height adjustment MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 5 of 1164

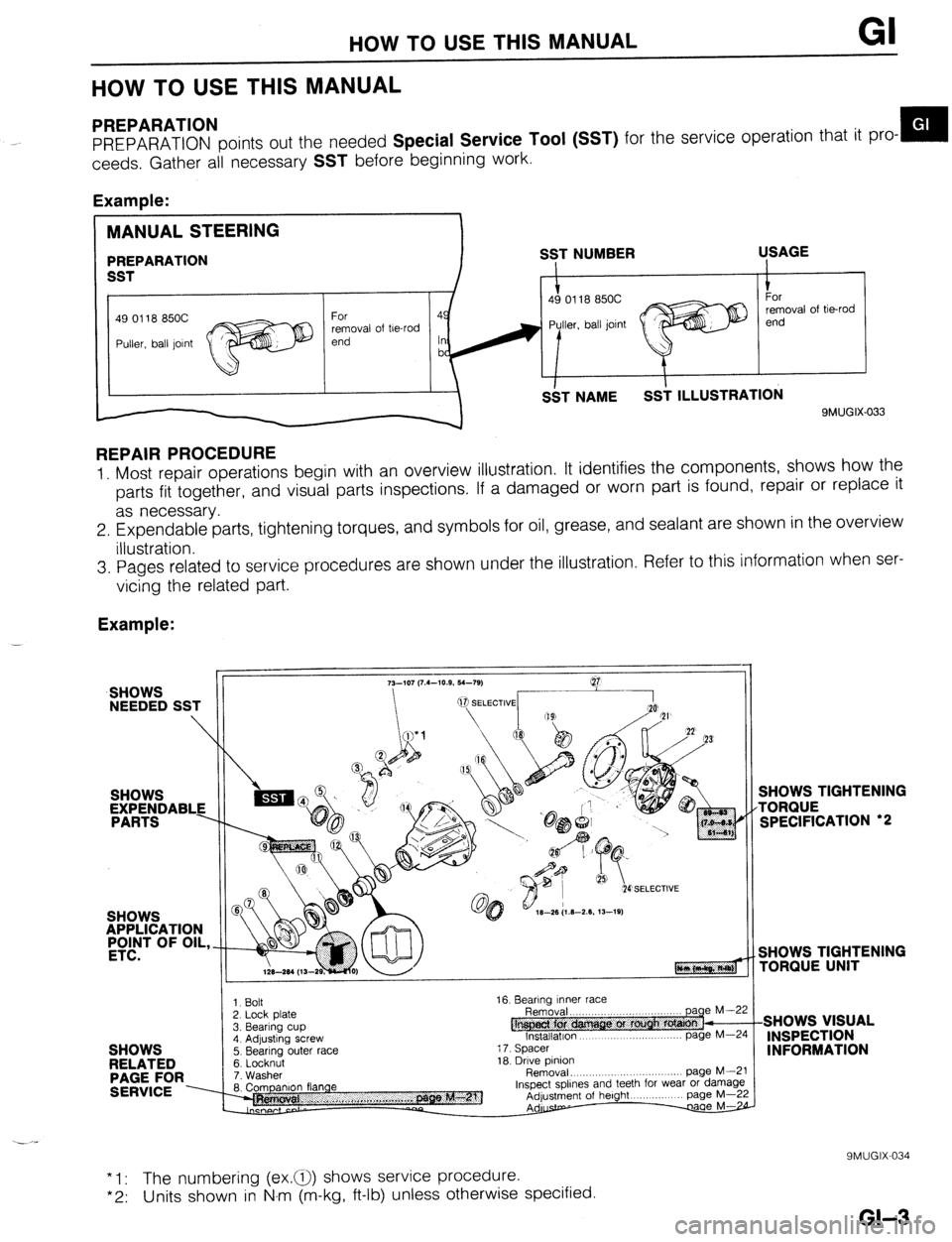

HOW TO USE THIS MANUAL GI

HOW TO USE THIS MANUAL

PREPARATION

PREPARATION points out the needed Special Service Tool (SST) for the service operation that it pro- m

ceeds. Gather all necessary

SST before beginning work.

Example:

49 0118 850C

removal of be-rod

9MUGIX-033

REPAIR PROCEDURE

1. Most repair operations begin with an overview illustration. It identifies the components, shows how the

parts fit together, and visual parts inspections. If a damaged or worn part is found, repair or replace it

as necessary.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration.

3. Pages related to service procedures are shown under the illustration. Refer to this information when ser-

vicing the related part.

Example:

SHOWS

NEEDED SST

SHOWS

APPLICATION

#T OF OIL,

SHOWS

RELATED

PAGE FOR

SERVICE ----

3. Bearing cup 1. Bolt

2. Lock Dlate

4. Adjusting screw

5. Bearing outer race

6. Locknut

7. Washer

8. Companion flange 16. Bearing Inner race

@ Removal. ,,,..,,,..

lnstallatlon page

page M--5 M-Z

i 7. Spacer

18. Drive pinion

Removal, .,,, ,.,, .,......... page M--i

Inspect spllnes and teeth for wear or damagl

Adjustment of height page M-2

Adurstp- w

SHOWS TIGHTENING

TORQUE

SPECIFICATION ‘2

SHOWS TIGHTENING

rORQlJE UNIT

SHOWS VISUAL

INSPECTION

INFORMATION

* 1: The numbering (ex.a) shows service procedure.

*2: Units shown in N.m (m-kg, ft-lb) unless otherwise specified.

9MUGIX-034

GI-3

Page 477 of 1164

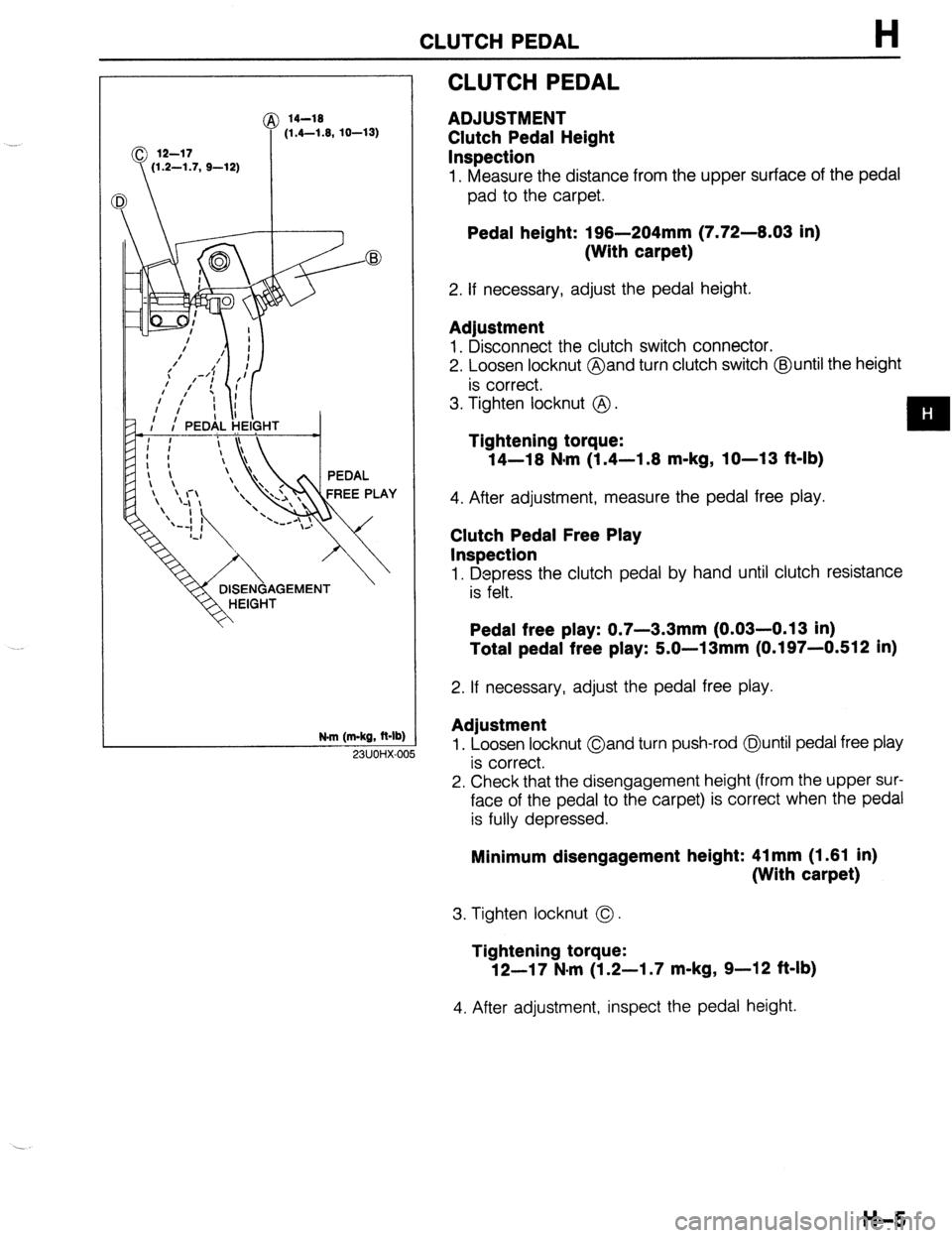

CLUTCH PEDAL H

@ 14-19

(1.4-1.9, 10-13)

N.m (m-kg, R-lb)

CLUTCH PEDAL

ADJUSTMENT

Clutch Pedal Height

Inspection

1. Measure the distance from the upper surface of the pedal

pad to the carpet.

Pedal height: 196-204mm (7.72-6.03 in)

(With carpet)

2. If necessary, adjust the pedal height.

Adjustment

1. Disconnect the clutch switch connector.

2. Loosen locknut @and turn clutch switch @until the height

is correct.

3. Tighten locknut @ .

Tightening torque:

14-16 N*m (1.4-1.6 m-kg, IO-13 f&lb)

4. After adjustment, measure the pedal free play.

Clutch Pedal Free Play

Inspection

1. Depress the clutch pedal by hand until clutch resistance

is felt.

Pedal free play: 0.7-3.3mm (0.03-0.13 in)

Total pedal free play: 5.0-13mm (0.197-0.512 in)

2. If necessary, adjust the pedal free play.

Adjustment

1. Loosen locknut Oand turn push-rod @until pedal free play

is correct.

2. Check that the disengagement height (from the upper sur-

face of the pedal to the carpet) is correct when the pedal

is fully depressed. 23UOHX-OC

Minimum disengagement height: 41 mm (1.61 in)

(With carpet)

3. Tighten locknut 0.

Tightening torque:

12-17 N-m (1.2-I .7 m-kg, 9-12 ft-lb)

4. After adjustment, inspect the pedal height.

H-5

Page 480 of 1164

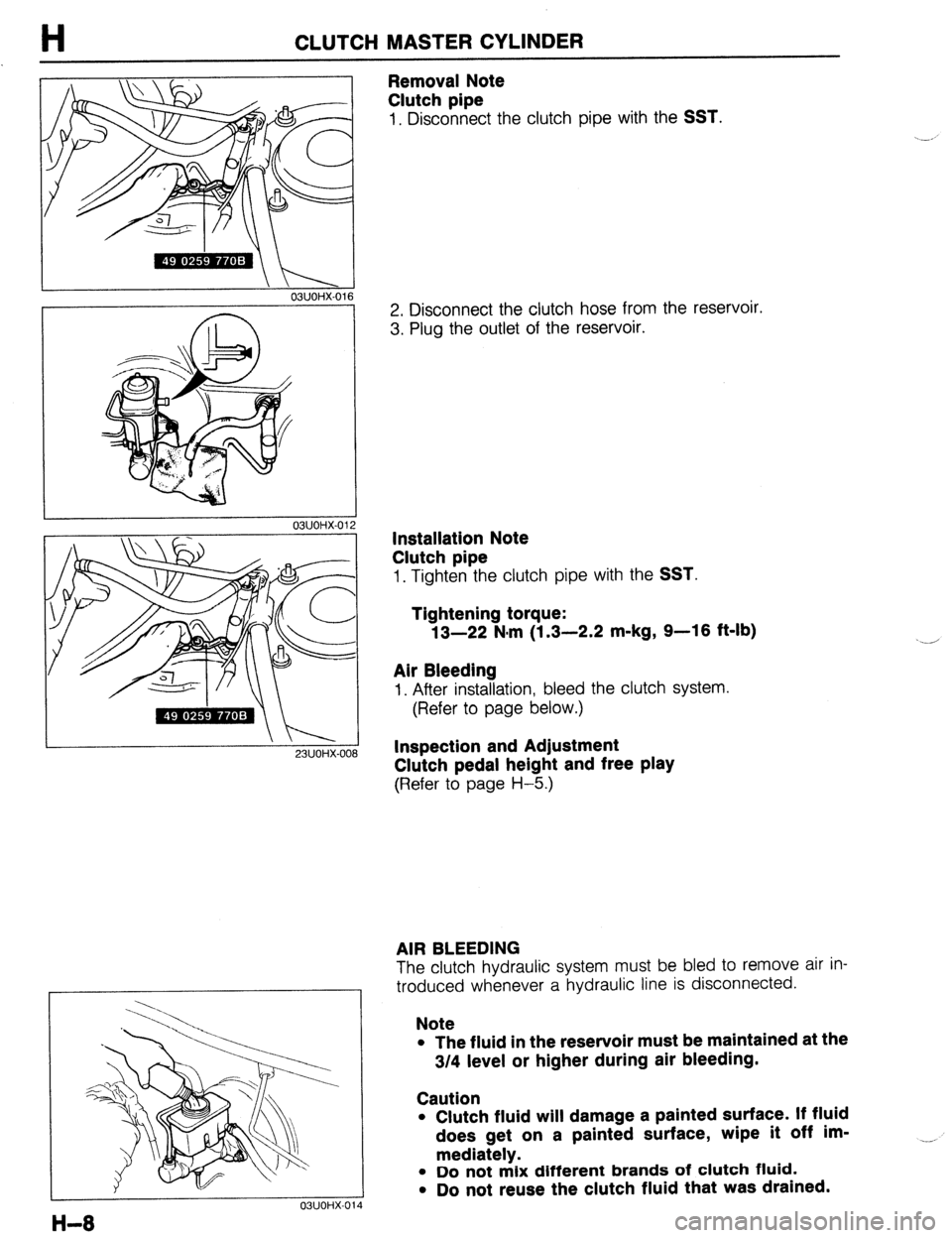

H CLUTCH MASTER CYLINDER

23UOHX-Ot ,a

\ I 03UOHX-016

7

I

03UOHX-014

Removal Note

Clutch pipe

1, Disconnect the clutch pipe with the SST.

2. Disconnect the clutch hose from the reservoir.

3. Plug the outlet of the reservoir.

Installation Note

Clutch pipe

1. Tighten the clutch pipe with the SST.

Tightening torque:

13-22 N.m (1.3-2.2 m-kg, 9-16 ft-lb)

Air Bleeding

I. After installation, bleed the clutch system.

(Refer to page below.)

Inspection and Adjustment

Clutch pedal height and free play

(Refer to page H-5.)

AIR BLEEDING

The clutch hydraulic system must be bled to remove air in-

troduced whenever a hydraulic line is disconnected.

Note

l The fluid in the reservoir must be maintained at the

3/4 level or higher during air bleeding.

Caution

l Clutch fluid will damage a painted surface. If fluid

does get on a painted surface, wipe it off im-

mediately.

l Do not mix different brands of clutch fluid.

l Do not reuse the clutch fluid that was drained. __,

Page 674 of 1164

P CONVENTIONAL BRAKE SYSTEM

03UOPX.01

03UOPX-01

03UOPX-01

23UOPX-0

BRAKE FLUID

Inspection

Leakage inspection

Depress the brake pedal several times, and inspect for leak-

age of the brake line system. __,

Brake Fluid Level

Leakage check

Verify that the fluid level in the reservoir is between the MAX

and MIN lines on the reservoir.

Add fluid if it is below MAX.

Replacement

1. Follow the procedure outlined in Air Bleeding.

(Refer to page P-6).

2. Continue bleeding and replacing the brake fluid until only

clean fluid is expelled.

3. Fill the reservoir to the MAX level.

BRAKEPEDAL

Inspection, On-vehicle

Brake pedal height

Inspection

Verify that the distance from the center on the pedal pad to

the floor mat is as specified.

Specification: 193-196mm (7.60-7.72 in)

Adjustment

1. Disconnect the stoplight switch connector.

2. Loosen locknuts @J and turn switch @ until it does not con-

tact the pedal.

3. Loosen locknuts (I?J and turn rod @ to adjust the height

of the brake pedal.

4. Tighten the stoplight switch until it contacts the pedal; then

turn it an additional 112 turn. Tighten locknuts @ and @I.

5. Connect the stoplight switch connector.

6. Verify operation of the stoplights.

P-8

Page 675 of 1164

CONVENTIONAL BRAKE SYSTEM

03UOPX-021

PEDAL-TO-FLOOR

CLEARANCE

03UOPX-02

Pedal Play

Inspection

1. Depress the pedal a few times to eliminate the vacuum in

the system.

2. Gently depress the pedal by hand and check the free play

(until resistance is felt).

Pedal play: 4-7mm (0.16-0.26 in)

Adjustment

1. Loosen locknut @and turn rod @to adjust the free play.

2. Verify the pedal height and the stoplight operation.

Pedal-To-Floor Clearance

Inspection

Verifv that the distance from the floor panel to the center of

the pedal pad is as specified when the pedal is depressed

with a force of 569 N (60

kg, 132 lb).

Pedal-to-floor clearance: 70mm (2.76 in) min.

If the distance is less than specified, check for the following

problems:

1. Air in brake system

2. Malfunction of automatic adjuster (Rear drum brakes)

3. Worn shoes or pads

P-9

Page 713 of 1164

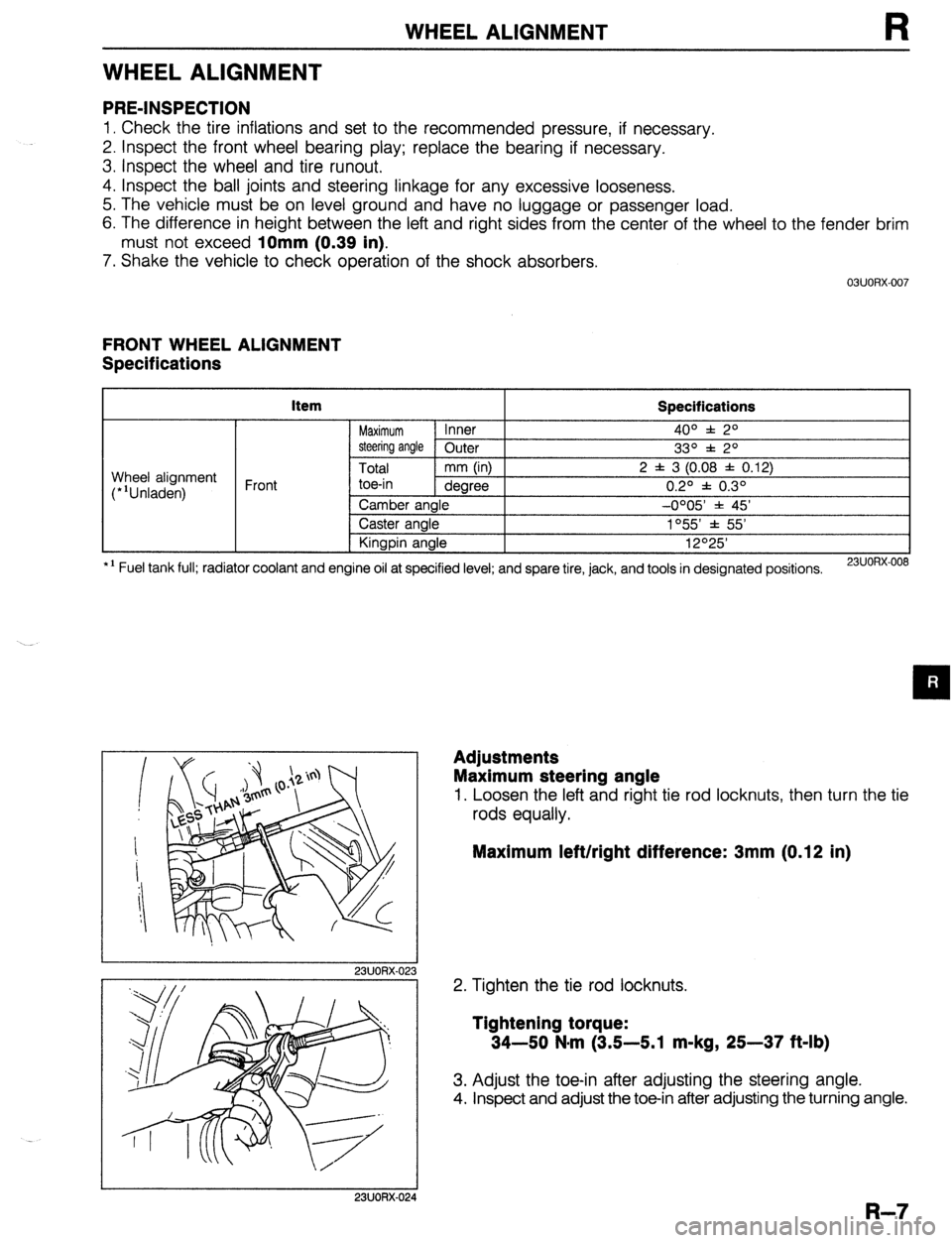

WHEEL ALIGNMENT

WHEEL ALIGNMENT

PRE-INSPECTION

1. Check the tire inflations and set to the recommended pressure, if necessary.

2. Inspect the front wheel bearing play; replace the bearing if necessary.

3. inspect the wheel and tire runout.

4. Inspect the ball joints and steering linkage for any excessive looseness.

5. The vehicle must be on level ground and have no luggage or passenger load.

6. The difference in height between the left and right sides from the center of the wheel to the fender brim

must not exceed

10mm (0.39 in).

7. Shake the vehicle to check operation of the shock absorbers.

03UORX.007

FRONT WHEEL ALIGNMENT

Specifications

item

Specifications

Maximum Inner 4o” f: 2O

steering angle Outer

33O f 2O

Total mm (in) 2 f 3 (0.08 f 0.12)

toe-in dearee 0.20 f 0.30 Wheel alignment

(*‘Unladen) Front

*I Fuel tank full; radiator coolant and Camber angle -0005 * 45’

Caster angle 1°55’ f 55’

Kingpin angle 12O25’

engine oil at specified level; and spare tire, jack, and tools in designated positions.

23UORX-008

I

I 23UORX-023

Adjustments

Maximum steering angle

1. Loosen the left and right tie rod locknuts, then turn the tie

rods equally.

Maximum left/right difference: 3mm (0.12 in)

2. Tighten the tie rod locknuts.

Tightening torque:

34-50 N-m (3.5-5.1 m-kg, 25-37 ft-lb)

3. Adjust the toe-in after adjusting the steering angle.

4. Inspect and adjust the toe-in after adjusting the turning angle.

I 23UORX-024

R-7

Page 770 of 1164

S TRUNK LID

03uosx-04’

HINGE (L.H.)

RIGHT SPRING -1

I

,i I

II

1

k

TRUNK LID

TRUNK LID

SEC.B--8

6 * 1.5 (0.31 * 0.06)

SECA-A mm (in)

03uosx-01

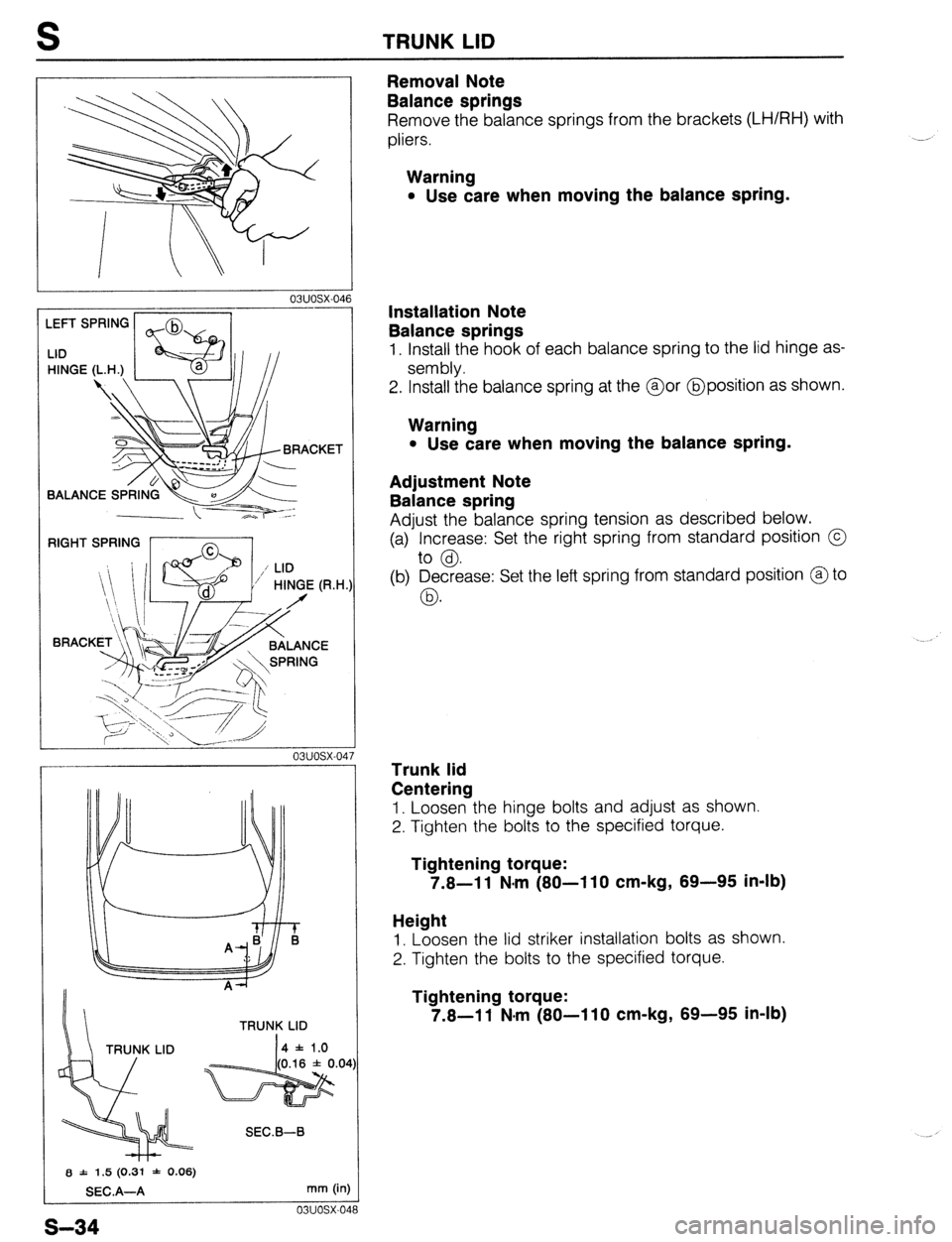

Removal Note

Balance springs

Remove the balance springs from the brackets (LH/RH) with

pliers.

Warning

l Use care when moving the balance spring.

Installation Note

Balance springs

1. Install the hook of each balance spring to the lid hinge as-

sembly.

2. Install the balance spring at the @or @position as shown.

Warning

l Use care when moving the balance spring.

Adjustment Note

Balance spring

Adjust the balance spring tension as described below.

(a) Increase: Set the right spring from standard position @

to @.

(b) Decrease: Set the left spring from standard position @to

03.

Trunk lid

Centering

1. Loosen the hinge bolts and adjust as shown.

2. Tighten the bolts to the specified torque.

Tightening torque:

7.8-l 1 N-m (80-l 10 cm-kg, 89-95 in-lb)

Height

1. Loosen the lid striker installation bolts as shown.

2. Tighten the bolts to the specified torque.

Tightening torque:

7.8-11 N-m (80-110 cm-kg, 89-95 in-lb)

s-34

Page 809 of 1164

WINDSHIELD WIPER AND WASHER S

ALIGNMEhT MARK

23UOSX.023

MOLDING END FACE

!6-

1.10-1.26)

/ COWL GRILLE END FACE

mm (in

o3uosx-l2!

tATCHBACK

-L I COWL dRlLLE

mm (in:

03uosx-131

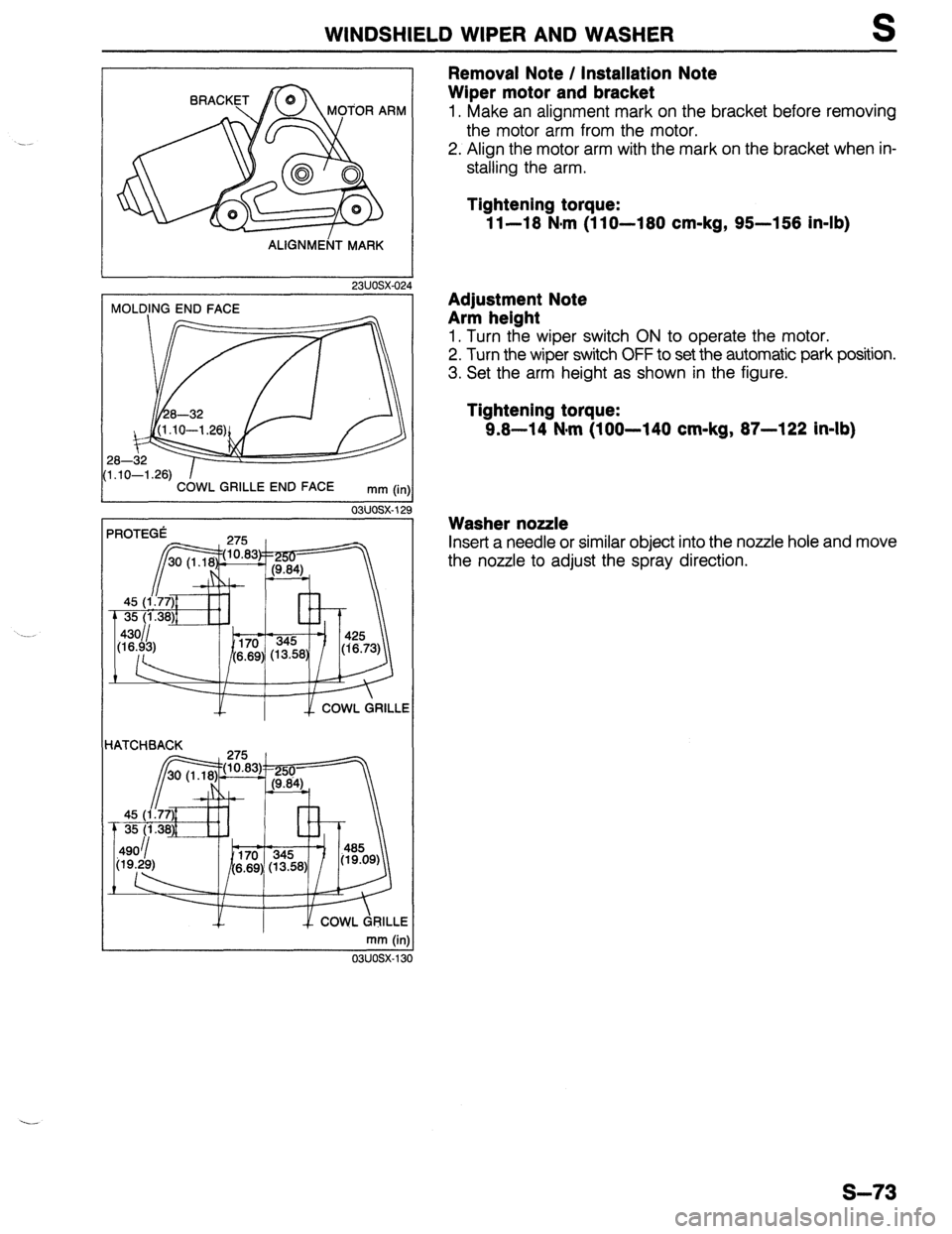

Removal Note / Installation Note

Wiper motor and bracket

1. Make an alignment mark on the bracket before removing

the motor arm from the motor.

2. Align the motor arm with the mark on the bracket when in-

stalling the arm.

Tightening torque:

1 l-18 N,m (1 lo-180 cm-kg, 95-158 in-lb)

Adjustment Note

Arm helght

1. Turn the wiper switch ON to operate the motor.

2. Turn the wiper switch OFF to set the automatic park position.

3. Set the arm height as shown in the figure.

Tightening torque:

9.8-14 N-m (100-140 cm-kg, 87-122 in-lb)

Washer nozzle

Insert a needle or similar object into the nozzle hole and move

the nozzle to adjust the spray direction.

s-73

Page 815 of 1164

REAR WIPER AND WASHER S

Wiper

Washer

1. Rear hatch lower trim

7. Trunk end trim

Removal / Installation . . . . . . . . . . . . . . . . page S-

98 Removal / Installation . . . . . . . . . . . . . . . . page

S- 98

2. Wiper arm cover 8. Trunk side cover

3. Rear wiper arm and blade Removal / Installation . . . . . . . . . . . . . . . . page S-

98

Adjustment

Note . . . . . . . . . . . . . . . . . . . . . . . page S- 79 9. Trunk side trim

4. Seal cap Removal / Installation . . . . . . . . . . . . . . . . page S-

98

5. Outer bushing 10. Rear header trim

6. Rear wiper motor Removal / Installation . . . . . . . . . . . . . . . . page S- 98

Inspection .,, ., . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page S- 77 11. Rear seat belt upper anchor

Removal / Installation . . . . . . . . . . . . . . . . page S-l 01

12. C-pillar trim

Removal / Installation . . . . . . . . . . . . . . . . page S-

98

13. Washer tank assembly

a. Washer tank

b. Washer motor

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page S- 77

14. Washer nozzle

Adjustment Note . . . . . . . . . . . . . . . . . . . . . . . page S-

79

15. Washer pipe

23UOSX-032

REAR WINDOW MOLDING

mm (in)

03uosx-14

REAR WINDQW MOLDING I

mm (in

03uosx-14

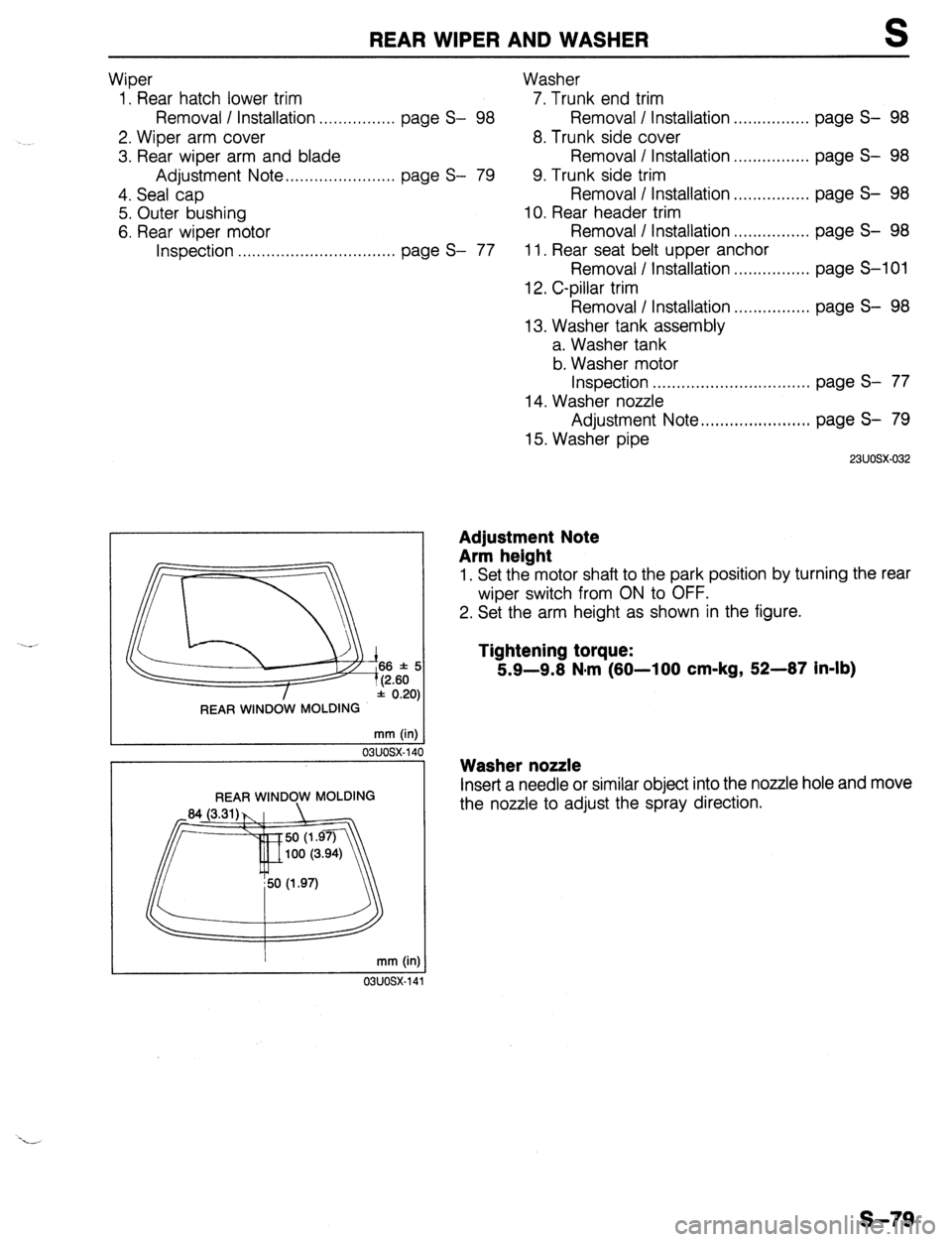

Adjustment Note

Arm height

1. Set the motor shaft to the park position by turning the rear

wiper switch from ON to OFF.

2. Set the arm height as shown in the figure.

Tightening torque:

5.9-9.8 N*m (80-100 cm-kg, 52-87 in-lb)

Washer nozzle

Inset-t a needle or similar object into the nozzle hole and move

the nozzle to adjust the spray direction.

s-79

Page 823 of 1164

SLIDING SUNROOF S

03UOSX-16d

(SUNROOF) (MOONROOF)

03UOSX-16!

ADJUSTING SCREW

SECA-A

D

__--__..-- ---__.-__

031JOSX 16

__-__

-~-

03UOSX-16

2. Install the guide rail cover and set plate.

3. Turn the motor using the emergency handle, and visually

check the sliding, tilt-down and tilt-up operations.

Adjustment Note

Sliding panel assembly

Height

Adjust so that the height difference between the sliding panel

and the roof panel is

1.5mm (0.06 in) max, referring to below.

(Front portion)

1. Loosen installation screws (1) and (2).

If the adjustment is only about

2mm (0.08 in) don’t loosen

screw (1).

2. Turn the screws to adjust.

Turning to the right raises; to the left lowers.

3. Tighten installation screws (1) and (2).

(Rear portion)

1. Loosen the adjusting screw.

2. Adjust by moving the sliding panel.

3. Tighten the adjusting screw.

S-987