technical specifications MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 1 of 1164

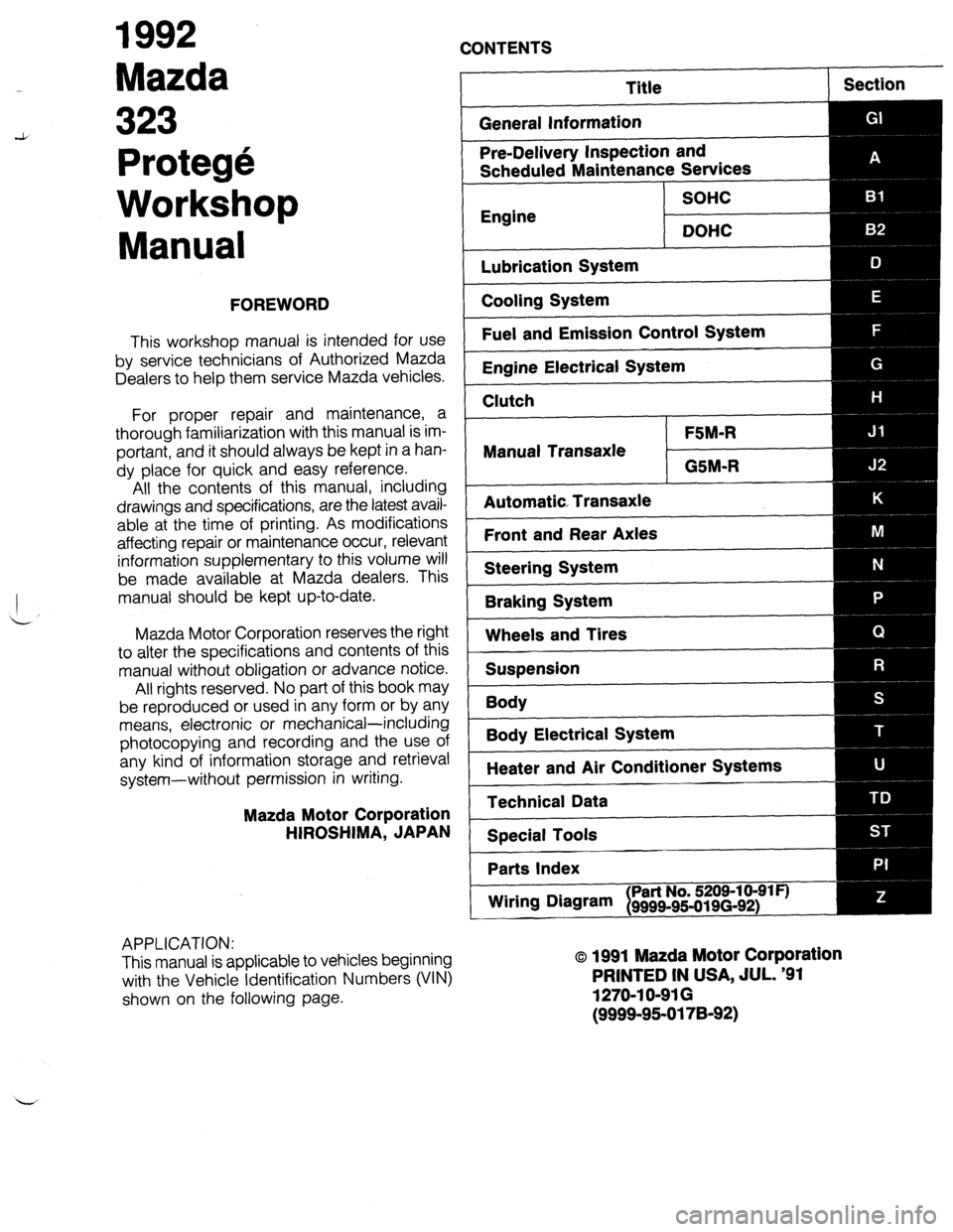

1992

Mazda

CONTENTS

Protege

Workshop

Manual

FOREWORD

This workshop manual is intended for use

by service technicians of Authorized Mazda

Dealers to help them service Mazda vehicles.

For proper repair and maintenance, a

thorough familiarization with this manual is im-

portant, and it should always be kept in a han-

dy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest avail-

able at the time of printing. As modifications

affecting repair or maintenance occur, relevant

information supplementary to this volume will

be made available at Mazda dealers. This

manual should be kept up-to-date.

Mazda Motor Corporation reserves the right

to alter the specifications and contents of this

manual without obligation or advance notice.

All rights reserved. No part of this book may

be reproduced or used in any form or by any

means, electronic or mechanical-including

photocopying and recording and the use of

any kind of information storage and retrieval

system-without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN)

shown on the following page.

Title

General Information Section

Pre-Delivery Inspection and

Scheduled Maintenance Services

SOHC

Engine

DOHC

Lubrication System

Cooling System

Fuel and Emission Control System

Engine Electrical System

Clutch

FSM-R

Manual Transaxle

GSM-R

Automatic Transaxle

Front and Rear Axles

Steering System

Braking System

Wheels and Tires

Suspension

Body

--

Body Electrical System

Heater and Air Conditioner Systems

Technical Data

Special Tools

Parts Index

Wiring DNvam

I Part No. 5209-10-91 F)

9999~95-019(3-92)

o 1991 Mazda Motor Corporation

PRINTED IN USA, JUL. ‘91

1270-l O-91 G

(9999-95-0178-92)

Page 1031 of 1164

TECHNICAL DATA TD

1 Throttle condition 1

nrllm pn-t

Mode Rr _ me/ flhrottle sensor 1 Shift 1 -.- -*r2d rpm

Vehicle speed I km/h (mohl , . ,

I

ioltage) 1 B6 sot

iC 1 BP SOHC 1 BP DOHC

66 SOHC 1 BP SOHC 1 BP

I I I

’ ni - n9 I’) 7nn-1 “50 2,500-3,05012,700-3.3001 I I DOHC

Fully opened 27-33 (17-201

3 D (4.0 volt) 50 2,050-2,55012,200-2,750]

40-50 i25-31 j

e I 300-500 1 450-650 / Q-15 16-9) 112-18 (7-111

00 3,250-3,45013,550-3.800~91-97 f56-60&G10’4 (61-64)hOO-106;62-&\I

s

i- f Fully closed

(0.5 volt)

YI -l&c

L, r vv-“,L

Dz + D3 2,150-2,7

D3 -+ DI 300--5O(

S3 -+ S2 3,200-3,4

’ L2 -+ LI 2,350-2,65012,200-2,50012,350-2.7001

43-49 ;27--3b1 ’ ‘I

M. FRONT AND REAR AXLES -

Item

Driveshaft Engine/Transaxle BP SOHC BP DOHC

Joint type

Length of shaft

Shaft diameter Front axle

Bearing play axial direction Rear axle

Bearing play axial direction Inside Tripod joint

Outside Ball joint

Right

919.3 (36.19) 918.7 (36.17) 630.7 (24.83)

mm (in) Left

637.8 (25.11) 640.2 (25.20) 621.2

637.1

(24.46) (25.08)

21.5 (0.85) 23.0 (0.91)

mm (in) 1 0.05 (0.002)

mm (in) I 0.05 (0.002)

N. STEERING SYSTEM Steering wheel

Outer diameter Item Specifications 370 (14.57)

Lock-to-lock I Steering gear

--

Type

Steering gear ratio

Backlash between rack and pinion mm (in)

N.r ’ ’ ” ’ n (cm-Kg, in-01

Preload measured by torque

*rrv~rrdl Rack and pinion

Infinite (00)

0 (0)

M/S : 0.9-l .3 (Q-13, 7.8-l 1.3)

P/S : 1.0-1.3 (10-14, 8.7-12)

Pinion preload ““l~jll~,,

9 (0.4

Preload measured by pull

scale with attachment

Limit of rack housing movement mm (in)

Distance between left and right brackets mm (in)

Rack stroke mm (in M/S : 900-l ,300 (31.8-45.9)

P/S : l,OOO-1,400 (35.3-49.4)

1.5 (0.06)

298.5 (11.75)

140 (5.511

Lubricant type (power steering)

Oil capacity (power steering) Drive belt

liter (US qt, Imp qt) I ATF: M-III or DexronW

0.8 (0.85, 0.70)

I New belt: 8-Q (0.31-0.35)

Deflection with force of 98 N (10 kg, 22 lb) mm (in) Used belt: 9-10 (0.35-0.39)

I imit: 11.5 (0.461

TD-17

Page 1032 of 1164

TD TECHNICAL DATA

P. BRAKING SYSTEM

Item

3rake type

Brake pedal

Height mm (in)

Free play mm (in)

Reserve travel mm (in)

Clearance when pedal depressed at 589 N (60 kg, 132 lb)

Master cylinder

Type

Master cylinder

Bore diameter mm (in) 1

Front disc brake

We

Thickness of pad

mm (in) Standard

Minimum

Thickness of disc plate

mm (in) Standard

Minimum

Runout of disc plate mm (in)

Cylinder bore

mm (in) Specifications

Front . . . . . disc, Rear . . . . . disc or drum

193-196 (7.60-7.72)

4-7 (0.16-0.28)

70 (2.76) min

Tandem

22.22 (0.875)

Ventilated

10 (0.39)

2 (0.08)

22 (0.87)

20 (0.79)

0.1 (0.004)

53.97 (2.12)

Rear brake (drum)

We

Thickness of lining

I Drum inside diameter

1

tiheel cylinder bore

I Parking brake

Type

Parking brake lever notches Leading & trailing

mm (in) Standard 4.5 (0.18)

Minimum 1 (0.04)

mm (in) Standard 200 (7.90)

Maximum 201 (7.91)

mm (in) 17.46 (0.687)

Mechanical two-rear-wheel control

When lever is pulled at 98N (10 kg, 22 lb)

Power brake unit

Diameter mm (in) 5-7

(a): 214 (8.43) (b): 239 (9.41)

More than 1,177 (12, 171)/196 (20, 44)

Fluid pressure per treading force

kPa (kg/cm’, psi)/N (kg, lb) (4

@I at 0 mmHg (0 inHg)

More than 7,063 (72, 1,024)/l 96 (20, 44)

at 500 mmHg (19.7 inHg)

More than 1,517 (15, 213)/196 (20, 44)

at 0 mmHg (0 inHg)

More than 8,593 (88, 1,261)/196 (20, 44)

at 500 mmHg (19.7 inHg)

Rear wheel hydraulic control rystem

Type Dual proportioning valve

_-_.

. .- ,. . . . !

P.IF

Switching point (Master cylinder pressure)

KPa (kg/cm-, PSI) ) z,4~j3 (25, 356)

(a): BP engine with SMTX, B6 engine

(b): BP engine with 4EATX ..-

-’

TD-18

Page 1033 of 1164

TECHNICAL DATA

Q. WHEELS AND TIRES

Item Specifications

Wheel

Size

Off set Standard: 13x5-J, 14x5 l/2-JJ

Temporary

mm (in) 1 _ spare: 14x4-T

45 (1.77)

I Diameter of oitch circle

mm (in) I 100 (3.94)

r I Pl

-

Inflation pressure kPa (kg/cm*, psi) Front 1 8

I 9

Runout limit

Unbalance limit mm (in) ;lii.raltLa’

a (02) ’

13 inch wheel: 11 (0.

R. SUSPENSION Item Specifications

Suspension type Strut

)e Double-acting, oil-filled

I Shock absorber tyf

Coil spring

Type

Dimension

Type Front Taper wound

Rear Straight wound

See next page

Torsion bar

I

I C.rrn,

19.1 (0.75)

20.0 (0.79)

22.0 (0.87)

21 .O f0.83)

Wheel alignment

(“‘Unladened) BP SOHC ;;a;

Diameter

mm (in) BP DOHC - ;la;t

Front -

B6 SOHC

Rear 20.0 (0.79)

Maximum Inner 4o” f 2O

steering angle Outer

Total mm (in) 2 f 3 (0.08 j

Front toe-in

dearee

.-.._

Rear

.--. I --- ~~

Camber angle

Caster angle

Kingpin angle

I Total

I mm OnI I I toe-in

1 dearee I , --U’-- 1

Camber angle

I 33O * 2O

: 0.12)

0.2O f 0.3O

-0OO5’ * 45’

1055’ * 55’

12O25’

2 f 3 (0.08 f 0.12)

0.2O f 0.3O

-0°20’ f 45’

l ’ Fuel tank full; radiator coolant and engine ail at specified level; and spare tire, jack, and tools in designated posmons.

TD-19

Page 1034 of 1164

TD TECHNICAL DATA

Coil Spring Specifications (See page R-5 for coil spring applications)

*’ Main identification mark color: Indicated on second coil from bottom. l * Auxiliary identification mark color: Indicated on third coil from bottom.

T. BODY ELECTRICAL SYSTEM

Item

Headlight

Frnnt tl wn sinnnl/Pnrkinn linht

Specification (W) (Bulb Trade number)

65145 (9004)

2718 II I 571

I

“‘VW, I u”“y’ 1. I” \’ ‘V’,

uinh mount stoplight 18.4 (1141)

turn single light 27 (1156)

Y-,-~p light 27 (1156)

Rear side marker light (Sedan) 3.8 (194)

License plate light 7.5 (89) [PROTEGE], 5 (168) [3HBl

Interior 10

Interior and spot lamp

spot 6

Interior lamp 10

‘i--” Spot lamp (in overhead console)

8 (67)

Cargo room lamp 5 (168)

Trunk room lamp 5 (168)

I I

ntminr Iamnc

I

Curtesy lamp

High beam

Turn light

Brake

Hold

) Charge 5 (168)

3.4

3.4

3

3 (158)

i

Oil pressure

Washer

Seat belt

Malfunction

Fuel

illumination 3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3.4 Indicator and

warning lamps

Check 3 (158)

Dif. lock

I 3 (158) .-

,

-.-’

I

I

TD-20

Page 1035 of 1164

TECHNICAL DATA TD

U. HEATER AND AIR CONDITIONER SYSTEMS

Item Specifications

Refrigerant amount

g (04

Refrigerant pressure kPa (kg/cm2, psi) 750-800 (26.5-28.2)

High: 1,177-1,619 (12.0-16.5, 171-235)

Low: 147-294 (1.5-3.0, 21-43)

Compressor

Magnetic clutch

Condenser fan

Recerver/Drier Capacity cc (cu in)

Compressor oil amount cc (cu in)

Electrical load w

Electrical load w

Capacity cc (cu in) 115 (7.0)

loo---120 (6.1-7.3)

31

77

330 (20.1)

STANDARD BOLT AND NUT TIGHTENING TORQUE

Diameter Pitch 4T 6T 8T

mm (in) mm (in) N-m m-kg ft-lb N.m m-kg ft-lb N.m m-kg ft-lb

6 (0.236) 1 (0.039) 4.2-6.2 0.43-0.63 3.1-4.6 6.9-9.8 0.7-1.0 5.0-7.2 7.8-11.8 0.8-1.2 5.8-8.8

8 (0.315) 1.25 (0.049) 9.8-14.7 1.0-1.5

7.2-10.8 16-23 1.6-2.3 12-17 18-26 1.8-2.7 13-20

10 (0.394) 1.25 (0.049) 20-28 2.0-2.9

14-21 31-46 3.2-4.7 23-34 36-54 3.7-5.5 27-40

12 (0.472) 1.5 (0.059) 34-50 3.5-5.1 25-37 55-80 5.6-8.2

41-59 63-93 6.4-9.5 46-69

14 (0,551) 1.5 (0.059)

- - - 75-103 7.7-10.5 56-76 102-137

lo-14 75-101

1 16 (0.630) 1 1.5 iO.059j 1 - 1 - - 116-157 12-16 85-116 156-211 16-22 115-156

1 18 ;0.709j Il.5 iO.O59 1 - 1 -

167

1 20 i0.787; Il.5 iO.059i 1 - 1 - 1 - 12:

31 _..

22 (0.866) 1 1.5 io.059j 1 - 1 - 1 - 1314-423 __ ._ ,--. -._,

1 I

24 (0.945) 1 1.5

(0.059) 1 -

- 1475-546 41-56 (298-4031536-7261 55-74 1396-536 -2251 17-23 123-166 221-299 23-31 163-221

-3141 24-32 171-231 308-417 31-43 227-307

37-43 331-312 417-564 43-58 307-416

TD-21