MERCEDES-BENZ AMG GT R-ROADSTER 2020 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: AMG GT R-ROADSTER, Model: MERCEDES-BENZ AMG GT R-ROADSTER 2020Pages: 441, PDF Size: 7.76 MB

Page 331 of 441

It is only permissible

tofit a di fferent wheel

size in theev ent of a flat tyre in order to

drive tothe specialist workshop.

R Do not make any modifications tothe brake

sy stem, the wheels or the tyres.

The use of shims or brake dust shields is not

permitted and may in validate theve hicle's

ge neral operating pe rmit.

R Vehicles with a tyre pressure monitoring

sy stem: allfitted wheels mu stbe equipped

with functioning sensors forth e tyre pres‐

sure monitoring sy stem.

R Attemp eratures below 7 °C use winter tyres

or all-season tyres mar ked M+S for all

wheels.

Wi nter tyres bearing thei snowflake

symbol in addition tothe M+S marking pro‐

vide the best possible grip in wintry road

conditions.

R For M+S tyres, only use tyres with the same

tread.

R Obser vethe maximum permissible speed for

th e M+S tyres fitted. If

th e tyre's maximum speed is below that of

th eve hicle, this must be indicated byan

appropriate label in the driver's field of

vision.

R Run in new tyres at moderate speeds forthe

fi rs t10 0 km.

R Replace the tyres af ter six years at the latest,

re ga rdless of wear.

R When replacing with tyres that do not

fe ature run-flat characteristics: vehicles

with MOExtended tyres are not equipped

with a TIREFIT kit at thefa ctor y.Equip the

ve hicle with a TIREFIT kit af terre placing with

tyres that do not feature run-flat characteris‐

tics, e.g. winter tyres.

% You can permanently limit the maximum

ve hicle speed for driving with winter tyres

(/ page 141).

Fo r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 322)R

Tyre pressure table (/ page 323)

R Notes on the emer gency spa rewheel

(/ page 335) &

WARNING Risk of accident caused by

non-app rove d tyre types

If yo u use tyre types that ha venot been

adap tedto changes made tothefa ctory

speed limit, this can ha vethefo llowing con‐

sequences:

R The tyres are not suitable for high speeds

and the cor responding driving dynamics.

R The tyres wear une venly and af fect the

ro adwor thiness of theve hicle.

R ABS, ESP ®

and cruise contro l operation

are restricted.

This can jeopardise road saf ety. #

Only use tyre types that ha vebeen

appr ovedfo rth e maximum permissible

speed set and theve hicle. 328

Wheels and tyres

Page 332 of 441

Note

s on inter changing wheels &

WARNING Risk of injury thro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions

may se verely impair the driving characteris‐

tics.

The disk brakes or wheel suspension compo‐

nents may also be damaged. #

Rotate front and rear wheels on lyifthe

wheels and tyres are of the same

dimensions. Inter

changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions can

re nder thege neral operating pe rmit in valid.

The wear pat tern s on the front and rear wheels

dif fer:

R Front wheels wear more on the shoulder of

th e tyre

R Rear wheels wear more in the cent reofthe

tyre Do not drive wi

thtyres that ha vetoo little tread

dep th. This significantly reduces traction on wet

ro ads (aquaplaning).

On vehicles with the same front and rear wheel

size, you can inter change the wheels every

5,000 to10,000 km, depending on thewe ar.

Ensure the direction of rotation is maintained for

th e wheels.

Obser vethe instructions and saf ety no tes on

"Changing a wheel" when doing so

(/ page 330). Note

s onstoring wheels When

storing wheels, obser vethefo llowing

no tes:

R Afterre moving wheels, store them in a cool,

dry and preferably dark place.

R Protect the tyres from conta ct withoil,

grease or fuel. Overview of

the ty re-change tool kit Apart from some countr

y-specific variants, vehi‐

cles are not equipped with a tyre-change tool kit.

Fo r more information on which tyre-changing

to ols are required and appr oved for per form ing a

wheel change on your vehicle, consult a qualified

specialist workshop.

Re quired tyre-change tool kits may include, for

ex ample:

R Jack

R Chock

R Wheel wrench

R Cent ring pin

% The jack weighs appr oximately 1.2 kg.

The maximum load capacity of the jack can

be found on thest icke r af fixe dto the jac k.

The jack is maintenance-free. If there is a

malfunction, please conta ct aqualified spe‐

cialist workshop. Wheels and tyres

329

Page 333 of 441

The tyre-change

tool kit is located on the left

side of the load compartment in thestow age

compartment behind service flap 1. Prepa

ring theve hicle for a wheel change Re

quirements:

R The requ ired tyre-change tool kit is available.

If yo ur vehicle is not equipped with the tyre-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Apply the electric parking brake manually. #

Movethe front wheels tothest ra ight-ahead

position. #

Shift the transmission toposition j. #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel you wish tochange. #

If necessar y,remo vethe hub cap co ver

( / page 330). #

Raise theve hicle (/ page 331). Fi

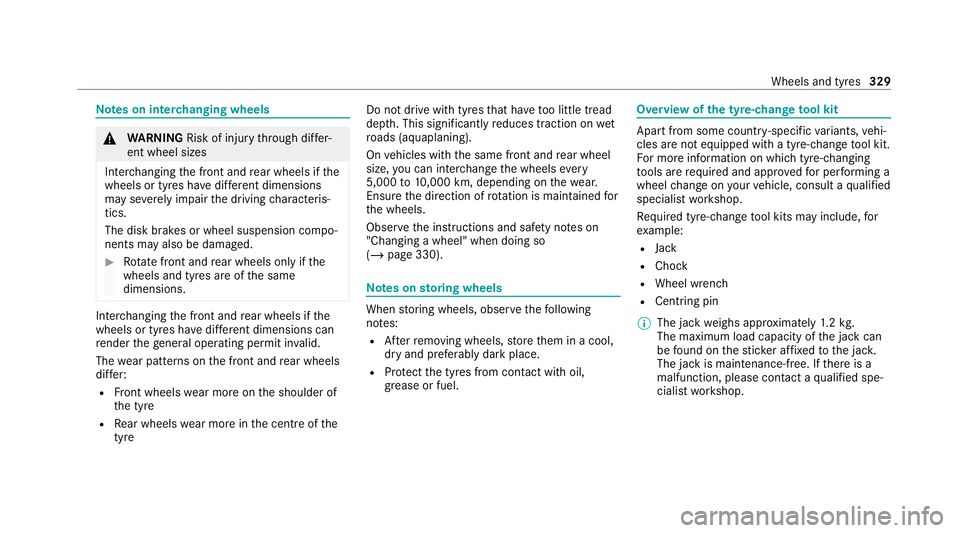

tting/ removing pla stic hub caps Re

moving #

Remo vesoc ket2 and wheel wrench 3

from theve hicle tool kit (/ page 329). #

Position soc ket2 on hub cap 1. #

Position wheel spanner 3on soc ket2. #

Using wheel spanner 3, turn hub cap1

anti-clo ckwise and remo veit.

Fi tting #

Before fitting, check hub cap 1and the

wheel area for dirt, and clean if necessar y.330

Wheels and tyres

Page 334 of 441

#

Position hub cap 1and turn until it is in the

ri ght position. #

Position soc ket2 on hub cap 1. #

Position wheel wrench 3on soc ket2 and

tighten hub cap 1.

Speci fied tigh tening torq ue: 25 Nm. Ra

ising theve hicle when changing a wheel Re

quirements:

R There are no persons in theve hicle.

R The vehicle has been prepared for a wheel

ch ange (/ page 330).

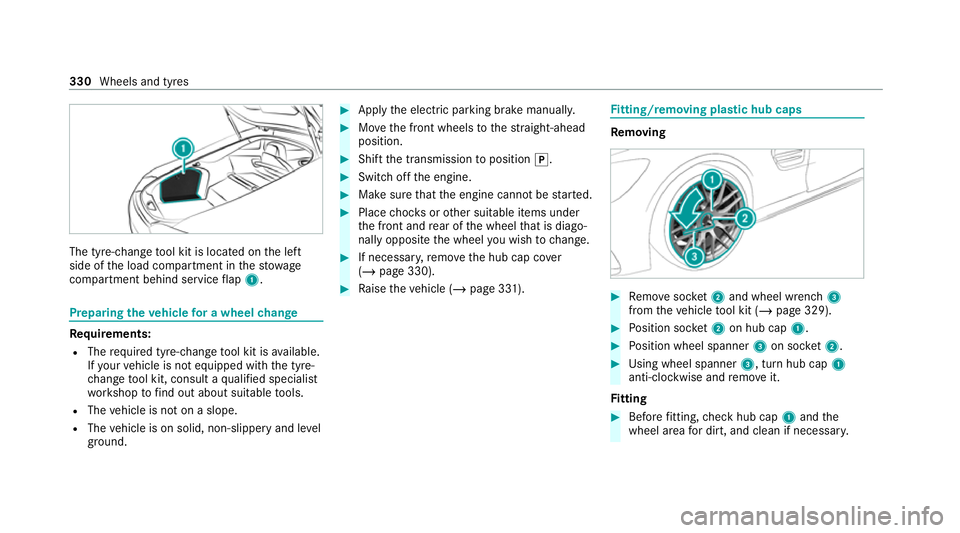

Important no tes on using the jack:

R Use only a vehicle-specific jack that has

been appr ovedby Mercedes-Benz toraise

th eve hicle.

R The jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle. R

The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

fl at, load-bearing, non-slip unde rlay.

R The foot ofthe jack must be positioned verti‐

cally under the jack support point. Ru

les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Never lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or theta il‐

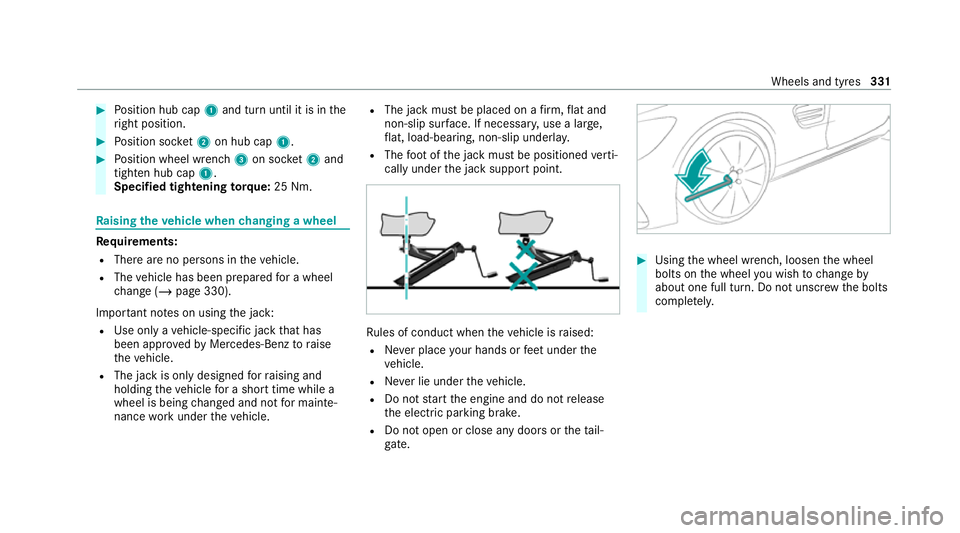

gate. #

Using the wheel wrench, loosen the wheel

bolts on the wheel you wish tochange by

about one full turn. Do not unscr ewthe bolts

comple tely. Wheels and tyres

331

Page 335 of 441

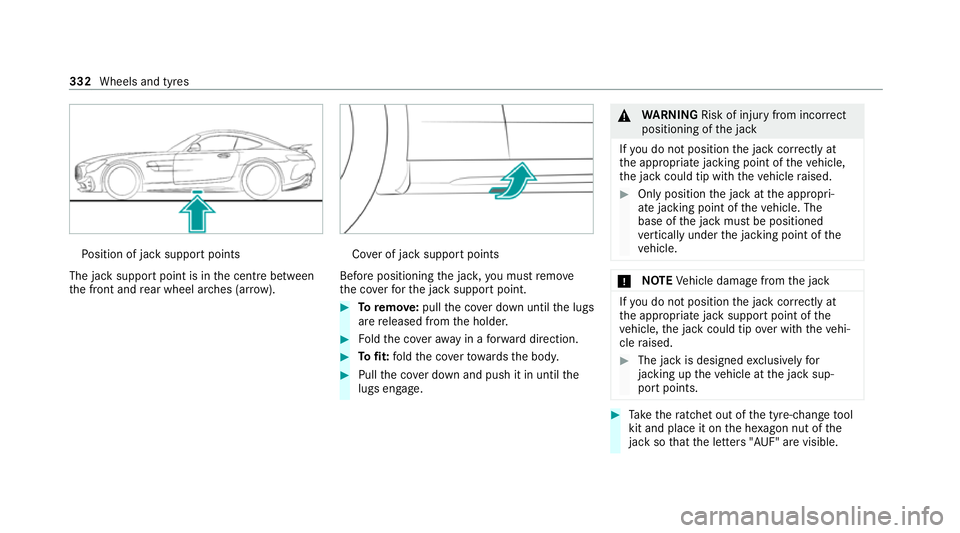

Po

sition of jack support points

The jack support point is in the cent rebetween

th e front and rear wheel ar ches (ar row). Co

ver of jack support points

Before positioning the jac k,you must remo ve

th e co verfo rth e jack support point. #

Toremo ve:pull the co ver down until the lugs

are released from the holder. #

Foldthe co veraw ay in a forw ard direction. #

Tofit: fold the co verto wa rdsth e body. #

Pull the co ver down and push it in until the

lugs engage. &

WARNING Risk of injury from incorrect

positioning of the jack

If yo u do not position the jack cor rectly at

th e appropriate jacking point of theve hicle,

th e jack could tip with theve hicle raised. #

Only position the jack at the appropri‐

ate jacking point of theve hicle. The

base of the jack must be positioned

ve rtically under the jacking point of the

ve hicle. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at

th e appropriate jack support point of the

ve hicle, the jack could tip over with theve hi‐

cle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. #

Take thera tchet out of the tyre-change tool

kit and place it on the he xagon nut of the

jack so that the letters "AUF" are visible. 332

Wheels and tyres

Page 336 of 441

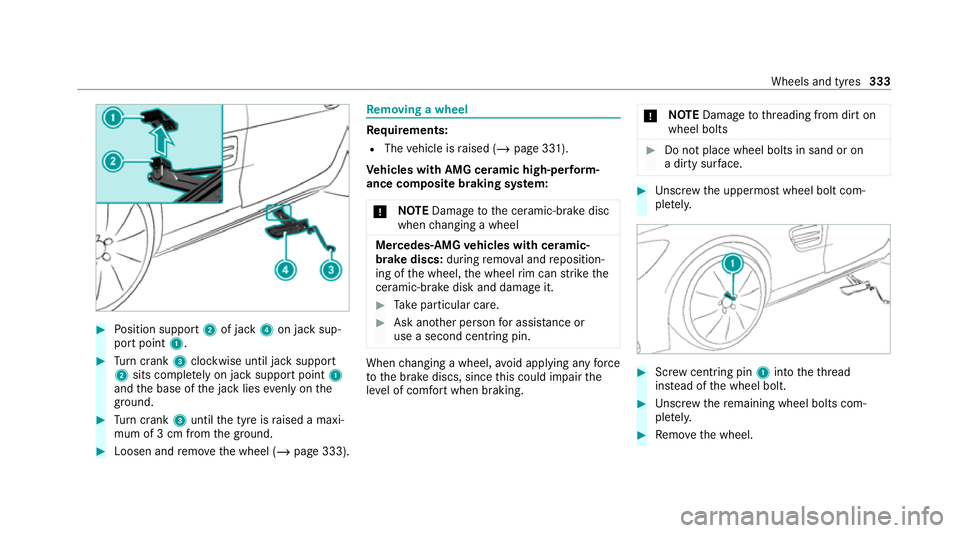

#

Position support 2of jack 4on jack sup‐

port point 1. #

Turn crank 3clockwise until jack suppo rt

2 sits comple tely on jack support point 1

and the base of the jack lies evenly on the

ground. #

Turn crank 3until the tyre is raised a maxi‐

mum of 3 cm from the ground. #

Loosen and remo vethe wheel (/ page 333). Re

moving a wheel Re

quirements:

R The vehicle is raised (/ page 331).

Ve hicles with AMG cera mic high-perform‐

ance composite braking sy stem:

* NO

TEDama getothe ceramic-brake disc

when changing a wheel Mercedes

-AMG vehicles with cera mic-

brake discs: during remo val and reposition‐

ing of the wheel, the wheel rim can strike the

ceramic-brake disk and damage it. #

Take particular care. #

Ask ano ther person for assi stance or

use a second centring pin. When

changing a wheel, avoid applying any force

to the brake discs, since this could impair the

le ve l of com fort when braking. *

NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the uppermost wheel bolt com‐

ple tely. #

Screw centring pin 1into theth re ad

ins tead of the wheel bolt. #

Unscr ew there maining wheel bolts com‐

ple tely. #

Remo vethe wheel. Wheels and tyres

333

Page 337 of 441

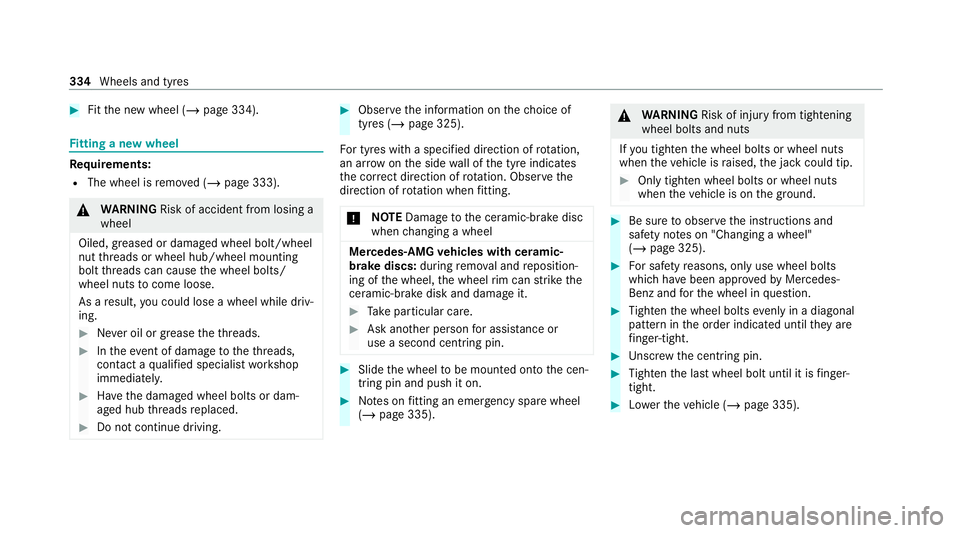

#

Fitthe new wheel (/ page 334).Fi

tting a new wheel Re

quirements:

R The wheel is remo ved (/ page 333). &

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/

wheel nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing. #

Never oil or grease theth re ads. #

Intheeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. #

Obser vethe information on thech oice of

tyres (/ page 325).

Fo r tyres with a specified direction of rotation,

an ar row on the side wall of the tyre indicates

th e cor rect dire ction of rotation. Obse rvethe

direction of rotation when fitting.

* NO

TEDama getothe ceramic-brake disc

when changing a wheel Mercedes

-AMG vehicles with cera mic-

brake discs: during remo val and reposition‐

ing of the wheel, the wheel rim can strike the

ceramic-brake disk and damage it. #

Take particular care. #

Ask ano ther person for assi stance or

use a second centring pin. #

Slide the wheel tobe mounted onto the cen‐

tring pin and push it on. #

Notes on fitting an eme rgency spare wheel

(/ page 335). &

WARNING Risk of injury from tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

Be sure toobser vethe instructions and

saf ety no tes on "Changing a wheel"

(/ page 325). #

For saf etyre asons, only use wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated until they are

fi nger-tight. #

Unscr ew the cent ring pin. #

Tighten the last wheel bolt until it is finger-

tight. #

Lowe rth eve hicle (/ page 335). 334

Wheels and tyres

Page 338 of 441

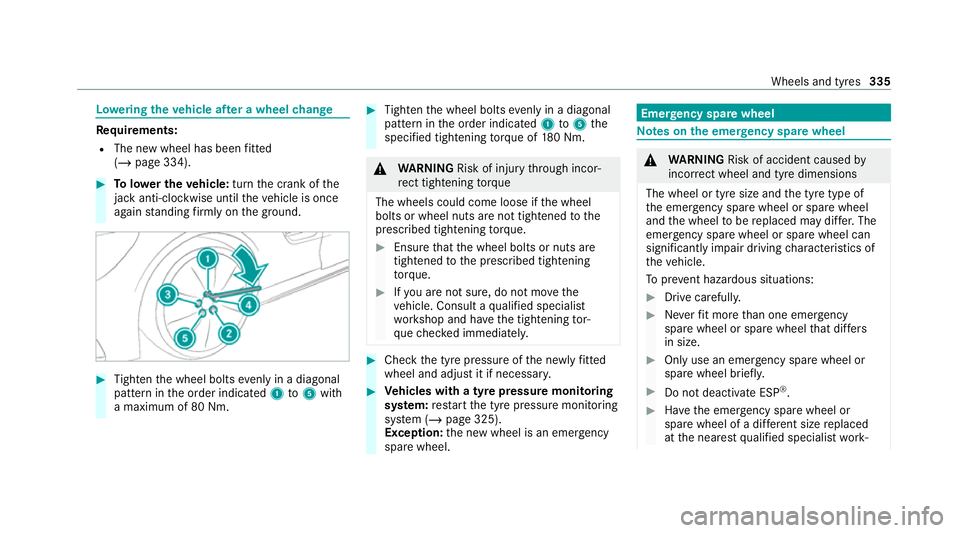

Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted

(/ page 334). #

Tolowe r the vehicle: turnthe crank of the

jack anti-clo ckwise until theve hicle is once

again standing firm lyon the ground. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated 1to5 with

a maximum of 80 Nm. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated 1to5 the

specified tightening torque of 180 Nm. &

WARNING Risk of injury thro ugh incor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed tightening torque. #

Ensu rethat the wheel bolts or nuts are

tightened tothe prescribed tightening

to rque. #

Ifyo u are not sure, do not mo vethe

ve hicle. Consult a qualified specialist

wo rkshop and ha vethe tightening tor‐

qu ech ecked immediately. #

Check the tyre pressure of the newly fitted

wheel and adjust it if necessa ry. #

Vehicles with a tyre pressure monitoring

sy stem: restart the tyre pressure monitoring

sy stem (/ page 325).

Exception: the new wheel is an emer gency

spa rewheel. Emer

gency spare wheel Note

s onthe emer gency spare wheel &

WARNING Risk of accident caused by

incor rect wheel and tyre dimensions

The wheel or tyre size and the tyre type of

th e emer gency spa rewheel or spare wheel

and the wheel tobe replaced may dif fer. The

emer gency spa rewheel or spare wheel can

significantly impair driving characteristics of

th eve hicle.

To preve nt hazardous situations: #

Drive carefully. #

Neverfit more than one emer gency

spa rewheel or spare wheel that dif fers

in size. #

Only use an emer gency spa rewheel or

spare wheel brief ly. #

Do not deacti vate ESP ®

. #

Have the emer gency spa rewheel or

spare wheel of a dif fere nt size replaced

at the nearest qualified specialist work‐ Wheels and tyres

335

Page 339 of 441

shop. The new wheel must ha

vethe

cor rect dimensions. Obser

vethefo llowing no tes on fitting an emer‐

ge ncy spa rewheel:

R Check the tyre pressure of the emer gency

spa rewheel fitted. Co rrect the pressure as

necessar y.

R The maximum permissible speed with an

emer gency spa rewheel fitted is 80 km/h.

R Do not fit th e emer gency spa rewheel with

sn ow ch ains.

R Replace the emer gency spa rewheel af ter six

ye ars at the latest, rega rdless of wear.

% Ve

hicles with a tyre pressure monitoring

sy stem: if an emer gency spa rewheel is fit‐

te dth e tyre pressure monitoring sy stem can‐

not function reliabl y.Fo r a few minutes af ter

an emer gency spa rewheel is fitted, the sys‐

te m may still display the tyre pressure of the

re mo ved wheel. Only restart the sy stem

again when the emer gency spa rewheel has

been replaced with a new wheel. Be sure

toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 322)

R Tyre pressure table (/ page 323)

R Notes on fitting tyres (/ page 325) Inflating

the emer gency spare wheel *

NO

TEOverheating due tothe tyre infla‐

tion compressor running too long #

Do not runth e tyre inflation compres‐

sor for longer than ten minu tes without

inter ruption. Re

quirements:

Comply with the manufacturer's saf ety no tes on

th est icke r of the emer gency spa rewheel and on

th e tyre inflation compressor. #

Remo vesticke r with the label 80 km/h from

th e tyre inflation compressor housing and

af fix it tothe instrument clus ter within the

driver's field of vision. #

Remo vethe tyre inflation compressor from

th estow agewell under the boot floor .

(/ page 306) #

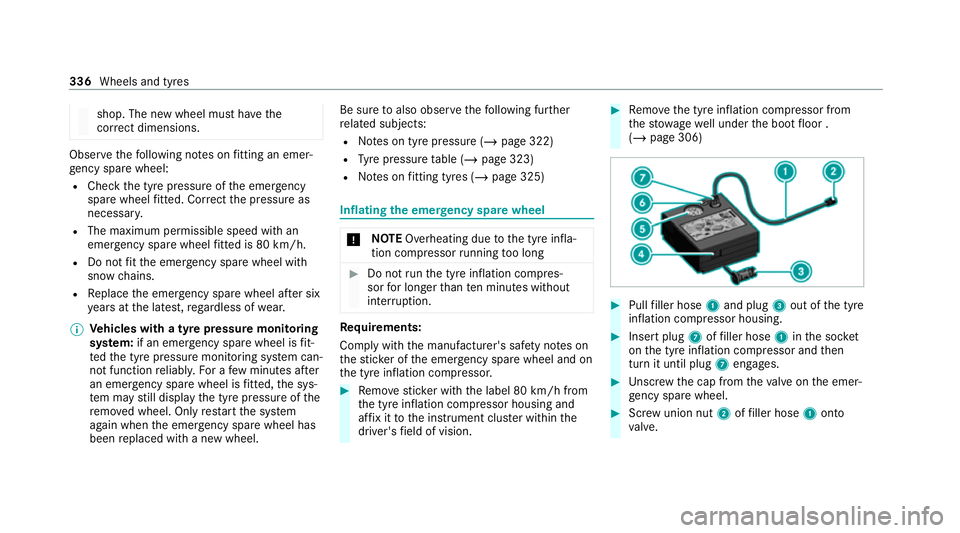

Pull filler hose 1and plug 3out of the tyre

inflation compressor housing. #

Insert plug 7offiller hose 1inthe soc ket

on the tyre inflation compressor and then

turn it until plug 7engages. #

Unscr ew the cap from theva lve on the emer‐

ge ncy spa rewheel. #

Screw union nut 2offiller hose 1onto

va lve. 336

Wheels and tyres

Page 340 of 441

#

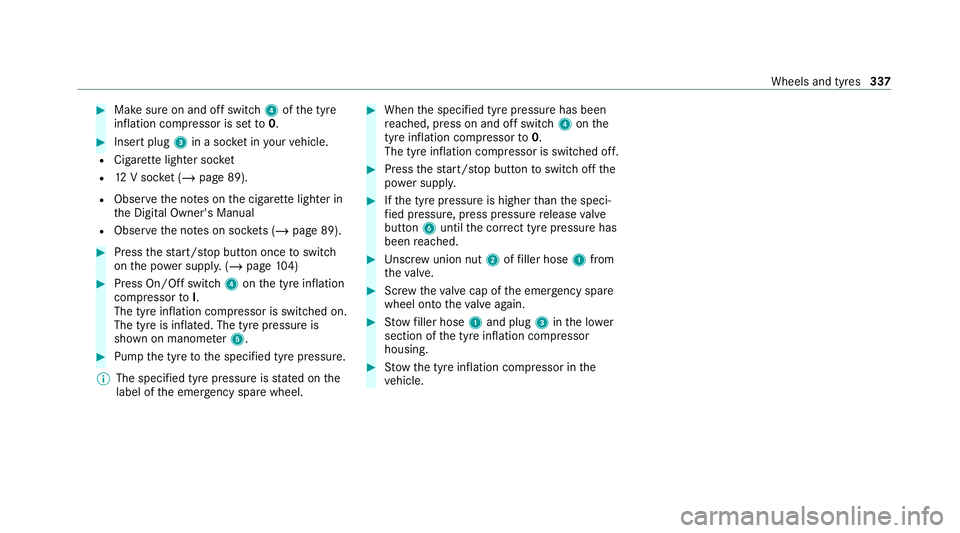

Make sure on and off switch 4ofthe tyre

inflation compressor is set to0. #

Insert plug 3in a soc ket in your vehicle.

R Cigar ette lighter soc ket

R 12V soc ket (/ page 89).

R Obse rveth e no tes on the cigar ette lighter in

th e Digital Owner's Manual

R Obser vethe no tes on soc kets (/ page 89). #

Press thest art/ stop button once toswitch

on the po wer supp ly. (/ page 104) #

Press On/Off switch 4onthe tyre inflation

compressor toI.

The tyre inflation compressor is switched on.

The tyre is inflated. The tyre pressure is

shown on manome ter5. #

Pump the tyre tothe specified tyre pressure.

% The specified tyre pressure is stated on the

label of the emer gency spa rewheel. #

When the specified tyre pressure has been

re ached, press on and off swit ch4 onthe

tyre inflation compressor to0.

The tyre inflation compressor is switched off. #

Press thest art/ stop button toswitch off the

po we r supp ly. #

Ifth e tyre pressure is higher than the speci‐

fi ed pressure, press pressure release valve

bu tton 6until the cor rect tyre pressure has

been reached. #

Unscr ew union nut 2offiller hose 1from

th eva lve. #

Screw theva lve cap of the emer gency spa re

wheel onto theva lve again. #

Stow filler hose 1and plug 3inthe lo wer

section of the tyre inflation compressor

housing. #

Stow th e tyre inflation compressor in the

ve hicle. Wheels and tyres

337