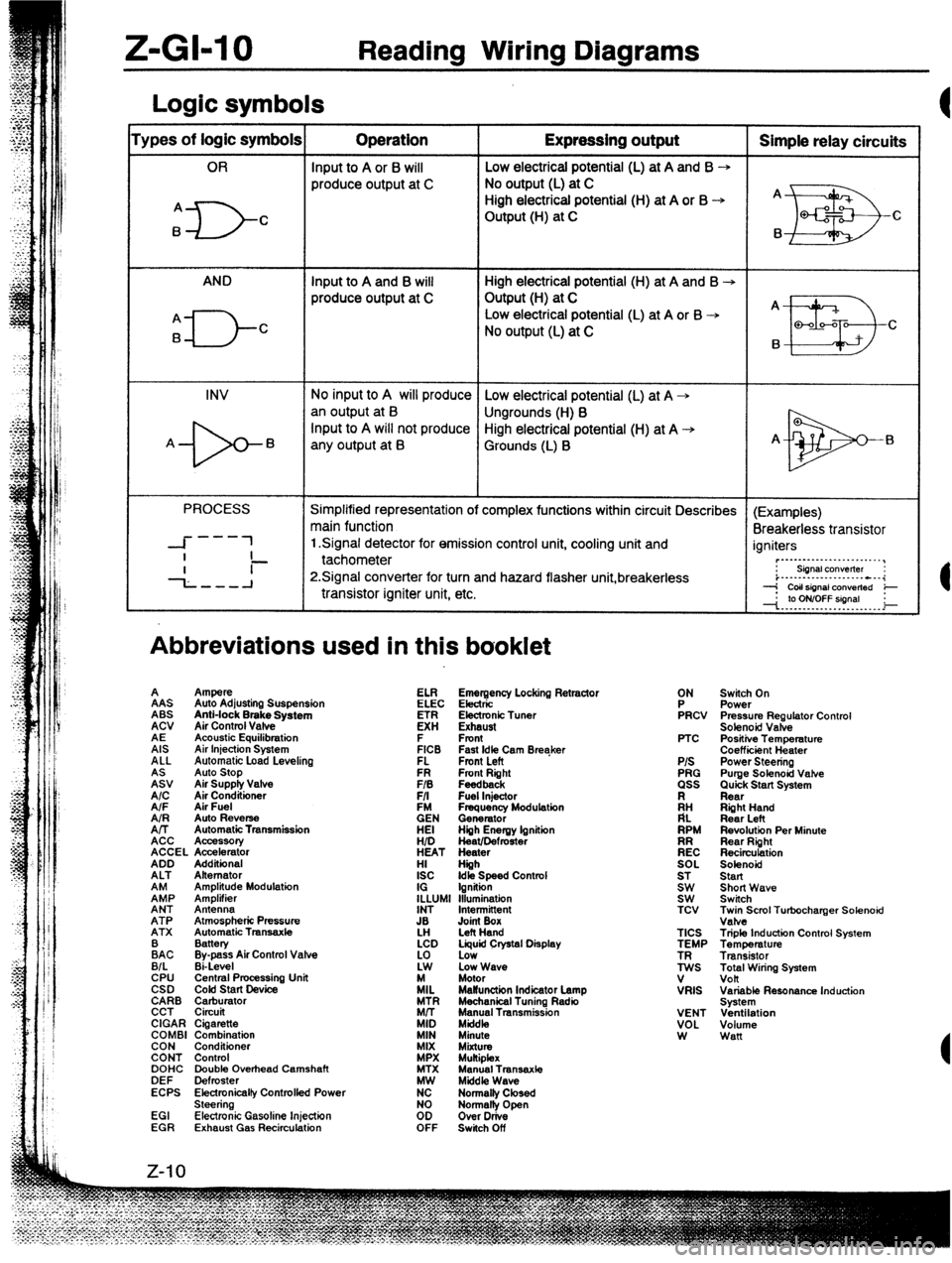

Z-GI-10 Reading Wiring Diagrams

Logic symbols

‘ypes of logic symbols Operation Expressing output Simple relay circuits

OR Input to A or 6 will Low electrical potential (L) at A and B --,

produce output at C No output (L) at C

High electrical potential (H) at A or B -+ A

A

ID- C Output (H) at C

EB Q-f2 c

B B

AND Input to A and B will High electrical potential (H) at A and B -+

produce output at C Output (H) at C

A _

A

El-- Low electrical potential (L) at A or B -+

B C

No output (L) at C

B

II!I3 Q-00-Q

C

INV No input to A will produce Low electrical potential (L) at A +

an output at B

Ungrounds (H) B

-b- Input to A will not produce High electrical potential (H) at A +

A B

any output at B Grounds (L) B A-

El

PROCESS Simplified representation of complex functions within circuit Describes (Examples)

main function

Breakerless transistor

---

-I- 1 1 Signal detector for emission control unit, cooling unit and

I igniters

- ~._..._...._._..._._..__,

--L--A tachometer

P.Signal converter for turn and hazard flasher unit,breakerless : siinalcon”elter :

i..-.--...-.........---i

transistor igniter unit, etc. --j CoIlsignal ConVerted e

--I. .‘p. Y?YT?!!9’. . _ i

Abbreviations used in this booklet

A

%J Ampere

Auto Stop

Air Supply Valve

A/C AAS

Air Conditioner Auto Adjusting Suspension

A/F Air Fuel ABS

AIR Anti-lock Brake System

Auto Reverse

A/T ACV

Automatic Transmission

ACC Air Control Vafve

Acc%K4tIory

ACCEL Accelerator

ADD AE

Additional Acoustic Equilibration

ALT Alternator

EP AIS

Amplitude Modulation Air Injection System

Amplifier ALL

ANT Antenna Automatic Load Levelino

ATP Atmospheric Pressure

ATX Automatic Tmnsaxle FR Fmnt Right ELI?

FIB Feedback

F/I Fuel Injector Emergency Locking Retractor

EN ELEC Electric

Frequency Modulation

Generator

HEI Electronic Tuner

Hiih Energy lgnitiin

HID K!

Heat/Defmster

HEAT Heater Exhaust

HI Hiih F

ISC Front

Idk Speed Contml

IG Ignition

ILLUMI Illumination FICB

INT Intermittent FL Fast Idle Cam Breaker

Fmnt Left

JB

LH Joint Box

Left Hand

:AC Battery

Bypass Air Control Valve

B/L Ei-Level

CPU Central Pmcessing Unit

CSD COM start Device

CARB Carburator

CCT Circuit

CIGAR Cigarette

COMBI Combination

CON Conditioner

CONT Control

DOHC Double Overhead Camshaft

DEF Defroster

ECPS Electronicalfy Controlfed Power

Steering

EGI Electronic Gasoline Injection

EGR Exhaust Gas Recirculation LCD Liquid Crystal Display

:i Low

Low Wave

/IL Motor

MaWunction Indicator Lamp

MTR Mechanical Tuning Radio

Mrr Manual Transmission

MID Mkfdk,

MIN Minute

MIX

MiXtUt MPX Mukiplex

MTX Manual Transaxte

K Middle Wave

Normalty Closed

too Normally Open

Over Drive

OFF Switch Off ON

FRCV

PTC

P/S

PRG

ass

ii:

RPM

EC

SOL

ST

Et TCV

TICS

TEMP

ES

V

VRIS

VENT

VOL

W Switch On

Power

Pressure Regulator Control

Solenoid Valve

Positiie Temperature

Coefficiint Heater

Power Steering

Purge Solenoid Vahe

Quick Start System

Rear

Riiht Hand

Rear Left

Revolution Per Minute

Rear Right

Recirculation

Solenoid

Start

Short Wave

Switch

~;eScml Turbocharger Solenoid

Triple Induction Control System

Temperature

Transistor

Total Wiring System

volt

Variable Resonance Induction

System

Ventilation

Volume

Wan