steering MAZDA PROTEGE 1992 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 661 of 1164

ENGINE SPEED SENSING POWER STEERING

POWER STEERING OIL PUMP

N

Removal / Installation

1. Remove in the order shown in the figure.

2. Install in the reverse order of remnvnl

. ..-.-..

d 2 19-25 (1.9-2.6, 14-19)

- Nm (m-kg, f&lb)

23UONX-043

1. Bolt

2. Nut

3. Nut

4. Adjusting bolt

5. Drive belt

Replacement .,....,.,.,,,,.,.....,..,,.... page N-42

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page N-42

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page N-41 6. Pressure hose

7. Return hose

8. Bolts

9. P/S oil pump assembly

N-37

Page 662 of 1164

N ENGINE SPEED SENSING POWER STEERING

Disassembly / Inspection / Assembly

1. The following procedures show replacement of the O-rings. If a problem is found in other parts, replace

the oil pump assembly.

2. Disassemble in the order shown in the figure, referring to

Disassembly Note.

3. Inspect all parts and replace as necessary.

4. Assemble in the reverse order of disassembly, referring to

Assembly Note,

1. Suction pipe

2. O-ring

3. Pressure-switch assembly

4. O-ring

5. Connector

6. O-ring

7. Control valve

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-40

8. Spring

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-40

9. Bracket

10. Pump body (rear)

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-39

Il. O-ring _,

12. Cam ring

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-39

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-40

13. Vane

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-39

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-40

14. Rotor

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page N-39

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-40

15. Side plate

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-40

16. O-ring

17. O-ring

18. Pin

19. Pump body (front)

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-39

N-38

Page 663 of 1164

ENGINE SPEED SENSING POWER STEERING

93GONX-05:

93GONX-056

93GONX-O!

93GONX-05

Disassembly note

Oil pump

Note

l As shown in the figure, when securing the oil pump

in a vise, be sure to use the SST so that force is not

applied to the pulley or shaft.

Assembly note

Rotor

1. Install the rotor to the shaft with the rotor’s identification mark

facing upward.

Cam ring

1. Install the cam ring so that its identification mark is facing

downward.

Vane

1. Install the vanes (10 pieces) to the rotor, with the R part of

the vanes facing outward.

Inspection

Note

l Replace the pump assembly if necessary.

Pump body

1. Check the front and rear pump bodies for cracking or oth-

er damage and for abnormal wear of the moving surface

of the rotor.

N-39

Page 664 of 1164

N ENGINE SPEED SENSING POWER STEERING

93GONX-05

I 93GONX-05!

Cam ring, rotor, vanes, side plate

1. Check the moving surface of the cam ring’s vanes for ab-

normal wear.

2. Check the moving surface of the side plate and the pump

bodies for abnormal wear.

3. Check the moving surface of the vane cam ring for abnor-

mal wear.

4. Check the clearance of the rotor and vanes.

4

Control valve and spring

1. Check the control valve for cracking and other damage, for

clogging, and for abnormal wear of the moving part.

2. Check the spring for damage.

Page 665 of 1164

ENGINE SPEED SENSING POWER STEERING N

P/S

23UONX-04!

PULLEY

P/S AND A/C

23UONX-04

DRIVE BELT

Inspection

1. Check the drive belts for wear, cracks, and fraying. Replace

as necessary.

2. Verify that the drive belts are correctly mounted on the

pulleys.

3. Check the drive belt deflection by applying moderate pres-

sure (98 N,

10 kg, 22 lb) midway between the pulleys.

Note

l Measure the belt deflection between the specified

pulleys.

0 A belt is considered “New” if it has been used on

a running engine for less than five minutes.

Set the deflection specification below accordingly.

* Check the belt deflection when the engine is cold,

or at least 30 minutes after the engine has stopped.

Deflection

mm (in)

New Used Limit

8-9.0 (0.31-0.35) 9.0-10.0 (0.35-0.39) 11.5 (0.45)

4. If the deflection is not within specification, adjust it.

23UONX-047

Drive belt tension check

WHEN SET

I

23UONX-048

Note

l Belt tension can be checked in place of belt

deflection.

aBelt tension can be measured between any two

pulleys.

Using the SST check the belt tension.

Tension

N (kg, lb)

New

491-589

(50-60, 11 O-l 32) Used

422-491

(43-50, 95-l 10) Limit

245

(25, 55)

N-41

Page 666 of 1164

N ENGINE SPEED SENSING POWER STEERING

13UONX-02

Adjustment

1. Loosen bolt @, nut @J, and locknut 0. Turn adjusting bolt

@? to adjust the belt to the specified tension.

2. Tighten locknut 0, bolt @, and nut @I to the specified

torques.

Tightening torque

Bolt @: 36-54 N-m (3.7-5.5 m-kg, 27-40 ft-lb)

Nut @J : 19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

Locknut 0:

31-46 Narn (3.2-4.7 m-kg, 23-34 f&lb)

Replacement

1. Loosen bolt @, nut 0, and locknut @.

2. Turn adjusting bolt @ to release the belt tension.

3. Remove the belt.

4. Install a new drive belt and adjust the tension and deflec-

tion. (Refer to above for adjustment.)

N-42

Page 671 of 1164

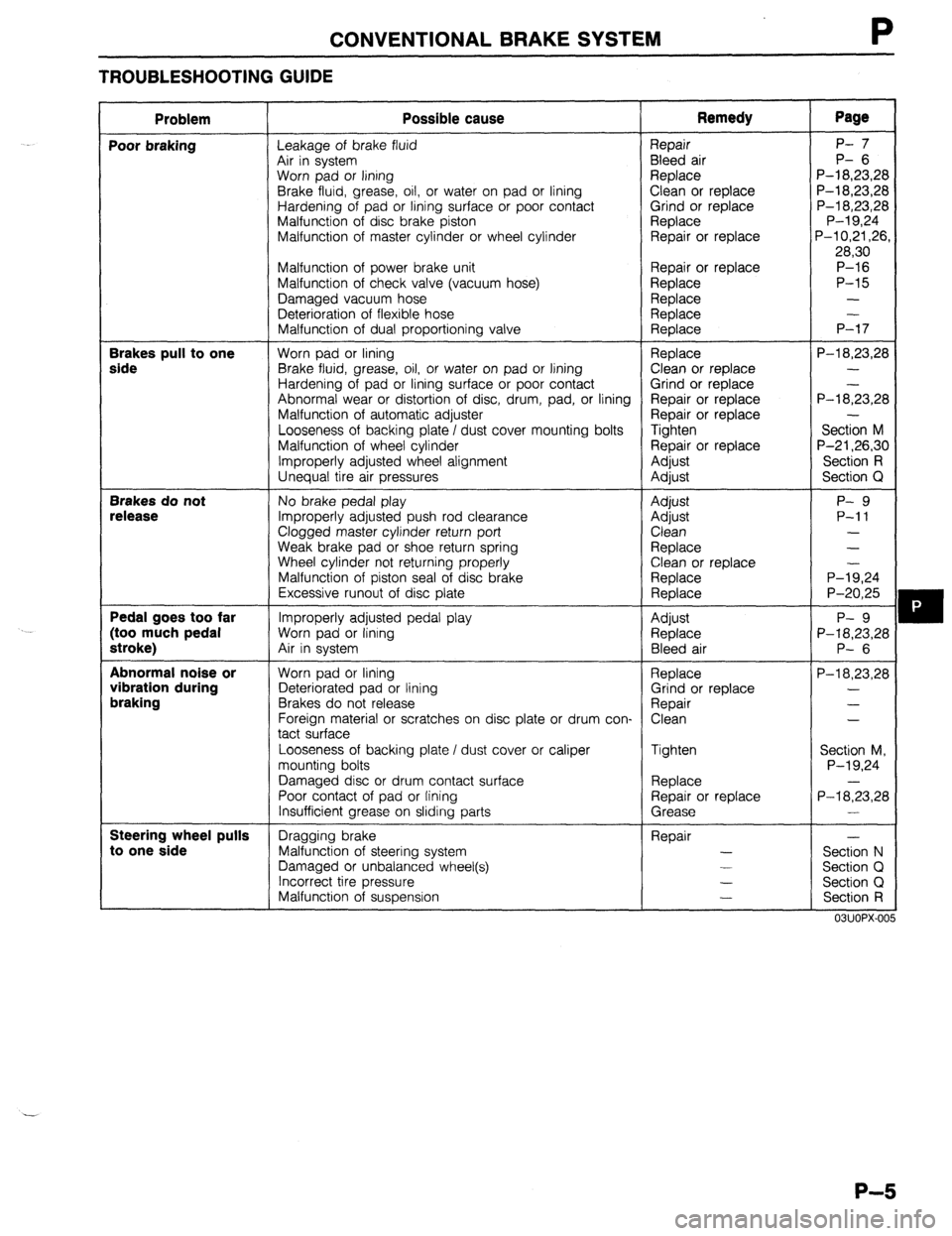

CONVENTIONAL BRAKE SYSTEM

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Poor braking

Leakage of brake fluid Repair P- 7

Air in system Bleed air P- 6

Worn pad or lining Replace P-l 8,23,28

Brake fluid, grease, oil, or water on pad or lining Clean or replace P-18,23,28

Hardening of pad or lining surface or poor contact Grind or replace P-l 8,23,28

Malfunction of disc brake piston Replace P-l 9,24

Malfunction of master cylinder or wheel cylinder Repair or replace P-l 0,21,26,

28,30

Malfunction of power brake unit Repair or replace P-16

Malfunction of check valve (vacuum hose) Replace P-15

Damaged vacuum hose Replace -

Deterioration of flexible hose Replace -

Malfunction of dual proportioning valve Replace P-17 Brakes pull to one

Worn pad or lining Replace P-l 8,23,28 side Brake fluid, grease, oil, or water on pad or lining Clean or replace -

Hardening of pad or lining surface or poor contact Grind or replace

Abnormal wear or distortion of disc, drum, pad, or lining Repair or replace P-l 8;3,28

Malfunction of automatic adjuster Repair or replace -

Looseness of backing plate I dust cover mounting bolts Tighten Section M

Malfunction of wheel cylinder Repair or replace P-21,26,30

Improperly adjusted wheel alignment Adjust Section R

Unequal tire air pressures

Adjust Section Q Brakes do not

No brake pedal play Adjust P- 9 release Improperly adjusted push rod clearance Adjust P-11

Clogged master cylinder return port Clean -

Weak brake pad or shoe return spring Replace -

Wheel cylinder not returning properly

Clean or replace

Malfunction of piston seal of disc brake Replace P-l;,24

Excessive runout of disc plate

Replace P-20,25 Pedal goes too far

Improperly adjusted pedal play Adjust P- 9 (too much pedal Worn pad or lining

Replace P-18,23,28 stroke) Air in system

Bleed air P- 6 Abnormal noise or

Worn pad or lining

Replace P-18,23,28 vibration during Deteriorated pad or lining Grind or replace - braking Brakes do not release Repair -

Foreign material or scratches on disc plate or drum con- Clean -

tact surface

Looseness of backing plate / dust cover or caliper Tighten

Section M,

mounting bolts P-l 9,24

Damaged disc or drum contact surface Replace -

Poor contact of pad or fining Repair or replace

P-18,23,28

Insufficient grease on sliding parts Grease - Steering wheel pulls

Dragging brake Repair - to one side Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Cl

Incorrect tire pressure -

Section Q

Malfunction of suspension -

Section R

mm> IAn\, ,.e

P-5

Page 673 of 1164

CONVENTIONAL BRAKE SYSTEM

G ‘lW /

03UOPX-01

03UOPX-01’

03UOPX-01,

23UOPX-00

Inspection, on-vehicle

Brake pipe

Check for cracks, damage, and corrosion of the brake pipe.

Replace the pipe or flare nut(s) if necessary.

Flexible hose

Check for scars, cracks, and swelling of flexible hose. Replace

the hose if necessary.

Removal

1. Remove the brake pipe with the SST.

2. Disconnect the clip and remove the flexible hose from the

bracket.

Installation

1. Fix the flexible hose in the bracket and connect the clip to it.

2. Connect the flexible hose to the brake pipe and tighten the

flare nut with the SST.

Caution

l Verify that the hose is not twisted.

l Verify that the hose does not contact other parts

when the vehicle bounces or when the steering

wheel is turned fully right or left.

Tightening torque:

13-22 N*m (1.3-2.2 m-kg, 9.4-16 ft-lb)

P-7

Page 702 of 1164

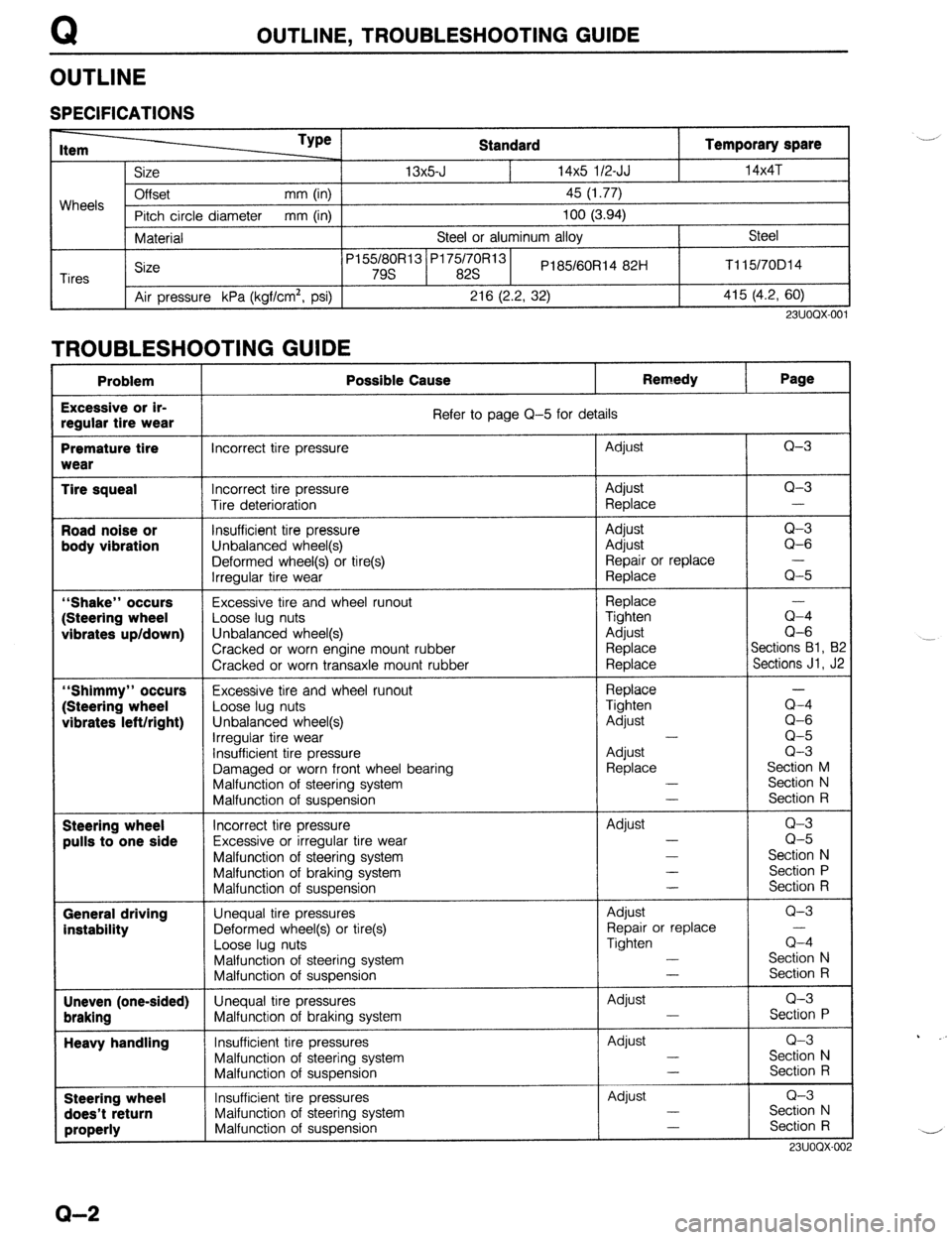

Q OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

Wheels

Tires Standard Temporary spare __/

Size 13x5-J 14x5 l/2-JJ l4x4T

Offset mm (in)

45 (1.77)

Pitch circle diameter mm (in)

100 (3.94)

Material Steel or aluminum alloy Steel

Size P155/80R13’P175/70R131

PI 85/60Rl4 82H Tll5/70D14

79s 82s

Air pressure kPa (kgflcm’, psi)

216 (2.2, 32) 415 (4.2, 60)

23UOQX-001

TROUBLESHOOTING GUIDE _____ -_- ____ _ __.- -. -.-.--

Problem Possible Cause Remedy Page

Excessive or ir-

regular tire wear Refer to page Q-5 for details

Premature tire incorrect tire pressure Adjust Q-3

wear

Tire squeal Incorrect tire pressure Adjust Q-3

Tire deterioration Replace -

Road noise or Insufficient tire pressure Adjust Q-3

body vibration

Unbalanced wheel(s) Adjust Q-6

Deformed wheel(s) or tire(s) Repair or replace

Irregular tire wear Replace Q-5

“Shake” occurs Excessive tire and wheel runout

Replace

(Steering wheel Loose lug nuts

Tighten a-4

vibrates up/down) Unbalanced wheel(s)

Adjust Q-6

Cracked or worn engine mount rubber

Replace Sections Bl, B:

Cracked or worn transaxle mount rubber

Replace Sections Jl, J2

“Shimmy” occurs Excessive tire and wheel runout

Replace

(Steering wheel

Loose lug nuts Tighten a-4

vibrates left/right) Unbalanced wheel(s)

Adjust Q-6

irregular tire wear -

Q-5

insufficient tire pressure

Adjust Q-3

Damaged or worn front wheel bearing

Replace Section M

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Steering wheel Incorrect tire pressure Adjust Q-3

pulls to one side Excessive or irregular tire wear -

Q-5

Malfunction of steering system -

Section N

Malfunction of braking system -

Section P

Malfunction of suspension -

Section R

General driving Unequal tire pressures Adjust Q-3

instability Deformed wheel(s) or tire(s) Repair or replace

Loose lug nuts Tighten Q-4

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Uneven (one-sided) Unequal tire pressures

Adjust Q-3

braking Malfunction of braking system -

Section P

Heavy handling Insufficient tire pressures Adjust Q-3

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Steering wheel Insufficient tire pressures Adjust Q-3

does’t return Malfunction of steering system -

Section N

properly Malfunction of suspension -

Section R

731100x-or . _. -,

Q-2

Page 708 of 1164

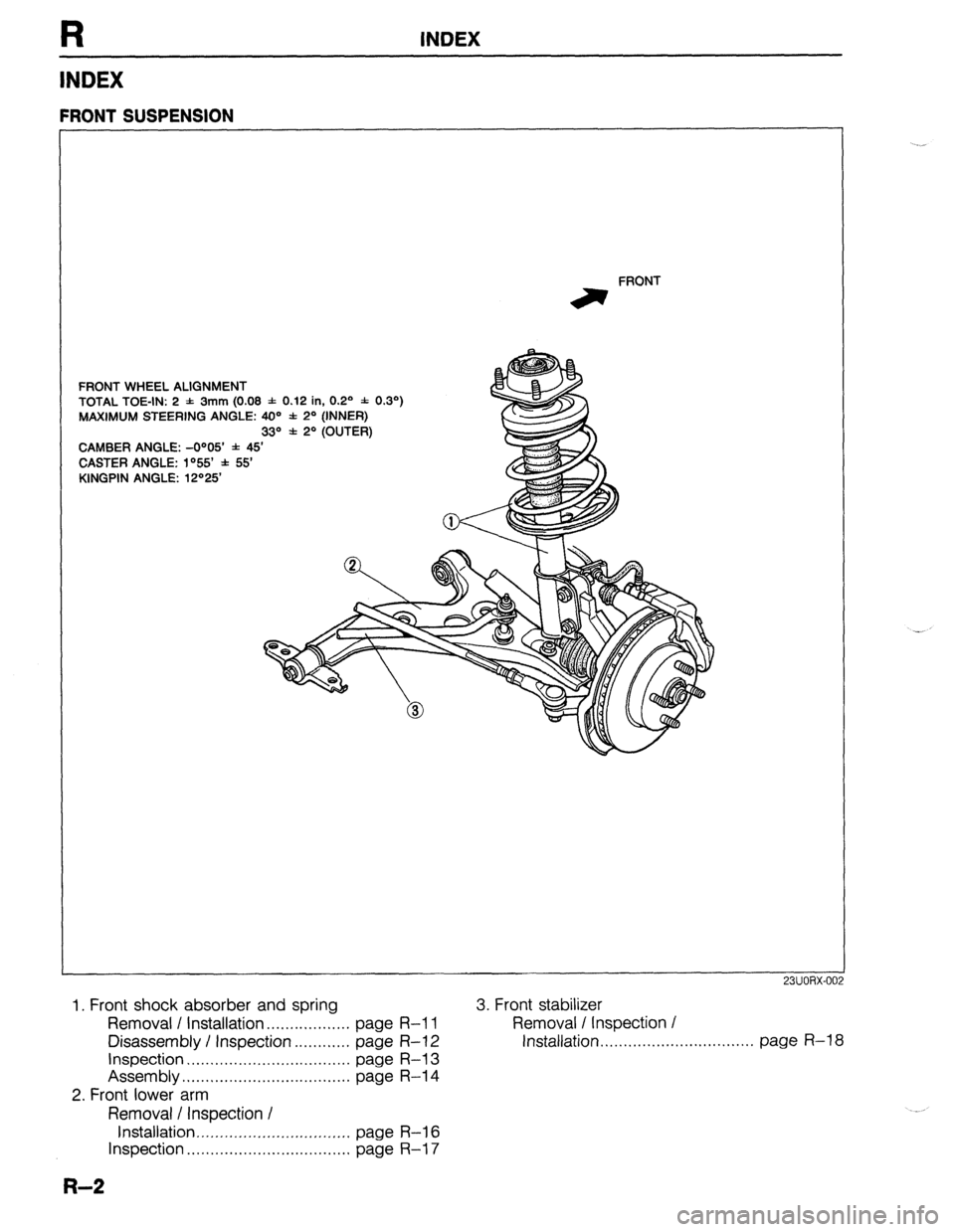

R INDEX

INDEX

FRONT WHEEL ALIGNMENT

TOTAL TOE-IN: 2 -1: 3mm (0.08 f 0.12 in, 0.2’ * 0.3’)

MAXIMUM STEERING ANGLE: 40=’ * 2’ (INNER)

33“ f 2O (OUTER)

CAMBER ANGLE: -O”05’ * 45’

CASTER ANGLE: lo55 f 55

KINGPIN ANGLE: 12“25 FRONT

irr

FRONT SUSPENSION

1. Front shock absorber and spring

Removal I Installation . . . . . . . . . . . . . . . . . . page R-l 1

Disassembly / Inspection . . . . . . . . . . . . page R-l 2

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 3

Assembly . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 4

2. Front lower arm

Removal / Inspection I

Installation ,,...,.......,...........,.._..,. page R-l 6

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 7

R-2

3. Front stabilizer

Removal / Inspection /

Installation, . . . . . . ,. . . . . . . . . . . . . . . . . . . . . . . . . page R-l 8