lock MERCEDES-BENZ C-Class 2000 W202 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2000, Model line: C-Class, Model: MERCEDES-BENZ C-Class 2000 W202Pages: 130, PDF Size: 2.43 MB

Page 84 of 130

Winter Driving

Have your car winterized at your authorized Mercedes-Benz dealer before the onset of winter.

• Change the engine oil if the engine contains an oil which is not approved for winter operation.

For viscosity (SAE/CCMC class) and filling quantity, see Capacities: Fuels, Coolants,

Lubricants etc. in Index.

• Check engine coolant anticorr osion/antifreeze concentration.

• Additive for the windshield washer and headl amp cleaning system: Add MB Concentrate "S"

to a premixed windshield washer solvent/ant ifreeze which is formulated for below freezing

temperatures (see Index).

• Test battery: Battery capacity drops with dec reasing ambient temperature. A well charged

battery helps to ensure that the engine can be started, even at low ambient temperatures.

• Tires: We recommend M+S rated radial-ply tires on all four wheels for the winter season.

Observe permissible maximum speed for M+S rated radial-ply tires and the legal speed limit.

Note:

In winter operation, the maximum effectiveness of the Antilock Brake System (ABS), Acceleration Slip Regulation

(ASR) or the Electronic Stab ility Program (ESP) can only be achieved with M+S rated radial-ply tires and/or snow

chains recommended by Mercedes-Benz. Snow chains maximize performance.

Snow Chains

Use only snow chains that are tested and recommended by Mercedes-Benz. Your authorized Mercedes-Benz

dealer will be glad to advise you on this subject. Ch ains should only be used on the rear wheels.

Follow the manufacturer's mounting instructions. Snow ch ains should only be driven on snow covered roads at

speeds not to exceed 30 mph (50 km/h). Remove chains as soon as possible when driving on roads without snow.

For tips on driving on slippery winter roads, refer to In dex. Vehicles with Acceleration Slip Regulation (ASR) or

Electronic Stability Program (ESP): When driving with snow chains, press the ASR or ESP control switch, refer to

Index.

Model C 43 AMG

Important !

Use of snow chains is permissible only on winter tire size 215/45 R 17 H M+S. Refer to "Rims - Tires" in section

"Technical Data" (see Index).

Travelling Abroad

Abroad, there is a widely-spread Mercedes-Benz service network at your disposal. If you plan to travel into areas

which are not listed in the index of your dealer directory, you should request pertinent information from your

authorized Mercedes-Benz dealer.

Page 85 of 130

Hood

To open:

To unlock the hood, pull release lever (1) under the driver's side of the instrument panel. At the same time handle

(2) will extend out of the radiator grill (it may be necessary to lift the hood up slightly).

Caution !

To avoid damage to the windshield wiper or hood, open the hood only with wiper in the parked position. Pull handle

(2) completely out of radiator grill and open hood (do not pull up on handle).

To close:

Lower hood and let it drop into lock from a height of approx. 1 ft. (30 cm), assisting with hands placed flat on edges

of hood (3). To avoid hood damage, if hood is not fully closed, repeat closing procedure. Do not push down on hood

to attempt to fully close it.

Warning!

To help prevent personal injury, stay clear of moving parts when the hood is open and the engine is running.

Be sure the hood is properly closed before driving. When closing hood, use extreme caution not to catch

hands or fingers. The engine is equipped with a transistorized ignition system. Because of the high voltage it

is dangerous to touch any components (ignition coils, spark plug sockets, diagnostic socket) of the ignition

system

• with the engine running,

• while starting the engine,

• if ignition is "on" and the engine is turned manually.

If you see flames, steam or smoke coming from the engine compartment, or if the coolant temperature

gauge indicates that the engine is overheated, do not open the hood. Move away from vehicle and do not

open the hood until the engine has cooled. If necessary, call a fire department.

Page 86 of 130

Example

Checking Coolant Level

To check the coolant level, the vehicle must be parked on level ground and the engine stopped.

Check coolant level only when coolant is cold.

The coolant level should reach the black top part of the reservoir.

Adding Coolant

If coolant has to be added, a 50/50 mixture of water and MB anticorrosion/antifreeze should be added. The drain

plugs

for the cooling system are located on the right side of the engine block and at the bottom of the radiator.

Anticorrosion/antifreeze, see Coolants in Index.

Warning!

In order to avoid possibly serious burns or injury:

•Use extreme caution when opening the hood if there are any signs of steam or coolant leaking from the

cooling system, or if the coolant temperature gauge indicates that the coolant is overheated.

•Do not remove pressure cap on coolant reservoir if engine temperature is above 194°F (90°C). Allow

engine to cool down before removing cap. The coolant reservoir contains hot fluid and is under pressure.

•Using a rag, slowly open cap approximately 1/2 turn to relieve excess pressure. If opened immediately,

scalding hot fluid and steam will be blown out under pressure.

•Do not spill antifreeze on hot engine parts. Antifreeze contains ethylene glycol which may burn if it comes

into contact with hot engine parts.

Page 88 of 130

Odometer Display Field

(Models C 280 and C 43 AMG)

Turn electronic key in steering lock to position 2 and wait until the symbols and appears in the

odometer display field. Within 1 second press button 0 twice.

The following messages are available:

"OK"

"-1.0 Q" (Canada: -1.0 L)

"-1.5 Q" (Canada: -1.5L)

"-2.0 Q" (Canada: -2.0 L)

If the message "-2.0 Q" (Canada: -2.0 L) blinks and a signal sounds, add oil to upper (max) mark of the dipstick.

"HI"

The message "Hi" blinks and a signal sounds.

Do not overfill the engine.

Excessive oil must be drained or siphoned. It could cause damage to engine and catalytic converter not covered

by the Mercedes-Benz Limited Warranty.

The symbol flashes in the odometer field if a proper oil level check cannot be performed. The oil level check

can be repeated after a short while. Perform the oil level check with the dipstick, if it cannot be completed via the

odometer display field. In this case we recommend that you have the system checked at a Mercedes-Benz dealer.

Notes:

If the symbols and are continuously illuminated after pressing button 0 twice and there is no change in the

odometer display field or the low engine oil level warning lamp comes on, a malfunction has occurred to the system .

Perform the engine oil level check with the dipstick. If no oil leaks are noted continue to drive to the nearest

Mercedes-Benz dealer to have the system checked.

Automatic Transmission Fluid Level

The transmission has a permanent fill of automatic transmission fluid. Regular automatic transmission fluid

level checks and changes are not required. For this reason the dipstick is omitted. If you notice fluid leaks or

gear shifting malfunctions, have your authorized Mercedes-Benz dealer check the transmission fluid level.

Page 90 of 130

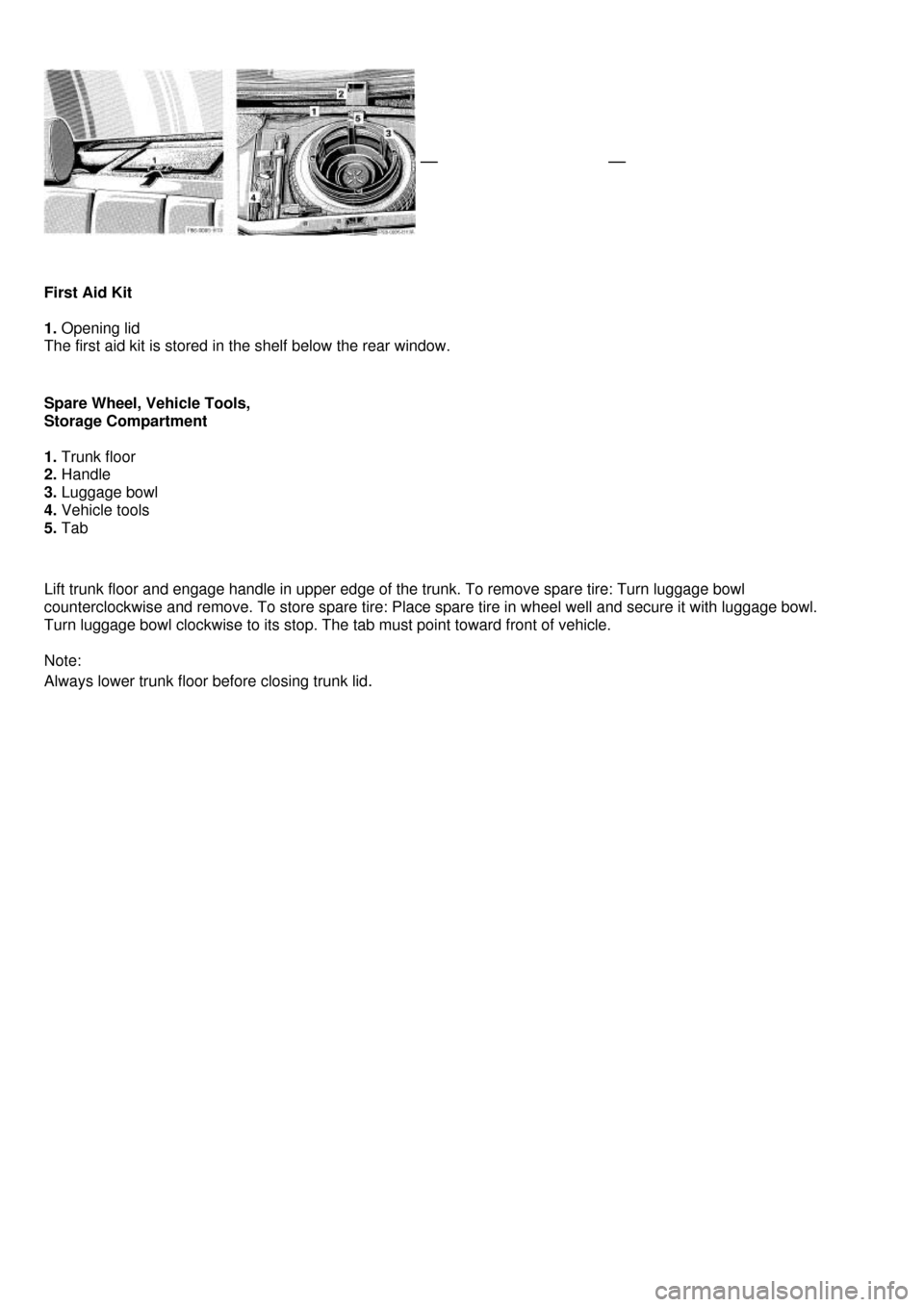

First Aid Kit

1. Opening lid

The first aid kit is stored in the shelf below the rear window.

Spare Wheel, Vehicle Tools,

Storage Compartment

1. Trunk floor

2. Handle

3. Luggage bowl

4. Vehicle tools

5. Tab

Lift trunk floor and engage handle in upper edge of the trunk. To remove spare tire: Turn luggage bowl

counterclockwise and remove. To store spare tire: Place spare tire in wheel well and secure it with luggage bowl.

Turn luggage bowl clockwise to its stop. The tab must point toward front of vehicle.

Note:

Always lower trunk floor before closing trunk lid.

Page 91 of 130

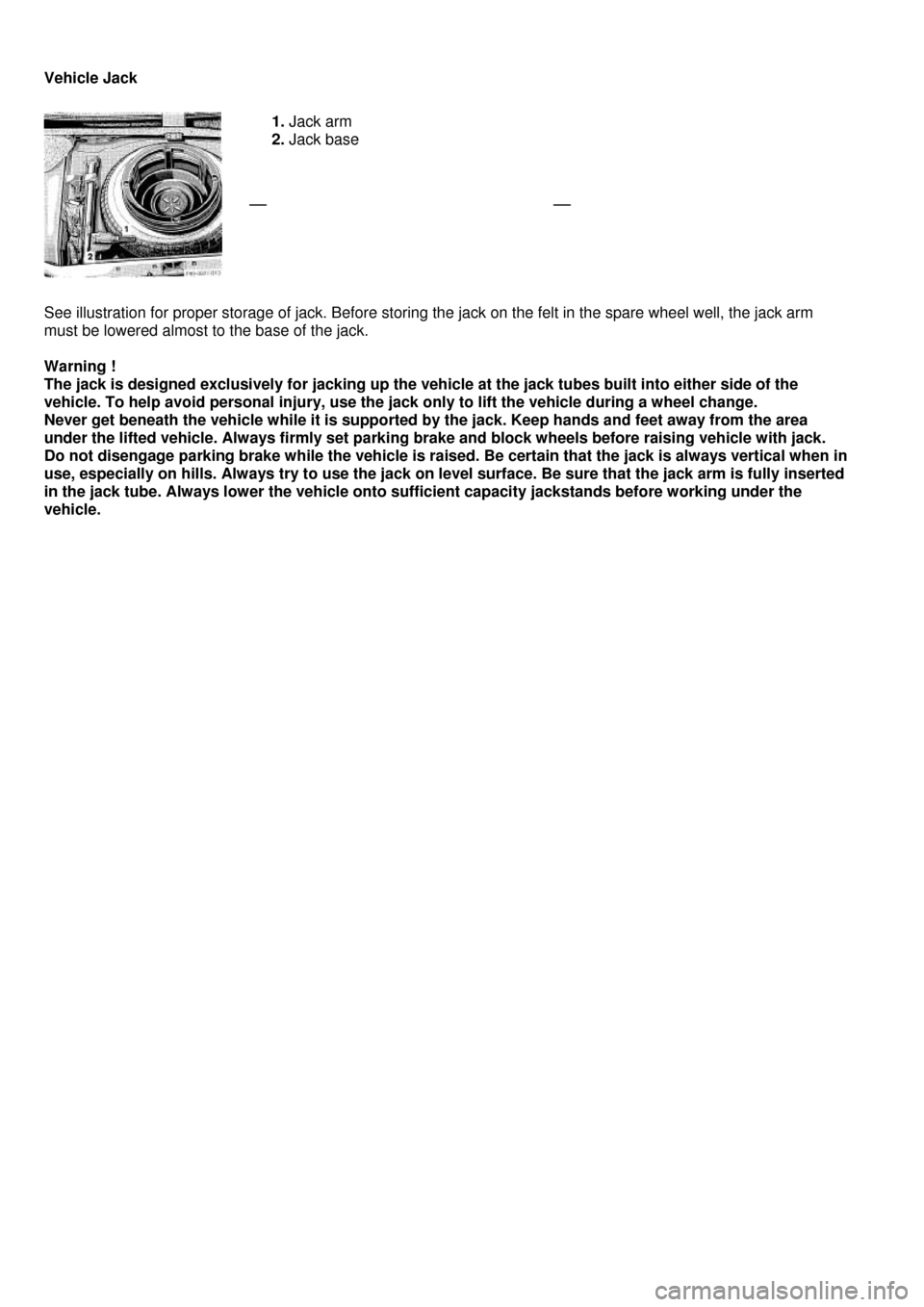

Vehicle Jack

1. Jack arm

2. Jack base

See illustration for proper storage of jack. Before storing the jack on the felt in the spare wheel well, the jack arm

must be lowered almost to the base of the jack.

Warning !

The jack is designed exclusively for jacking up the vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported by the jack. Keep hands and feet away from the area

under the lifted vehicle. Always firmly set parking brake and block wheels before raising vehicle with jack.

Do not disengage parking brake while the vehicle is raised. Be certain that the jack is always vertical when in

use, especially on hills. Always try to use the jack on level surface. Be sure that the jack arm is fully inserted

in the jack tube. Always lower the vehicle onto sufficient capacity jackstands before working under the

vehicle.

Page 93 of 130

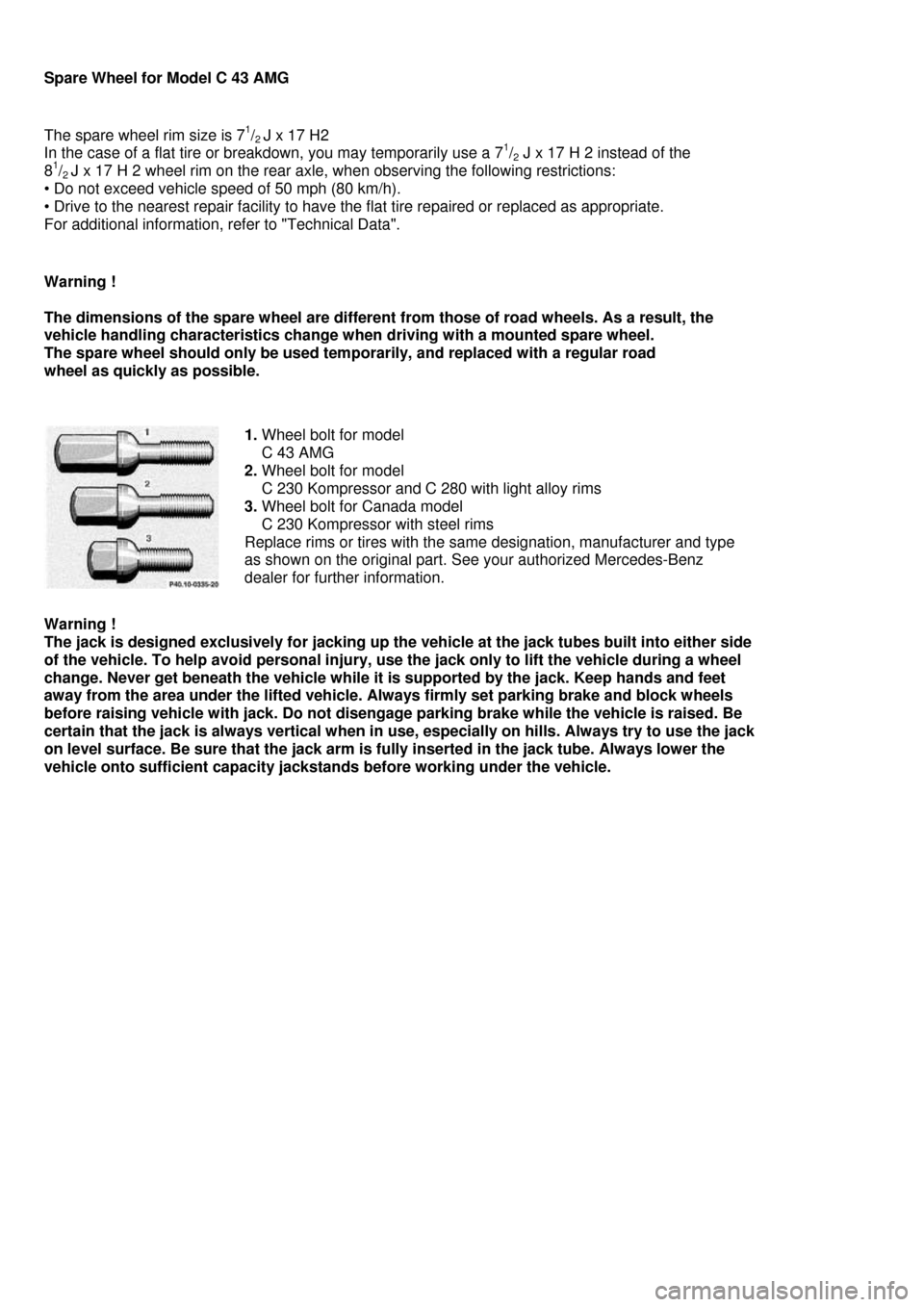

Spare Wheel for Model C 43 AMG

The spare wheel rim size is 71/2 J x 17 H2

In the case of a flat tire or breakdown, you may temporarily use a 71/2 J x 17 H 2 instead of the

81/2 J x 17 H 2 wheel rim on the rear axle, when observing the following restrictions:

• Do not exceed vehicle speed of 50 mph (80 km/h).

• Drive to the nearest repair facility to have the flat tire repaired or replaced as appropriate.

For additional information, refer to "Technical Data".

Warning !

The dimensions of the spare wheel are different from those of road wheels. As a result, the

vehicle handling characteristics change when driving with a mounted spare wheel.

The spare wheel should only be used temporarily, and replaced with a regular road

wheel as quickly as possible.

1. Wheel bolt for model

C 43 AMG

2. Wheel bolt for model

C 230 Kompressor and C 280 with light alloy rims

3. Wheel bolt for Canada model

C 230 Kompressor with steel rims

Replace rims or tires with the same designation, manufacturer and type

as shown on the original part. See your authorized Mercedes-Benz

dealer for further information.

Warning !

The jack is designed exclusively for jacking up the vehicle at the jack tubes built into either side

of the vehicle. To help avoid personal injury, use the jack only to lift the vehicle during a wheel

change. Never get beneath the vehicle while it is supported by the jack. Keep hands and feet

away from the area under the lifted vehicle. Always firmly set parking brake and block wheels

before raising vehicle with jack. Do not disengage parking brake while the vehicle is raised. Be

certain that the jack is always vertical when in use, especially on hills. Always try to use the jack

on level surface. Be sure that the jack arm is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before working under the vehicle.

Page 94 of 130

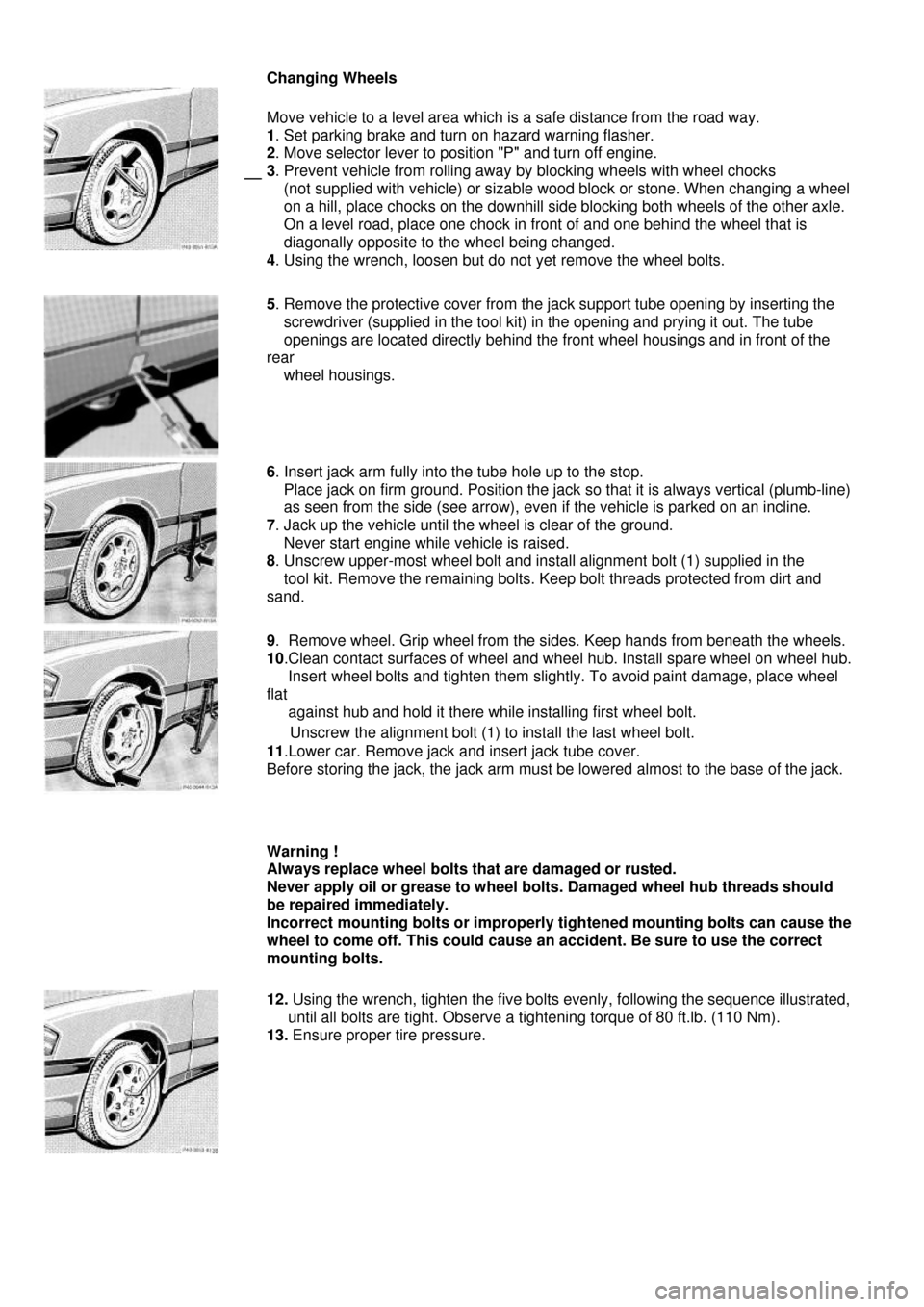

Changing Wheels

Move vehicle to a level area which is a safe distance from the road way.

1. Set parking brake and turn on hazard warning flasher.

2. Move selector lever to position "P" and turn off engine.

3. Prevent vehicle from rolling away by blocking wheels with wheel chocks

(not supplied with vehicle) or sizable wood block or stone. When changing a wheel

on a hill, place chocks on the downhill side blocking both wheels of the other axle.

On a level road, place one chock in front of and one behind the wheel that is

diagonally opposite to the wheel being changed.

4. Using the wrench, loosen but do not yet remove the wheel bolts.

5. Remove the protective cover from the jack support tube opening by inserting the

screwdriver (supplied in the tool kit) in the opening and prying it out. The tube

openings are located directly behind the front wheel housings and in front of the

rear

wheel housings.

6. Insert jack arm fully into the tube hole up to the stop.

Place jack on firm ground. Position the jack so that it is always vertical (plumb-line)

as seen from the side (see arrow), even if the vehicle is parked on an incline.

7. Jack up the vehicle until the wheel is clear of the ground.

Never start engine while vehicle is raised.

8. Unscrew upper-most wheel bolt and install alignment bolt (1) supplied in the

tool kit. Remove the remaining bolts. Keep bolt threads protected from dirt and

sand.

9. Remove wheel. Grip wheel from the sides. Keep hands from beneath the wheels.

10.Clean contact surfaces of wheel and wheel hub. Install spare wheel on wheel hub.

Insert wheel bolts and tighten them slightly. To avoid paint damage, place wheel

flat

against hub and hold it there while installing first wheel bolt.

Unscrew the alignment bolt (1) to install the last wheel bolt.

11.Lower car. Remove jack and insert jack tube cover.

Before storing the jack, the jack arm must be lowered almost to the base of the jack.

Warning !

Always replace wheel bolts that are damaged or rusted.

Never apply oil or grease to wheel bolts. Damaged wheel hub threads should

be repaired immediately.

Incorrect mounting bolts or improperly tightened mounting bolts can cause the

wheel to come off. This could cause an accident. Be sure to use the correct

mounting bolts.

12. Using the wrench, tighten the five bolts evenly, following the sequence illustrated,

until all bolts are tight. Observe a tightening torque of 80 ft.lb. (110 Nm).

13. Ensure proper tire pressure.

Page 97 of 130

Bulb for High Beam H1 (55 W)

Open hood.

Move retaining clamps (4) aside and remove cover (3). Pull off electrical connector (10). Unhook clamping ring

and pull out bulb together with clamping ring. Remove bulb. Insert new bulb (seating properly in cutouts of bulb

socket), mount clamping ring. Reinstall and push electrical connector on securely. Reinstall cover and fasten

with retaining clamp (4).

Turn Signal, Parking, Side Marker and Standing Lamp

(2357 NA [28.5/8.3 W/30/2.2 cp bulb])

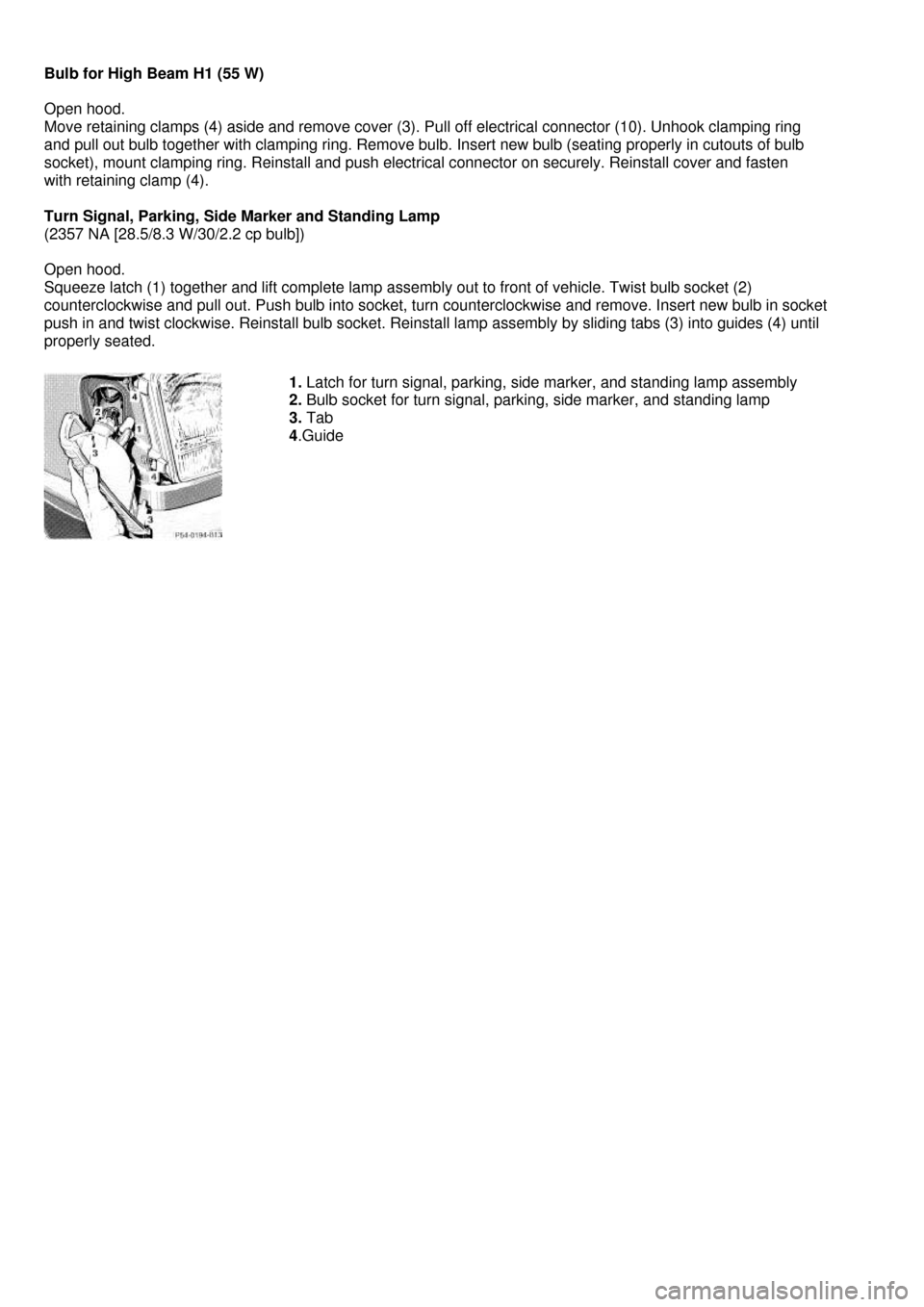

Open hood.

Squeeze latch (1) together and lift complete lamp assembly out to front of vehicle. Twist bulb socket (2)

counterclockwise and pull out. Push bulb into socket, turn counterclockwise and remove. Insert new bulb in socket

push in and twist clockwise. Reinstall bulb socket. Reinstall lamp assembly by sliding tabs (3) into guides (4) until

properly seated.

1. Latch for turn signal, parking, side marker, and standing lamp assembly

2. Bulb socket for turn signal, parking, side marker, and standing lamp

3. Tab

4.Guide

Page 98 of 130

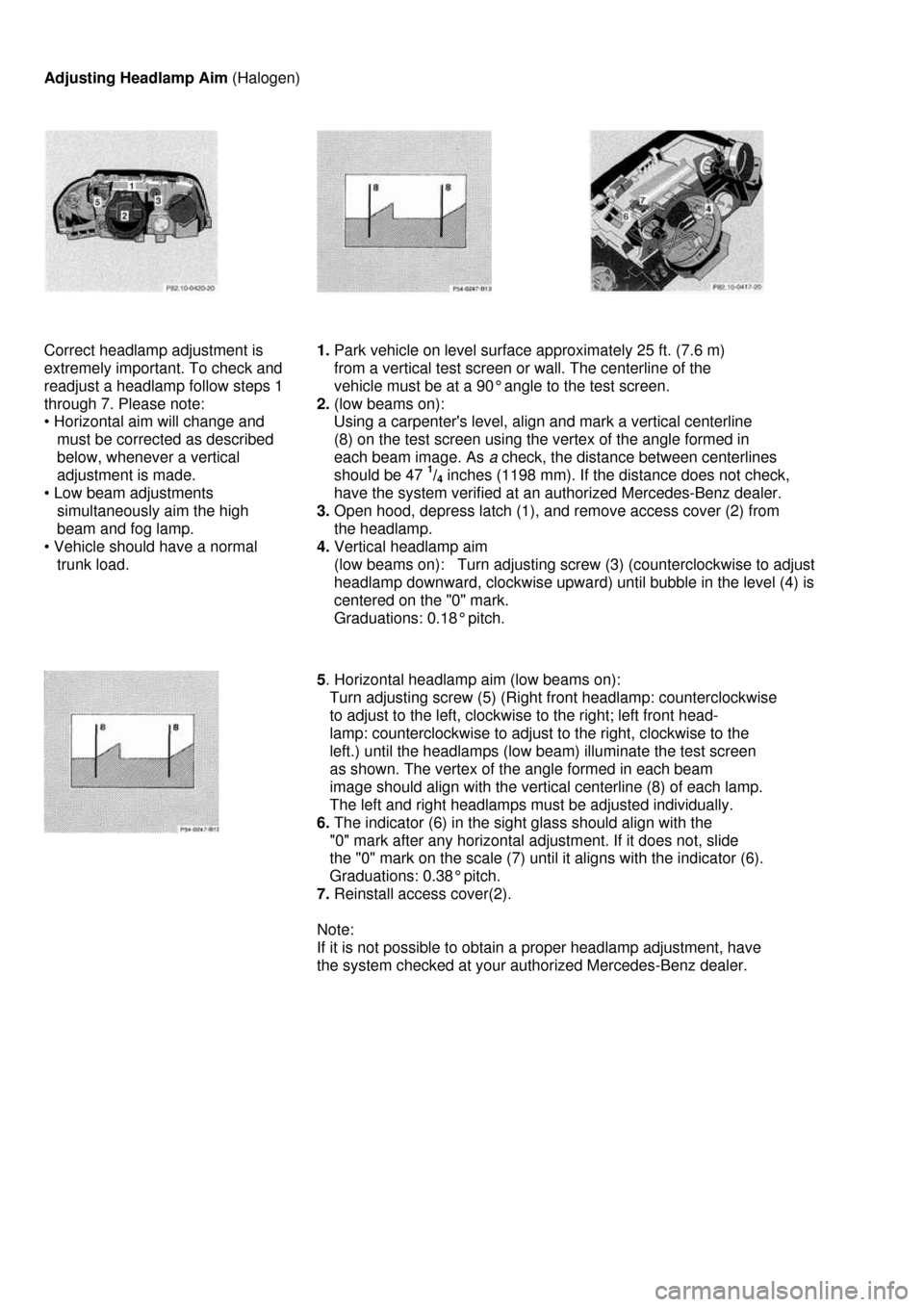

Adjusting Headlamp Aim (Halogen)

Correct headlamp adjustment is

extremely important. To check and

readjust a headlamp follow steps 1

through 7. Please note:

• Horizontal aim will change and

must be corrected as described

below, whenever a vertical

adjustment is made.

• Low beam adjustments

simultaneously aim the high

beam and fog lamp.

• Vehicle should have a normal

trunk load.

1. Park vehicle on level surface approximately 25 ft. (7.6 m)

from a vertical test screen or wall. The centerline of the

vehicle must be at a 90° angle to the test screen.

2. (low beams on):

Using a carpenter's level, align and mark a vertical centerline

(8) on the test screen using the vertex of the angle formed in

each beam image. As a check, the distance between centerlines

should be 47 1/4 inches (1198 mm). If the distance does not check,

have the system verified at an authorized Mercedes-Benz dealer.

3. Open hood, depress latch (1), and remove access cover (2) from

the headlamp.

4. Vertical headlamp aim

(low beams on): Turn adjusting screw (3) (counterclockwise to adjust

headlamp downward, clockwise upward) until bubble in the level (4) is

centered on the "0" mark.

Graduations: 0.18° pitch.

5. Horizontal headlamp aim (low beams on):

Turn adjusting screw (5) (Right front headlamp: counterclockwise

to adjust to the left, clockwise to the right; left front head-

lamp: counterclockwise to adjust to the right, clockwise to the

left.) until the headlamps (low beam) illuminate the test screen

as shown. The vertex of the angle formed in each beam

image should align with the vertical centerline (8) of each lamp.

The left and right headlamps must be adjusted individually.

6. The indicator (6) in the sight glass should align with the

"0" mark after any horizontal adjustment. If it does not, slide

the "0" mark on the scale (7) until it aligns with the indicator (6).

Graduations: 0.38° pitch.

7. Reinstall access cover(2).

Note:

If it is not possible to obtain a proper headlamp adjustment, have

the system checked at your authorized Mercedes-Benz dealer.