tow MERCEDES-BENZ B-CLASS HATCHBACK 2011 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: B-CLASS HATCHBACK, Model: MERCEDES-BENZ B-CLASS HATCHBACK 2011Pages: 329, PDF Size: 7.91 MB

Page 270 of 329

You can obtain further information, e.g.

regarding service work, fro

maMercedes-

Benz Service Centre or directly from

Mercedes-Benz.

Driving abroad

An extensive Mercedes-Benz Service network

is also available in other countries. The

Service Hotline's current telephone numbers

for use when you are abroad are to be found

in the "Mercedes-Benz Service24h" section

of the Service Booklet. Care

Notes on care

H

Environmental note

Dispose of empty packaging and cleaning

cloths in an environmentally responsible man-

ner.

! For cleaning your vehicle, do not use any

of the following:

R dry, rough or hard cloths

R abrasive cleaning agents

R solvents

R cleaning agents containing solvents

Do not scrub.

Do not touch the surfaces or protective

films with hard objects, e.g. a ring or ice

scraper. You could otherwise scratch or

damage the surfaces and protective film.

! Do not park up the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after clean-

ing. Braking heats the brake discs and the

brake pads/linings, thus drying them. The

vehicle can then be parked up.

Regular care of your vehicle is a condition for

retaining the quality in the long term. Use care products and cleaning agents rec-

ommended and approved by Mercedes-Benz. Care of the exterior

Automatic car wash G

WARNING

Braking efficiency is reduced after washing

the vehicle. This could cause an accident. For

this reason, following a car wash, drive with

particular care until the brakes are dry. G

WARNING

The vehicle is braked when the HOLD function

or DISTRONIC PLUS is activated. Therefore,

deactivate the HOLD function and DISTRONIC

PLUS before the vehicle is washed in an auto-

matic car wash.

! Make sure that the automatic transmis-

sion is in position Nwhen washing your

vehicle in a tow-through car wash. The vehi-

cle could be damaged if the transmission is

in another position.

! Make sure that:

R the side windows and sliding sunroof are

closed completely.

R the blower for the ventilation/heating is

switched off (OFF button is depressed/

airflow control is turned to position 0).

R the windscreen wiper switch is at posi-

tion 0.

The vehicle could otherwise be damaged.

You can wash the vehicle in an automatic car

wash from the very start.

Wash off excess dirt before cleaning the vehi-

cle in an automatic car wash.

After using an automatic car wash, wipe off

wax from the windscreen and the wiper

blades. This will prevent smears and reduce

wiping noises caused by residue on the wind-

screen. Care

267Maintenance and care Z

Page 271 of 329

Washing by hand

In some countries, washing by hand is only

allowed at wash bays that are specially

designed for this purpose. Observe the legal

requirements for each individual country.

X Do not use hot water and do not wash the

vehicle in direct sunlight.

X Use a soft sponge to clean.

X Use a mild cleaning agent, such as a car

shampoo approved by Mercedes-Benz.

X Thoroughly hose dow nthe vehicle with a

gentle jet of water.

X Do not point the water jet directly towards

the air inlet.

X Use plenty of water and rinse out the

sponge frequently.

X Rinse the vehicle with clean water and dry

thoroughly with a chamois.

X Do not let the cleaning agent dry on the

paintwork.

When using the vehicle in winter, remove all

traces of road salt deposits carefully and as

soon as possible.

High-pressure cleaning equipment G

WARNING

Do not use high-pressure cleaners with circu-

lar-jet nozzles (dirt grinders) to clean your

vehicle, in particular the tyres. You could oth-

erwise damage the tyres and cause an acci-

dent.

! Always maintain a distance of at least

30 cm between the vehicle and the high-

pressure cleaner nozzle. Information about

the correct distance is available from the

equipment manufacturer.

Move the high-pressure cleaner nozzle

around when cleaning your vehicle.

Do not aim directly at any of the following:

R tyres

R door gaps, roof gaps, joints etc.

R electrical components R

battery

R connectors

R lights

R seals

R trim elements

R ventilation slots

Damaged seals or electrical components

can lead to leaks or failures.

Cleaning the wheels !

Do not use acidic wheel cleaning products

to remove brake dust. This could damage

wheel bolts and brake components.

! Do not park up the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after clean-

ing. Braking heats the brake discs and the

brake pads/linings, thus drying them. The

vehicle can then be parked up.

Cleaning the paintwork !

Do not affix:

R stickers

R films

R magnetic plates or similar items

to painted surfaces. You could otherwise

damage the paintwork.

X Remove impurities immediately, where

possible, whilst avoiding rubbing too hard.

X Soak insect remains with insect remover

and rinse off the treated areas afterwards.

X Soak bird droppings with water and rinse

off the treated areas afterwards.

X Remove coolant, brake fluid, tree resin,

oils, fuels and greases by rubbing gently

with a cloth soaked in petroleum ether or

lighter fluid. 268

CareMaintenance and care

Page 274 of 329

Cleaning the exhaust pipe

!

Do no tclean the exhaust pipe with alka-

line-based cleaning agents, such as wheel

cleaner.

X Clean the exhaust pipe with a chrome care

produc ttested and approved by Mercedes-

Benz.

Impurities combined with the effects of road

grit and corrosive environmental factors may

cause flash rust to form on the surface. You

can restore the original shine of the exhaust

pipe by cleaning it regularly, especially in win-

ter and after washing.

Cleaning the trailer tow hitch H

Environmental note

Dispose of oily and greasy cloths in an envi-

ronmentally-responsible manner.

! Do not clean the ball coupling with a high-

pressure cleaner. Do not use solvents.

! Observe the note on care provided by the

trailer manufacturer. X

Remove rust, e.g. with a wire brush.

X Remove dirt with a clean, lint-free cloth or

a brush.

X After cleaning, lightly oil or grease ball cou-

pling :.

X Check that the vehicle's trailer tow hitch is

working properly.

i Maintenance of the ball coupling and

trailer tow hitch can also be performed at a qualified specialist workshop, e.g. a

Mercedes-Benz Service Centre. Interior care

Cleaning the display !

For cleaning, do not use any of the fol-

lowing:

R alcohol-based thinner or petrol

R abrasive cleaning agents

R commercially-available household clean-

ing agents

These may damage the display surface. Do

not put pressure on the display surface

when cleaning. This could lead to irrepara-

ble damage to the display.

X Before cleaning the display, make sure that

it is switched off and has cooled down.

X Clean the display surface using a commer-

cially available microfibre cloth and TFT/

LCD display cleaner.

X Dry the display surface using a dry micro-

fibre cloth.

Cleaning the plastic trim G

WARNING

When cleaning the steering wheel boss and

dashboard, do not use cockpit sprays or

cleaning agents containing solvents. Cleaning

agents containing solvents cause the surface

to become porous, and as aresult plastic

parts may break away and be thrown around

the interior when an airbag is deployed, which

may result in severe injuries.

! Do not affix the following to plastic surfa-

ces:

R stickers

R films

R scented oil bottles or similar items

You could otherwise damage the plastic. Care

271Maintenance and care Z

Page 276 of 329

Useful information

............................274

Where will I find...? ...........................274

Flat tyre ............................................. 276

Battery ............................................... 280

Jump-starting .................................... 283

Towing and tow-starting ..................284

Electrical fuses ................................. 287 273Breakdown assistance

Page 277 of 329

Useful information

i This Owner's Manual describes all models

and all standard and optional equipment

available to your vehicle at the time of pub-

lication of the Owner's Manual. Country-

specific deviations are possible. Please

note that your vehicle may not be equipped

with all features described. This also

applies to safety-relevan tsystems and

functions.

i Please read the information on qualified

specialist workshops (Y page 22).Where will I find...?

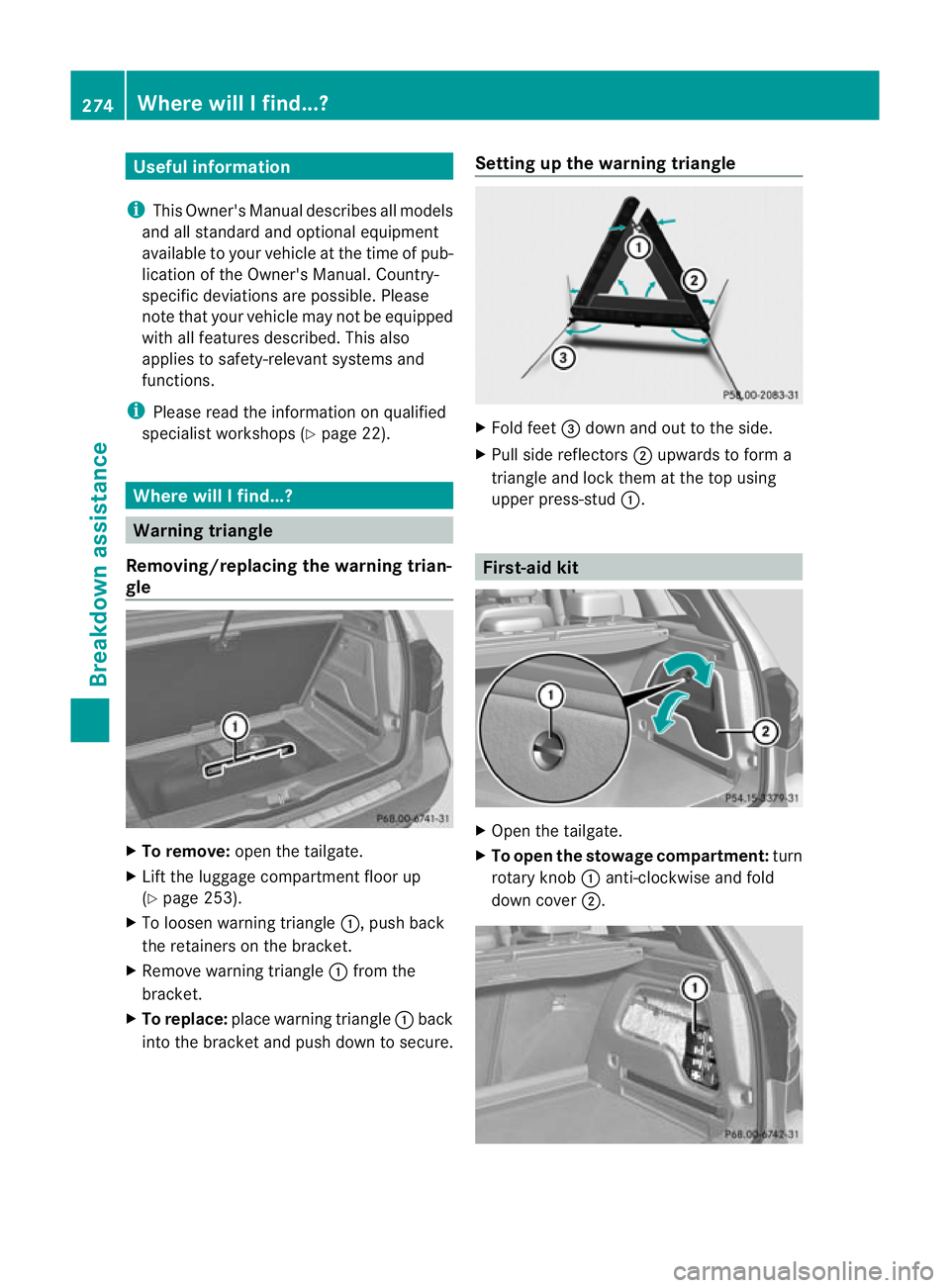

Warning triangle

Removing/replacing the warning trian-

gle X

To remove: openthe tailgate.

X Lift the luggage compartmentf loor up

(Y page 253).

X To loosen warning triangle :, push back

the retainers on the bracket.

X Remove warning triangle :from the

bracket.

X To replace: place warning triangle :back

into the bracket and push down to secure. Setting up the warning triangle

X

Fold feet =down and out to the side.

X Pull side reflectors ;upwards to form a

triangle and lock the matthe top using

upper press-stud :. First-aid kit

X

Open the tailgate.

X To open the stowage compartment: turn

rotary knob :anti-clockwise and fold

down cover ;.274

Where will I find...?Breakdown assistance

Page 278 of 329

X

Remove first-aid kit =.

i Chec kthe expiry date on the first-aid kit

at least once a year. Replace the contents

if necessary, and replace any missing

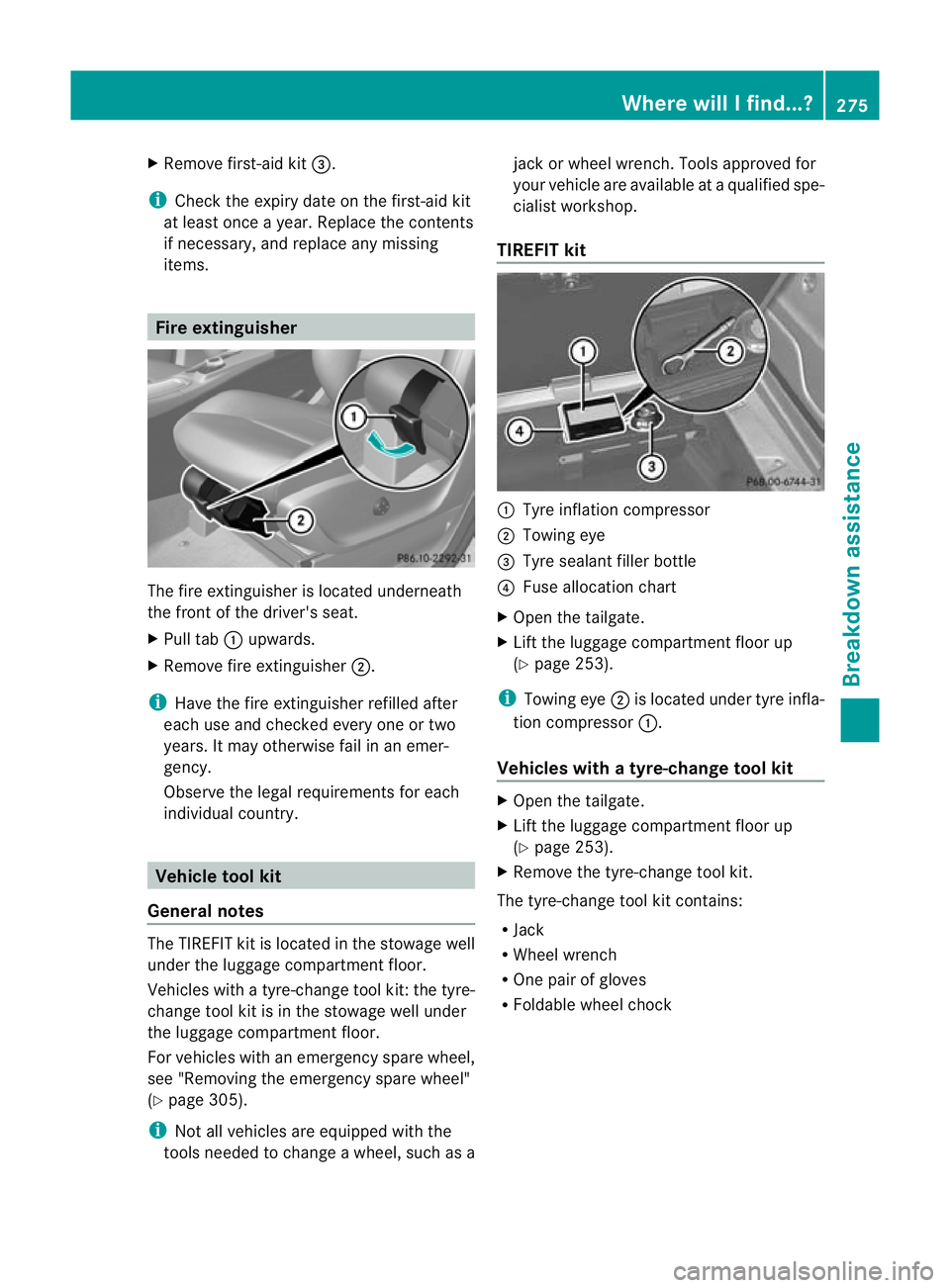

items. Fire extinguisher

The fire extinguisher is located underneath

the front of the driver's seat.

X

Pull tab :upwards.

X Remove fire extinguisher ;.

i Have the fire extinguisher refilled after

each use and checked every one or two

years. It may otherwise fail in an emer-

gency.

Observe the legal requirements for each

individual country. Vehicle tool kit

General notes The TIREFIT kit is located in the stowage well

under the luggage compartmentf loor.

Vehicles with a tyre-change tool kit :the tyre-

change tool kit is in the stowage well under

the luggage compartmentf loor.

For vehicles with an emergency spare wheel,

see "Removing the emergency spare wheel"

(Y page 305).

i Not all vehicles are equipped with the

tools needed to change a wheel, such as a jac

korw heel wrench. Tools approved for

your vehicle are available at a qualified spe-

cialist workshop.

TIREFIT kit :

Tyre inflation compressor

; Towing eye

= Tyre sealant filler bottle

? Fuse allocation chart

X Open the tailgate.

X Lift the luggage compartmentf loor up

(Y page 253).

i Towing eye ;is located under tyre infla-

tion compressor :.

Vehicles with a tyre-change tool kit X

Open the tailgate.

X Lift the luggage compartmen tfloor up

(Y page 253).

X Remove the tyre-change tool kit.

The tyre-change tool kit contains:

R Jack

R Wheel wrench

R One pair of gloves

R Foldable wheel chock Where will I find...?

275Breakdown assistance

Page 281 of 329

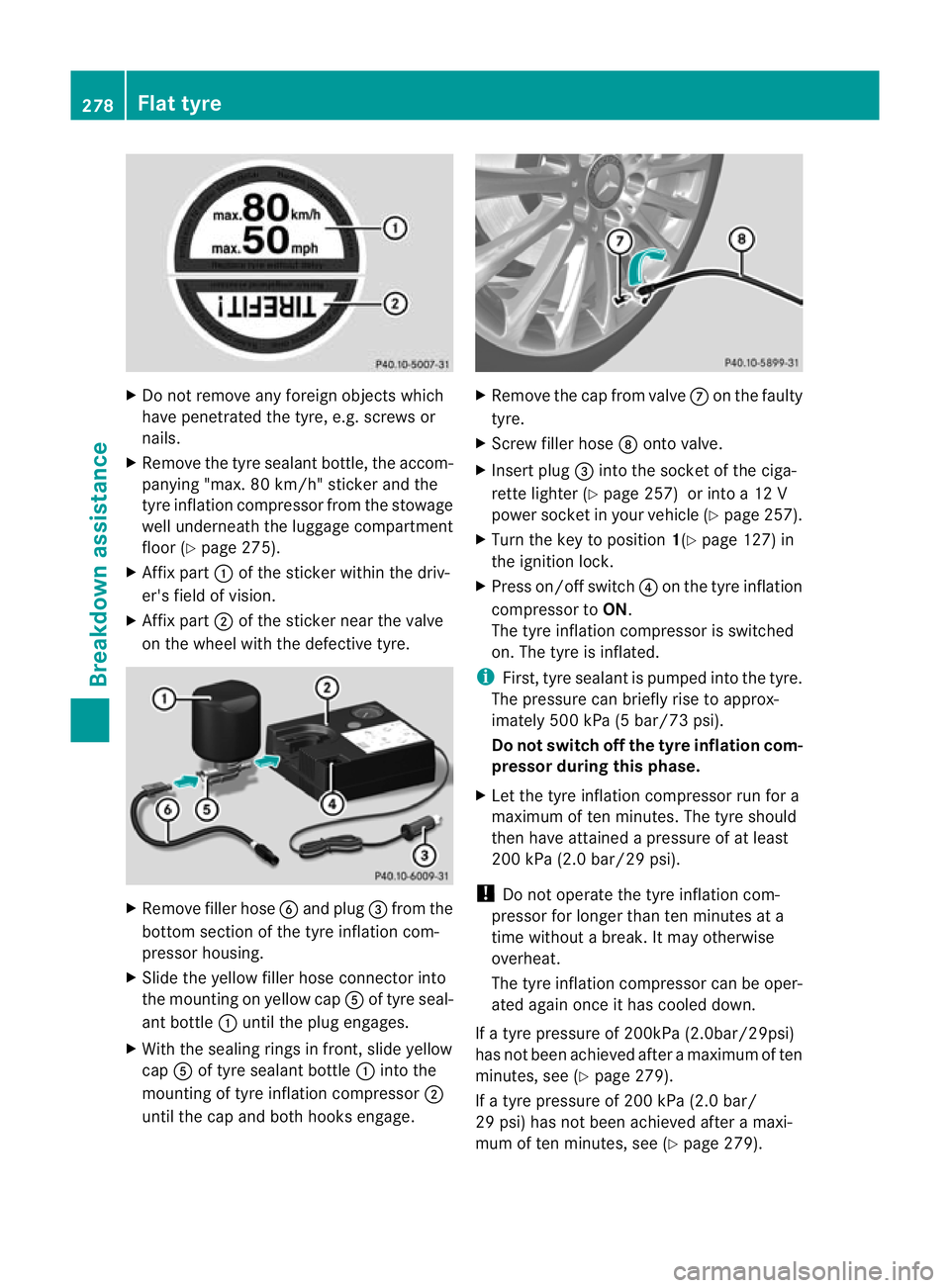

X

Do not remove any foreign objects which

have penetrated the tyre, e.g .screws or

nails.

X Remove the tyre sealant bottle, the accom-

panying "max. 80 km/h" sticker and the

tyre inflation compressor from the stowage

well underneath the luggage compartment

floor (Y page 275).

X Affix part :of the sticker within the driv-

er's field of vision.

X Affix part ;of the sticker near the valve

on the wheel with the defective tyre. X

Remove fille rhose Band plug =from the

bottom section of the tyre inflation com-

pressor housing.

X Slide the yellow filler hose connector into

the mounting on yellow cap Aof tyre seal-

ant bottle :until the plug engages.

X With the sealing rings in front, slide yellow

cap Aof tyre sealant bottle :into the

mounting of tyre inflation compressor ;

until the cap and both hooks engage. X

Remove the cap from valve Con the faulty

tyre.

X Screw filler hose Donto valve.

X Insert plug =into the socket of the ciga-

rette lighter (Y page 257) or into a 12 V

power socket in your vehicle (Y page 257).

X Turn the key to position 1(Ypage 127) in

the ignition lock.

X Press on/offs witch?on the tyre inflation

compressor to ON.

The tyre inflatio ncompressor is switched

on. The tyre is inflated.

i First, tyre sealant is pumped into the tyre.

The pressure can briefly rise to approx-

imately 500 kPa (5 bar/73 psi).

Do not switch off the tyre inflation com-

pressor during this phase.

X Let the tyre inflation compressor run for a

maximum of ten minutes. The tyre should

then have attained a pressure of at least

200 kPa (2.0 bar/29 psi).

! Do not operate the tyre inflation com-

pressor for longer than ten minutes at a

time without a break. It may otherwise

overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

If a tyre pressure of 200kPa (2.0bar/29psi)

has not been achieved after a maximum of ten

minutes, see (Y page 279).

If a tyre pressure of 200 kPa (2.0 bar/

29 psi) has not been achieved after a maxi-

mum of ten minutes, see (Y page 279).278

Flat tyreBreakdown assistance

Page 282 of 329

i

If tyre sealant leaks out, allow it to dry. It

can then be removed like a layer of film.

If you get tyre sealant on yourc lothing,

have it cleaned as soon as possible with

perchloroethylene.

Tyre pressure of 200 kPa (2.0 bar/

29 psi) not reached If

ap ressure of 200 kPa (2.0 ba r/29 psi) has

not been achieved after ten minutes:

X Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

X Very slowly drive forwards or reverse

approximately 10 m.

X Pump up the tyre again.

After a maximum of ten minutes, the tyre

pressure must be at least 200 kPa (2.0 bar/

29 psi). G

WARNING

If the required tyre pressure is not reached

after the specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this instance. Damaged tyres and a tyre

pressure that is too low can significantly

impair the vehicle's braking and driving char-

acteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

Tyre pressure of 200 kPa (2.0 bar/

29 psi) is reached X

Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

! After use, excess tyre sealant may run out

of the filler hose .This could cause stains.

Therefore, place the filler hose in the plastic

bag that contained the TIREFIT kit.

X Stow the tyre sealant bottle, the tyre infla-

tion compressor and the warning triangle.

X Pull away immediately. G

WARNING

At yre temporarily sealed with tyre sealant

impairs the driving characteristics and is not

suitable for higher speeds .There is a risk of

accident.

You should therefore adapt your driving style

accordingly and drive carefully. Do not exceed

the specified maximum speed with a tyre that

has been repaired using tyre sealant.

The maximum speed for a tyre sealed with

tyre sealant is 80 km/h. The "max. 80 km/h"

sticker must be affixed to the instrumentc lus-

ter within the driver's field of vision.

X Stop after driving for approximately ten

minutes and chec kthe tyre pressure with

the tyre inflation compressor.

The tyre pressure must now be at least

130 kPa (1.3 bar/19 psi). G

WARNING

If the required tyre pressure is not reached

after driving for a short period, the tyre is too

badly damaged. The tyre sealant cannot

repair the tyre in this instance. Damaged tyres

and a tyre pressure that is too low can signif-

icantly impair the vehicle's braking and driv-

ing characteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i In your vehicle, you will find a sticker with

the Mercedes-Ben zService24h telephone

number, e.g. on the B-pillar on the driver's

side.

X Correct the tyre pressure if it is still at least

130 kPa (1.3 bar/19 psi) (see the fuel filler

flap for values).

X To increase the tyre pressure: switch on

the tyre inflation compressor. Flat tyre

279Breakdown assistance Z

Page 283 of 329

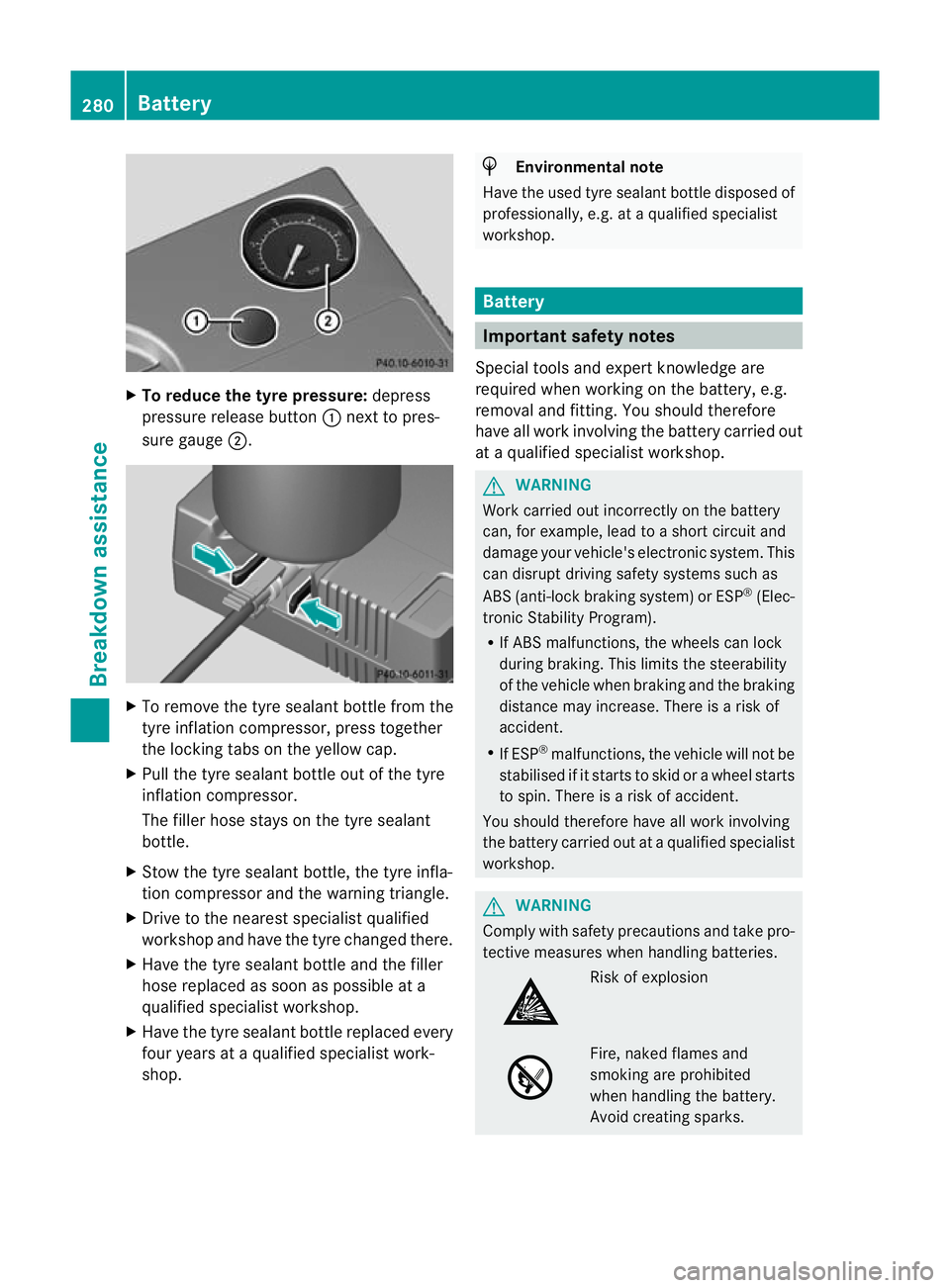

X

To reduce the tyre pressure: depress

pressure release button :next to pres-

sure gauge ;. X

To remove the tyre sealant bottle from the

tyre inflation compressor ,press together

the locking tabs on the yellow cap.

X Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filler hose stays on the tyre sealant

bottle.

X Stow the tyre sealant bottle, the tyre infla-

tion compresso rand the warning triangle.

X Drive to the neares tspecialist qualified

workshop and have the tyre changed there.

X Have the tyre sealant bottle and the filler

hose replaced as soon as possible at a

qualified specialist workshop.

X Have the tyre sealant bottle replaced every

four years at a qualified specialist work-

shop. H

Environmental note

Have the used tyre sealant bottle disposed of

professionally, e.g. at aqualified specialist

workshop. Battery

Important safety notes

Special tools and exper tknowledge are

required when working on the battery, e.g.

removal and fitting. Yo ushould therefore

have all work involving the battery carried out

at a qualified specialist workshop. G

WARNING

Work carried out incorrectly on the battery

can, for example, lead to a short circuit and

damage your vehicle's electronic system. This

can disrupt driving safety systems such as

ABS (anti-lock braking system) or ESP ®

(Elec-

tronic Stability Program).

R If ABS malfunctions, the wheels can lock

during braking. This limits the steerability

of the vehicle when braking and the braking

distance may increase. There is a risk of

accident.

R If ESP ®

malfunctions, the vehicle will not be

stabilised if it starts to skid or a wheel starts

to spin. There is a risk of accident.

You should therefore have all work involving

the battery carried out at a qualified specialist

workshop. G

WARNING

Comply with safety precautions and take pro-

tective measures when handling batteries. Risk of explosion

Fire, naked flames and

smoking are prohibited

when handling the battery.

Avoid creating sparks.280

BatteryBreakdown assistance

Page 287 of 329

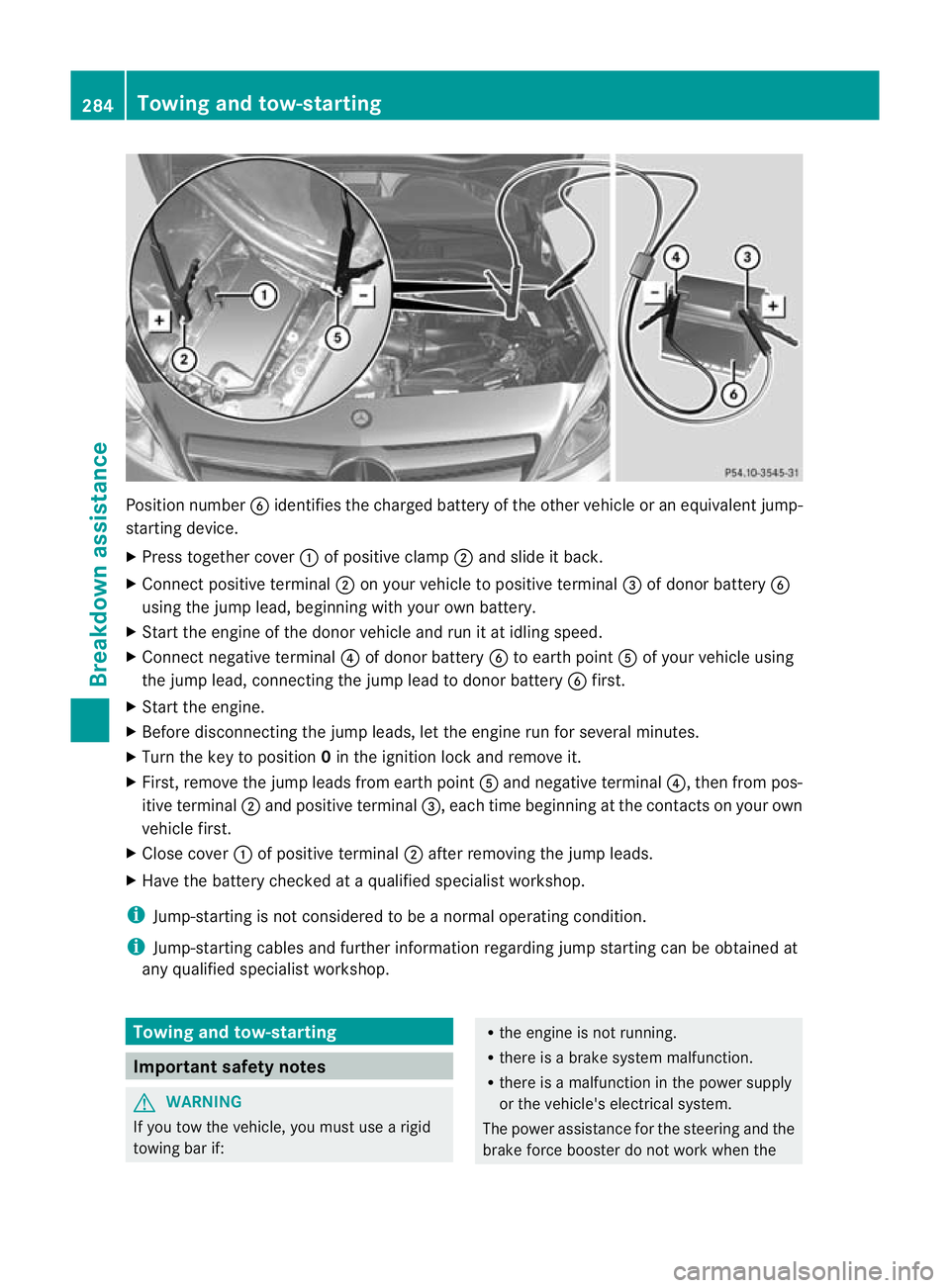

Position number

Bidentifies the charged battery of the other vehicle or an equivalent jump-

starting device.

X Press together cover :of positive clamp ;and slide it back.

X Connec tpositive terminal ;on your vehicle to positive terminal =of donor battery B

using the jump lead, beginning with your own battery.

X Start the engine of the donor vehicle and run it at idling speed.

X Connect negative terminal ?of donor battery Bto earth point Aof your vehicle using

the jump lead, connectingt he jump lead to donor battery Bfirst.

X Start the engine.

X Before disconnecting the jump leads, let the engine run for several minutes.

X Turn the key to position 0in the ignition lock and remove it.

X First, remove the jump leads from earth point Aand negative terminal ?, then from pos-

itive terminal ;and positive terminal =, each time beginning at the contacts on your own

vehicle first.

X Close cover :of positive terminal ;after removing the jump leads.

X Have the battery checked at a qualified specialist workshop.

i Jump-starting is not considered to be a normal operating condition.

i Jump-starting cables and further information regarding jump starting can be obtained at

any qualified specialist workshop. Towing and tow-starting

Important safety notes

G

WARNING

If you tow the vehicle, you must use a rigid

towing bar if: R

the engine is not running.

R there is a brake system malfunction.

R there is a malfunction in the power supply

or the vehicle's electrical system.

The power assistance for the steering and the

brake force booster do not work when the 284

Towing and tow-startingBreakdown assistance