ECU MERCEDES-BENZ G-CLASS SUV 2012 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2012Pages: 357, PDF Size: 8.86 MB

Page 330 of 357

i

The tyre pressure values given for low

loads are minimum values which offer you

good ride comfor tcharacteristics.

However, you can also use the values given

for higher loads. These are permissible and

will not adversely affect the running of the

vehicle. Checking the tyre pressures

Important safety notes Observe the notes on tyre pressure:

(Y

page 325).

Information on air pressure for the tyres on

your vehicle can be found:

R on the vehicle's tyre and loading informa-

tion table on the B-pillar (Y page 326)

R on the tyre pressure label on the fuel filler

flap (Y page 326)

R in the "Tyre pressure information" section

R in the "Tyre pressure information" section

(Y page 325)

Checking the tyre pressure manually To determine and set the correct tyre pres-

sure, proceed as follows:

X Remove the valve cap of the tyre that is to

be checked.

X Press the tyre pressure gauge securely

onto the valve.

X Read the tyre pressure and compare it with

the recommended value on the tyre and

loading information table on the B-pillar on

the driver's side of your vehicle

(Y page 326).

X The tyre pressure is too low: increase the

tyre pressure to the recommended value.

X The tyre pressure is too high: press down

the metal pin in the valve using the tip of a

pen, for example.

Air is released from the tyre.

X Check the tyre pressure again with the tyre

pressure gauge. X

Screw the valve cap onto the valve.

X Repeatt hese steps for the other tyres. Tyre pressure monitor

Important safety notes It is the driver's responsibility to set the tyre

pressure to the recommended cold tyre pres-

sure suitable for the operating situation

(Y

page 325). Note that the correct tyre pres-

sure for the current operating situation must

first be taught-in to the tyre pressure monitor.

if there is a substantial loss of pressure, the

warning threshold for the warning message is

aligned to the reference values taught-in.

Restart the tyre pressure monitor after

adjusting to the cold tyre pressure

(Y page 328). The current pressures are

saved as new reference values. This will

ensure that a warning message will only

appearift he tyre pressure drops significantly.

The tyre pressure monitor does not warn you

of an incorrectly set tyre pressure. Observe

the notes on the recommended tyre pressure

(Y page 325).

The tyre pressure monitor is not able to warn

you of a sudden loss of pressure, e.g. if the

tyre is penetrated by a foreign object. In the

event of a sudden loss of pressure, bring the

vehicle to a halt by braking carefully. Avoid

abrupt steering manoeuvres.

If a tyre pressure monitor system is fitted, the

vehicle's wheels have sensors fitted that

monitor the tyre pressures in all four tyres.

The tyre pressure monitor warns you when

the pressure drops in one or more of the

tyres. The tyre pressure monitor only func-

tions if the correct sensors are fitted to all

wheels.

Information on tyre pressures is displayed in

the multifunction display. After a few minutes

of driving, the current tyre pressure of each

tyre is shown in the multifunction display.

The tyre pressure values indicated by the on-

board computer may differ from those meas- Tyre pressure

327Wheels and tyres Z

Page 333 of 357

On vehicles that have the same size front and

rear wheels, you can interchange the wheels

every 5000 km to 10,000 km depending on

the degree of tyre wear. Maintain the direc-

tion of tyre rotation.

Cleant he contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is interchanged. Check the tyre pressure and

reactivate the tyre pressure monitor

(Y page 327) if necessary. Direction of rotation

Tyres with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of aquaplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tyre indicates

its correct direction of rotation.

You may fit the spare wheel against the direc-

tion of rotation. Observe the time restriction

on use as well as the speed limitation speci-

fied on the spare wheel. Storing wheels

Store tyres that are not being used in a cool,

dry and preferably dark place. Protect the

tyres against oil, grease, petrol and diesel. Cleaning the wheels

G

WARNING

Do not use high-pressure cleaners with circu-

lar-jet nozzles (dirt grinders) to clean your

vehicle, in particular the tyres. You could oth-

erwise damage the tyres and cause an acci-

dent. Fitting

awheel

Preparing the vehicle X

Prepare the vehicle as described

(Y page 309).

X If a trailer is coupled to the vehicle, uncou-

ple it.

X Remove the vehicle tool kit and the jack

(Y page 306).

X Secure the vehicle to prevent it from rolling

away.

X Remove the spare wheel from the spare

wheel bracket (Y page 307).

Securing the vehicle against rolling

away X

On level ground: place chocks or other

suitable items unde rthe front and rear of

the wheel that is diagonally opposite the

wheel you wish to change.

X On downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

The following must be observed when raising

the vehicle:

R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If the jack is

used incorrectly, it could tip over while the

vehicle is raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel 330

Changing

awheelWheels and tyres

Page 334 of 357

is being changed. It is not suited for per-

forming maintenance work under the vehi-

cle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Neve rdisen-

gage the parking brake while the vehicle is

raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jac kunderlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure tha tthe distance between the

underside of the tyres and the ground does

not exceed 3 cm.

R never place your hands or feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door or the tailgate

when the vehicle is raised.

R make sure that no persons are present in

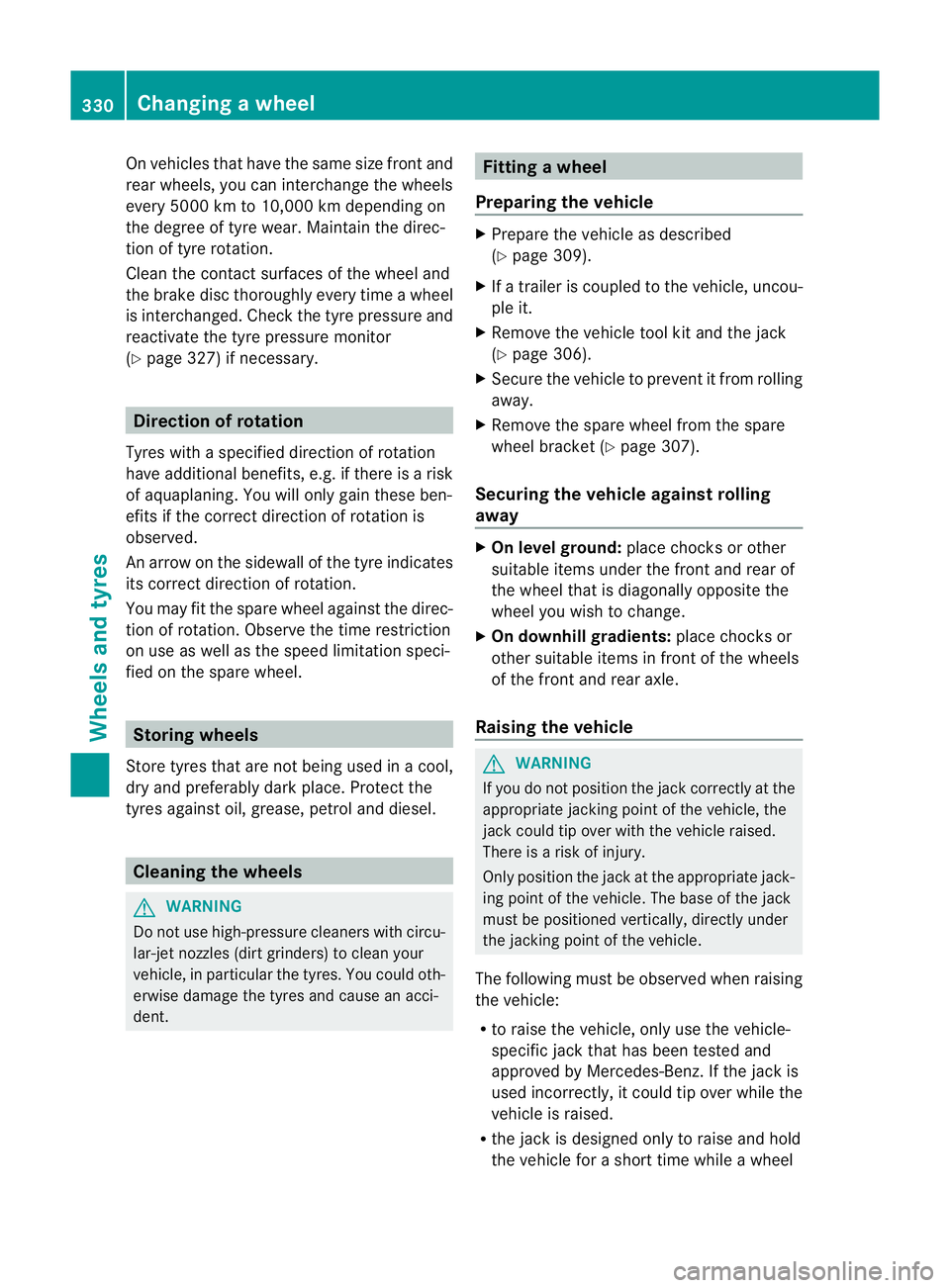

the vehicle when the vehicle is raised. X

Using wheel wrench :, loosen the bolts on

the wheel you wish to change by about one full turn. Do not unscrew the wheel bolts

completely.

Pump lever

;

Notch on pump lever

X Assemble the pump lever for the jack. It can

be found with the vehicle tool kit

(Y page 306). X

Turn pressure release screw =clockwise

as far as it will go using notch ;on the

pump lever.

Pressure release screw =is closed.

i Do not turn pressure release screw =by

more than one to two revolutions. Other-

wise, hydraulic fluid could escape. Changing

awheel

331Wheels and tyres Z

Page 335 of 357

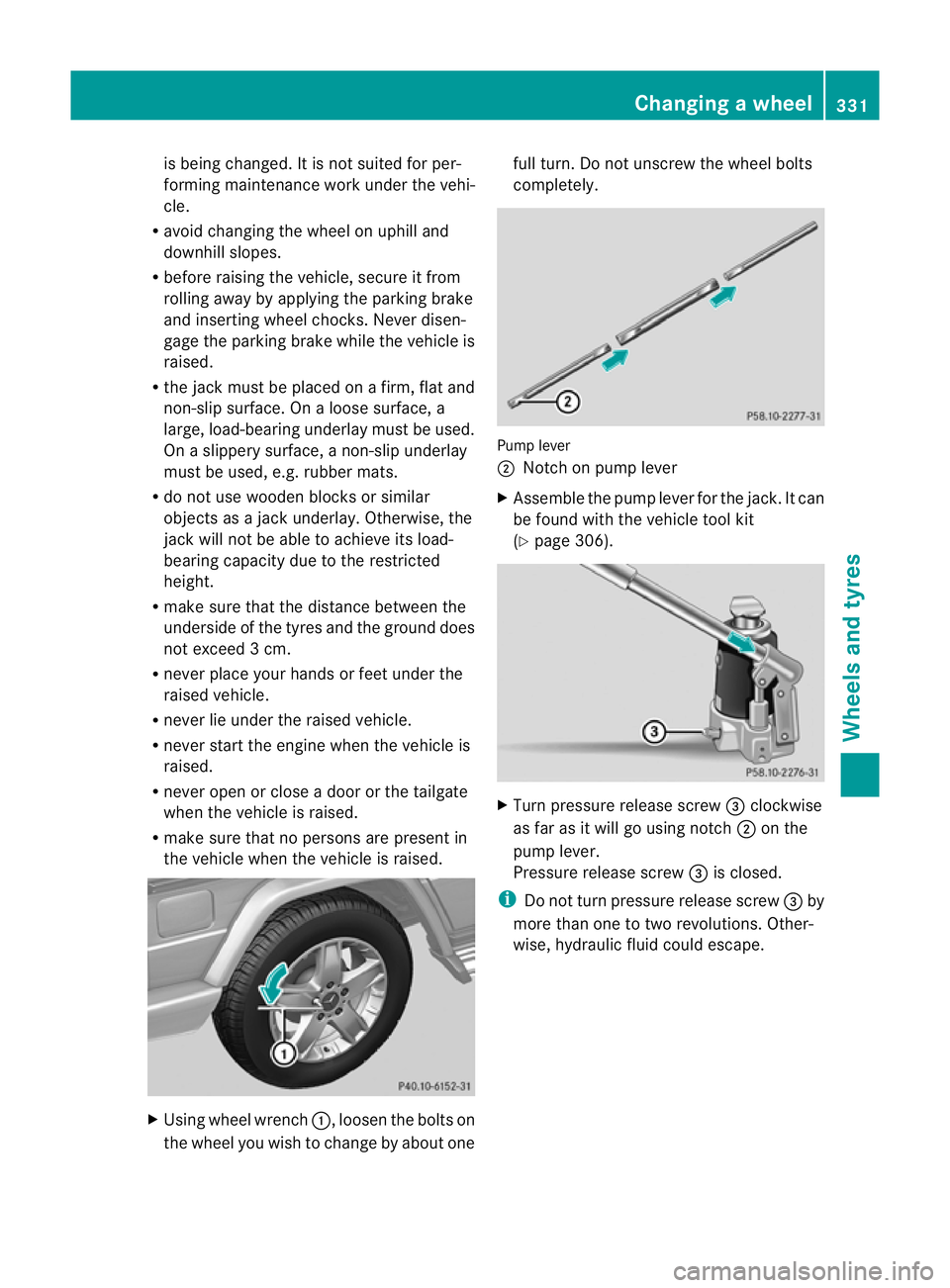

X

Position jack :on the axle carrier

tube ;of the front or rear axle. Jack :

must always stand vertically, even on

slopes.

X Raise the vehicle by pumping in the direc-

tion of the arrow, until the tyre is a maxi-

mum of 3 cm off the ground.

Removing awheel !

Do not place wheel bolts in sand or dirt.

The threads of the wheel bolts and wheel

hubs could otherwise be damaged when

the bolts are tightened.

X Unscrew the wheel bolts.

X Remove the wheel.

Fitting anew wheel G

WARNING

If a wheel hub thread is damaged, do not drive

the vehicle any further .Contactaqualified

specialist workshop. G

WARNING

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel. Other wheel bolts could

work loose or damage the brake system.

Do not tighten the wheel bolts completely

while the vehicle is still jacked up. The vehicle

could topple off the jack. Always pay attention to the instructions and

safety notices in "Changing a wheel"

(Y

page 329).

X Clean the wheel and wheel hub contact

surfaces.

X Place the new wheel on the wheel hub and

push it on.

X Tighten the wheel bolts until they are fin-

ger-tight.

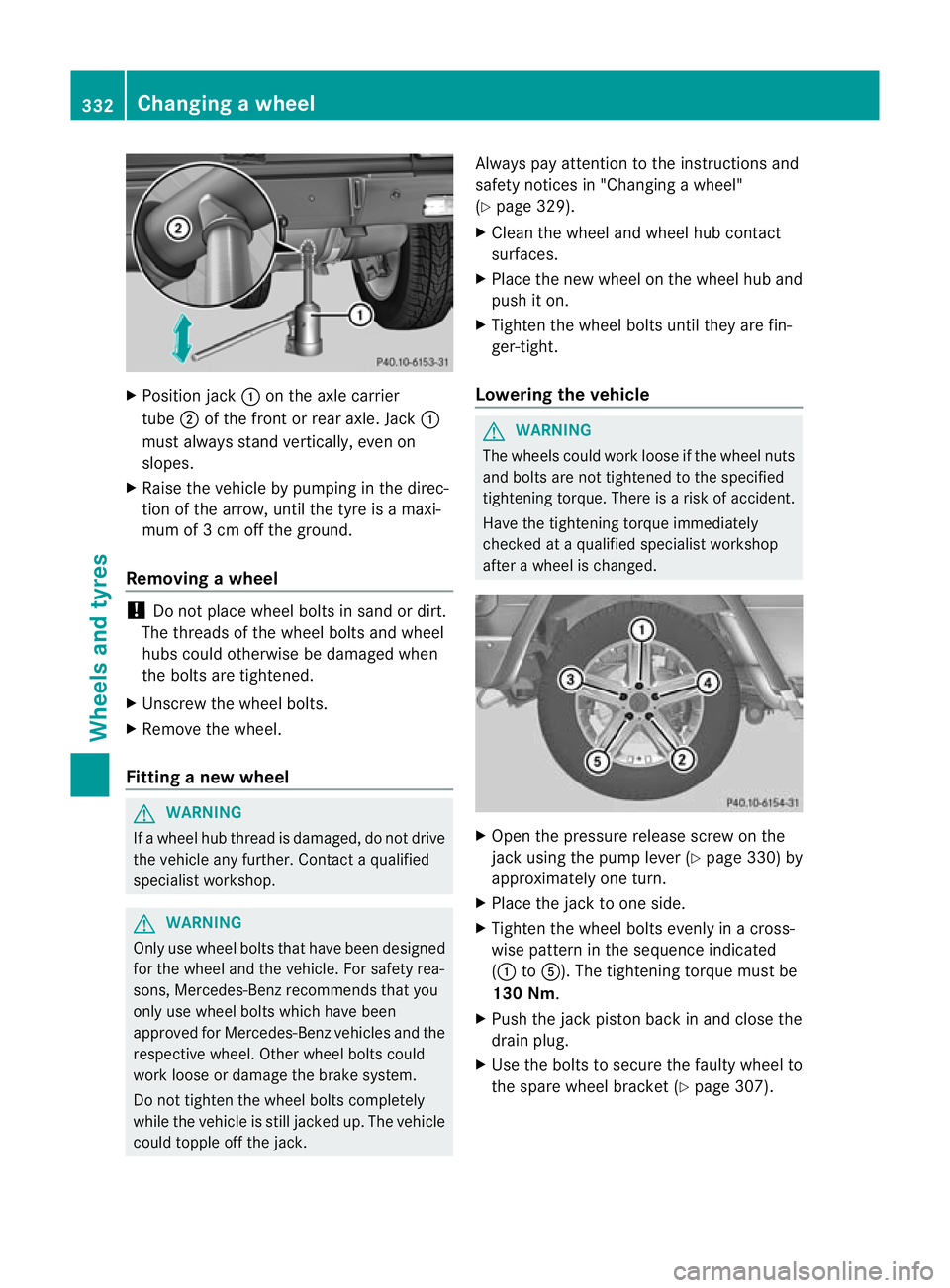

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed. X

Open the pressure release screw on the

jack using the pump lever (Y page 330) by

approximately one turn.

X Place the jack to one side.

X Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indicated

(: toA). The tightening torque must be

130 Nm.

X Push the jack piston back in and close the

drain plug.

X Use the bolts to secure the faulty wheel to

the spare wheel bracket (Y page 307).332

Changing

awheelWheels and tyres