inflation pressure MERCEDES-BENZ E-Class SEDAN 2017 W213 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-Class SEDAN, Model: MERCEDES-BENZ E-Class SEDAN 2017 W213Pages: 446, PDF Size: 6.23 MB

Page 301 of 446

#Stop af terd riving fora pproxima tely ten

minutes and checkt he tir epressur eusing

th et irei nflation compressor.

The tir epressur emustn ow be at least

13 0k Pa(1.3 bar/1 9psi).

&

WARNING Risk of accident duetot he

specified tir epressur enotbeing reached

If th es pecified tir epressur eafter ab rief

driv eisn otreached, thet ireist oo badly

damaged. The tir esealant cannot repair the

tir eint his ins tance.

Dama gedt ires and tir epressur ethat is too

lo wc an significantl yimp air brakin gproper‐

ties and handlin gcharacteristics.

#Do no tcontinue driving.

#Consult aqualified specialis tworks hop.

In cases suc hasthe one mentioned abo ve,c on‐

ta ct an au thorized Mercedes-Benz Center .Or

call 1-800-FOR-MERCedes (in theU SA)or

1-800-387-0 100( in Canada).

#Cor rect thet irep ressur eifitiss tillatl east

13 0k Pa(1.3 bar/1 9psi).S ee theT irea nd

Loading Info rmatio nplacar dont he driver's

side B‑pillar or thet irep ressur etable in the

fuel filler flap forv alues.

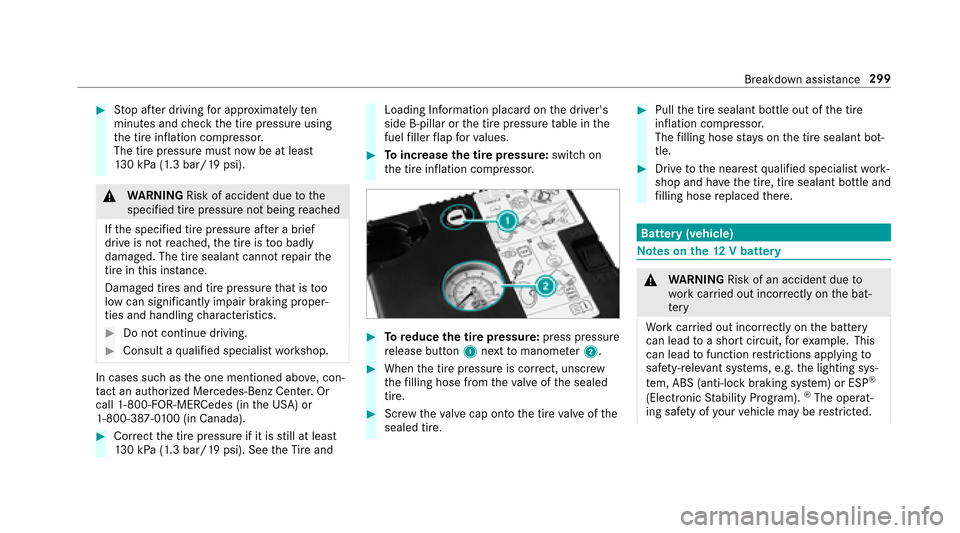

#To increase thet irep ressure: switchon

th et irei nflation compressor.

#To reduce the tir epress ure: press pressure

re lease button 1next tomanome ter2.

#When thet irep ressur eisc orrect, unscr ew

th ef illing hose from thev alveoft he sealed

tire.

#Scr ew thev alvec ap ont othe tir evalveoft he

sealed tire.

#Pull thet ires ealant bottle out of thet ire

inflation compressor.

The filling hose stay sont he tiresealant bot‐

tle.

#Driv etot he neares tqualified specialis twork‐

shop and ha vethet ire, tir esealant bottle and

fi lling hose replaced there.

Bat tery (vehicle)

Note sont he12Vb attery

&

WARNING Risk of an accident duet o

wo rkcar ried out incor rectly on theb at‐

te ry

Wo rkcar ried out incor rectl yont he battery

can lead toas hor tcircuit ,for example. This

can lead tofunction restrictions applying to

saf ety-re leva nt sy stems, e.g. thel ighting sys‐

te m, ABS (anti-lo ckbraking sy stem) or ESP

®

(Elect ronic StabilityP rogram).®The ope rat‐

ing saf etyofy ourvehicle ma yberestricted.

Breakdown assis tance 299

Page 318 of 446

RMaximum tirepressur e(→page325)

Checking thet irep ressur emanually

#Read thet irep ressur efor thec urrent operat‐

ing conditions from thet irea nd loading infor‐

mation table or thet irep ressur etable.

Obser vethen otes on tir epressure.

#Re mo vethev alvec ap of thet iretob e

ch ecked.

#Press thet irep ressur egaug esecurel yonto

th ev alve.

#Read thet irep ressure.

#Ifth et irep ressur eisl owerthan ther ecom‐

mended value, inc rease thet irep ressur eto

th er ecommende dvalue.

#Ifth et irep ressur eish igher than ther ecom‐

mended value, release air .Todos o, press

down them etal pin in thev alve, e.g. using

th et ip of apen fore xamp le. Then checkt he

tir ep ressur eagain usingt he tirepressure

ga uge.

#Sc rewt he valvec ap ont othe valve. Fu

rther related subjects:

RNo tesont irep ressur e(→page312)

RTire pressur etable (→pag e314)

RTire and Loading Info rmatio nplacard

(→pag e319)

Tire pressur emonitoring sy stem

Fu nction of thet irep ressur emonitoring sys‐

te m

&

DANG ER Risk of accidentd uetoincor‐

re ct tir epressure

Ever ytire, including thes par e(if pr ovided),

should be checkedw hen cold at leas toncea

mont hand inflated tothep ressur erecom‐

mended bythev ehicle manufacturer (see

Ti re and Loading Info rmatio nplacar dont he

B-pi llaronthed rive r’ss ide or thet irep res‐

sur elabel on thei nside of thef uel filler flap

of your vehicle). If your vehicle has tires of a

dif fere nt size than thes ize indicated on the

Ti re and Loading Info rmatio nplacar dort he

tirep ressur etable, youn eedtod etermine

th ep roper tir epressur efor those tires.

As an added saf etyf eature, your vehicle has

been equipped wit hatirep ressur emonitor‐

ing sy stem (TPMS) that illuminates alow tire

pressur eindicator lam pwhen oneorm oreo f

yo ur tires ar esignif icantl yunderinflated.

Ac cordingly ,ifthe lo wtirep ressur eindicator

lam plights up, yous hould stop and check

yo ur tires as soonasp ossible, and inflate

th em tothep roper pressure. Driving on a

significantly underinflated tir ecauses thet ire

to ove rheat and can lead totiref ailure.

Und erinflation also increases fuel consump‐

tion and reduces tir etread life, and may

af fect thev ehicle's handling and braking abil‐

ity .P lease no tethat theT PMS is no tasubsti‐

tut efor proper tir emaintenance, and it is the

driver's responsibility tomaintain cor rect tire

pressure, evenifu nderinflatio nhasnot

re ached thel evel to trig gerillumination of

th eT PMS lo wtirep ressur eindicator lamp.

Yo ur vehicle has also been equipped wit ha

TPMS malfunction indicator toindicat ewhen

316

Wheels and tires

Page 437 of 446

Telephonem enuoverview. ..................2 35

Te lephoneo peration ............................ 239

UsingN ear Field Communication

(NFC) .................................................. .238

Te lephone number

Dialin g(on-boar dcomputer) ................ 203

Te mp erature ............................................ 122

Te mp eratur egrade .................................. 323

Te xt messages ......................................... 242

Callin gasender .................................. .244

Command s(Vo iceC ontrol System) ..... 214

Composing .......................................... 243

Confi guring thet extm essage sdis‐

pla yed. ................................................ .243

Deleting ............................................... 244

No tes. .................................................. 242

Re ad-aloud function ............................ 243

Re ading. .............................................. 243

Re plying .............................................. .244

Sending ............................................... 243

Ti e-d owne yes................................ ...

......... 99

Time Manual time setting. ............................ 226 SettingD

aylight SavingT ime (Sum‐

mer). ................................................... 226

Setting thet ime and dat eautomati‐

call y..................................................... 225

Setting thet ime zon e.......................... 225

Setting thet ime/dat eformat .............. 226

TIN (Tir eIdentification Number) ............3 24

Ti re and Loading Information placard ....319

Ti re ch aracteristics ................................. 326

Ti re inflation compressor

see TIREFIT kit

Ti re information table .............................. 319

Ti re labeling ............................................ .323

Cha racteristics .................................... 326

DO T,Tire Identification Number (TIN)

.............................................................3 24

Load inde x........................................... 326

Load rating .......................................... 326

Maximum tir eloa d. ............................. 325

Maximum tir epressur e....................... 325

Overvie w............................................. 323

Spee drating ....................................... .326

Te mp eratur egrade .............................. 323

Ti re Quality Grading ............................. 323 Ti

re size designation ............................3 26

Tr action grade .................................... .323

Tr ead wear grade .... ...

.........................

.323

Ti re load (maximum) .............................. .325

Ti re pressure

Checking (manually) ............................ 316

Checkin g(tire pressur emonitoring

sy stem) ................................................ 317

Maximum ............................................ 325

No tes. .................................................. 312

Re startin gthe tir epressur emonitor‐

ing sy stem .......................................... .318

Ti re pressur emonitoring sy stem

(function) ............................................. 316

Ti re pressur etable .............................. .314

Ti re pressur emonitoring sy stem

Checkin gthe tir epressur e.................. .317

Fu nctio n............................................... 316

Re startin g........................................... .318

Te ch nica ldata. ..................................... 319

Ti re pressur etable ..................................3 14

Ti re Quality Grading ................................ 323

Ti re tread .................................................. 311

Index 435