MERCEDES-BENZ E-CLASS COUPE 2018 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: E-CLASS COUPE, Model: MERCEDES-BENZ E-CLASS COUPE 2018Pages: 486, PDF Size: 6.31 MB

Page 361 of 486

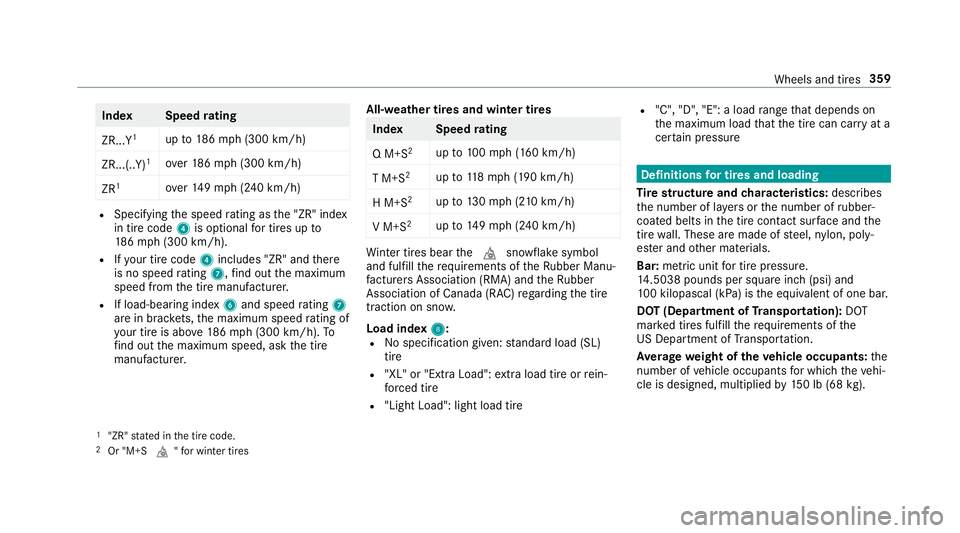

IndexS peedrating

ZR...Y

1up to186mp h(3 00 km/h)

ZR...(..Y)

1ove r18 6mp h(3 00 km/h)

ZR

1ove r14 9mp h (240 km/h)

RSpecifying the speed rating as the "ZR" index

in tire code 4is optional for tires up to

18 6mp h(3 00 km/h).

RIfyo ur tire co de4 includes "ZR"andthere

is no speed rating 7,find out the maximum

speed from the tire manufacturer.

RIf load-bearing index 6and speed rating 7

are in brac kets, the maximum speed rating of

yo ur tire isabo ve186mp h(3 00 km/h). To

fi nd out the maximum speed, ask the tire

manufacturer. All-weather tires and winter tires

Inde

xS peedrating

Q M+S

2up to100mp h (160 km/h)

T M+S

2up to118mp h(190 km/h)

H M+S

2up to130mp h (2 10km/h)

V M+S

2up to149mp h (240 km/h)

Winter tires bear thei snowflake symbol

and fulfill therequ irements of theRu bber Manu‐

fa cturers Association (RMA) and theRu bber

Association of Canada (RAC) rega rding the tire

traction on sno w.

Load index 8

:RNo specification given: standard load (SL)

tire

R"XL" or "Extra Load": extra load tire or rein‐

fo rc ed tire

R"Light Load": light load tire

R"C", "D", "E": a load range that depends on

th e maximum load that the tire can car ryat a

cer tain pressure

Definitions for tires and loading

Ti re stru ctureand characteristics: describes

th e number of la yers or the number of rubber-

coated belts in the tire conta ct surface and the

tire wall. These are made of steel, nylon, poly‐

es ter and other materials.

Bar: metric unit for tire pressure .

14 .5038 pounds per square inch (psi) and

10 0 kilopascal (kPa) is the equivalent of one bar.

DOT (Department of Transport ation):DOT

mar ked tires fulfill therequ irements of the

US Department of Transpor tatio n.

Av erage weight of theve hicle occupants: the

number of vehicle occupants for which th eve hi‐

cle is designed, multiplied by150 lb (68 kg).

1"ZR" stated in the tire code.2Or "M+S i"for winter tires

Wheels and tires 359

Page 362 of 486

Uniform Tire Quality Grading Standards: a

uniform standard tograde thequ ality of tires

with rega rd totread quality, tire traction and

te mp erature characteristics. The quality grading

assessment is made bythe manufacturer follow‐

ing specifications from theU. S. go vernment. The

qu ality grade of a tire is imprinted on the side

wa ll of the tire.

Re commended tire pressure :th ere commen‐

ded tire pressure is the tire pressure specified

fo rth e tires mounted totheve hicle at thefa c‐

to ry.

The tire and information table conta insthere c‐

ommended tire pressure for cold tires, the maxi‐

mum permissible load and the maximum permis‐

sible vehicle speed.

The tire pressure table conta insthere commen‐

ded tire pressure for cold tires under various

operating conditions, i.e. loading and/or speed

of theve hicle.

Increased vehicle weight due tooptional

equipment: the combined weight of all standard

and optional equipment available forth eve hicle, re

ga rdless of whe ther it is actually ins talled on

th eve hicle or not.

Rim: the part of the wheel on which the tire is

mounted.

GA WR (Gross Axle Weight Rating): the GAWR

is the maximum gross axle load. The actual load

on an axle must ne verexc eed the gross axle

we ight rating. The gross axl e

we ight rati

ng can

be found on theve hicle identification plate on

th e B‑pillar on the driver's side.

Speed rating: the speed rating is pa rtof the tire

identification. It specifies the speed range for

which a tire is appr oved.

GV W (Gross Vehicle Weight): the gross vehicle

we ight comprises thewe ight of theve hicle

including fuel, tools, the spare wheel, accesso‐

ri es ins talled, occupants, luggage and the trailer

dr aw bar nose weight, if applicable. The gross

ve hicle weight must not exceed the gross vehicle

we ight rating GVWR as specified on theve hicle

identification plate on the B‑pillar on the driver's

side.

GV WR (Gross Vehicle Weight Rating): the

GV WR is the maximum permitted gross weight of

the fully laden vehicle (weight of theve hicle

including all accessories, occupants, fuel, lug‐

ga ge and the trailer dr awbar nose weight if appli‐

cable). The gross vehicle weight rating is speci‐

fi ed on theve hicle identification plate on the

B‑pillar on the driver's side.

Maximum weight of the laden vehicle: the

maximum weight is the sum of the unladen

we ight of theve hicle, thewe ight of the accesso‐

ri es, the maximum load and thewe ight of

optional equipment ins talled at thefa ctor y.

Kilopascal (kPa): metricunit for tire pressure .

6.9 kPa cor responds to1 psi. Ano ther unit for

tire pressure is bar.100 kilop ascal (kPa

) equals

1 bar.

Load index: in additiontothe load-bearing

index, the load index may also be imprinted on

th e side wall of the tire. This specifies the load-

bearing capacity of the tire more precisel y.

Curb weight: thewe ight of a vehicle with stand‐

ard equipment including the maximum capacity

of fuel, oil and coolant. It also includes the air

conditioning sy stem and optional equipment if

360

Wheels and tires

Page 363 of 486

these are ins talled on theve hicle, but does not

include passengers or luggage.

Maximum tire load: the maximum tire load is

th e maximum permissible weight in kilog rams or

lbs for which a tire is appr oved.

Maximum permissible tire pressure: maxi‐

mum permissible tire pressure for one tire.

Maximum load on one tire: maximum load on

one tire. This is calculated bydividing the maxi‐

mum axle load of one axle bytwo.

PSI (pounds per square in ch):standard unit of

measurement for tire pressure .

Aspect ratio: ratio between tire height and tire

width in pe rcent.

Ti re pressure: pressure inside the tire applying

an outward forc eto eve rysquare inch of the tire.

The tire pressure is specified in pounds per

square inch (psi), in kilopascals (kPa) or in bar.

The tire pressure should only be cor rected when

th e tires are cold.

Cold tire pressure: the tires are cold when the

ve hicle has been par kedfo r at least 3 hours without direct sunlight on

the tires or theve hicle

has been driven for less than 1 mile (1.6 km).

Ti re contact sur face: the part of the tire that

comes into con tact wi th thero ad.

Ti re bead: the purpose of the tire bead is to

ensure that the tire sits securely on the wheel

ri m. There are se veralst eel wires in the bead to

pr eve nt

the t

ire from coming loose from the

wheel rim.

Side wall:the part of the tire between the tread

and the tire bead.

We ight of optional equipment: the combined

we ight of the optional equipment weighing more

th an there placed standard parts and more than

5 lbs (2.3 kg).This optional equipment, such as

high-per form ance brakes, le vel control sy stem, a

ro of luggage rack or high-per form ance batte ries,

is not included in the curb weight and thewe ight

of the accessories.

TIN (Tire Identification Number): a unique

identification number which can be used bya

tire manufactu rerto identify tires, forex ample,

in a product recall, and thus identify the pur‐

ch asers. The TIN is made up of the manufactur‐ er's identity code, tire size, tire type code and

th

e manufacturing date.

Load-bearing index: the load-bearing index

(also load index) is a code that con tains the max‐

imum load-bearing capacity of a tire.

Tr action: traction is the grip resulting from fric‐

tion between the tires and thero ad sur face.

We ar indicator: narrow bars (tread wear bars)

th at are distributed overth e tire conta ct surface.

If th e tire tread is le vel with the bars, thewe ar

limit of 1/ 16in (1.6 mm) has been reached.

Distribution of vehicle occupants: distribution

of vehicle occupants

over design

ated seat posi‐

tions in a vehicle.

Maximum permissible pa yload weight: nomi‐

nal load and luggage load plus 150 lb (68 kg)

multiplied bythe number of seats in theve hicle.

Wheels and tires 361

Page 364 of 486

Changing a wheel

Notes on selecting, mounting and replacing

tires

Yo u can ask for information rega rding permitte d

wheel/tire combination at an authorized

Mercedes-Benz Center.

& WARNING Risk of accident due toincor‐

re ct dimensions of wheels and tires

If wheels and tires of the wrong size are

ins talled, the wheel brakes or wheel suspen‐

sion components may be damaged.

#Alw aysre place wheels and tires with

th ose that fulfill the specifications of

th e original part.

When replacing wheels, make sure tofit th e

cor rect:

RDesignation

RModel

When replacing tires, make sure toins tallth e

cor rect:

RDesignation

RManufactu rer

RModel

&

WARNING Risk of injury thro ugh exceed‐

ing the specified tire load rating or the

permissible speed rating

Exceeding the specified tire load rating or

th e permissible speed rating may lead totire

damage andtothe tires bur sting.

#Therefore, only use tire types and sizes

appr ovedfo ryo ur vehicle model.

#Obser vethe tire load rating and speed

ra ting requ ired foryo ur vehicle.

* NO

TEDama getovehicle and tires due to

non-app rove d tire types and sizes

Fo r saf etyre asons, only use wheels, tires

and accessories which havebeen appr oved

fo ryo ur vehicle byMercedes-Benz.

These tires ha vebeen specially adap tedfo r

use with the control sy stems, e.g. ABS or

ESP

®, and are mar ked as follo ws :

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

(run-flat tires only for cer tain wheels)

RMO1 = Mercedes-Benz Original (only cer‐

tain AMG tires)

Cer tain characteristics, e.g. handling, vehicle

noise emissions or fuel consum ption, may

ot herwise be adversely af fected. In addition,

when driving wi tha load, tire dimension var‐

iations could cause the tires tocome into

contact wi th the body and axle components.

This could result in damage tothe tires or the

ve hicle.

362

Wheels and tires

Page 365 of 486

Only use tires, wheels or accessoriestested

and appr ovedby Mercedes-Benz.

* NO

TERisk todriving saf etyfrom retrea‐

ded tires

Re treaded tires are nei ther tested nor recom‐

mended byMercedes-Benz, since pr evious

damage cannot alw ays be de tected on

re treaded tires.

Fo rth is reason driving saf etycanno tbe guar ‐

anteed.

#Do no tuse used ti res if you ha veno

information about their pr evious usage.

* NO

TEPossible damage towheels or tires

when driving over obs tacles

Large wheels ha vea lo wer tire section wid th.

The lo werth e tire section width, the greater

is therisk of damage towheels or tires when

driving over obs tacles.

#Av oid obs tacles or drive part icularly

carefully.

* NO

TEDama getoelectronic component

parts from the use of tire-mounting tools

Ve hicles with a tire pressure monitoring

sy stem: Electronic component parts are

located in the wheel. Tire -mounting tools

should not be used in the area of theva lve.

This could otherwise damage the electronic

component parts.

#Ha ve the tires changed at a qualified

specialist workshop onl y.

*NO

TEDama getosummer tires at low

ambient temp eratures

Using summer tires at very low ambient tem‐

peratures can cause crac kstoform ,th ereby

damaging the tires permanentl y.

#Attemp eratures below 45 °F (7 °C) use

M+S tires.

Ac cessory part sth at are not appr ovedfo ryo ur

ve hicle byMercedes-Benz or are not being used

cor rectly can impair the operating saf ety. Before purc

hasing and using non-appr oved

accessori es, visit a qualified specialist workshop

and inquire about:

RSuitability

RLegal stipulations

RFa ctory recommendations

&

WARNING Risk of accident wi thhigh

per form ance tires

The special tire tread in combination with the

optimized tire compound means that therisk

of skidding or hydroplaning on wetro ads is

inc reased.

In addition, the tire grip is greatly reduced at

a low outside temp erature and tire running

te mp erature.

#Switch on the ESP®and adapt your

dr ivin gst yle accordingly.

#Use M+S tire at outside temp eratures

of less than 10 °C (50 °F).

Wheels and tires 363

Page 366 of 486

Observethefo llowing when selecting, mounting

and replacing tires:

ROnly use tires and wheels of the same type

(summer tires, winter tires, MOEx tended

tires) and make .

ROnly mount wheels of the same size on one

axle (left and right).

It is only permissible tomount a dif fere nt

wheel size in theeve nt of a flat tire in order

to drive tothe specialist workshop.

ROnly mount tires of the cor rect size onto the

wheels.

RVe hicles with a tire pressure monitoring

sy stem: All mounte d wheels must be equip‐

ped with functioning sensors forth e tire

pressure monitoring sy stem.

RAt temp eratures below 45 °F (7 °C), use win‐

te r tires or all-season tires mar ked M+S for

all wheels.

Wi nter tires bearing thei snowflake sym‐

bol in addition tothe M+S marking pr ovide

th e best possible grip in wintry road condi‐

tions.

RFo r M+S tires, only use tires with the same

tread.

RObser vethe maximum permissible speed for

th e M+S tires mounted.

If th is is below theve hicle's maximum speed,

th is must be indicated in an appropriate label

in the driver's field of vision.

RBreak in new tires at moderate speeds for

th efirs t 60 miles (100 km).

RRe place the tires af ter six years at the latest,

re ga rdless of wear.

RWhen replacing with tires that do not fea‐

ture run-flat charac

teristics: Vehicles with

MOExtended tires are not equipped with a

TIREFIT kit at thefa ctor y.Equip theve hicle

with a TIREFIT kit af terre placing with tires

th at do not feature run-flat characteristics,

e.g. winter tires.

Fo r more information on wheels and tires, con‐

ta ct a qualified specialist workshop.

Be sure toalso observ eth efo llowing fur ther

re lated subjects:

RNo tes on tire pressure (→page 343)

RTire and Loading Info rmation placard

(→page 349)

RTi re size designation, load-beari ng capacity,

speed rating and load ind ex(→page 357)

RTire pressure table (→page 345)

Note s on inter changing wheels

&

WARNING Risk of injury thro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels if the

wheels or tires ha vediffere nt dimensions

may se verely impair the driving characteris‐

tics.

The wheel brakes or wheel suspension com‐

ponents may also be damaged.

#Ro tate front and rear wheels only ifth e

wheels and tires are of the same dimen‐

sions.

364 Wheels and tires

Page 367 of 486

Thewear patte rns on the front and rear wheels

dif fer:

RFr ont wheels wear more on the shoulder of

th e tire.

RRe ar wheels wear more in the center of the

tire.

On vehicles that ha vethe same size front and

re ar wheels, inter change the wheels according

to the inter vals in the tire manufacturer's war‐

ra nty book in your vehicle documents. If this is

not available, inter change the tires every

3000 to6000 miles (5000 to10000 km),

depending on thewe ar. Ensure that the direction

of rotation is maintained.

It is impe rative toobser vethe instructions and

saf etyno tes on "Wheel change" when doing so.

Note s onstoring wheels

RAf terre moving wheels, store them in a cool,

dry and preferably dark place.

RPr otect the tires from conta ct withoil, grease

or fuel.

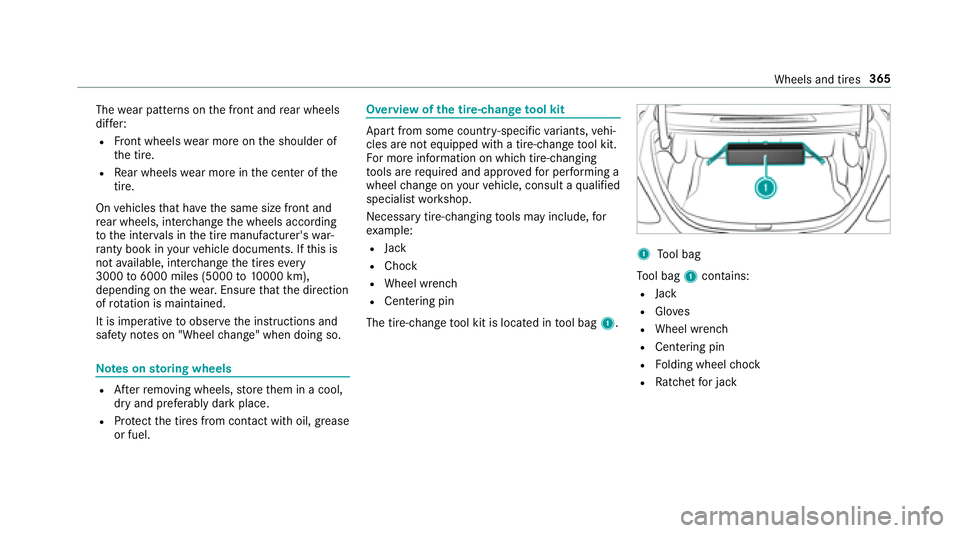

Overview of the tire-chan getool kit

Apart from some countr y-specific variants, vehi‐

cles are not equipped with a tire-change tool kit.

Fo r more information on which tire-changing

to ols are required and appr oved for per form ing a

wheel change on your vehicle, consult a qualified

specialist workshop.

Necessary tire-changing tools may include, for

ex ample:

RJack

RChock

RWheel wrench

RCentering pin

The tire-change tool kit is located in tool bag 1.

1Tool bag

To ol bag 1contains:

RJack

RGloves

RWheel wrench

RCentering pin

RFo lding wheel chock

RRa tchet for jack

Wheels and tires 365

Page 368 of 486

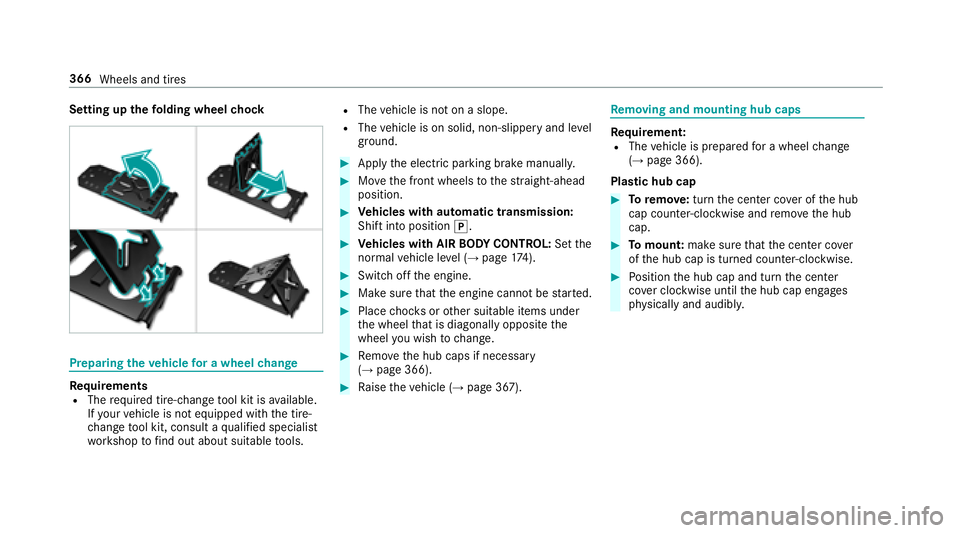

Setting upthefo lding wheel chock

Prepa ring theve hicle for a wheel change

Re quirementsRThe requ ired tire-change tool kit is available.

If yo ur vehicle is not equipped with the tire-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

RThe vehicle is not on a slope.

RThe vehicle is on solid, non-slippery and le vel

ground .

#Applythe electric parking brake manually.

#Mo vethe front wheels tothest ra ight-ahead

position.

#Ve hicles with automatic transmission:

Shift into position j.

#Vehicles with AIR BODY CONT ROL:Set the

normal vehicle le vel (→page 174).

#Switch off the engine.

#Make sure that the engine cannot bestar ted.

#Place choc ks orother suitable items under

th e wheel that is diagonally opposite the

wheel you wish tochange.

#Re mo vethe hub caps if necessary

(→page 366).

#Ra ise theve hicle (→page 367).

Re moving and mounting hub caps

Requirement:RThe vehicle is prepared for a wheel change

(→page 366).

Plast ic hub cap

#Toremo ve:turn the center co ver of the hub

cap counter-clockwise and remo vethe hub

cap.

#To mount: makesurethat the center co ver

of the hub cap is turned counter-clockwise.

#Po sition the hub cap and turn the center

co ver clockwise until the hub cap engages

ph ysically and audibly.

366

Wheels and tires

Page 369 of 486

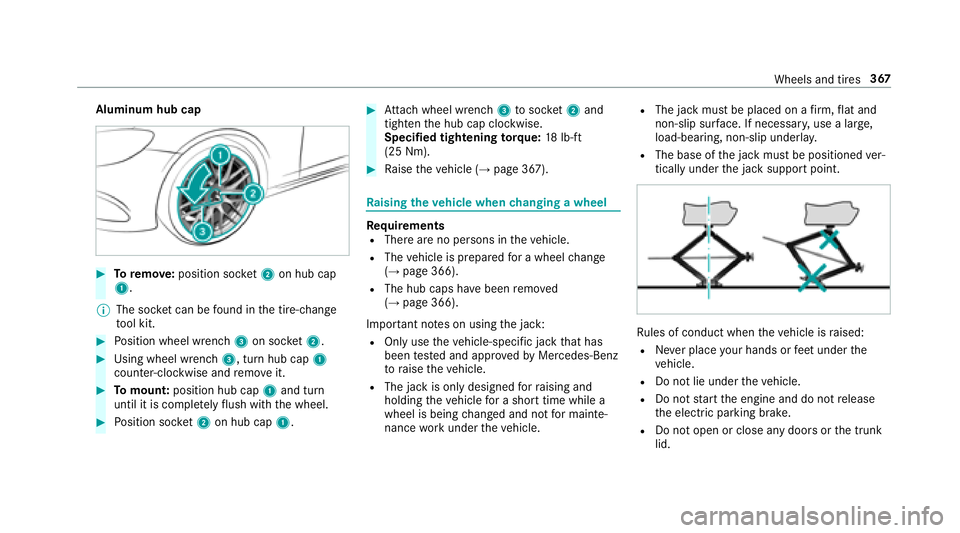

Aluminum hub cap

#Toremo ve:position soc ket2 on hub cap

1.

% The soc ket can be found inthe tire-change

to ol kit.

#Po sition wheel wrench 3on soc ket2.

#Using wheel wrench 3, turn hub cap1

counter-clo ckwise and remo veit.

#To mount: position hub cap 1and turn

until it is compl etely flush withth e wheel.

#Po sition soc ket2 on hub cap 1.

#Attach wheel wrench 3tosoc ket2 and

tighten the hub cap clockwise.

Specified tightening torq ue: 18lb-ft

(25 Nm).

#Ra ise theve hicle (→page 367).

Ra ising theve hicle when changing a wheel

Re quirementsRThere are no persons in theve hicle.

RThe vehicle is prepared for a wheel change

(→page 366).

RThe hub caps ha vebeen remo ved

(→page 366).

Impor tant no tes on using the jack:

ROnly use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle.

RThe jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle.

RThe jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

load-bearing, non-slip underla y.

RThe base ofthe jack must be positioned ver‐

tically under the jack support point.

Ru les of conduct when theve hicle is raised:

RNe ver place your hands or feet under the

ve hicle.

RDo not lie under theve hicle.

RDo not start the engine and do not release

th e electric parking brake.

RDo not open or close any doors or the trunk

lid.

Wheels and tires 367

Page 370 of 486

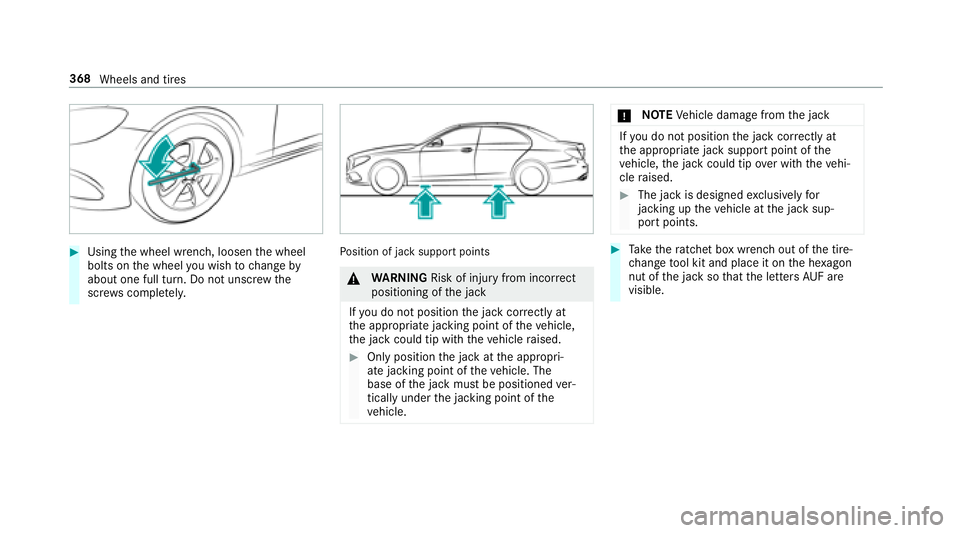

#Usingthe wheel wrench, loosen the wheel

bolts on the wheel youwish tochange by

about one full turn. Do not unscr ewthe

scr ews comple tely.Po sition of jack support points

&

WARNING Risk of injury from incorrect

positioning of the jack

If yo u do not position the jack cor rectly at

th e appropriate jacking point of theve hicle,

th e jack could tip with theve hicle raised.

#Only position the jack at the appropri‐

ate jacking point of theve hicle. The

base of the jack must be positioned ver‐

tically under the jacking point of the

ve hicle.

* NO

TEVehicle damage from the jack

Ifyo udo not position the jack cor rectly at

th e appropriate jack support point of the

ve hicle, the jack could tip over with theve hi‐

cle raised.

#The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points.

#Ta ke thera tchet box wrench out of the tire-

ch ange tool kit and place it on the he xagon

nut of the jack so that the letters AUF are

visible.

368 Wheels and tires