alternator MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 446 of 1164

G CHARGING SYSTEM

03UOGX-011

CIRCUIT DIAGRAM

CHARGING SYSTEM

PREPARATION

SST

I I

49 9200 020

Tension gauge,

V-ribbed belt For

inspection of

drive belt tension

STATOR

1 DIODE TRIO

T l-f-l /

-I J

WARNING

t

I --.- I I I I 15A

e I

I I -L

-E-

I IC REGULATOR

0

-

BATTERY = IGNITION

SWITCH

03u0tix-012

The alternator has a self-diagnostic function to warn of the following

If a problem arises, the alternator warning lamp illuminates. problems in the charging system.

1. S terminal circtiit open

2. No voltage output

3. Field coil circuit open

4. B terminal circuit open

5. Voltage output too high

G-6

Page 447 of 1164

CHARGING SYSTEM G

TROUBLESHOOTING

INSPlhdN

ACTION

1

Check battery voltage Yes Go to next step Specification: Above 12.4V

No

Check battery ri-page G-8

2 Start engine and check if alternator warning

Yes Go to Step 4

lamp goes out

No Go to next step

3 Check if voltages at alternator terminals are Yes Check wire harness between battery and terminal B

3. Turn all electrical loads ON and depress

2,500-3,000 rpm

l Do not ground terminal B

G-7

Page 450 of 1164

G

ALTERNATOR

Removal / Installation

CHARGING SYSTEM

Caution

l Be sure the battery connections are not reversed, because this will damage the rectifier.

l Do not use high-voltage testers such as a megger, because they will damage the rectifier.

l Remember that battery voltage is always applied to the alternator B terminal.

l Do not ground the L terminal while the engine is running.

l Do not start the engine while the connector is disconnected from the L and S terminals.

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary

3. Install in the reverse order of removal.

N.m (m-kg, R-lb)

OSlJOGX b20

1. Negative battery cable

2. Vacuum hose

3. Solenoid bracket (If equipped)

4. Connector

5. B terminal wire

Inspect for damage and corroston 6. Drive belt

Inspection. . . . ., ~.. ,. ,.... . , page G-l 4

Adjustment ,~, ,.,., ,. ,. ,, ,.. page G-l 4

Replacement . . . . . . . . page

G-l 4

7. Alternator

Disassembly / Assembly ,........,... page G-l 1

Inspection... ,, . . . . . . . . . . . . . . . . . . . . . . . . . . . page G-l 2

G-10

Page 454 of 1164

G CHARGING SYSTEM

WATER PUMP 13UOGX-00,

03UOGX-03:

I /I I III

I f 03UOGX-03:

03UOGX-034

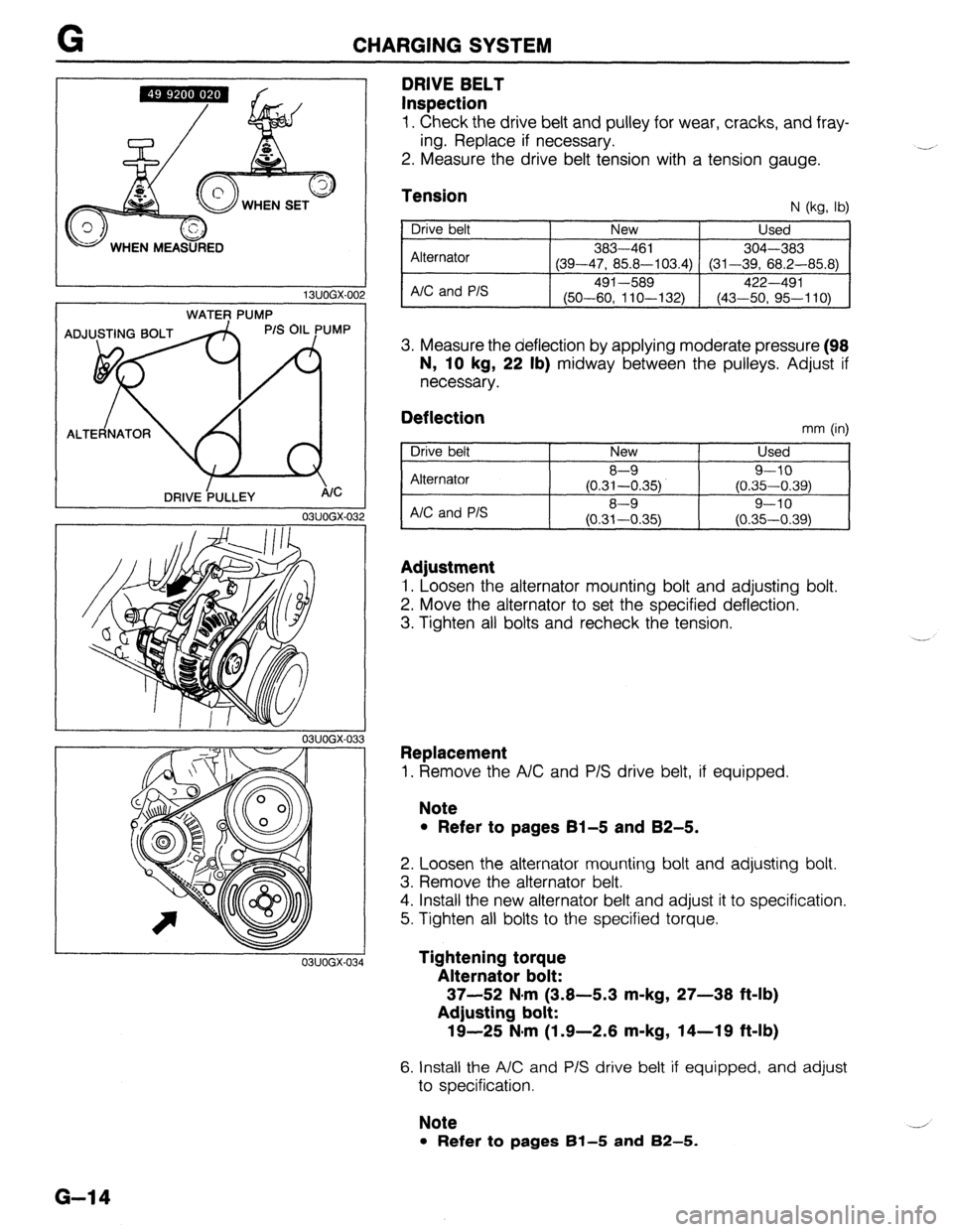

DRIVE BELT

Inspection

1. Check the drive belt and pulley for wear, cracks, and fray-

ing. Replace if necessary.

2. Measure the drive belt tension with a tension gauge. .-A

Tension N (kg, lb)

Drive belt

Alternator

A/C and P/S New Used

383-461

304-303

(39-47, 85.8-103.4) (31-39, 68.2-85.8)

491-589 422-491

(50-60, 11 O-l 32) (43-50, 95-110)

3. Measure the deflection by applying moderate pressure (98

N, 10

kg, 22 lb) midway between the pulleys. Adjust if

necessary.

Deflection mm (in)

Drive belt

Alternator

AIC and P/S New Used

8-9 9-10

(0.31-0.35) (0.35-0.39)

8-9 9-10

(0.31-0.35) (0.35-0.39)

Adjustment

1. Loosen the alternator mounting bolt and adjusting bolt.

2. Move the alternator to set the specified deflection.

3. Tighten all bolts and recheck the tension.

Replacement

1. Remove the A/C and P/S drive belt, if equipped.

Note

l Refer to pages 61-5 and 82-5.

2. Loosen the alternator mounting bolt and adjusting bolt.

3. Remove the alternator belt.

4. Install the new alternator belt and adjust it to specification.

5. Tighten all bolts to the specified torque.

Tightening torque

Alternator bolt:

37-52 N#rn (3.8-5.3 m-kg, 27-38 ft-lb)

Adjusting bolt:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

6. Install the A/C and P/S drive belt if equipped, and adjust

to specification.

Note

l Refer to pages 61-5 and 82-5.

G-14

Page 869 of 1164

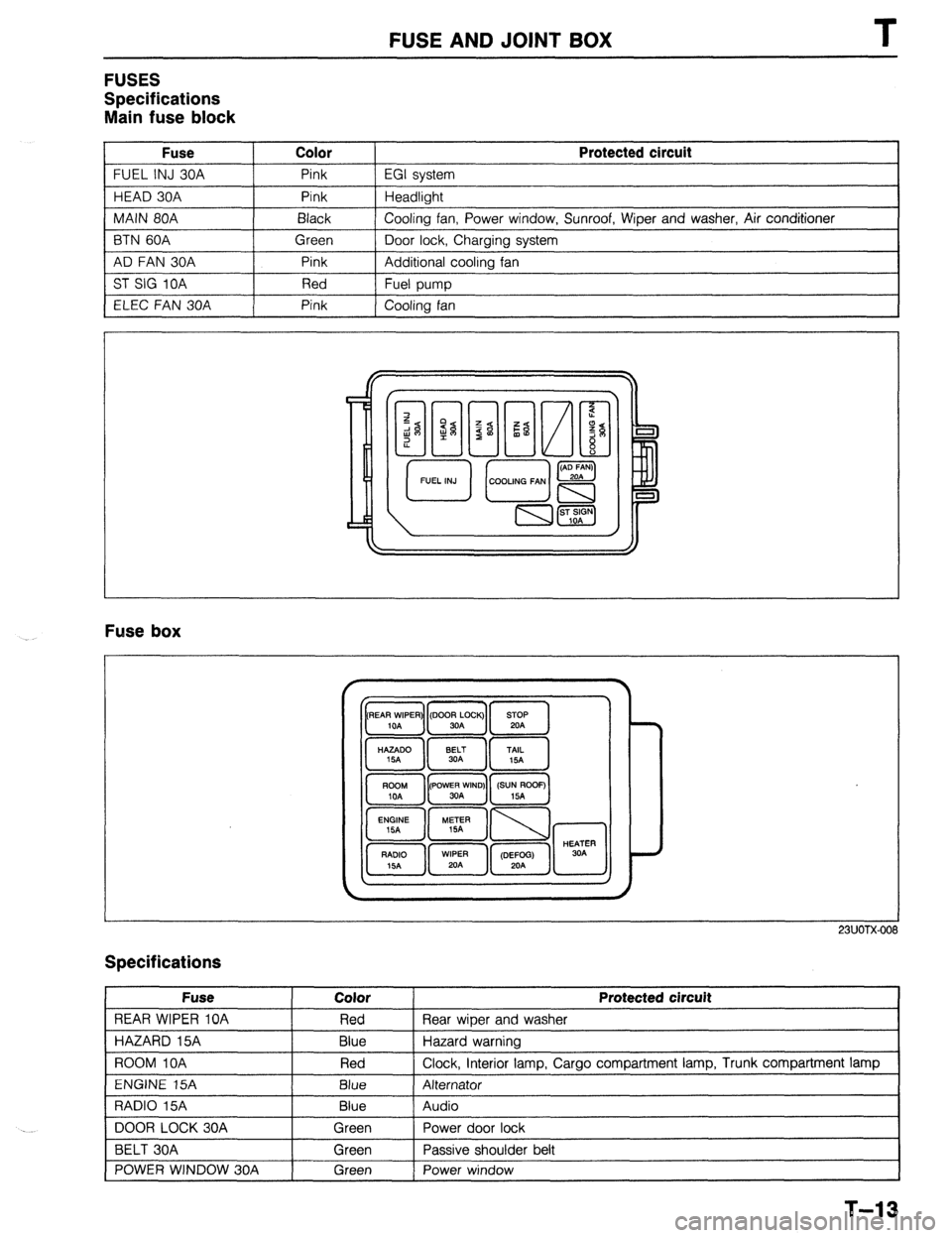

FUSE AND JOINT BOX

FUSES

Specifications

Main fuse block

Fuse Color

FUEL INJ 30A Pink

HEAD 30A Pink

MAIN 80A Black

BTN 60A Green

AD FAN 30A Pink

ST SIG 10A Red

ELEC FAN 30A Pink Protected circuit

EGI system

Headlight

Cooling fan, Power window, Sunroof, Wiper and washer, Air conditioner

Door lock, Charging system

Additional cooling fan

Fuel pump

Cooling fan

Fuse box

23UOTX-001

Specifications

Fuse

REAR WIPER 10A

HAZARD 15A

ROOM IOA

ENGINE 15A

RADIO 15A

DOOR LOCK 30A

BELT 30A

POWER WINDOW 30A Color

Red

Blue

Red

Blue

Blue

Green

Green

Green Protected circuit

Rear wiper and washer

Hazard warning

Clock, interior lamp, Cargo compartment lamp, Trunk compartment lamp

Alternator

Audio

Power door lock

Passive shoulder belt

Power window

1

T-13

Page 917 of 1164

WARNING SYSTEM T

13UOTX-07

63U15X-05

, I//

‘nF -

-

-

FUEL

13UOTX.08C

- CHARGE

13UOTX-08

13UOTX-08

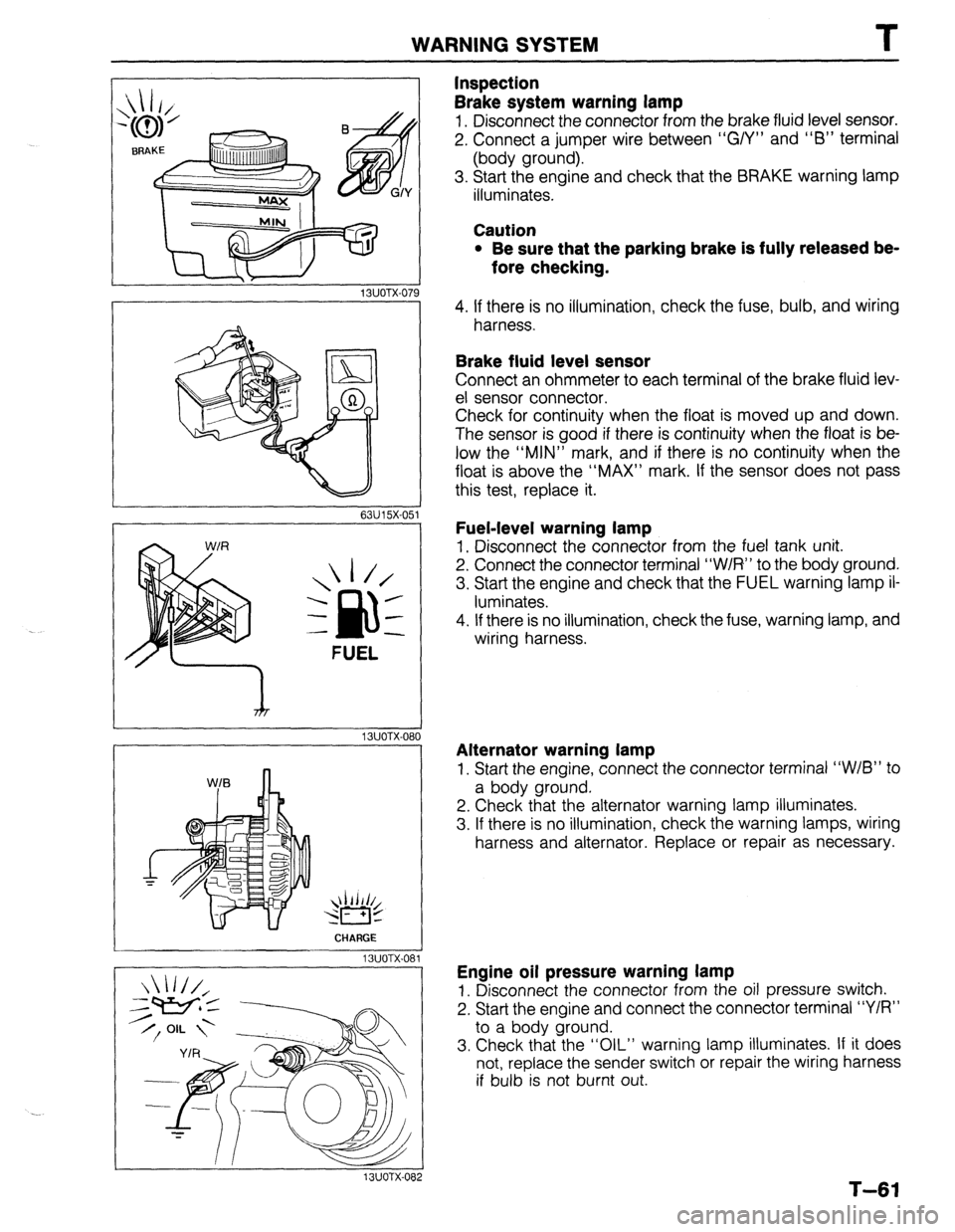

Inspection

Brake system warning lamp

1. Disconnect the connector from the brake fluid level sensor.

2. Connect a jumper wire between “G/Y” and “6” terminal

(body ground).

3. Start the engine and check that the BRAKE warning lamp

illuminates.

Caution

l Be sure that the parking brake is fully released be-

fore checking.

4. If there is no illumination, check the fuse, bulb, and wiring

harness.

Brake fluid level sensor

Connect an ohmmeter to each terminal of the brake fluid lev-

el sensor connector.

Check for continuity when the float is moved up and down.

The sensor is good if there is continuity when the float is be-

low the “MIN” mark, and if there is no continuity when the

float is above the “MAX” mark. If the sensor does not pass

this test, replace it.

Fuel-level warning lamp

1. Disconnect the connector from the fuel tank unit.

2. Connect the connector terminal “W/R” to the body ground.

3. Start the engine and check that the FUEL warning lamp il-

luminates.

4. If there is no illumination, check the fuse, warning lamp, and

wiring harness.

Alternator warning lamp

1. Start the engine, connect the connector terminal “W/B” to

a body ground.

2. Check that the alternator warning lamp illuminates.

3. If there is no illumination, check the warning lamps, wiring

harness and alternator. Replace or repair as necessary.

Engine oil pressure warning lamp

1. Disconnect the connector from the oil pressure switch.

2. Start the engine and connect the connector terminal “Y/R”

to a body ground.

3. Check that the “OIL” warning lamp illuminates. If it does

not, replace the sender switch or repair the wiring harness

if bulb is not burnt out.

T-61

Page 920 of 1164

2L BUZZER 2A 28 2C 2D 1A 3K l--r nnmn

I I‘ I

1C 3L 2E 2G IL iG 1F 1D tB

3F 38 3G 1E 3D

l-l rt

II l-l

l-l It II l-l 1J 11 1H

1G IF 1E 1D 1C 1B 1A 2L 2K 2J 21 2H 2G 2F 2E 2D 2C 28 2A

r-l It ,I 3L 3K 3J 31 3H 3G 3F 3E 3D 3C 3B 3A

Ter- I I minal Connected to 1 1A Combination switch

1B Ground

IC Fuel tank unit

1 ID 1 EGI control unit

I

II L 1J 1

L Ter-

minal Connected to

2A Speed sensor output

28 Light switch (high beam)

2C Turn switch (L)

20 Turn switch (R)

2E Ground

2F Ground

2L 1 IGI battery Ter-

minal Connected to

3A

38 Alternator

3c

30 Oil pressure switch

3E

3F Parking brake switch, Brake fluid switch

3G Passive shoulder belt control unit

3H h

I 31

3J

3K

IG2 battery

3L Water temperature gauge unit

Page 953 of 1164

AUDIO T

Noise Suppression Chart

Cause

‘uel pump noise Remedy Move speaker wiring away from fuel pump wire.

REAR HARNESS FUEL

PUMP

Wotor noise

Wiper, washer, power

window, for example) 1. Check grounding.

2. Install condensers to motor circuit.

Turn signal noise Connect condenser (0.5 pF) to power line of filter unit. Note

CONDENSER

4lternator noise

l Condenser should be placed near flasher unit.

Connect condenser (0.5 pF) near alternator.

TO RADIO

CONDENSER

97UOTX-1

T-97

Page 1024 of 1164

TD TECHNICAL DATA

G. ENGINE ELECTRICAL SYSTEM

3attery Dark

current*’

Alternator 86 SOHC BP SOHC

I BP DOHC

MTX 1 ATX 1 MTX 1 ATX

Voltage V 12

Type and capacity (20-hour rate) 55D23L (60AH) 1 55D23L (60AH)

mA Max. 20.0

Type A.C

output V-A 12-65

Regulator type Transistorized (built-in IC regulator)

Regulated voltage V 14.1-14.7

Brush length Standard 21.5 (0.846)

mm (in) Minimum 8.0 (0.315)

Drive belt deflection

New 8-Q (0.31-0.35)

;riL’F,i Used Q-10 (0.35-0.39)

Coaxial

Type Direct Direct Coaxial

reduction Direct

reductior

Starter output V-kW 12-0.85 12-0.95 12-1.4 12-0.95 12-1.4

Brush length Standard 17 (0.67) 17 (0.67) 17.5 (0.69) 17 (0.67) 17.5 (0.69

mm (in) Minimum 11.5 (0.453) 11.5 (0.453) 10.0 (0.39) 11.5 (0.453) 10.0 (0.39

Distributor Electronic spark advance (photo diode)

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded) 6O-8O 4O-6O 9”-11 O

Ignition coil Resistance Primary coil winding 0.81 -O.QQg

(at 20% [68OF]) Secondary coil winding lo-16 kg

SK&E-1 1 BKR5E-11

NGK

BKRGE-11 BKRGE-11

BKR7E-11

Spark plug Type

NIPPONDENSO KlGPR-Ull

K20PRUll KlGPR-Ull

K20PRUll

K22PRUll *:

. Plug gap

Firing order mm (in) 1.0-l .l (0.039-0.043)

l-3-4-2

---

’ Dark current is the constant flow of current while the ignition switch IS UFF.

(i.e engine control unit, audio, etc.) ..-

._*

T&l 0

Page 1049 of 1164

PARTS INDEX

‘I

A

ACCELERATOR CABLE ............................. F-l 14

ACCELERATOR PEDAL ............................. F-l 14

AIR CONDITIONER ...................................... u-30

A/C RELAY.. ........................................... U-56

A/C SWITCH ...........................................

U-57

COMPRESSOR.. ..................................... U-41

CONDENSER.. ....................................... U-53

CONDENSER FAN ................................. u-57

CONDENSER FAN RELAY .................... U-56

COOLING UNIT ..................................... U-38

MAGNETIC CLUTCH ............................. u-51

RECEIVER/DRIER .................................. U-52

REFRIGERANT PRESSURE SWITCH.. .. U-55

AIR FLOW METER ..................................... F-l 68

AIR VALVE.. ................................................ F-l 16

ALTERNATOR .............................................. G-10

ANTENNA FEEDER

AUDIO

....... .......................................................................................... T-i;

AUTOMATIC TRANSAXLE ............................. K-l

2-4 BRAKE BAND ................................ K-l 97

3-4 CLUTCH.. ....................................... K-l 87

ACCUMULATORS ................................ K-l 67

ATF ....................................................... K-135

ATF THERMOSENSOR ........................ K-142

BEARING COVER ASSEMBLY ............ K-208

CLUTCH ASSEMBLY ........................... K-l 72

CONTROL VALVE BODY.. .....

K-21 0,224,234

DIFFERENTIAL ..................................... K-236

DRIVE PLATE.. ..................................... K-267

EC-AT CONTROL UNIT ....................... K-144

HOLD SWITCH ..................................... K-140

HYDRAULIC CIRCUIT .......................... K-278

IDLER GEAR ........................................ K-203

INHIBITOR SWITCH ............................. K-l 41

LOW AND REVERSE BRAKE .............. K-192

MAIN CONTROL VALVE BODY .......... K-220

OIL COOLER.. ...................................... K-265

OIL PUMP ............................................

K-169

OIL SEAL ..............................................

K-209

ONE-WAY CLUTCH 2

CARRIER HUB ASSEMBLY ............... K-185

OUTPUT GEAR .................................... K-206

P RANGE SWITCH.. ............................. K-271

PREMAIN CONTROL VALVE BODY .a. K-218

PULSE GENERATOR ........................... K-142

SELECTOR LEVER ............................... K-272

SHIFT MECHANISM ............................. K-269

SHIFT-LOCK ACTUATOR

..................... K-271

SMALL SUN GEAR AND

ONE-WAY CLUTCH 1 ........................ K-l 82

SOLENOID VALVE.. ............................. K-l 43

SPEEDSENSOR .................................. K-l 43

THROTTLE CABLE .............................. K-l 37

TORQlJE CONVERTER.. ...................... K-l 66

TRANSAXLE UNIT. ......... K-149,153,246,261 UPPER CONTROL VALVE BODY.. ..... K-215

BACK-UP LIGHT SWITCH..

..........................

BATTERY T;4;

- .......................................................

BLOWER UNIT ............................................

U-23

BRAKE FLUID.. .............................................. P-8

BRAKE MASTER CYLINDER. ...................... P-10

BRAKE PEDAL ...............................................

P-8

C

CALIPER .................................................. P-21,26

CARGO COMPARTMENT LAMP ................. T-54

CENTRAL PROCESSING UNIT..

.................. T-55

CHARCOAL CANISTER ............................. F-l 41

CHECK VALVE (TWO-WAY) .......................

CHECK-AND-CUT VALVE - .......................... ;-;b$

CIRCUIT OPENING RELAY.. ...................... F-129

CLUTCH COVER ......................................... H-l 7

CLUTCH DISC ............................................. H-l 7

CLUTCH FLUID ............................................. H-4

CLUTCH MASTER CYLINDER.. .................... H-7

CLUTCH PEDAL ............................................ H-5

CLUTCH RELEASE CYLINDER..

................. H-12

CLUTCH SWITCH (MTX) ............................ F-l 72

COMBINATION SWITCH .............................. T-23

COWL GRILLE ............................................. S-53

CRUISE CONTROL UNIT.. ...................... T-78,85

D

DASHBOARD ............................................... S-94

DASHPOT ................................................... F-l 42

DISTRIBUTOR .............................................. G-20

DOOR LOCK TIMER UNIT ........................... T-17

DOOR MIRROR ............................................ S-54

REMOTE CONTROL MIRROR ............... S-56

REMOTE CONTROL MIRROR SWITCH. S-55

DOOR SPEAKER .......................................... T-98

DRIVE SHAFT.. ....................................... M-l 7,21

DRL RELAY.. ................................................ T-18

DRL RESISTOR ............................................ T-46

DUAL PROPORTIONING VALVE..

............... P-l 6

DYNAMIC CHAMBER ................................ F-l 12

E

ELECTRIC COOLING FAN SYSTEM ........... E-13

ENGINE (B6 & BP SOHC) ........................... Bl-2

CAMSHAFT ..........................................

Bl-58

CAMSHAFT PULLEY ...........................

Bl-65

CONNECTING ROD ............................. 81-63

PI-I