air bleeding MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 473 of 1164

H

CLUTCH

INDEX ......................................................

OUTLINE ..................................................

SPECIFICATIONS .................................... H- 3

TROUBLESHOOTING GUIDE.. .................... H- 3

CLUTCH FLUID ......................................... H- 4

PREPARATION ....................................... H- 4

REPLACEMENT ...................................... H- 4

CLUTCH PEDAL ....................................... H- 5

ADJUSTMENT ........................................ H- 5

REMOVAL / INSPECTION / INSTALLATION.. H- 6

CLUTCH MASTER CYLINDER.. ................... H- 7

PREPARATION ....................................... H- 7

REMOVAL / INSPECTION / INSTALLATION.. H- 7

AIR BLEEDING ....................................... H- 6

OVERHAUL ............................................ H-10

CLUTCH RELEASE CYLINDER ................... H-l 2

PREPARATION ....................................... H-12

REMOVAL / INSTALLATION ...................... H-l 2

AIR BLEEDING (REFER TO PAGE H-8)

OVERHAUL ............................................ H-13

CLUTCH UNIT .......................................... H-14

PREPARATION ....................................... H-14

REMOVAL I INSTALLATION.. .................... H-15

RELEASE BEARING .................................. H-17

INSPECTION .......................................... H-17

CLUTCH COVER ....................................... H-17

INSPECTION .......................................... H-17

CLUTCH DISC .......................................... H-17

INSPECTION .......................................... H-17

PILOT BEARING ....................................... H-16

INSPECTION .......................................... H-16

FLYWHEEL ............................................... H-16

INSPECTION .......................................... H-16

23UOHX-001

Page 474 of 1164

H INDEX

NDEX

CLUTCH SWITCH

SERVICE, SECTION F

23UOHX-00:

2

5. Clutch release fork

Removal / Installation . . . . . . . . . . . . . . . . . . page

H-l 5

6. Clutch cover 1. Clutch pedal

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H- 5

Removal / Inspection /

installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H- 6

2. Clutch master cylinder

Removal I Inspection I

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H- 7

Air bleeding ,............,..... I ,.,........, page H- 8

Overhaul . . . . . . . . . . . . . . . . . . . . . . . . I ,,.,........

page H-10

3. Clutch release cylinder

Removal / Installation.. . . . . . . . . . . . . . . . . page

H-l 2

Air bleeding . . . . . . . . . . . ..*..................

page H- 8

Overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page

H-l 3

4. Release bearing

Removal / installation . . . . . . . . . . . . . . . . . . page

H-l 5

Inspection ,.....,..,.,~.,..........,.,,..,,.. page H-l 7

H-2

Removal / Installation .,.......,..,..... page H-l 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H-l 7

7. Clutch disc

Removal I Installation . . . . . . . . . . . . . . . . . . page

H-l 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H-l 7

8. Pilot bearing

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page H-l 8

Removal / Installation.. . . . . . . . . . . . . . . .

page H-l 5

9. Flywheel

Removal I Installation . . . . . . . . . . . . . . . . . . page

H-l 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page H-18

Page 476 of 1164

H CLUTCH FLUID

CLUTCH FLUID

PREPARATION

SST

49 0259 7708 For

Wrench, flare nut ~ air bleeding

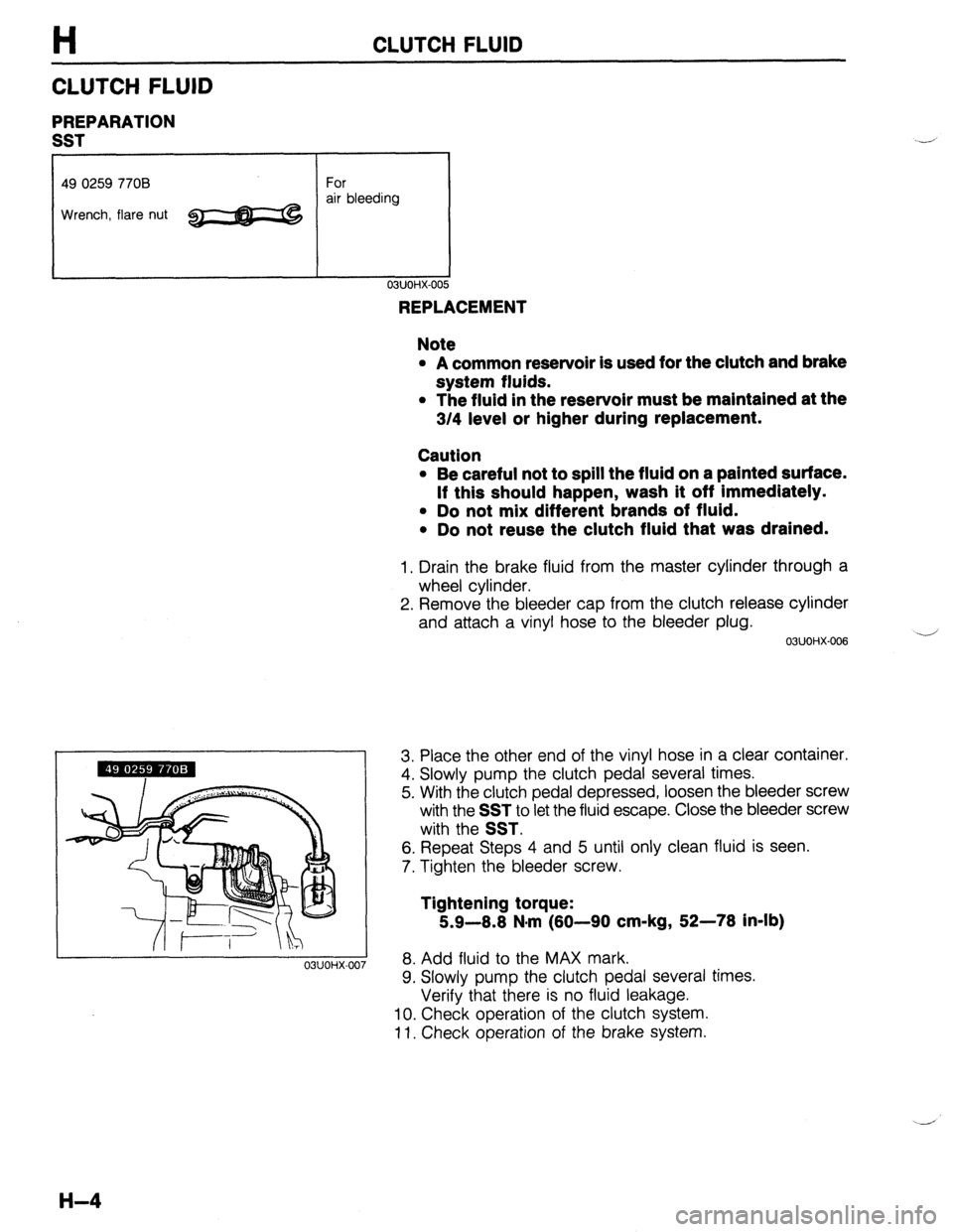

03UOHX-007

REPLACEMENT

Note

l A common reservoir is used for the clutch and brake

system fluids.

l The fluid in the reservoir must be maintained at the

3/4 level or higher during replacement.

Caution

l Be careful not to spill the fluid on a painted surface.

If this should happen, wash it off Immediately.

l Do not mix different brands of fluid.

l Do not reuse the clutch fluid that was drained.

1. Drain the brake fluid from the master cylinder through a

wheel cylinder.

2. Remove the bleeder cap from the clutch release cylinder

and attach a vinyl hose to the bleeder plug.

03UOHX-006 -

3. Place the other end of the vinyl hose in a clear container.

4. Slowly pump the clutch pedal several times.

5. With the clutch pedal depressed, loosen the bleeder screw

with the

SST to let the fluid escape. Close the bleeder screw

with the

SST.

6. Repeat Steps 4 and 5 until only clean fluid is seen.

7. Tighten the bleeder screw.

Tightening torque:

5.9-8.8 N.m (80-90 cm-kg, 52-78 in-lb)

8. Add fluid to the MAX mark.

9. Slowly pump the clutch pedal several times.

Verify that there is no fluid leakage.

10. Check operation of the clutch system.

11. Check operation of the brake system.

H-4

Page 479 of 1164

CLUTCH MASTER CYLINDER H

CLUTCH MASTER CYLINDER

PREPARATION

SST

49 0259 770B

Wrench, flare nut For

disconnecting

and connecting

clutch pipe

I I 03UOHX-01

REMOVAL / INSPECTION / INSTALLATION

Caution

l Clutch fluid will damage painted surfaces. Be sure to use a container or rags to collect it. If

fluid gets on a painted surface, wipe it off immediately with a rag.

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to

Installation Note.

N.m (m-kg, R-lb

23UOHX-007

1. Battery

2. Diagnosis connector

3. Clutch pipe

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page H- 8

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page H-

8

4. Clip

5. Nut

6. Clutch master cylinder

Check for fluid leakage from the cylinder

bore

Overhaul . . . . . . . ..*........*................ page H-10

Air bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page H- 8

7. Gasket

H-7

Page 480 of 1164

H CLUTCH MASTER CYLINDER

23UOHX-Ot ,a

\ I 03UOHX-016

7

I

03UOHX-014

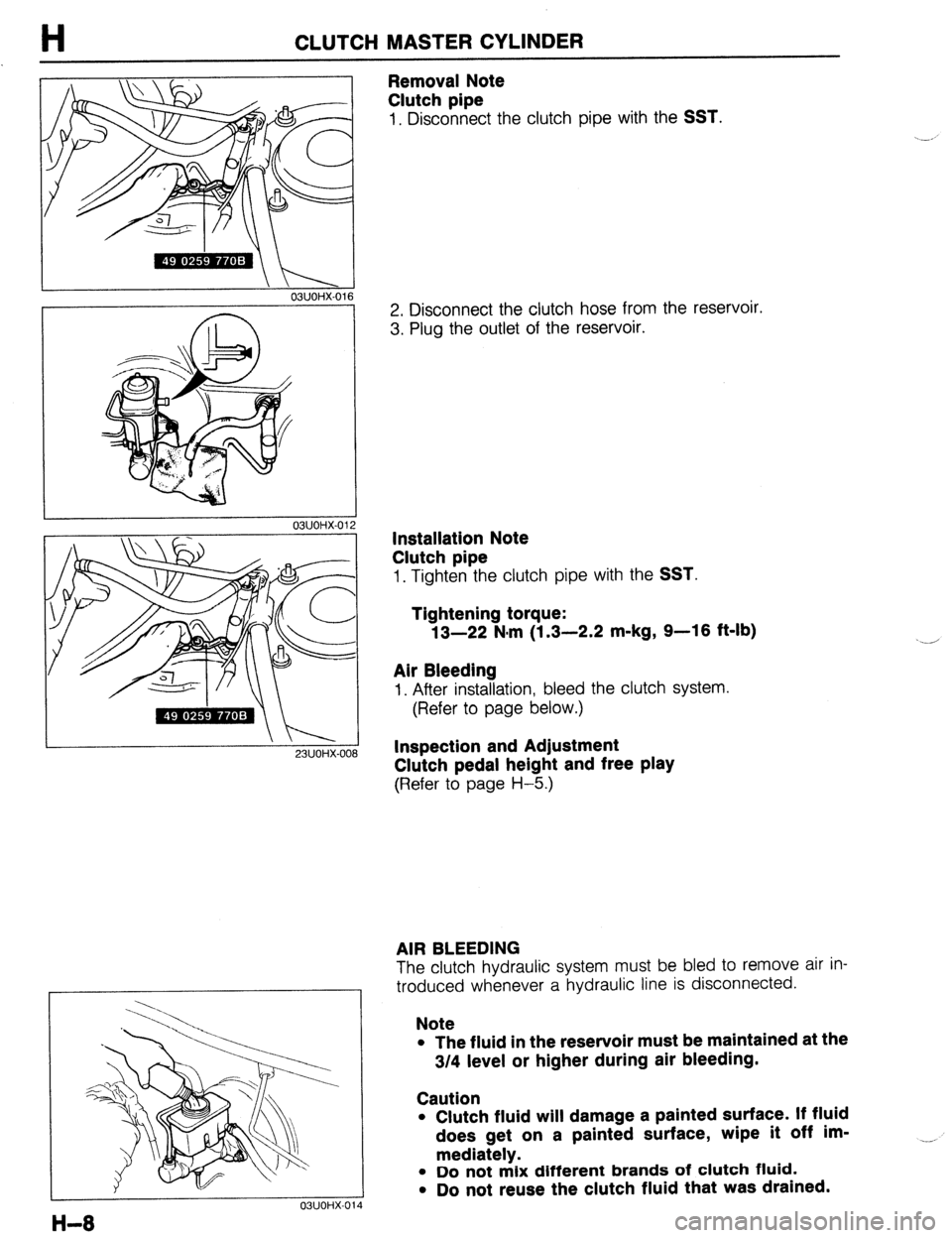

Removal Note

Clutch pipe

1, Disconnect the clutch pipe with the SST.

2. Disconnect the clutch hose from the reservoir.

3. Plug the outlet of the reservoir.

Installation Note

Clutch pipe

1. Tighten the clutch pipe with the SST.

Tightening torque:

13-22 N.m (1.3-2.2 m-kg, 9-16 ft-lb)

Air Bleeding

I. After installation, bleed the clutch system.

(Refer to page below.)

Inspection and Adjustment

Clutch pedal height and free play

(Refer to page H-5.)

AIR BLEEDING

The clutch hydraulic system must be bled to remove air in-

troduced whenever a hydraulic line is disconnected.

Note

l The fluid in the reservoir must be maintained at the

3/4 level or higher during air bleeding.

Caution

l Clutch fluid will damage a painted surface. If fluid

does get on a painted surface, wipe it off im-

mediately.

l Do not mix different brands of clutch fluid.

l Do not reuse the clutch fluid that was drained. __,

Page 485 of 1164

CLUTCH RELEASE CYLINDER

Installation Note

Clutch pipe

H

1. Tighten the clutch pipe with the SST.

Tightening torque:

13-22 N-m (1.3-2.2 m-kg, 9-16 ft-lb)

Air Bleeding

1. After installation, bleed the clutch system.

(Refer to page below.)

23UOHX-011

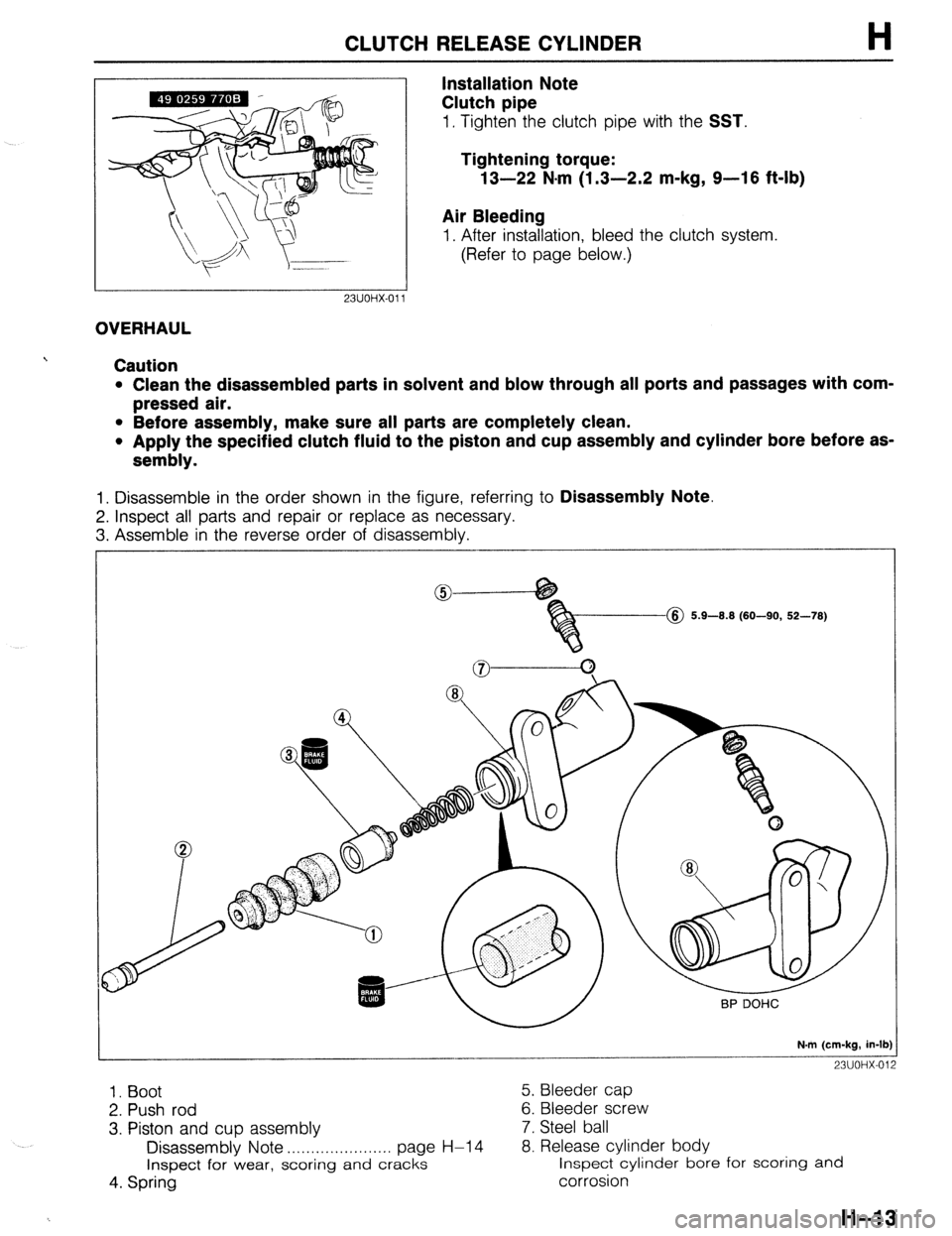

OVERHAUL

Caution

l Clean the disassembled parts in solvent and blow through all ports and passages with com-

pressed air.

l Before assembly, make sure all parts are completely clean.

l Apply the specified clutch fluid to the piston and cup assembly and cylinder bore before as-

sembly.

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

@ 5.9-8.8 (60-90, 52-78)

N.m (cm-kg, in-lb)

23UOHX-012

1. Boot 5. Bleeder cap

2. Push rod 6. Bleeder screw

3. Piston and cup assembly 7. Steel ball

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page H-l 4 8. Release cylinder body

Inspect for wear, scoring

and cracks inspect cylinder bore for scoring and

4. Spring corrosion

H-13

Page 625 of 1164

N

STEERING SYSTEM

INDEX ......................................................

MANUAL STEERING ............................... ;I g

ENGINE SPEED SENSING POWER

STEERING (ESPS) ................................. N- 3

OUTLINE ..................................................

SPECIFICATIONS .................................... ;I ::

MANUAL STEERING ..................................

PREPARATION ....................................... ;I ;

TROUBLESHOOTING GUIDE.. .................. N- 5

BOOT ................................................... N- 6

STEERING WHEEL AND COLUMN.. .......... N- 6

STEERING GEAR AND LINKAGE .............. N-13

ENGINE SPEED SENSING POWER

STEERING .............................................. N-23

PREPARATION ....................................... N-23

TROUBLESHOOTING GUIDE.. .................. N-25

AIR BLEEDING ....................................... N-26

STEERING WHEEL AND COLUMN.. .......... N-26

POWER STEERING FLUID.. ...................... N-27

STEERING GEAR AND LINKAGE .............. N-30

POWER STEERING OIL PUMP.. ................ N-37

DRIVE BELT ........................................... N-41

23UONX-001

Page 627 of 1164

INDEX

ENGINE SPEED SENSING POWER STEERING (ESPS)

FLUID

ATF M STEERING WHEEL PLAY

O-30mm (O-l .18 in)

SPECIFICATION

-IIt or Dexron@lI

I T nFFl FCTIC-IN

--. --w. .-.. NEW: 8.0-9.0mm (0.31-0.35 in)

USED: 9.0-lO.Omm (0.35-0.39 in)

LIMIT: 11.5mm (0.45 in)

23UONX-00

1. Boot

4. Drive belt

Removal / installation

.................. page N- 6 Inspection ................................... page N-41

2. Steering gear and linkage Adjustment .................................

page N-42

Removal / Installation.. ................ page N-30 Replacement .............................. page N-42

Disassembly / Inspection.. ..........

page N-31 5. Power steering fluid

Assembly..

.................................. page N-34 Air bleeding ................................ page N-26

3. Power steering oil pump Inspection.. .................................

page N-27

Removal I Installation

.................. page N-37 6. Steering wheel and column

Disassembly / Inspection I Inspection (On-vehicle).

.............. page N-26

Assembly ..................................

page N-38 Removal / Installation..

................ page N- 9

Disassembly / Assembly ............. page

N-l 0

Inspection ................................... page N-l 1

N-3

Page 650 of 1164

ENGINE SPEED SENSING POWER STEERING

23UONX-03

03UONX-032

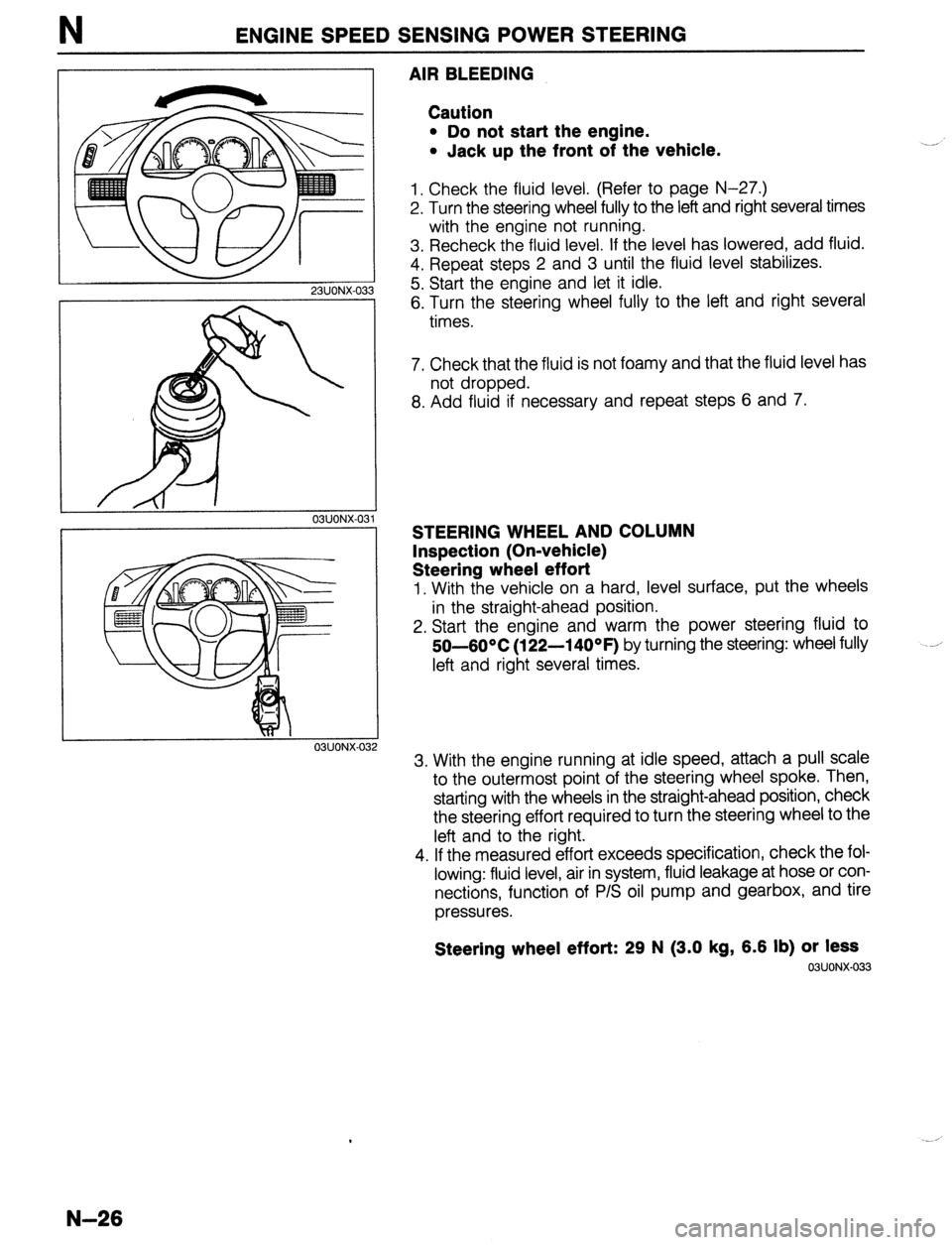

AIR BLEEDING

Caution

l Do not start the engine.

l Jack up the front of the vehicle.

1. Check the fluid level. (Refer to page N-27.)

2. Turn the steering wheel fully to the left and right several times

with the engine not running.

3. Recheck the fluid level. If the level has lowered, add fluid.

4. Repeat steps 2 and 3 until the fluid level stabilizes.

5. Start the engine and let it idle.

6. Turn the steering wheel fully to the left and right several

times.

7. Check that the fluid is not foamy and that the fluid level has

not dropped.

8. Add fluid if necessary and repeat steps 6 and 7.

STEERING WHEEL AND COLUMN

Inspection (On-vehicle)

Steering wheel effort

1. With the vehicle on a hard, level surface, put the wheels

in the straight-ahead position.

2. Start the engine and warm the power steering fluid to

50-60°C

(122-14OOF) by turning the steering: wheel fully

left and right several times.

3. With the engine running at idle speed, attach a pull scale

to the outermost point of the steering wheel spoke. Then,

starting with the wheels in the straight-ahead position, check

the steering effort required to turn the steering wheel to the

left and to the right.

4. If the measured effort exceeds specification, check the fol-

lowing: fluid level, air in system, fluid leakage at hose or con-

nections, function of P/S oil pump and gearbox, and tire

pressures.

Steering wheel effort: 29 N (3.0 kg, 6.6 lb) or less 03UONX-033

N-26

Page 667 of 1164

P

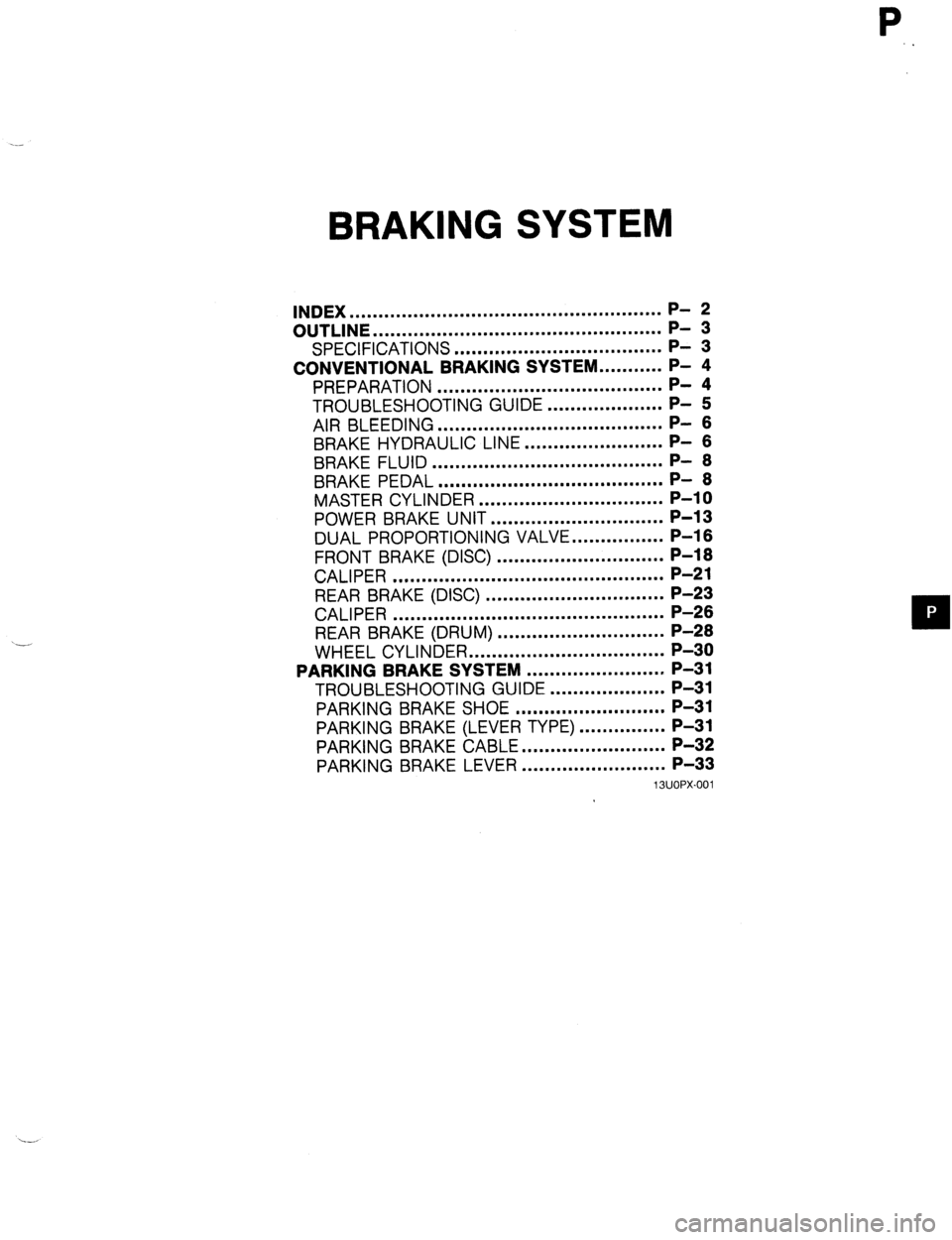

BRAKING SYSTEM

INDEX ......................................................

OUTLINE .................................................. ;I g

SPECIFICATIONS .................................... P- 3

CONVENTIONAL BRAKING SYSTEM.. ......... P- 4

PREPARATION ....................................... P- 4

TROUBLESHOOTING GUIDE .................... P- 5

AIR BLEEDING .......................................

BRAKE HYDRAULIC LINE.. -

...................... F- t

BRAKE FLUID ........................................

BRAKE PEDAL ....................................... ;I ;

MASTER CYLINDER ................................ P-l 0

POWER BRAKE UNIT .............................. P-13

DUAL PROPORTIONING VALVE.. .............. P-l 6

FRONT BRAKE (DISC) ............................. P-16

CALIPER ............................................... P-21

REAR BRAKE (DISC) ............................... P-23

CALIPER ............................................... P-26

REAR BRAKE (DRUM) ............................. P-28

WHEEL CYLINDER .................................. P-30

PARKING BRAKE SYSTEM ........................ P-31

TROUBLESHOOTING GUIDE .................... P-31

PARKING BRAKE SHOE .......................... P-31

PARKING BRAKE (LEVER TYPE) ............... P-31

PARKING BRAKE CABLE.. ....................... P-32

PARKING BRAKE LEVER ......................... P-33

13UOPX-001