ad blue MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 17 of 1164

CAUTION GI

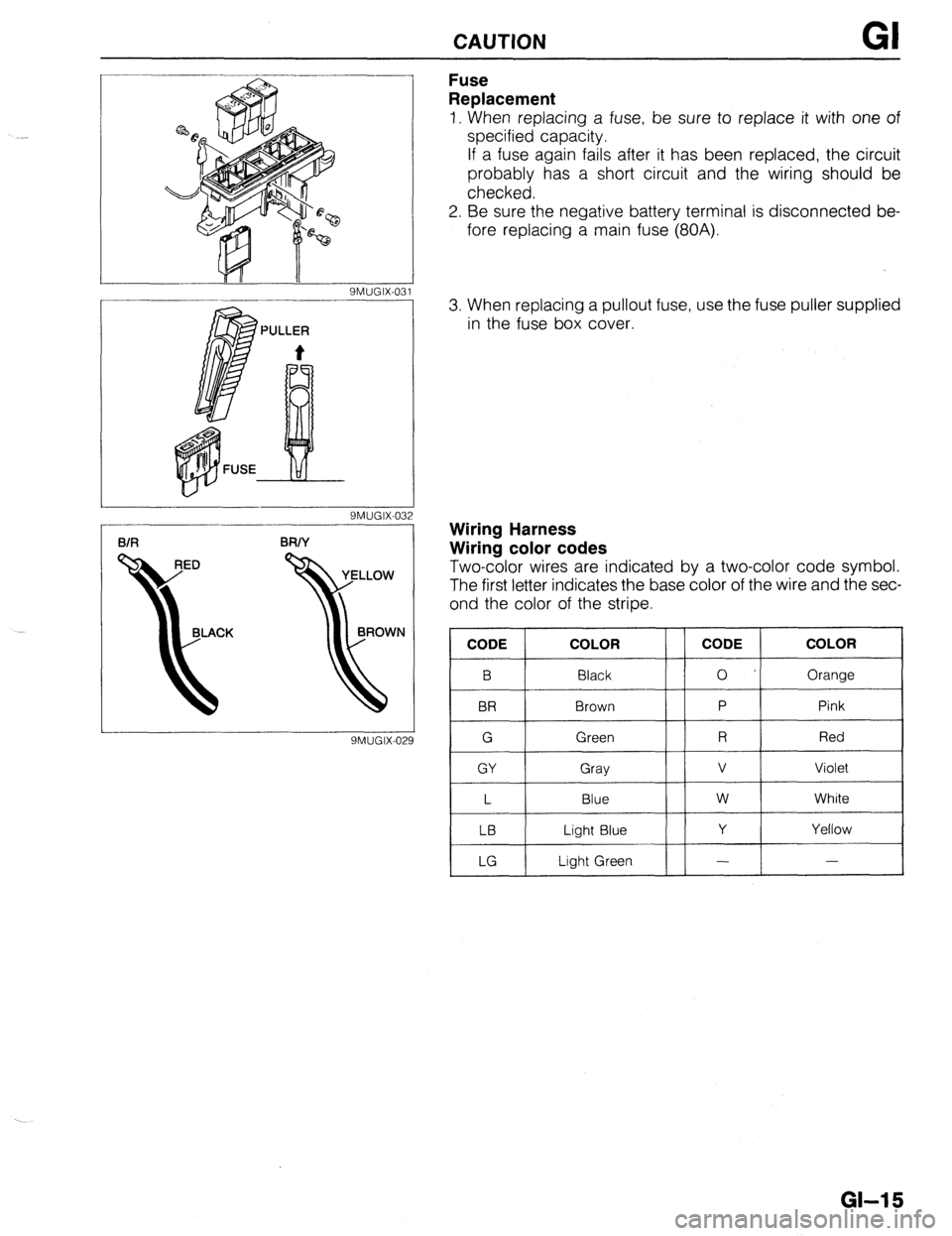

9MUGIX-032

9MUGIX-029

Fuse

Replacement

1. When replacing a fuse, be sure to replace it with one of

specified capacity.

If a fuse again fails after it has been replaced, the circuit

probably has a short circuit and the wiring should be

checked.

2. Be sure the negative battery terminal is disconnected be-

fore replacing a main fuse (80A).

3. When replacing a pullout fuse, use the fuse puller supplied

in the fuse box cover.

Wiring Harness

Wiring color codes

Two-color wires are indicated by a two-color code symbol.

The first letter indicates the base color of the wire and the sec-

ond the color of the stripe.

CODE COLOR

B Black

BR Brown

G Green

GY Gray

L Blue

LB Light Blue

LG Light Green CODE COLOR

0 Orange

P Pink

R Red

v Violet

w White

Y Yellow

- -

GI-15

Page 52 of 1164

Bl ON-VEHICLE MAINTENANCE

8 e

93UOlA.08

EX

03UOBl-035

HEAD COVER

)

23UOBl-023

Steps After Installation

1, Connect the negative battery cable.

2. Start the engine and fully warm up.

3. Verify that there is no tappet noise. 2. Install the rocker arm and rocker shaft assembly.

Caution

l The bolts must be tightened gradually and in the or-

der shown in the figure.

Tightening torque:

22-28 N-m (2.2-2.9 m-kg, 18-21 ft-lb)

BP SOHC

1. Assemble the rocker arm and rocker shaft assembly as

shown in the figure.

Caution

l Face the rocker shaft identification mark upward.

l The installation bolt holes are different for the ex-

haust and intake sides.

Identification mark

IN . . . . . . . . . . White

EX . . . . . . . . . . . Blue

2. Install the rocker arm and rocker shaft assembly.

3. Tighten the rocker arm bolts in two or three steps in the or-

der shown in the figure.

Tightening torque:

22-28 Nsrn (2.2-2.9 m-kg, 16-21 ft-lb)

Cylinder head cover

1. Install the cylinder head cover.

Tightening torque

Bolt @:

4.9-8.8 N-m (50-90 cmikg, 43-78 in-lb)

Bolt @:

7.8-l 1 Nnrn (80-l 10 cm-kg, 69-95 in-lb)

Caution

l If the head cover gasket is reused, apply sealant in

the groove as shown.

03UOBl-038

.-

Bl-22

Page 87 of 1164

INSPECTION / REPAIR Bl

-- 05lJOBX-13

.- __--- 0

-_.--__I__

--

05UOBX.131

B6 SOHC

EX

IN

BP SOHC --~ -____

03uoEI-09

--__.

86 SOHC -

23UOBl-073

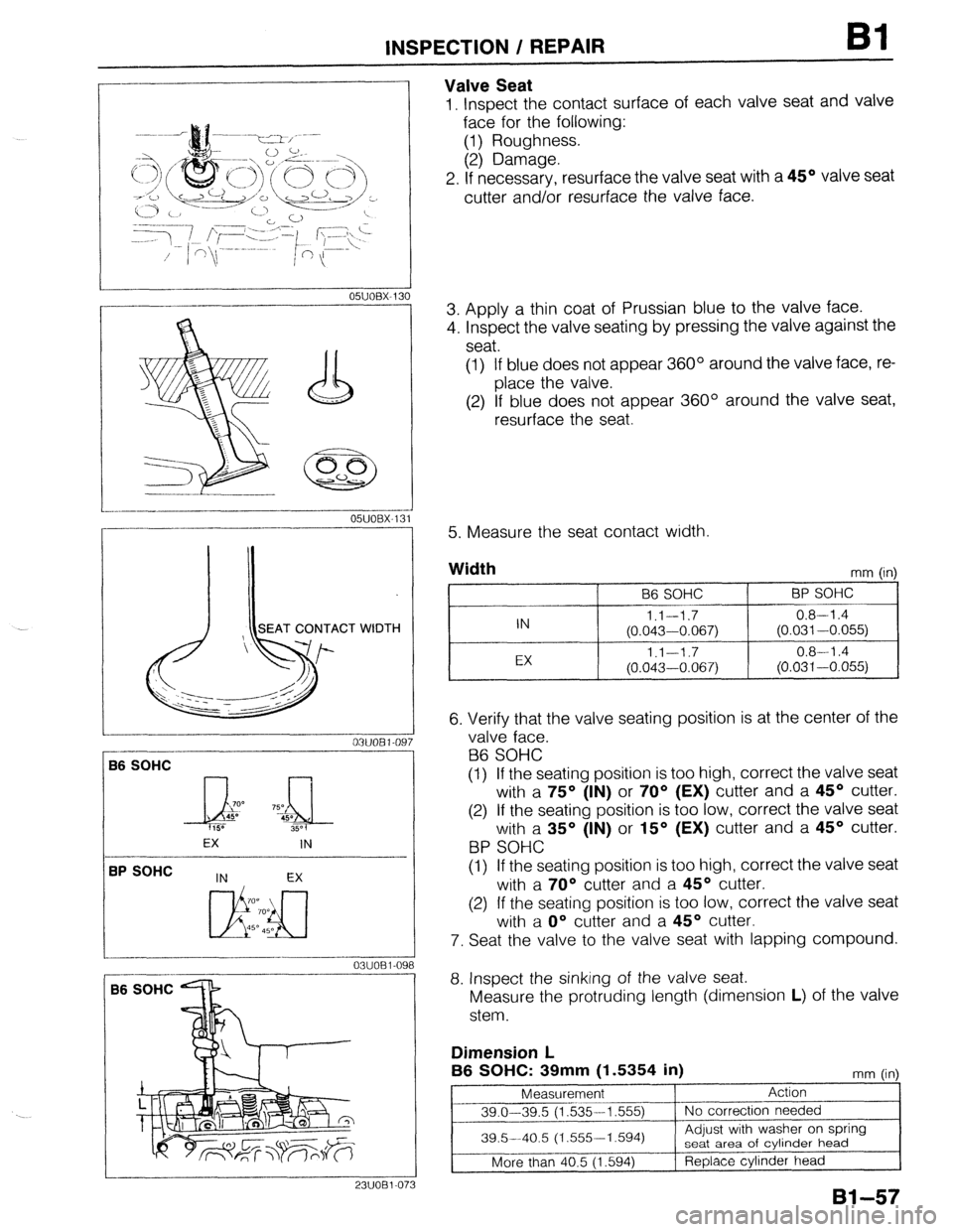

Valve Seat

1, Inspect the contact surface of each valve seat and valve

face for the following:

(1) Roughness.

(2) Damage.

2. If necessary, resurface the valve seat with a 45O valve seat

cutter and/or resurface the valve face.

3. Apply a thin coat of Prussian blue to the valve face.

4. Inspect the valve seating by pressing the valve against the

seat.

(1) If blue does not appear 360° around the valve face, re-

place the valve.

(2) If blue does not appear 360° around the valve seat,

resurface the seat

5. Measure the seat contact width.

Width

mm (in)

96 SOHC BP SOHC

IN l.l--1.7 0.8-l .4

(0.043-0.067) (0.031-0.055)

EX 1.1-1.7 0.8-l .4

(0.043-0.067) (0.031-0.055)

6. Verify that the valve seating position is at the center of the

valve face.

B6 SOHC

(1) If the seating position is too high, correct the valve seat

with a 75O (IN) or 70° (EX) cutter and a 45O cutter.

(2) If the seating position is too low, correct the valve seat

with a 35O (IN) or 15O (EX) cutter and a 45O cutter.

BP SOHC

(1) If the seating position is too high, correct the valve seat

with a 70° cutter and a 45O cutter.

(2) If the seating position is too low, correct the valve seat

with a O” cutter and a 45O cutter.

7. Seat the valve to the valve seat with lapping compound.

8. Inspect the sinking of the valve seat.

Measure the protruding length (dimension L) of the valve

stem.

Dimension L

B6 SOHC: 39mm

(1.5354 in) mm fin

Page 189 of 1164

INSPECTION / REPAIR 82

OWOBX-13

SEAT CONTACT WIDTH

I OWOBX-132

IN EX

700

Li!!b!J

700

45O 450

r

----

0311082 Oe

_---- _---

1

05UOBX-1:

Gi

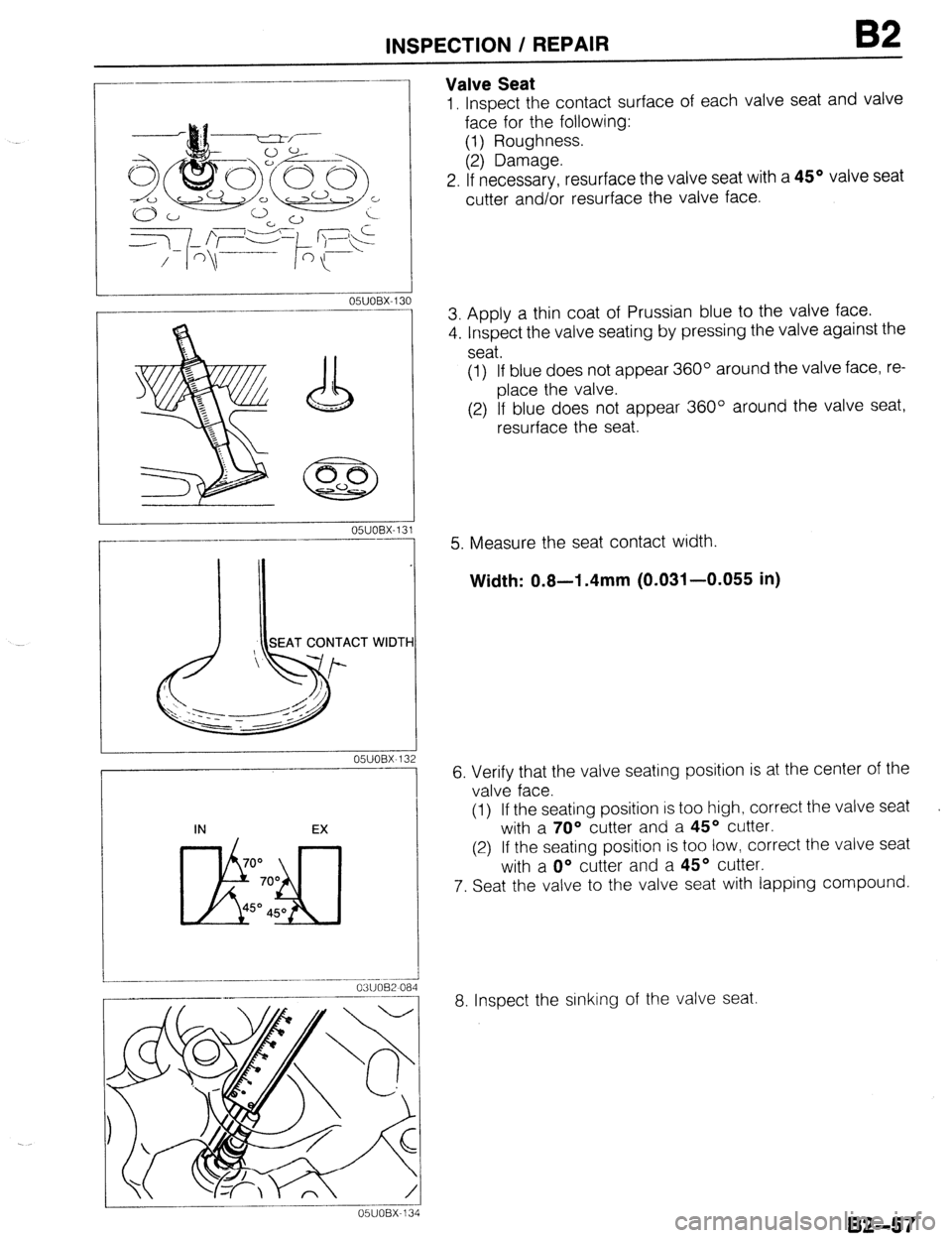

Valve Seat

1, Inspect the contact surface of each valve seat and valve

face for the following:

(1) Roughness.

(2) Damage.

2. If necessarv, resurface the valve seat with a 45’ valve seat

cutter and/br resurface the valve face.

3. Apply a thin coat of Prussian blue to the valve face.

4. Inspect the valve seating by pressing the valve against the

seat.

(1) If blue does not appear 360° around the valve face, re-

place the valve.

(2) If blue does not appear 360° around the valve seat,

resurface the seat.

5. Measure the seat contact width.

Width: 0.8-l .4mm (0.031-0.055 in)

6. Verify that the valve seating position is at the center of the

valve face.

(1) If the seating position is too high, correct the valve seat

with a 70° cutter and a 45O cutter.

(2) If the seating position is too low, correct the valve seat

with a O” cutter and a 45’ cutter.

7. Seat the valve to the valve seat with lapping compound.

8. Inspect the sinking of the valve seat.

B2-57

Page 296 of 1164

F TROUBLESHOOTING GUIDE

SYMPTOM TROUBLESHOOTING

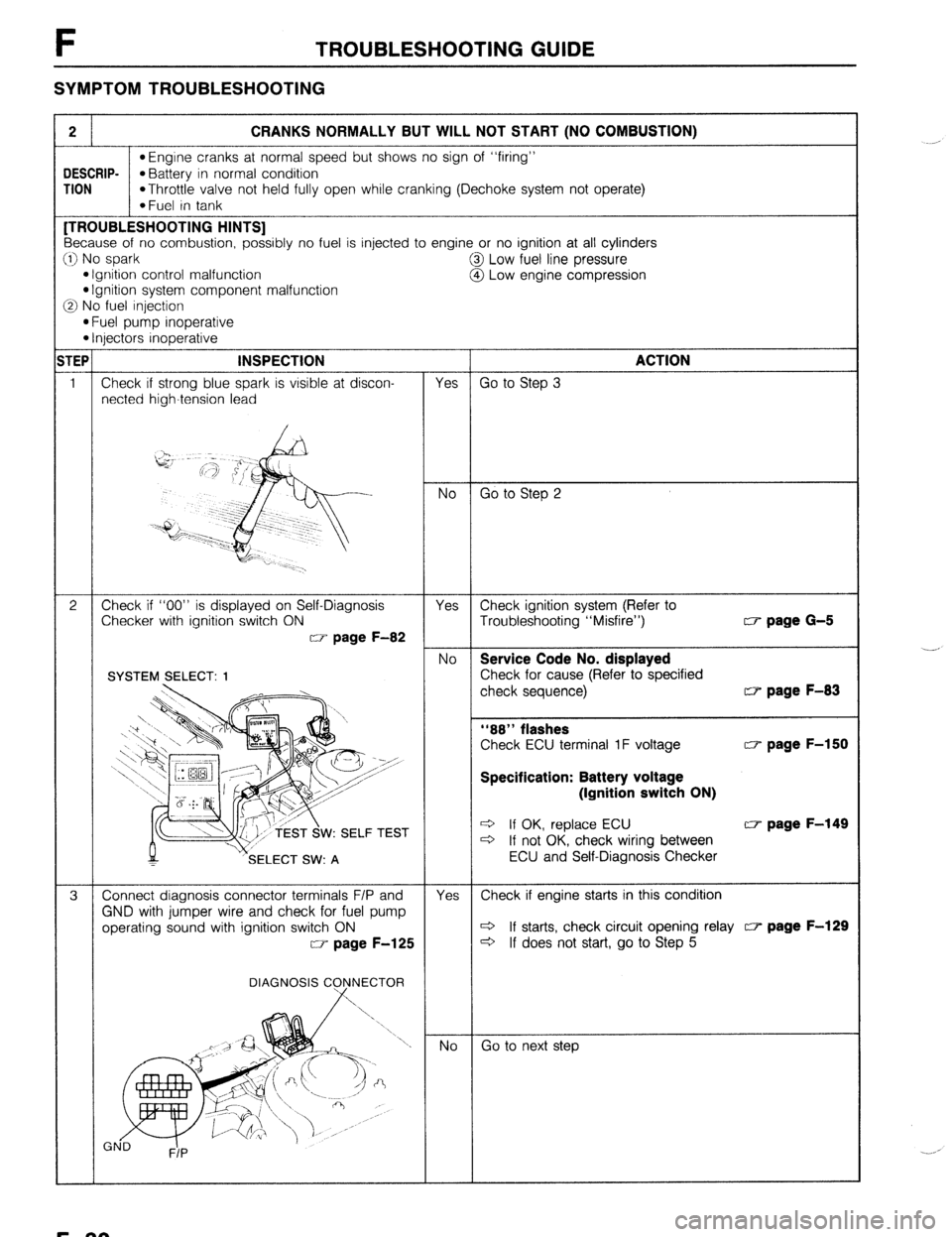

2 CRANKS NORMALLY BUT WILL NOT START (NO COMBUSTION)

l Engine cranks at normal speed but shows no sign of “firing”

DESCRIP-

*Battery in normal condition

TION

*Throttle valve not held fully open while cranking (Dechoke system not operate)

*Fuel in tank [TROUBLESHOOTING HINTS]

Because of no combustion, possibly no fuel is injected to engine or no ignition at all cylinders

:I) No spark

@I Low fuel line pressure

l Ignition control malfunction

@ Low engine compression l Ignition system component malfunction

3 No fuel injection

l Fuel pump inoperative l Injectors inoperative

TEP INSPECTION

ACTION

1 Check if strong blue spark is visible at discon-

Yes Go to Step 3

netted high-tension lead

No Go to Step 2

2 Check if “00” is displayed on Self-Diagnosis

Yes Check ignition system (Refer to

Checker with ignition switch ON

Troubleshooting “Misfire”) w page G-5

w page F-82

No Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST e If OK, replace ECU w page F-149 c3 If not OK, check wiring between

SELECT SW: A ECU and Self-Diagnosis Checker

3 Connect diagnosis connector terminals F/P and

Yes Check if engine starts in this condition

GND with jumper wire and check for fuel pump

operating sound with ignition switch ON c3 If starts, check circuit opening relay c7 page F-129

w page F-125

c3 If does not start, go to Step 5

DIAGNOSIS C

Go to next step ._-,

._. ,

F-30

Page 308 of 1164

![MAZDA PROTEGE 1992 Workshop Manual F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D MAZDA PROTEGE 1992 Workshop Manual F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D](/img/28/57077/w960_57077-307.png)

F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D Air/Fuel mixture too lean @ Incorrect idle speed

l Air leakage l Idle speed misadjustment l Fuel injection control malfunction l Idle speed control malfunction

*Low fuel line pressure @ One or more spark plugs not firing

3 One or more injectors clogged or not operating @ Low engine compression

3 Low intake air amount @ Airflow meter stuck INSPECTION

1

1

2

3

4

5

6

- Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM2ELECT: 1

M v’SELECT SW: A TEST

Check if ECU terminal voltages are OK

MTX...Especially 2D, 20 and 2Q

ATX... Especially 2B, 2E and 3D CT page F-150

Disconnect high-tension lead at idle and check if

engine speed decreases equally at each cylinder

Check for injector operating sound at idle

Check if battery voltage exists at injector connec-

tor (W/R) wire

Check if strong blue spark is visible at discon-

nected high-tension lead

, Yes No Service Code No. displayed

Check for cause (Refer to specified

:heck sequence) “88” flashes

Check ECU terminal IF voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

3 If OK, replace ECU w page F-149 3 If not OK, check wiring between

ECU and Self-Diaanosis Checker Yes

Go to next step No

Check for cause Yes

Go to Step 8 No

Go to next step

Go to Step 6

Go to Step 5 Yes

No

Yes

No

Yes

No I-

30 to next step w page F-83

0 page F-151

Check if injector resistance is OK c7 page F-131

Resistance: Approx. 12-l 852

c3 If OK, check wiring between ECU

and injector

c3 If not OK, replace injector w page F-131

Check wiring between ECU and injector

Go to next step

Check high-tension lead w page G-17

Q If OK, check distributor cap and

rotor w page G-22

c3 If not OK, replace high-tension lead

F-42

Page 319 of 1164

TROUBLESHOOTING GUIDE F

No Replace airflow meter

9

Check for injector operating sound at idle Yes Go to Step 11

No Go to next Step

10 Check if battery voltage exists at injector connec- Yes Check if injector resistance is OK CT page F-131

tor (W/R) wire Resistance: 12-l 6fi

c3 If OK, check wiring between ECU

and injector

c3 If not OK, replace injector CT page F-131

No

Check wiring between ECU and injector

11 Check if strong blue spark is visible at discon-

Yes Go to next step

netted high-tension lead

No Check high-tension lead

+ If OK, check distributor cap and

rotor w page G-22

* If not OK, replace high-tension lead

12

Check if spark plugs are OK Yes Check for correct engine compression CT page Bl-10

w page G-16 82-10

Compression (Minimum):

. BP SOHC

834 kPa (8.5 kg/cm2, 121 psi)300 rpm

BON BUILDUP l BP DOHC

883 kPa (9.0 kg/cm*, 128 psi)-300 rpm

l.O-l.lmm ’ B6 DAMAGE AND 932 kPa (9.5 kg/cm’, 135 psi)-300 rpm DETERIORATION

c3 If OK, go to next step

c13 If not OK, check for cause CT page Bl-10

B2-10

No

Clean or replace w page G-18

13

Check for injector leakage Yes Replace injector CT page F-131

w page F-132

No Go

to next step

14 Try known good ECU and check if condition im-

proves cc7 page F-149

23UOFX-030

F-53

Page 445 of 1164

TROUBLESHOOTING GUIDE G

3 Cranks slowly

STEP INSPECTION ACTION

1 Check if engine cranks normally with fully Yes Check charging system CT page G-7

charged battery

No Go to next step

2 Check starter cable connection for looseness Yes Repair or replace connection

and corrosion

OBUOGX-OC

I 1 4

.

Alternator warning lamp illuminates when engine running

STEP INSPECTION ACTION

1 Check for correct battery voltage at idle Yes Check wire harness between alternator L terminal and aI*

Specification: 14.1--14.7V ternator warning lamp

No Check charging system w page G-7

03UOGX-008

5 I Discharged battery I 1TEP INSPECTION

f Check charging system w page G-7 -

6

TEF

1

r

--

Yes

03UOGX-009

ACTION

Turn ignition switch ON and check dark current as shown

Dark current: Below 20mA

No Repair or replace parts as necessary 1

Misfire

INSPECTION

-

Disconnect high-tension lead from each spark

plug and check for strong blue spark while

cranking

, i

Yes

No T-

I

ACTION

- Check spark plug w page G-f8

~3 If OK, engine electrical system normal

~3 If not OK, clean or replace spark plug

Check ignition system ci’ page G-16

1 03UOGX-010

G-5

Page 448 of 1164

G CHARGING SYSTEM

INDICATOR

NG POINT

OSUOGX-Ol!

BATTERY

Inspection

Indicator sign (If equipped)

1. Check that the indicator is blue.

2. If the indicator is not blue, check if the electrolyte level lies

between the upper and lower lines.

3. If low, add distilled water, being careful not to overfill.

4. If the electrolyte level is acceptable and yet the indicator

is not blue, the battery must be recharged.

Specific gravity of electrolyte

Measure the specific gravity with a hydrometer.

Specification: 1.27-l .29 (at 20°C [66OF])

Note

l If the battery charge indicator is not blue when the

specific gravity is normal, the indicator could be

defective.

Battery discharge test

I I Measure open circuit voltage of battery with a digital voltmeter capable of

reading O.OlV

I

I I

1 Below i 2.4V

Abo”;t 12.4V

I 1 I

Quick charge for 2 hours

and recheck voltage

c Below 12.4V Above 12.4V

l Apply test load (see test load chart) to the battery

using a battery load tester

l Record battery voltage at the end of 15 seconds; is

voltage more than specification? YES

Measure open circuit Below 12.4V Above 12.4V

Charge battery J Test load

Battery

] Load (A)

55D23L 180

Battery voltage with load

Approximate Minimum

battery temp. voltage (V)

21 OC (70°F) 9.6

15OC (60%) 9.5

10°C (50°F) 9.4

4% (40°F) 9.3

-1 ‘C (30°F) 9.1

-7OC (20°F) 8.9

-12OC (lOoF) 8.7

-18% ( 0“F)

8.5

23UOGX-003 /

L_,*

G-8

Page 456 of 1164

G IGNITION SYSTEM

TROUBLESHOOTING

iTEP

INSPECTION

ACTION

1

Check if MIL illuminates when engine is running Yes Check for malfunction code number

and perform troubleshooting (TEN ter-

minal grounded) c7 Section F

No Go to next step

2 Drsconnect high-tension lead from distributor and

Yes

check for strong blue spark while cranking en-

l Check distributor cap and rotor v page G-22

gine * Check high-tension lead

KP page G-19 c7 page G-17

+ Ignition system normal

No

Go to next step

3 Check if resistance of ignition coil is OK

Yes

Go to next step ~7

page G-19

Specification (at 20°C [66”9):

Primary coil winding: 0.81-0.99Q No

Replace ignition coil

Secondary coil winding: IO-16 kQ

-i

Check if resistance of high-tension leads is OK Yes Go to next step

D= page G-17

Specification: 16 kQ per 1 m (3.28 ft)

No Replace high-tension lead

5 Check if igniter is OK

m- page G-23 Yes

Replace ECU

No

Replace igniter

03UOGX-03

G-16