oil change MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 37 of 1164

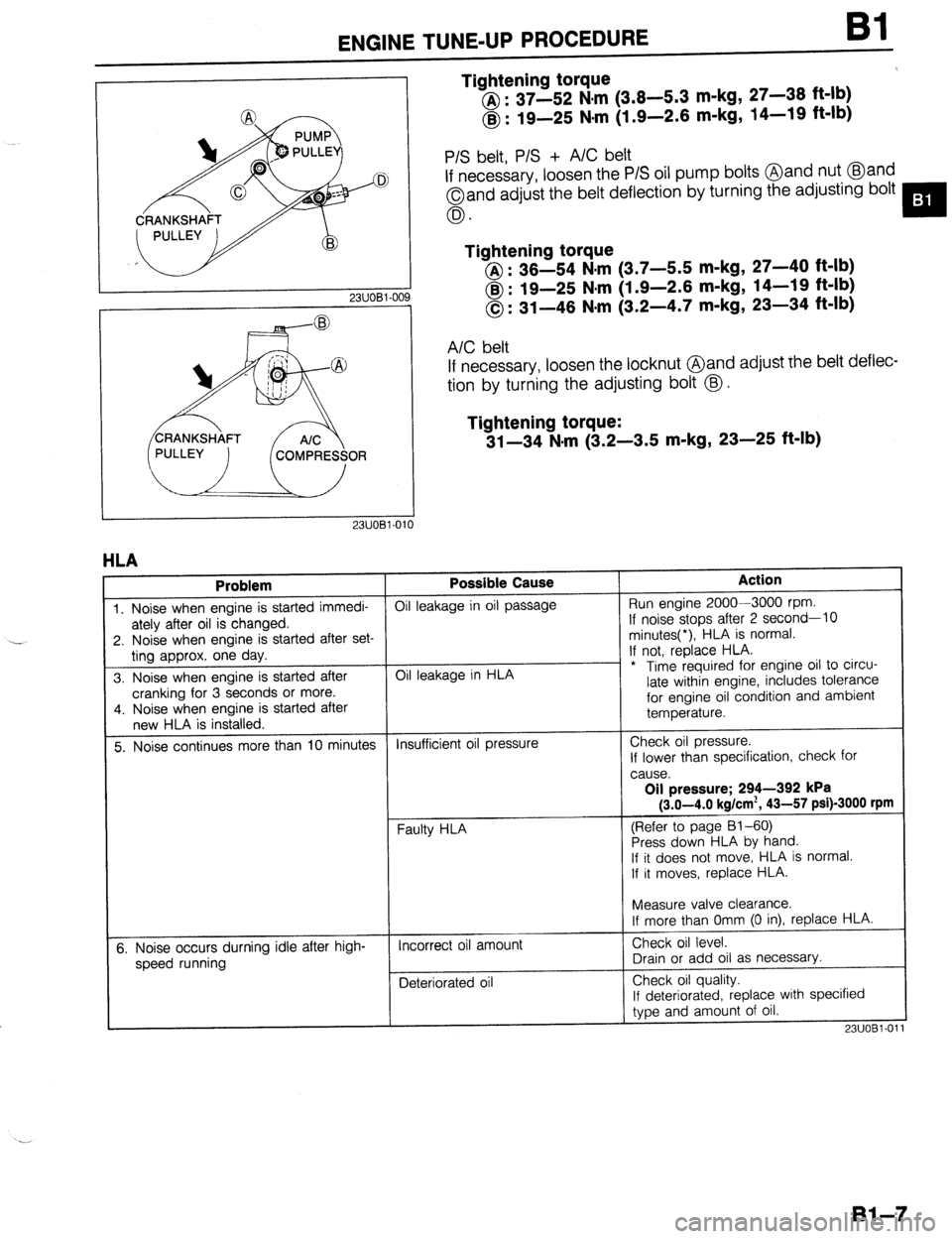

ENGINE TUNE-UP PROCEDURE Bl

Tightening torque

@ : 37-52 N,m (3.8-5.3 m-kg, 27-38 ft-lb)

@ : 19-25 Nsm (1.9-2.6 m-kg, 14-19 ft-lb)

23UOBl-OC

P/S belt, P/S + A/C belt

If necessary, loosen the P/S oil pump bolts @and nut @and

Oand adjust the belt deflection by turning the adjusting bolt

0.

Tightening torque

@I : 36-54 N.m (3.7-5.5 m-kg, 27-40 ft-lb)

@ : 19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

0: 31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb)

A/C belt

If necessary, loosen the locknut @and adjust rhe belt deflec-

tion by turning the adjusting bolt @.

Tightening torque:

31-34 N-m (3.2-3.5 m-kg, 23-25 ft-lb)

1

HLA

Problem Possible Cause Action

1. Noise when engine is started immedi- Oil leakage in oil passage Run engine 2000-3000 rpm.

ately after oil is changed. If noise stops after 2 second-10

2. Noise when engine is started after set- minutes(*), HLA is normal.

ting approx. one day. If not, replace HLA.

3. Noise when engine is started after Oil leakage in HLA - * Time required for engine oil to circu-

cranking for 3 seconds or more. late within engine, includes tolerance

4. Noise when engine is started after for engine oil condition and ambient

new HLA is installed. temperature.

5. Noise continues more than 10 minutes Insufficient oil pressure Check oil pressure.

If lower than specification, check for

cause.

Oil pressure; 294-392 kPa

(3.0-4.0 kg/cm*, 43-57 psi)-3000 rpm

(Refer to page 81-60)

Press down HLA by hand.

If it does not move,. HLA is normal.

If it moves, replace HLA.

t

I

Measure valve clearance.

If more than Omm (0 in), replace HLA.

5. Noise occurs durning idle after high-

speed running Incorrect oil amount

Deteriorated oil Check oil level.

Drain or add oil as necessary.

Check oil quality.

If deteriorated, replace with specified

type and amount of oil.

23UOBl-01

Bl-7

Page 139 of 1164

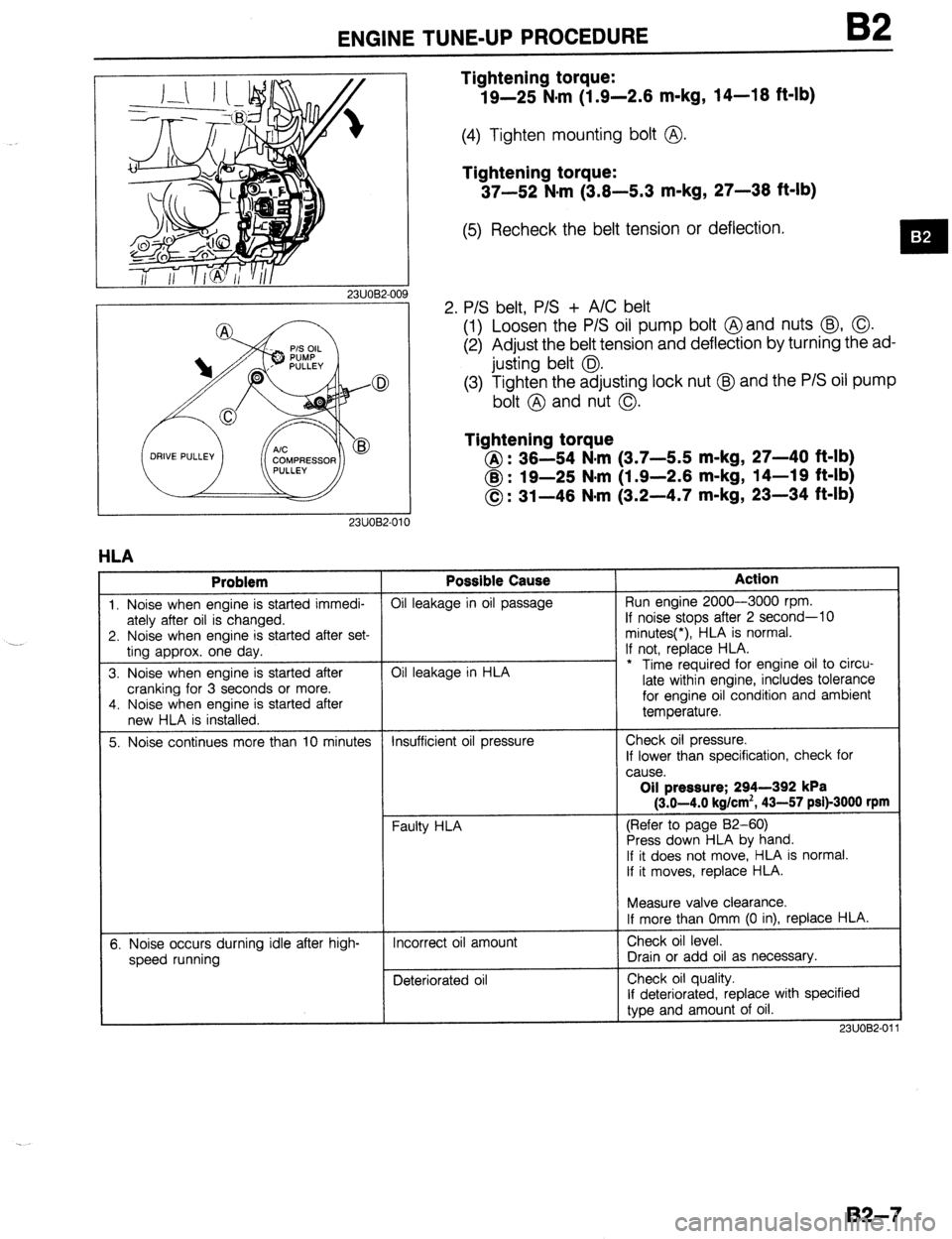

ENGINE TUNE-UP PROCEDURE 92

23UOB2-OC

DRIVE PULLEY

I I

2311082.010

HLA

I Problem

1. Noise when engine is started immedi-

ately after oil is changed.

2. Noise when engine is started after set-

tina aporox. one dav.

3. Noise when engine is started after

cranking for 3 seconds or more.

4. Noise when engine is started after

new HLA is installed.

5. Noise continues more than 10 minutes

6. Noise occurs durning idle after high-

“”

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-16 ft-lb)

(4) Tighten mounting bolt @.

Tightening torque:

37-52 N#rn (3.6-5.3 m-kg, 27-36 ft-lb)

(5) Recheck the belt tension or deflection.

2. P/S belt, P/S + A/C belt

(1) Loosen the P/S oil pump bolt @and nuts @, 0.

(2) Adjust the belt tension and deflection by turning the ad-

justing belt 0.

(3) Tighten the adjusting lock nut @J and the P/S oil pump

bolt @ and nut 0.

Tightening torque

@: 36-54 N-m (3.7-5.5 m-kg, 27-40 ft-lb)

@ : 19-25 N*m (1.9-2.6 m-kg, 14-19 ft-lb)

0: 31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb) Possible Cause

Oil leakage in oil passage

Oil leakage in HLA

Insufficient oil pressure

Faulty HLA

Incorrect oil amount

Deteriorated oil Action Run engine 2000-3000 rpm.

If noise stops after 2 second-10

minutes(*), HLA is normal.

If not, replace HLA.

* Time required for engine oil to circu-

late within engine, includes tolerance

for engine oil condition and ambient

temperature.

Check oil pressure.

If lower than specification, check for

cause. Oil pressure; 294-392 kPa

(3.0-4.0 kg/cm’, 43-57 psi)-3000 rpm

(Refer to page 82-60)

Press down HLA by hand.

If it does not move, HLA is normal.

If it moves, replace HLA.

Measure valve clearance.

If more than Omm (0 in), replace HLA.

Check oil level.

Drain or add oil as necessary.

Check oil quality.

If deteriorated, replace with specified

type and amount of oil.

2311082-01

B2-7

Page 293 of 1164

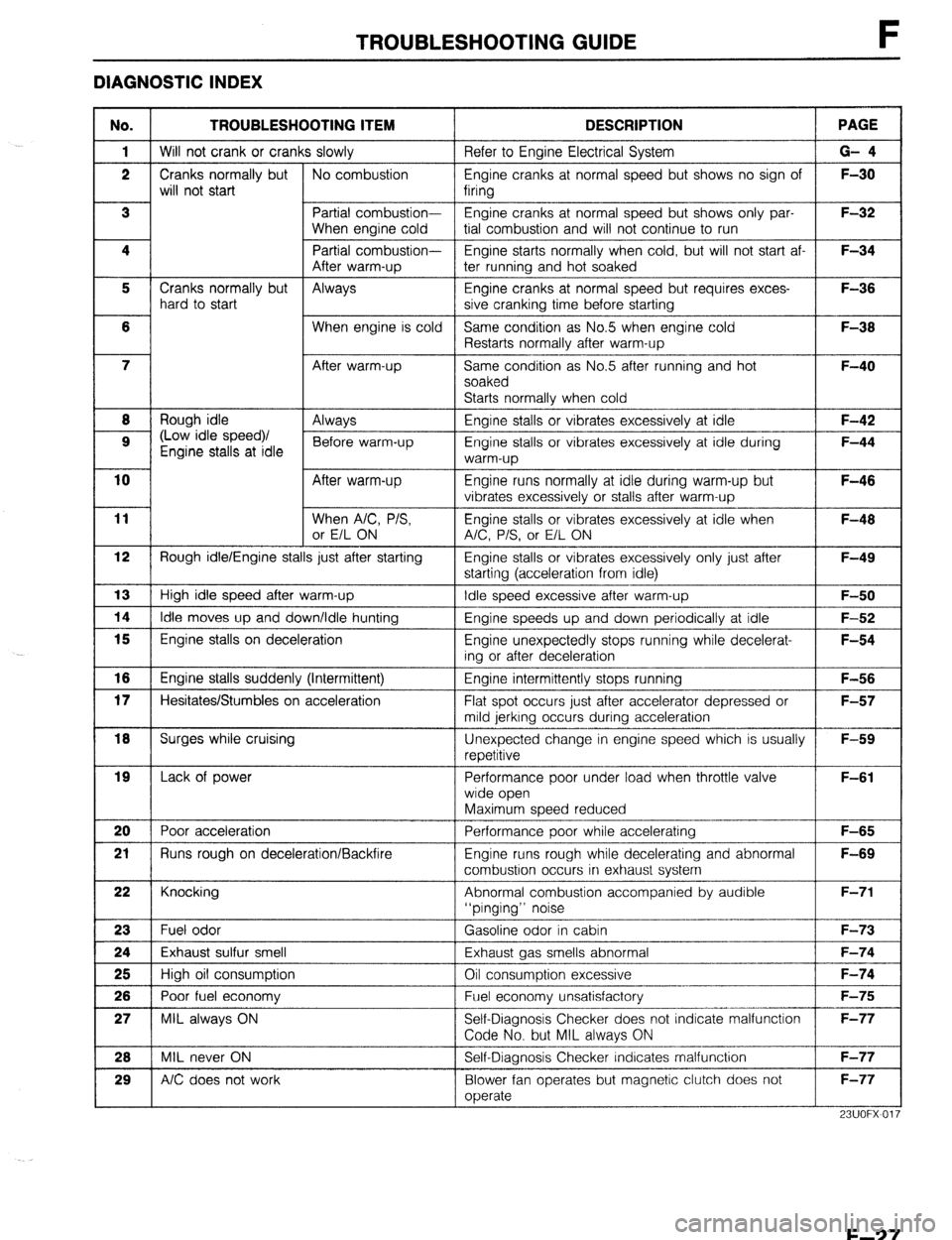

TROUBLESHOOTING GUIDE

DIAGNOSTIC INDEX

No. TROUBLESHOOTING ITEM DESCRIPTION

1 Will not crank or cranks slowly Refer to Engine Electrical System PAGE

G- 4

Engine cranks at normal speed but shows no sign of 1 F-30

Engine cranks at normal speed but shows only par-

I

tial combustion and will not continue to run

Engine starts normally when cold, but will not start af-

After warm-up

5 Cranks normally but

Always

hard to start Engine cranks at normal speed but requires exces-

sive cranking time before starting F-36

F-38

I----

F-40 Same condition as No.5 when engine cold

Restarts normally after warm-up

Same cond;ion as No.5 after running and hot

soaked

Starts normally when cold

8

H

Rough idle

9 (Low idle speed)/

Engine stalls at idle Enaine stalls or vibrates excessivelv at idle

Engine stalls or vibrates excessively at idle during

warm-up 1 F-42

F-44

Engine runs normally at idle during warm-up but

vibrates excessively or stalls after warm-up

Engine stalls or vibrates excessively at idle when

A/C, P/S, or E/L ON F-46

F-46

starting (acceleration from idle)

l---- Engine stalls or vibrates excessively only just after

Idle speed excessive after warm-up 1 F-50 F-49 12 Rough idle/Engine stalls just after starting

13 High idle speed after warm-up

1 14 1 Idle moves up and down/Idle hunting Engine speeds up and down periodically at idle

1 F-52

I l5 I Engine stalls on deceleration

Engine unexpectedly stops running while decelerat-

ing or after deceleration F-54

Engine intermittently stops running

Flat spot occurs just after accelerator depressed or

mild jerkrng occurs during acceleration

Unexpected change in engine speed which is usually

repetitive F-56

F-57

F-59 16 Engine stalls suddenly (Intermittent)

17 Hesitates/Stumbles on acceleration

1 18 1 Surges while cruising

19

I I

Lack of power Performance poor under load when throttle valve F-61

wide open

Maximum speed reduced

Performance poor-while accelerating

-I- F-65 20 Poor acceleration

21 Runs rough on deceleration/Backfire Engine runs rough while decelerating and abnormal

combustion occurs in exhaust system F-69

Abnormal combustion accompanied by audible

“pinging” noise

Gasoline odor in cabin 22 Knocking

23 Fuel odor

24 Exhaust sulfur smell

26 High oil consumption Exhaust gas smells abnormal

Oil consumption excessive

Fuel economy unsatisfactory 1 26 1 Poor fuel economy 1 F-75

Self-Diagnosis Checker does not indicate malfunction

23UOFX~O’

F-27

Page 329 of 1164

TROUBLESHOOTING GUIDE F

DAMAGE AND

DETERIORATION

Check if resistance of high-tension leads are OK Resistance: 16 kQ per 1 m (3.26 ft)

li;;g

‘&

d No

Replace

.

12 Check if resistance of ignition coil is OK Yes Go to next step c7 page G-19

Resistance (at 20°C [6SaF]):

Primary coil winding . . . . . . . . 0.61-0.99n

Secondary coil winding.... lo-16 kdl

PRIMARY COIL SECONDARY COIL

WINDING

WINDING

No

Replace

13 Check for correct engine compression Yes Go to next step u page Bl-10

92-10 No

Check engine condition ~7 page 81-10

Engine compression: 82-l 0

. BP DOHC

*Worn piston, piston rings or cylinder 663 kPa (9.0 kg/cm2, 126 psi)-300 rpm wall

l BP SOHC l Defective cylinder head gasket 634 kPa (6.5 kg/cm2, 121 psi)-300 rpm l Distorted cylinder head

l 66 l improper valve seating 932 kPa (9.5 kg/cm2, 136 psi)300 rpm *Valve sticking in guide

14 Change fuel and check if condition improves Yes Change fuel to another brand

No SOHC

Go to Step 16 DOHC

Go to next step

F-63

Page 340 of 1164

![MAZDA PROTEGE 1992 Workshop Manual F TROUBLESHOOTING GUIDE

I 24 I EXHAUST SULFUR SMELL I

DESCRIP-

l Exhaust gas smells abnormally

TION

[TROUBLESHOOTING HINTS]

High sulfur content fuel used

STEP INSPECTION

1

Change fuel to anot MAZDA PROTEGE 1992 Workshop Manual F TROUBLESHOOTING GUIDE

I 24 I EXHAUST SULFUR SMELL I

DESCRIP-

l Exhaust gas smells abnormally

TION

[TROUBLESHOOTING HINTS]

High sulfur content fuel used

STEP INSPECTION

1

Change fuel to anot](/img/28/57077/w960_57077-339.png)

F TROUBLESHOOTING GUIDE

I 24 I EXHAUST SULFUR SMELL I

DESCRIP-

l Exhaust gas smells abnormally

TION

[TROUBLESHOOTING HINTS]

High sulfur content fuel used

STEP INSPECTION

1

Change fuel to another brand ACTION

03UOFX-039

25 HIGH OIL CONSUMPTION

DESCRIP-

l Oil consumption excessive

TION

[TROUBLESHOOTING HINTS]

@ PCV system malfunction

@ Engine malfunction (Oil working up, working down, or leakage)

iTEP

INSPECTION

1 Check if PCV hose, ventilation hose or their at- Yes Repair or replace

taching nipples are separated, damaged,

clogged, or restricted

w page F-138 No Go to next step

2 Check if air pressure or oil is present at ventila- Yes Go to next step

tion hose ACTION

No Check engine condition w page 81-3

82-3

l Oil leakage

*Worn valve seal

*Worn valve stem

*Worn valve guide

3 Check if vacuum is felt at PCV valve at idle Yes Check engine condition w page 91-3

w page F-138 82-3

*Worn piston ring groove

*Stuck piston rings l

Worn piston or cylinder

No Replace PCV valve

23UOFX-040 /-.

F-74

Page 344 of 1164

F ENGINE TUNE-UP

ENGINE TUNE-UP

PREPARATlON

SST

I

I I

49 BO19 9AO

System Selector For

inspection of igni-

tion timing and

idle speed

hA ‘I

03UOFX-04

03UOFX-04

03UOFX-04

NG POINT

03UOFX-04 03UOFX-045

BASIC INSPECTION

Engine Oil

1. Remove the engine oil level gauge and check the engine

oil level and oil condition.

2. Add or change the oil as necessary.

Coolant

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap before carefully

removing it.

1. Remove the coolant level gauge from the coolant reservoir.

2. Check that the coolant level is between the L and F marks

of the gauge.

3. Add coolant if necessary.

Battery

1. Check for corrosion on the terminals and for loose cable

connections. If necessary, clean the clamps and tighten

them firmly.

2. Check that the electrolyte level is between the UPPER LEV-

EL and LOWER LEVEL marks.

3. Add distilled water if necessary.

4. Check the specific gravity with a hydrometer.

Gravity: 1.27-l .29 (at 20% [68OF] )

Page 496 of 1164

Jl TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Problem

Shift lever won’t shift

smoothly or is hard

to shift

Too much play in

shift lever

I------

Difficult to shift

Won’t stay in gear

Abnormal noise

I

Possible cause

Seized shift lever ball

Seized change control rod joint

Bent change control rod

Worn change control rod bushing

Weak shift lever ball spring

Worn shift lever ball bushing

Bent change rod

No grease in transaxle control

Insufficient oil

Deterioration of oil quality

Wear or play of shift fork or shift rod

Worn synchronizer ring

Worn synchronizer cone of gear

Bad contact of synchronizer ring and cone of gear

Excessive longitudinal play of gears

Worn bearing

Worn synchronizer key spring

Excessive primary shaft gear bearing preload

improperly adjusted change guide plate

Bent change control rod

Worn change control rod bushing

Weak shift lever ball spring

improperly installed extension bar

Worn shift fork

Worn clutch hub

Worn clutch hub sleeve

Worn gear sliding part of both shaft gears

Worn gear sliding part of each gear

Worn steel sliding groove of control end

Weak spring pressing against steel ball

Excessive thrust clearance

Worn bearing

Improperly installed engine mount

Insufficient oil

Deterioration of oil quality

Worn bearing

Worn sliding surfaces of gears or shafts

Excessive gear backlash

Damaged gear teeth

Foreign material in gears

Damaged differential gear or excessive backlash Remedy Replace

Replace

Replace

Replace

Replace

Replace

Replace

Lubricate with grease

Add oil

Replace with oil of

specified quality

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Replace

Replace

Tighten

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Tighten

Add oil

Replace

Adjust or replace

Replace

Replace

Replace with oil of

specified quality

Replace

Adjust or replace Page Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl- 7

Jl- 7

Jl-14

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-36

Jl-17

Jl-56

Jl-56

Jl-56

Jl-56

Jl-14

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-14

Jl-14

Jl-22, 24

Jl-22, 24

Jl-48

Jl- 7

Jl- 7

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-53

03UOJl-OC --

-../

51-6

Page 507 of 1164

TRANSAXLE Jl

Clutch Housing and Transaxle Case Components

Caution

l Do not remove oil seals unless necessary.

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

-

.ACE

23UOJl-O(

1. Speedometer driven gear 17. Boot 28. Adjust shim

assembly 18. Oil seal (Change rod) 29. Adjust shim

2. Oil seal (Differential) Disassembly Note 30. Bearing outer race

Disassembly Note ,.,,,..,............. page Jl-18 (Differential)

..................... page Jl-19 19. Bushing Disassembly Note

Replacement (On-vehicle) 20. Oil seal (Primary shaft) ..................... page Jl-19

.....................

page Jl-20 Disassembly Note 31. Adjust shim (Differential)

3. Pivot ..................... page Jl-19 Disassembly Note

4. Bleeder 21. Bearing outer race ..................... page Jl-19

5. Bleeder cover Disassembly Note 32. Transaxle case

6. Gasket ..................... page Jl-18 33. Roll pin

7. Roll pin 22. Funnel 34. O-ring

8. Blind plug Disassembly Note 35. Driven gear

Disassembly Note ..................... page Jl-18 36. Packing

..................... page Jl-18 23. Bearing outer race 37. Oil seal

9. Reverse lever shaft (Differential) (Speedometer gear cace)

Disassembly Note Disassembly Note Disassembly Note

..................... page Jl-18 ..................... page Jl-19 ..................... page Jl-19

10. Lever set spring 24. Clutch housing 38. Gear case

11. Reverse lever 25. Oil passage 39. Joint

Inspection ....... page Jl-27 26. Oil seal (Differential) 40. Change rod

12. Guide plate assembly Disassembly Note

13. Roll pin ..................... page Jl-19

14. Selector Replacement (On-vehicle)

15. Change arm ..................... page Ji-20

16. Change rod assembly 27, Bearing outer race

Jl-17

Page 508 of 1164

Jl TRANSAXLE

03UOJl-025

Disassembly note

Blind plug

1. Remove the roll pin with pliers.

03UOJi-027

03UOJ 1.029

Jl-18

Reverse lever shaft

1. Protect the reverse lever shaft with a rag and remove the

shaft with pliers.

Oil seal (Change rod)

1 .Remove the oil seal with a screwdriver.

Funnel and bearing outer race (Secondary shaft)

Note

l Remove the bearing outer race with a screwdriver

if necessary.

1) Insert a screwdriver between the clutch housing

and bearing outer race.

2)Pt-y the bearing outer race free.

03UOJl-028

1. Remove the bearing outer race by lifting out the funnel and

race together.

Page 526 of 1164

TRANSAXLE

I

\m/ 7.8-11 N-m

1. Change

rod

2. Joint

3. Bearing outer race

4. Funnel

Assembly Note 11. Oil passage

29. Guide plate assembly

12. Oil

seal (Differential) 30.

Gear case

Assembly Note 31, Oil seal

,.................... page Jl -41 (Speedometer gear cace)

13. Transaxle case Assembly Note

. . . . . . . . . . . . . . . . . . . . .

page Jl-42

5. Bearing outer race

Assembly Note

. . . . . . . . . . . . . . . . . . . . . page Jl-42

6. Bearing outer race

(Differential)

Assembly Note

. . . . . . . . . . . . . . . . . . . . . page Jl-41

7. Adjust shim (Differential)

Assembly Note

. . . . . . . . . . . . . . . ...*.. page Jl-41

8. Bearing outer race

(Secondary shaft gear)

Assembly Note

,..*.,...............

page Jl -41

9. Adjust shim

(Secondary shaft gear)

Assembly Note

. . . . . . ...*. . . . . . . . . . . page Jl-41

IO. Adjust shim

(Primary shaft gear)

Assembly Note

14. Reverse lever . . . . . . . . . . . . . . . . . . . . . page Jl-41

15. Lever set spring 32. Packing

16. Reverse lever shaft 33. O-ring

17. Roll pin 34. Drive gear

18. Blind plug 35. Roll pin

19. Oil seal (Primary shaft gear) (Speedometer driven gear

Assembly Note assembly)

. . . . . . . . . . . . . . . . . . . . . page Jl-42 Assembly Note

20. Gasket ..,......*. ..,,...... page Jl-41

21. Bleeder cover 36. Speedometer driven gear

22. Bushing assembly

23. Oil seal (Change rod) 37. Bleeder

Assembly Note 38. Pivot

..,..,...,........... page Jl-42 39. Oil seal (Differential)

24. Boot Assembly Note

Assembly Note . . . . . . . . . . . . . . . . . ...* page Jl-41

.,.,.,............... page Jl-42 40. Clutch housing

25. Change rod

Assembly Note

. ..*.................

page J l-42 .,................... page Jl-42

26. Change arm

27. Selector

28. Roll pin

Jl-36