charging MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 451 of 1164

CHARGING SYSTEM G

Disassembly / Assembly

1. Disassemble in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

P-105 N.m (9.5-11 m-kg, 61-79 ft.lb)

N-m (cm-kg, in-l

OBUOGX-0

1. Pulley 6. Rectifier

2. Front cover Inspection .,,,..,,,,.....,,.,.,,............. page G-13

3. Rotor 7. Brush holder assembly

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page G-12 Inspection

4. Rear bracket (Brush and brush spring) . . . . . . . . . page G-13

5. Stator 8. Bearing

Inspection . . . . . . . . . . . . . . . . . . . . . . . . page G-l 2 Inspection .,.,,...,......,......,............ page G-13

G-l 1

Page 452 of 1164

![MAZDA PROTEGE 1992 Owners Manual G CHARGING SYSTEM

23UOGX-OO!

23UOGX-00

03UOGX-02,

03UOGX-02

Inspection

Rotor

1. Measure the resistance between the slip rings with an

ohmmeter.

Specification: 3.5-4.5Q [at 20°C (66OF)]

2. I MAZDA PROTEGE 1992 Owners Manual G CHARGING SYSTEM

23UOGX-OO!

23UOGX-00

03UOGX-02,

03UOGX-02

Inspection

Rotor

1. Measure the resistance between the slip rings with an

ohmmeter.

Specification: 3.5-4.5Q [at 20°C (66OF)]

2. I](/img/28/57077/w960_57077-451.png)

G CHARGING SYSTEM

23UOGX-OO!

23UOGX-00

03UOGX-02,

03UOGX-02

Inspection

Rotor

1. Measure the resistance between the slip rings with an

ohmmeter.

Specification: 3.5-4.5Q [at 20°C (66OF)]

2. If not within specification, replace the rotor.

3. (1) Check continuity between each slip ring and the core

with an ohmmeter.

(2) Replace the rotor if there is continuity.

4. Check if the slip ring surface is rough. Use fine sandpaper

to repair it if necessary.

Stator

1. Check for continuity between the stator coil leads with an

ohmmeter.

2. Replace the stator it there is no continuity.

3. Check continuity between the stator coil leads and the core

with an ohmmeter.

4. Replace the stator if there is continuity.

G-12

Page 453 of 1164

CHARGING SYSTEM G

L

23UOGX.00

P2 I9

WEAR LIMIT

03UOGX-021

03UOGX-02C

03UOGXz

Rectifier

1. Check continuity of the diodes with an ohmmeter.

Negative

E

B

T

Pl, P2,

P3

Pl, P2, P3

Positive

PI,

P2, P3

E

B

T

Continuity

Yes

No

No

No

Yes

Yes

2. Replace the rectifier if necessary.

Brush

If a brush is worn almost to or beyond the limit, replace the

brushes.

Standard: 21Smm (0.848 in)

Minimum: 8.0mm (0.315 in)

Brush spring

1. Measure the force of the brush spring with a spring pres-

sure gauge.

2. Replace the spring if necessary.

Standard force:

3.1-4.3 N (320-440 g, 11.3-15.5 oz)

Minimum: 1.6-2.4 N (160-240 g, 5.6-8.5 oz)

Note

l Read the spring pressure with the brush tip project-

ing 2mm (0.079 in).

Bearing

1. Check for abnormal noise, looseness, or sticking

2. Replace the bearing(s) if necessary.

G-l 3

Page 454 of 1164

G CHARGING SYSTEM

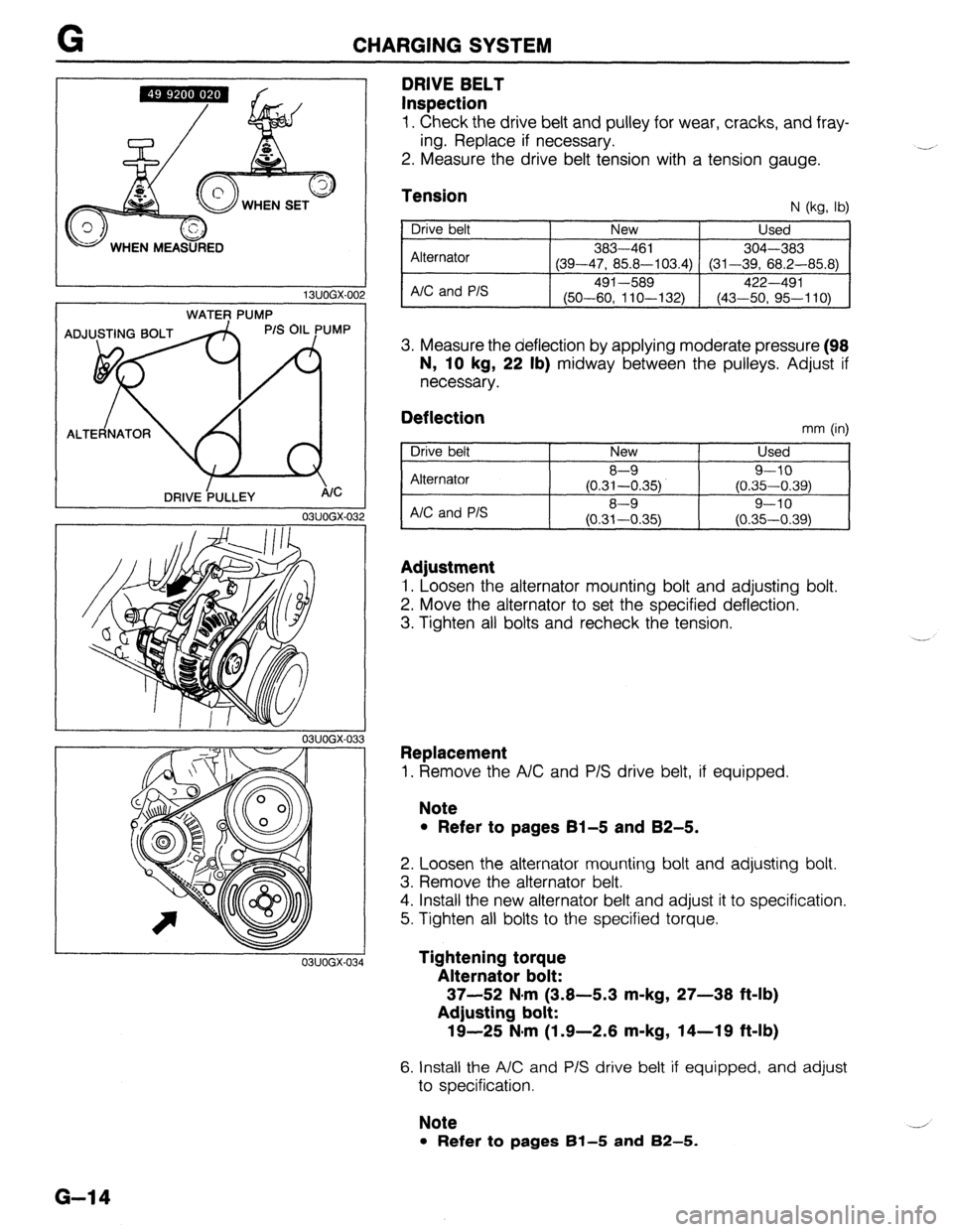

WATER PUMP 13UOGX-00,

03UOGX-03:

I /I I III

I f 03UOGX-03:

03UOGX-034

DRIVE BELT

Inspection

1. Check the drive belt and pulley for wear, cracks, and fray-

ing. Replace if necessary.

2. Measure the drive belt tension with a tension gauge. .-A

Tension N (kg, lb)

Drive belt

Alternator

A/C and P/S New Used

383-461

304-303

(39-47, 85.8-103.4) (31-39, 68.2-85.8)

491-589 422-491

(50-60, 11 O-l 32) (43-50, 95-110)

3. Measure the deflection by applying moderate pressure (98

N, 10

kg, 22 lb) midway between the pulleys. Adjust if

necessary.

Deflection mm (in)

Drive belt

Alternator

AIC and P/S New Used

8-9 9-10

(0.31-0.35) (0.35-0.39)

8-9 9-10

(0.31-0.35) (0.35-0.39)

Adjustment

1. Loosen the alternator mounting bolt and adjusting bolt.

2. Move the alternator to set the specified deflection.

3. Tighten all bolts and recheck the tension.

Replacement

1. Remove the A/C and P/S drive belt, if equipped.

Note

l Refer to pages 61-5 and 82-5.

2. Loosen the alternator mounting bolt and adjusting bolt.

3. Remove the alternator belt.

4. Install the new alternator belt and adjust it to specification.

5. Tighten all bolts to the specified torque.

Tightening torque

Alternator bolt:

37-52 N#rn (3.8-5.3 m-kg, 27-38 ft-lb)

Adjusting bolt:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

6. Install the A/C and P/S drive belt if equipped, and adjust

to specification.

Note

l Refer to pages 61-5 and 82-5.

G-14

Page 869 of 1164

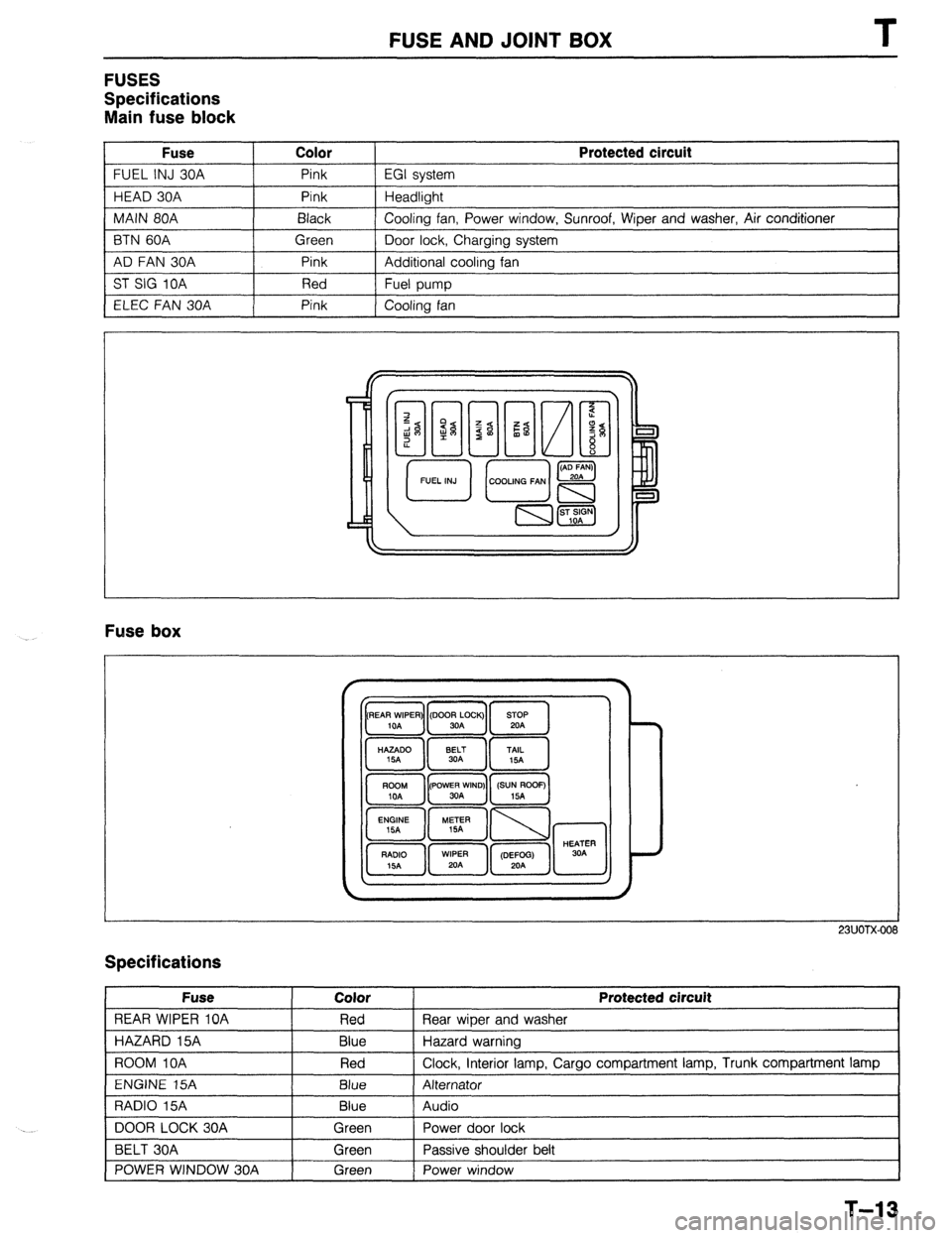

FUSE AND JOINT BOX

FUSES

Specifications

Main fuse block

Fuse Color

FUEL INJ 30A Pink

HEAD 30A Pink

MAIN 80A Black

BTN 60A Green

AD FAN 30A Pink

ST SIG 10A Red

ELEC FAN 30A Pink Protected circuit

EGI system

Headlight

Cooling fan, Power window, Sunroof, Wiper and washer, Air conditioner

Door lock, Charging system

Additional cooling fan

Fuel pump

Cooling fan

Fuse box

23UOTX-001

Specifications

Fuse

REAR WIPER 10A

HAZARD 15A

ROOM IOA

ENGINE 15A

RADIO 15A

DOOR LOCK 30A

BELT 30A

POWER WINDOW 30A Color

Red

Blue

Red

Blue

Blue

Green

Green

Green Protected circuit

Rear wiper and washer

Hazard warning

Clock, interior lamp, Cargo compartment lamp, Trunk compartment lamp

Alternator

Audio

Power door lock

Passive shoulder belt

Power window

1

T-13

Page 973 of 1164

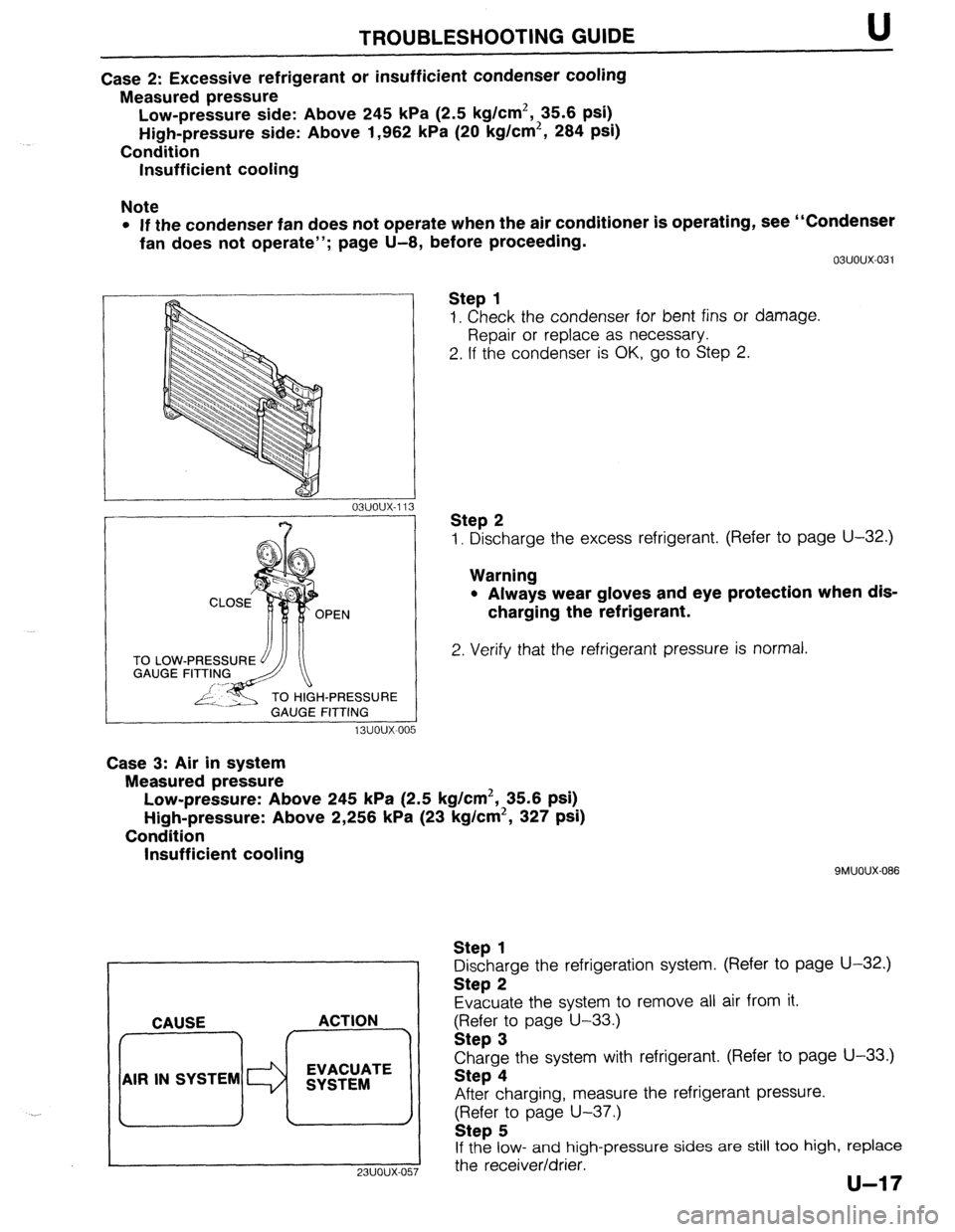

TROUBLESHOOTING GUIDE U

Case 2: Excessive refrigerant or insufficient condenser cooling

Measured pressure

Low-pressure side: Above 245 kPa (2.5 kg/cm2, 35.6 psi)

High-pressure side: Above 1,962 kPa (20 kg/cm2, 284 psi)

Condition

Insufficient cooling

Note

l If the condenser fan does not operate when the air conditioner is operating, see “Condenser

fan does not operate”; page U-8, before proceeding.

TO LOW

GAUGE

H-PRESSURE

GAUGE FITTING

13uoux-00 5 03uoux-031

Step 1

1. Check the condenser for bent fins or damage.

Repair or replace as necessary.

2. If the condenser is OK, go to Step 2.

Step 2

1. Discharge the excess refrigerant. (Refer to page U-32.)

Warning

l Always wear gloves and eye protection when dis-

charging the refrigerant.

2. Verify that the refrigerant pressure is normal.

Case 3: Air in system

Measured pressure

Low-pressure: Above 245 kPa (2.5 kg/cm2, 35.6 psi)

High-pressure: Above 2,256 kPa (23 kg/cm2, 327 psi)

Condition

Insufficient cooling

. . CAUSE ACTION

AIR IN SYSTEM EVACUATE

SYSTEM

9MUOUX-086

Step 1

Discharge the refrigeration system. (Refer to page U-32.)

Step 2

Evacuate the system to remove all air from it.

gFI;;r; page U-33.)

Charge the system with refrigerant. (Refer to page U-33.)

Step 4

After charging, measure the refrigerant pressure.

(Refer to page U-37.)

Step 5

If the low- and high-pressure sides are still too high, replace

I

23UOUX-057 the receiver/drier.

Page 974 of 1164

U TROU6LESHOOTlNG GUIDE

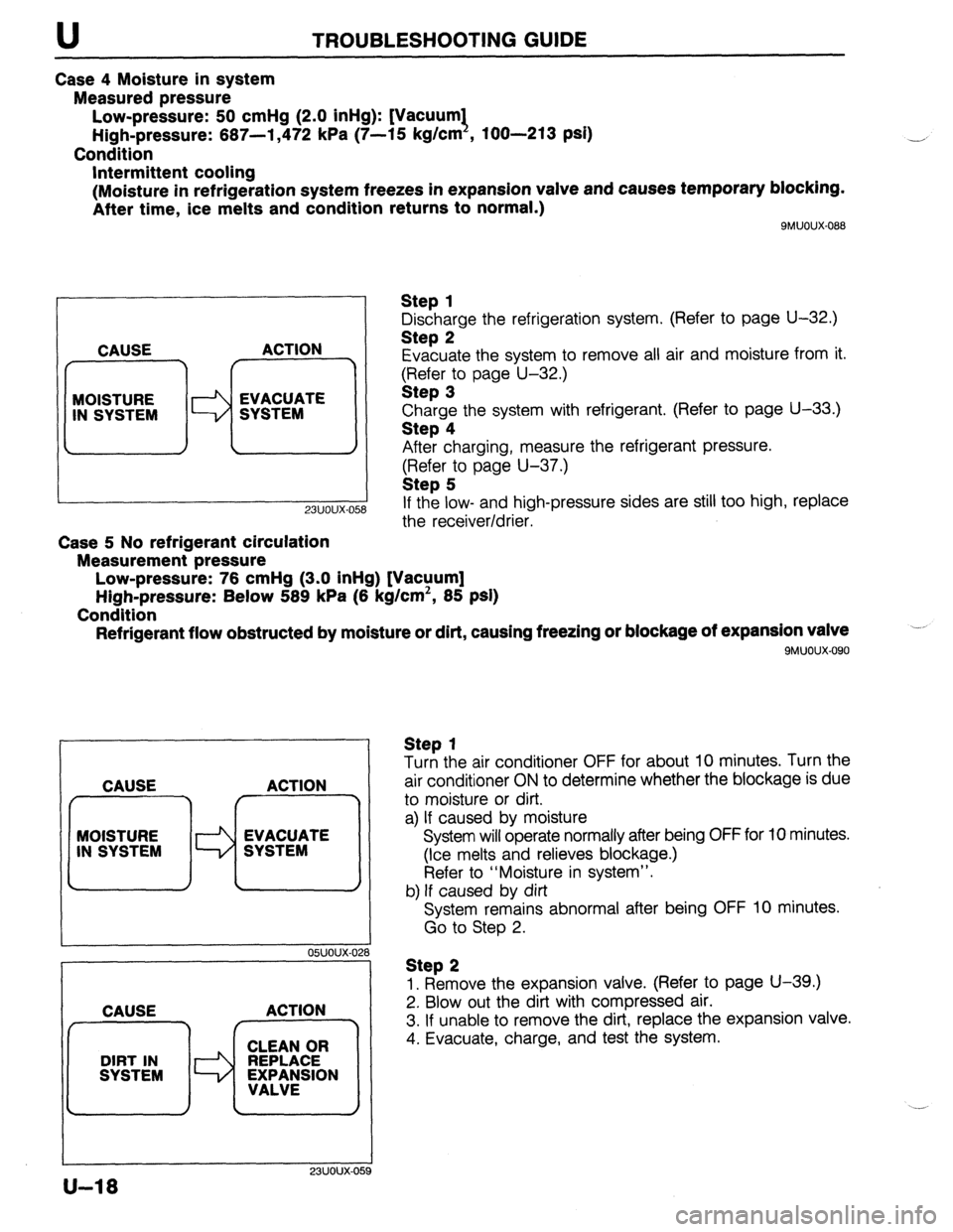

Case 4 Moisture in system

Measured pressure

Low-pressure: 50 cmHg (2.0 inHg): [Vacuum1

High-pressure: 667-l ,472 kPa (7-15 kg/cm , loo-213 psi)

Condition

Intermittent cooling

(Moisture in refrigeration system freezes in expansion valve and causes temporary blocking.

After time, ice melts and condition returns to normal.)

SMUOUX-088

CAUSE ACTION

7 r

MOISTURE

IN SYSTEM WW;MTE

-

23uoux-O!

Case 5 No refrigerant circulation

Measurement pressure

Low-pressure: 76 cmHg (3.0 inHg) [Vacuum]

High-pressure: Below 589 kPa (6 kg/cm’, 85 psi)

Condition

Refrigerant flow obstructed by moisture or dirt, causing freezing or blockage of expansion valve

9MUOUX.090

Step 1

Discharge the refrigeration system, (Refer to page U-32.)

Step 2

Evacuate the system to remove all air and moisture from it.

$?&$r:o page U-32.)

Charge the system with refrigerant. (Refer to page U-33.)

Step 4

After charging, measure the refrigerant pressure.

(Refer to page U-37.)

Step 5

If the low- and high-pressure sides are still too high, replace

the receiver/drier.

CAUSE ACTION

f r^‘---7

MOISTURE

Id EVACUATE

IN SYSTEM SYSTEM

I I

05UOUX-02

CAUSE ACTION

23UOUX-OE

Step 1

Turn the air conditioner OFF for about 10 minutes. Turn the

air conditioner ON to determine whether the blockage is due

to moisture or dirt.

a) If caused by moisture

System will operate normally after being OFF for 10 minutes.

(Ice melts and relieves blockage.)

Refer to “Moisture in system”.

b) If caused by dirt

System remains abnormal after being OFF 10 minutes.

Go to Step 2.

Step 2

1. Remove the expansion valve. (Refer to page U-39.)

2. Blow out the dirt with compressed air.

3. If unable to remove the dirt, replace the expansion valve.

4. Evacuate, charge, and test the system.

U-18

Page 988 of 1164

CHARGING HOSE

CLOSED

CLOSED

23UOUX-061

CHARGING HOSE

CHARGING VALVE CLOSED 0

23UOUX.061

3. Connect high-and low-pressure side charging hoses and

stop valves to the refrigerant system service valves.

23UOUX-062

FREON (REFRIGERANT RECOVERY

ND RECYCLING

CONTAINER

VALVE

Manifold gauge set/Stop valve installation

Caution

l Connect all charging hoses via stop valves to avoid

venting the refrigerant remaining in the hoses into

the atomosphere. _A

l Do not disconnect the stop valve from the charg-

ing hose when there is refrigerant remaining in the

hose.

1. Turn the knob counterclockwise to close the stop valve.

2. Install the stop valve to the end of the charging hose of the

manifold gauge set.

Caution

l Verify that high-and low-pressure side valves of the

manifold gauge set are fully closed before connect-

ing the charging hose and stop valve to the refriger-

ant system service valve.

23UOUX-063 Evacuation/Airtiahtness test

1. Connect the manifold gauge set and stop valves to the

refrigerant system service valves.

2. Connect the center hose of the manifold gauge set to the

vacuum pump inlet.

3. Prepare as follows according to the charging method.

Charging from service container.

Connect the charging hose and service container valve to the

manifold gauge set air purge valve.

I

23UOUX-06

U-32

4

Refrigerant recovery operation.

Remove the refrigerant from the refrigerant system by using

a freon (refrigerant) recovery and recycling system.

Caution

. Never vent the refrigerant into the atomosphere.

l When using a freon recovery and recycling system,

follow the operation instructions provided by the

equipment manufacturer.

_-,

Page 989 of 1164

U

r

I

23UOUX-061

23UOUX-067

23UOUX-061 3

Caution

l Connect the charging hose to the air purge valve

via its tap pin side.

l Do not disconnect the charging hose or the serv-

ice container valve until the charging operation is

completed.

l Do not open the service container valve when not

used.

Charging from freon recovery and recycling system.

Connect the charging hose and stop valve to the manifold

gauge set air purge valve.

23UOUX-065

Caution

l Connect the charging hose to the air purge valve

via its tap pin side.

l Do not disconnect the charging hose or stop valve

until the charging operation is completed.

l Do not open the stop valve when not used.

4. Start the vacuum pump and open the high-and low-pressure

side valves of the manifold gauge set.

5. Start the pump and let it operate for 15 minutes.

6. Check high- and low-pressure side gauge readings. When

both of them are at 750 mmHg or more, close the manifold

gauge set valves.

7. Stop the vacuum pump and wait for about 5 minutes.

8. Verity that the low-pressure side gauge reading does not

change.

9. If the reading changes, retighten the piping connections and

repeat the evacuation operation.

10. If not changed, check for leaks (see below) and charge the

system.

u-33

Page 990 of 1164

ENGINE sro~i32 U

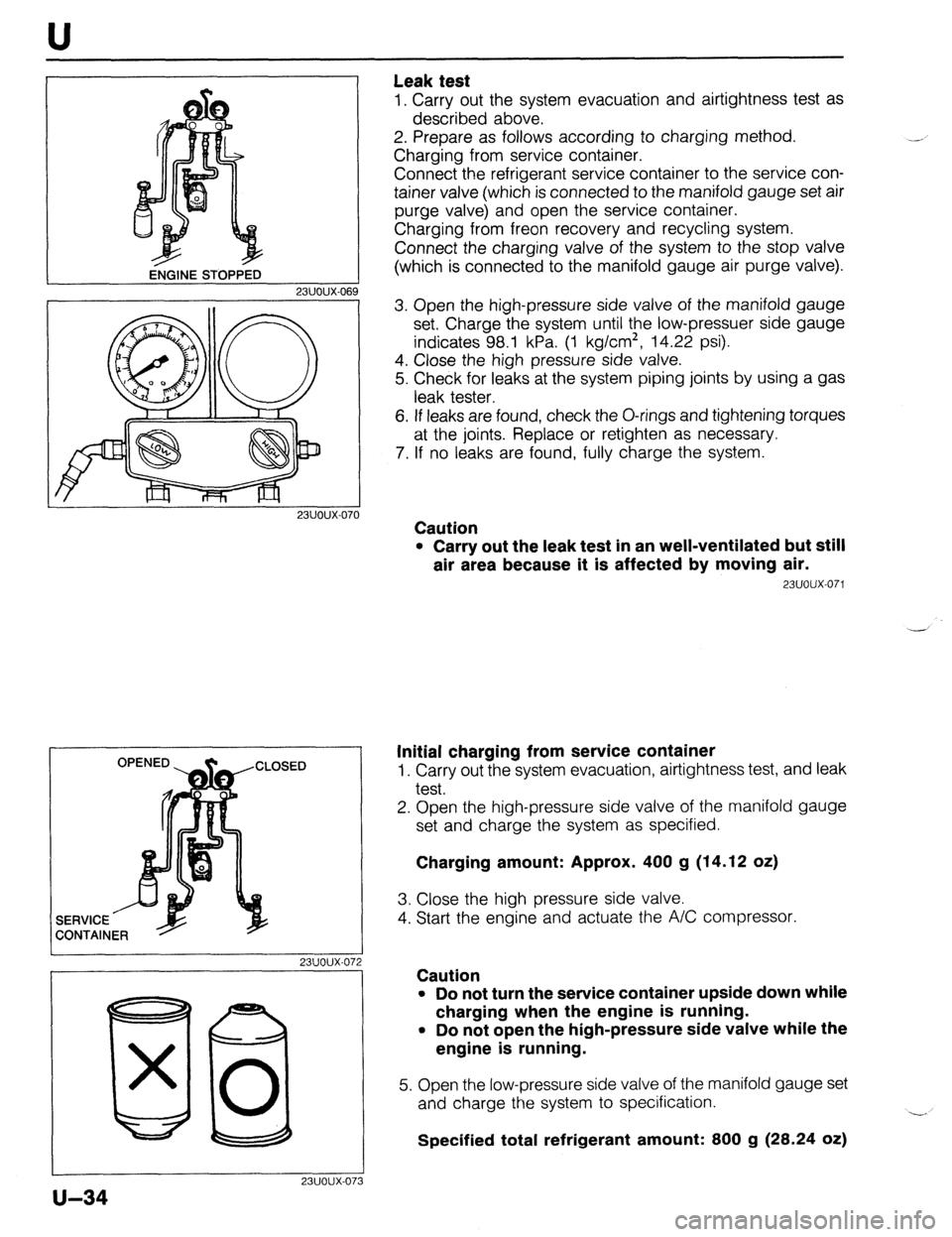

Leak test

1. Carry out the system evacuation and airtightness test as

described above.

2. Prepare as follows according to charging method.

Charging from service container.

Connect the refrigerant service container to the service con-

tainer valve (which is connected to the manifold gauge set air

purge valve) and open the service container.

Charging from freon recovery and recycling system.

Connect the charging valve of the system to the stop valve

(which is connected to the manifold gauge air purge valve).

23UOUX-06

23UOUX-070

I 23UOUX-072

I

80 x 0

23UOUX-07

u-34

3

3. Open the high-pressure side valve of the manifold gauge

set. Charge the system until the low-pressuer side gauge

indicates 98.1 kPa. (1 kg/cm*, 14.22 psi).

4. Close the high pressure side valve.

5. Check for leaks at the system piping joints by using a gas

leak tester.

6. If leaks are found, check the O-rings and tightening torques

at the joints. Replace or retighten as necessary.

7. If no leaks are found, fully charge the system.

Caution

l Carry out the leak test in an well-ventilated but still

air area because it is affected by moving air.

23UOUX-071

Initial charging from service container

1. Carry out the system evacuation, airtightness test, and leak

test.

2. Open the high-pressure side valve of the manifold gauge

set and charge the system as specified.

Charging amount: Approx. 400 g (14.12 oz)

3. Close the high pressure side valve.

4. Start the engine and actuate the A/C compressor.

Caution

l Do not turn the service container upside down while

charging when the engine is running.

l Do not open the high-pressure side valve while the

engine is running.

5. Open the low-pressure side valve of the manifold gauge set

and charge the system to specification.

Specified total refrigerant amount: 800 g (28.24 oz) -.