lock MERCEDES-BENZ G-CLASS SUV 2013 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2013Pages: 364, PDF Size: 9.62 MB

Page 315 of 364

Towing in the event of malfunctions

General notes !

If you are removing the propeller shaft,

use M10 nuts as spacers on the M8 bolts

and secure them with M8 nuts.

New self-locking nuts must be used when

the propeller shafts are refitted.

X Observe the safety notes as you do so

(Y page 310).

i Consult an authorized Mercedes-Benz

Center.

Engine damage, gear damage or

electrical malfunctions X

Move the selector lever to

position N(Y page 145).

X Shift the transfer case to

neutral (Y page 200).

In the event of damage to the transfer

case Have the propeller shafts between the axles

and the transfer case removed.

In the event

of

damage to the front axleHave the propeller shaft between the rear

axle and the transfer case removed.

Have the vehicle towed with the front axle

raised.

In the event of damage to the rear axle

Have the propeller shaft between the front

axle and the transfer case removed.

Have the vehicle towed with the rear axle

raised and with wheel rollers under the front

axle. Fuses

Important safety notes

G

WARNING

Only use fuses that have been approved for

Mercedes-Benz vehicles and that have the

correct fuse rating for the systems

concerned. Do not attempt

to repair or bridge

faulty fuses. Using fuses that have not been

approved or attempting to repair or bridge

faulty fuses could cause the fuse to be

overloaded and result in a fire. Have the cause

traced and rectified at a qualified specialist

workshop.

! Only use fuses that have been approved

for Mercedes-Benz vehicles and which

have the correct fuse rating for the system

concerned. Otherwise, components or

systems could be damaged.

The fuses in your vehicle serve to close down

faulty circuits. If a fuse blows, all the

components on the circuit and their functions

stop operating.

Blown fuses must be replaced with fuses of

the same rating, which you can recognize by

the color and value. The fuse ratings are listed

in the fuse allocation chart.

i If a fuse has blown, contact a breakdown

service or an authorized Mercedes-Benz

Center.

If a newly inserted fuse also blows, have the

cause traced and rectified at a qualified

specialist workshop, e.g. an authorized

Mercedes-Benz Center. Before changing a fuse

X Park the vehicle and apply the parking

brake.

X Switch off all electrical consumers.

X Remove the SmartKey from the ignition

lock.

All indicator lamps in

the instrument cluster

must be off. Fuses

313

Breakdown assistance Z

Page 321 of 364

Information on the dimensions and types of

wheels and tires

for

your vehicle can be found

in the "Wheel/tire combinations" section

(Y page 344).

Information on air pressure for the tires on

your vehicle can be found:

R on the tire pressure label on the fuel filler

flap

R in the "Tire pressure" section

i Further information on wheels and tires

can be obtained at any qualified specialist

workshop. Operation

Notes on driving

If the vehicle is

heavily loaded, check the tire

pressures and correct them if necessary.

When parking your vehicle, make sure that

the tires do not get deformed by the curb or

other obstacles. If it is necessary to drive over

curbs, speed humps or similar elevations, try

to do so slowly and at an obtuse angle.

Otherwise, the tires, particularly the

sidewalls, may be damaged. Regular checking of wheels and tires

G

WARNING

Regularly check the tires for damage.

Damaged tires can cause tire inflation

pressure loss. As a result, you could lose

control of your vehicle.

Worn, old tires can

cause accidents. If the tire

tread is worn to minimum tread depth, or if

the tires have sustained damage, replace

them.

R Regularly check the wheels and tires of

your vehicle for damage at least once a

month, as well as after driving off-road or

on rough roads. Damage includes bulges

and deformation on tires, cuts, punctures,

cracks or severe corrosion on wheels, for example. Damaged wheels can cause a

loss of tire pressure.

R Regularly check the tire tread depth and

the condition of the

tread across the whole

width of the tire (Y page 319). In order to

inspect the inner side of the tire surface,

turn the steering wheel to full lock.

R All wheels must have a valve cap to protect

the valve against dirt and moisture. Do not

install anything onto the valve other than

the standard valve cap or a valve cap

approved by Mercedes-Benz for your

vehicle.

Do not install anything onto the valve, such

as tire pressure monitoring systems.

R You should regularly check the pressure of

all your tires including the spare wheel,

particularly prior to long trips. Adjust the

tire pressure as necessary ( Y page 327).

The service life of tires depends, among other

things, on the following factors:

R Driving style

R Tire pressure

R Distance covered Tire tread

G

WARNING

Although the applicable federal motor vehicle

safety laws consider a tire to be worn when

the treadwear indicators (TWI)

become visible

at approximately 00CD inches (1.6 mm), we

recommend that you do not allow your tires

to wear down to that level. As tread depth

approaches 00CE inches (3 mm) the adhesion

properties on a wet road are sharply reduced.

Depending upon the weather and/or road

surface (conditions), the tire traction varies

widely. Operation

319

Wheels and tires Z

Page 329 of 364

The operation of the tire pressure monitor can

be affected by interference from radio

transmitting equipment (e.g. radio

headphones, two-way radios) that may be

being operated in or near the vehicle.

i

USA only:

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause interference,

and

2. this device

must accept any interference

received, including interference that may

cause undesired operation of the device.

Any unauthorized modification to this

device could void the user's authority to

operate the equipment.

i Canada only:

This device complies with RSS-210 of

Industry Canada. Operation is subject to

the following two conditions:

1. This device may not cause interference,

and

2. this device must accept any interference

received, including interference that may

cause undesired operation.

Any unauthorized modification to this

device could void the user's authority to

operate the equipment.

Checking tire pressure electronically X

Make sure that the SmartKey is in

position 2 (Y page 139) in

the ignition lock.

X Press the 0059 or 0065 button on the

steering wheel to select the Serv. menu.

X Press the 0063 or 0064 button to select

Tire Pressure.

X Press button 0076.

The current tire pressure

for each wheel will

be displayed in the multifunction display.

If the vehicle has been parked for over

20 minutes, the message Tire pressure will be displayed after driving a

few minutes appears.

After a teach-in period, the tire pressure

monitor automatically recognizes

new

wheels

or new sensors. As long as a clear allocation

of the tire pressure values to the individual

wheels is not possible, the Tire Pressure

Monitor Active display message is shown

instead of the tire pressure display. The tire

pressures are already being monitored.

i If a spare wheel is mounted, the system

may continue to show the tire pressure of

the wheel that has been removed for a few

minutes. If this occurs, note that the value

displayed for the position where the spare

wheel is mounted is not the same as the

spare wheel's current tire pressure.

Tire pressure monitor warning

messages If the tire pressure monitor detects a

significant pressure loss

on

one or more tires,

a warning message is shown in the

multifunction display. A warning tone also

sounds and the tire pressure warning lamp

lights up in the instrument cluster.

Each tire that is affected by a significant loss

of pressure is highlighted in the pressure

display.

X If the Correct Tire PressureCorrect

Tire Pressure message appears in the

multifunction display, check the tire

pressure on all four

wheels and correct it if

necessary.

i If the wheel positions on the vehicle are

interchanged, the tire pressures may be

displayed for the wrong positions for a

short time. This is rectified after a few

minutes of driving, and the tire pressures

are displayed for the correct positions.

Restarting the tire pressure monitor When you restart the tire pressure monitor,

all existing warning

messages

are deleted and

the warning lamps go out. The monitor uses Tire pressure

327

Wheels and tires Z

Page 330 of 364

the currently set tire pressures as the

reference values for monitoring. In most

cases, the tire pressure monitor will

automatically detect the new reference

values after you have changed the tire

pressure. However, you can also define

reference values manually

as

described here.

X Set the tire pressure to the value

recommended for the corresponding

driving situation on the Tire and Loading

Information placard on the driver's side

B-pillar ( Y page 322).

Additional tire pressure values

for different

loads can also be found on the tire pressure

table on the inside of the fuel filler flap

(Y page 322).

X Make sure that the tire pressure is correct

on all four wheels.

X Make sure that the SmartKey is in

position 2 (Y page 139) in

the ignition lock.

X Press the 0059 or 0065 button on the

steering wheel to select the Serv. menu.

X Press the 0063 or 0064 button to select

Tire Pressure.

X Press the 0076 button.

The multifunction display shows the

current tire pressure for

the individual tires

or the Tire pressure will be

displayed after driving a few

minutes message.

X Press the 0064 button.

The Use Current Pressures as New

Reference Values message appears in

the multifunction display.

If you wish to confirm the restart:

X Press the 0076 button.

The Tire Press. Monitor Restarted

message appears in the multifunction

display.

After driving for

a

few minutes, the system

checks whether the current tire pressures

are within the specified range. The new tire

pressures are then accepted as reference

values and monitored. If you wish to cancel the restart:

X

Press the 0041 button.

The tire pressure values stored at the last

restart will continue to be monitored. Loading the vehicle

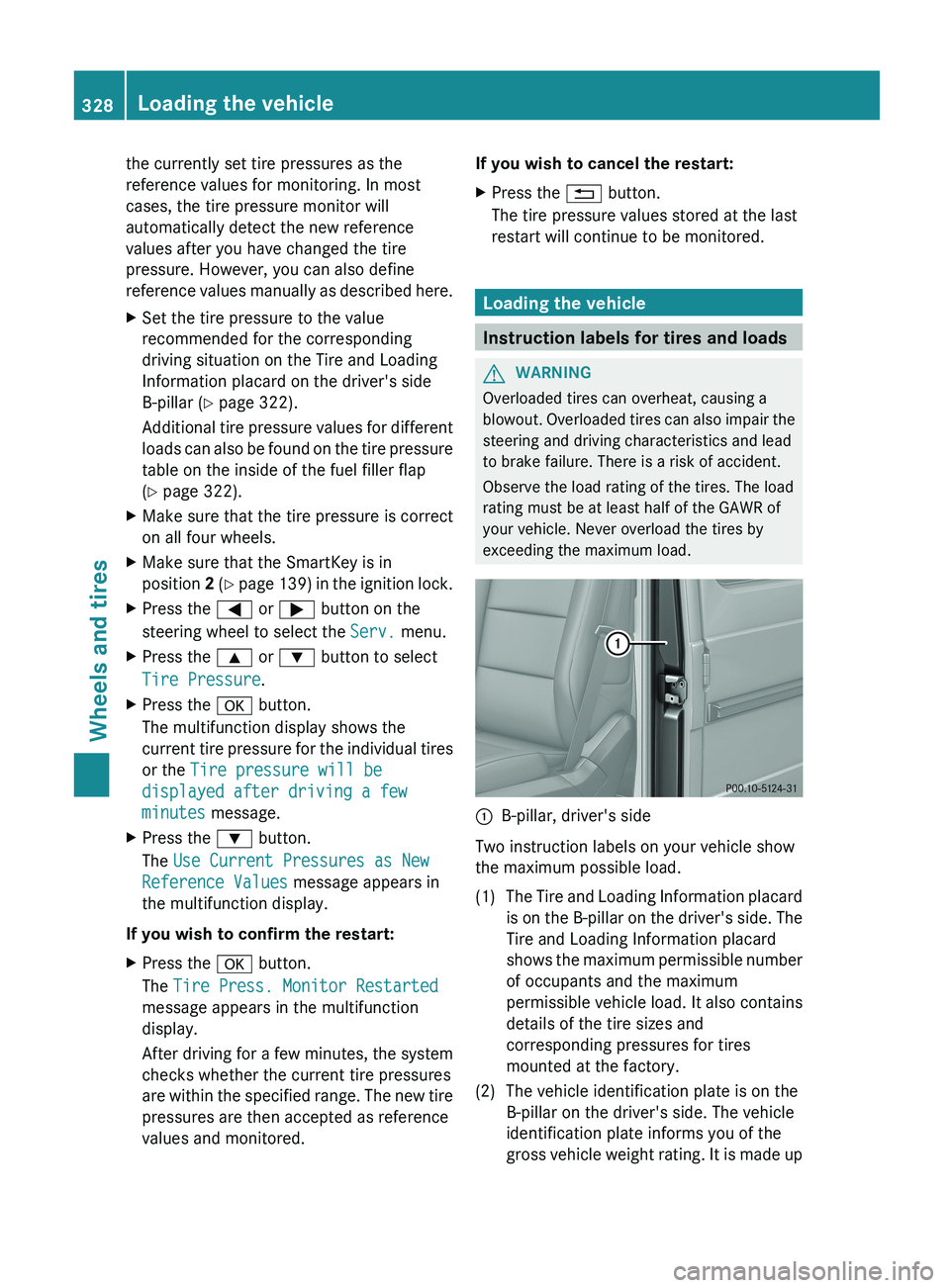

Instruction labels for tires and loads

G

WARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can

also impair the

steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load. 0043

B-pillar, driver's side

Two instruction labels on your vehicle show

the maximum possible load.

(1) The Tire and Loading Information placard is on the B-pillar

on the driver's side. The

Tire and Loading Information placard

shows the maximum permissible number

of occupants and the maximum

permissible vehicle load. It also contains

details of the tire sizes and

corresponding pressures for tires

mounted at the factory.

(2) The vehicle identification plate is on the B-pillar on the driver's side. The vehicle

identification plate informs you of the

gross vehicle weight rating.

It is made up328

Loading the vehicle

Wheels and tires

Page 344 of 364

the wheel that is diagonally opposite the

wheel you wish to change.

X On downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle.

! The jack is designed exclusively for

jacking up the vehicle

at the jacking points.

Otherwise, your vehicle could be damaged.

The following must be observed when raising

the vehicle:

R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If used

incorrectly, the jack could tip over with the

vehicle raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for

performing maintenance work under the

vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats. R

do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tires

and the ground does

not exceed 1.2 inches (3 cm).

R never place your hands and feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door or the tailgate

when the vehicle is raised.

R make sure that no persons are present in

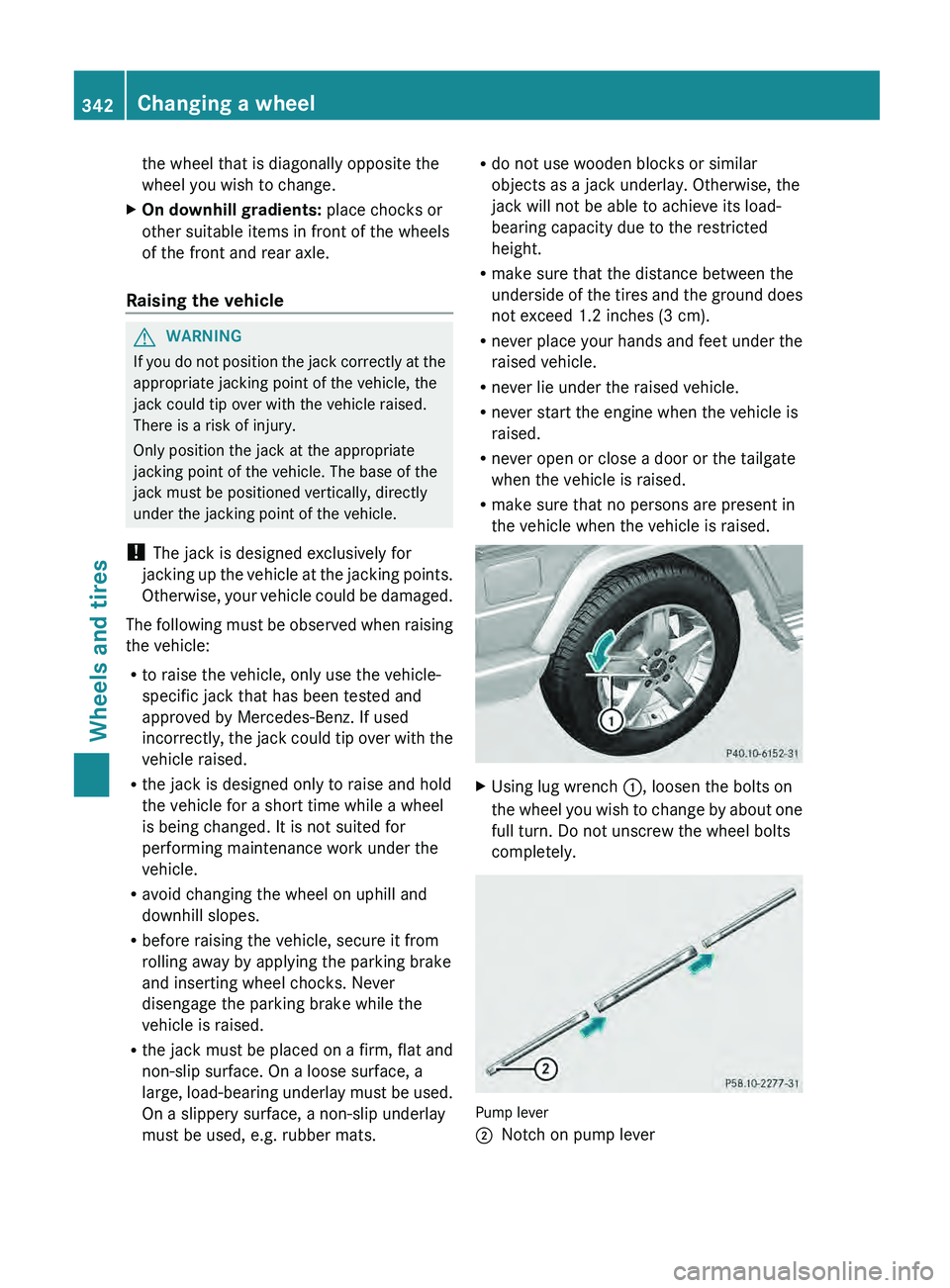

the vehicle when the vehicle is raised. X

Using lug wrench 0043, loosen the bolts on

the wheel you wish

to change by about one

full turn. Do not unscrew the wheel bolts

completely. Pump lever

0044

Notch on pump lever342

Changing a wheel

Wheels and tires

Page 345 of 364

X

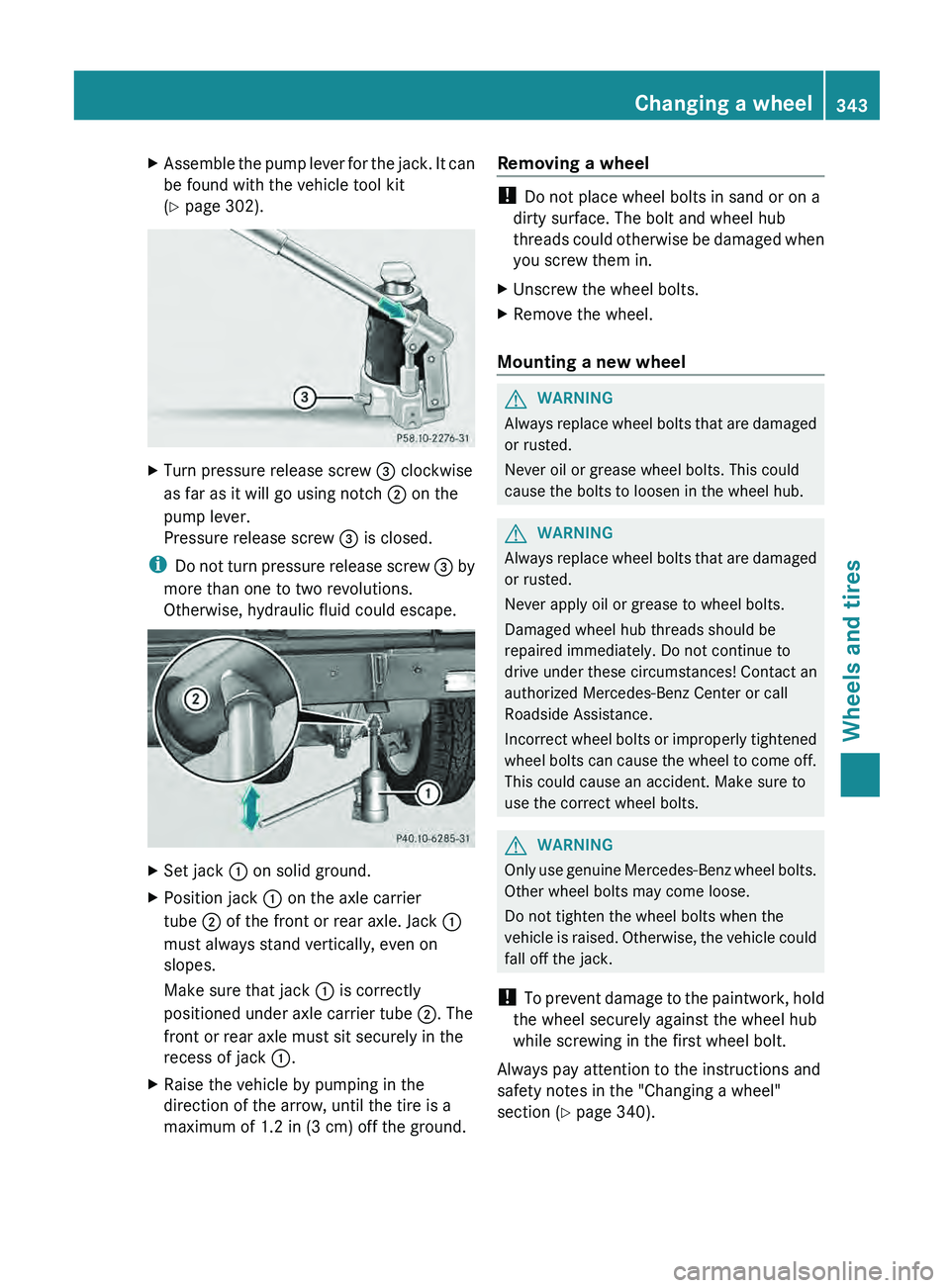

Assemble the pump lever for the jack. It can

be found with the vehicle tool kit

(Y page 302). X

Turn pressure release screw 0087 clockwise

as far as it will go using notch 0044 on the

pump lever.

Pressure release screw 0087 is closed.

i Do not turn

pressure

release screw 0087 by

more than one to two revolutions.

Otherwise, hydraulic fluid could escape. X

Set jack 0043 on solid ground.

X Position jack 0043 on the axle carrier

tube 0044 of the front or rear axle. Jack 0043

must always stand vertically, even on

slopes.

Make sure that jack 0043 is correctly

positioned under axle carrier tube 0044. The

front or rear axle must sit securely in the

recess of jack 0043.

X Raise the vehicle by pumping in the

direction of the arrow, until the tire is a

maximum of 1.2 in (3 cm ) off the ground.Removing a wheel !

Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be

damaged when

you screw them in.

X Unscrew the wheel bolts.

X Remove the wheel.

Mounting a new wheel G

WARNING

Always replace wheel bolts that are damaged

or rusted.

Never oil or grease wheel bolts. This could

cause the bolts to loosen in the wheel hub. G

WARNING

Always replace wheel bolts that are damaged

or rusted.

Never apply oil or grease to wheel bolts.

Damaged wheel hub threads should be

repaired immediately. Do not continue to

drive under these circumstances! Contact an

authorized Mercedes-Benz Center or call

Roadside Assistance.

Incorrect wheel bolts or

improperly tightened

wheel bolts can cause the wheel to come off.

This could cause an accident. Make sure to

use the correct wheel bolts. G

WARNING

Only use genuine Mercedes-Benz wheel bolts.

Other wheel bolts may come loose.

Do not tighten the wheel bolts when the

vehicle is raised. Otherwise,

the vehicle could

fall off the jack.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel"

section ( Y page 340). Changing a wheel

343

Wheels and tires Z

Page 354 of 364

!

To ensure the longevity and full

performance of the engine, only premium-

grade unleaded gasoline may be used.

If there is no premium-grade unleaded

gasoline available and regular unleaded

gasoline must be used,

please observe the

following precautions:

R only fill the fuel tank to half full with

regular unleaded gasoline and fill the rest

with premium-grade unleaded gasoline

as soon as possible.

R do not drive at the maximum speed.

R avoid sudden acceleration.

R if the vehicle is carrying a light load, e.g.

two passengers without luggage, do not

allow the engine to rev above 3000 rpm.

R if the vehicle is fully loaded or is being

operated in mountainous terrain, do not

depress the accelerator pedal further

than 00C3 of the pedal travel.

! Use a filter when refueling from a fuel can.

Otherwise, the fuel lines and/or injection

system could be blocked by particles from

the fuel can.

Only refuel using premium-grade unleaded

gasoline with a minimum octane rating of 91.

Reformulated Gasoline (RFG) and/or

unleaded gasoline with additives can be used.

The concentration of additives in the fuel,

however, must not exceed 10%, e.g.:

R Ethanol

R TAME

R ETBE

R IPA

R TBA

For MTBE, the concentration should not

exceed 15%.

The concentration of methanol in gasoline,

including other additives, must not exceed

3%.

Using mixtures of methanol and ethanol is not

permitted. Gasohol, a mixture of 10% ethanol

and 90% unleaded gasoline, may be used. All of these mix fuels must fulfill the fuel

requirements, e.g.:

R

knock resistance

R boiling point

R vapor pressure

You will usually find

information about the fuel

grade on the pump. If you cannot find the

label on the pump, ask the staff for

assistance.

i For further information, consult an

authorized Mercedes-Benz Center or on

the Internet at http://www.mbusa.com

(USA only).

Information on refueling (Y page 153).

AMG vehicles

! Only refuel using super-grade unleaded

gasoline with at least 98 RON/88 MON

that conforms to European standard

EN 228 or an equivalent specification.

You could otherwise impair engine output

or damage the engine.

! Premium-grade unleaded gasoline with

an octane rating of 95 RON/85 MON may

be used as a temporary measure if the

recommended fuel is not available. This

may reduce engine performance and

increase fuel consumption. Do not drive at

full throttle.

! Regular unleaded gasoline with an octane

rating of 91 RON/82.5 MON may also be

used as an emergency measure if the

recommended fuel is not available.

Doing so results in noticeably higher fuel

consumption, and the engine power output

is noticeably reduced. Avoid driving at full

throttle.

If only regular unleaded gasoline with an

octane rating of 91 RON/82.5 MON or

lower is available, you must have the

vehicle adapted to this fuel at a qualified

specialist workshop. 352

Service products and filling capacities

Technical data

Page 358 of 364

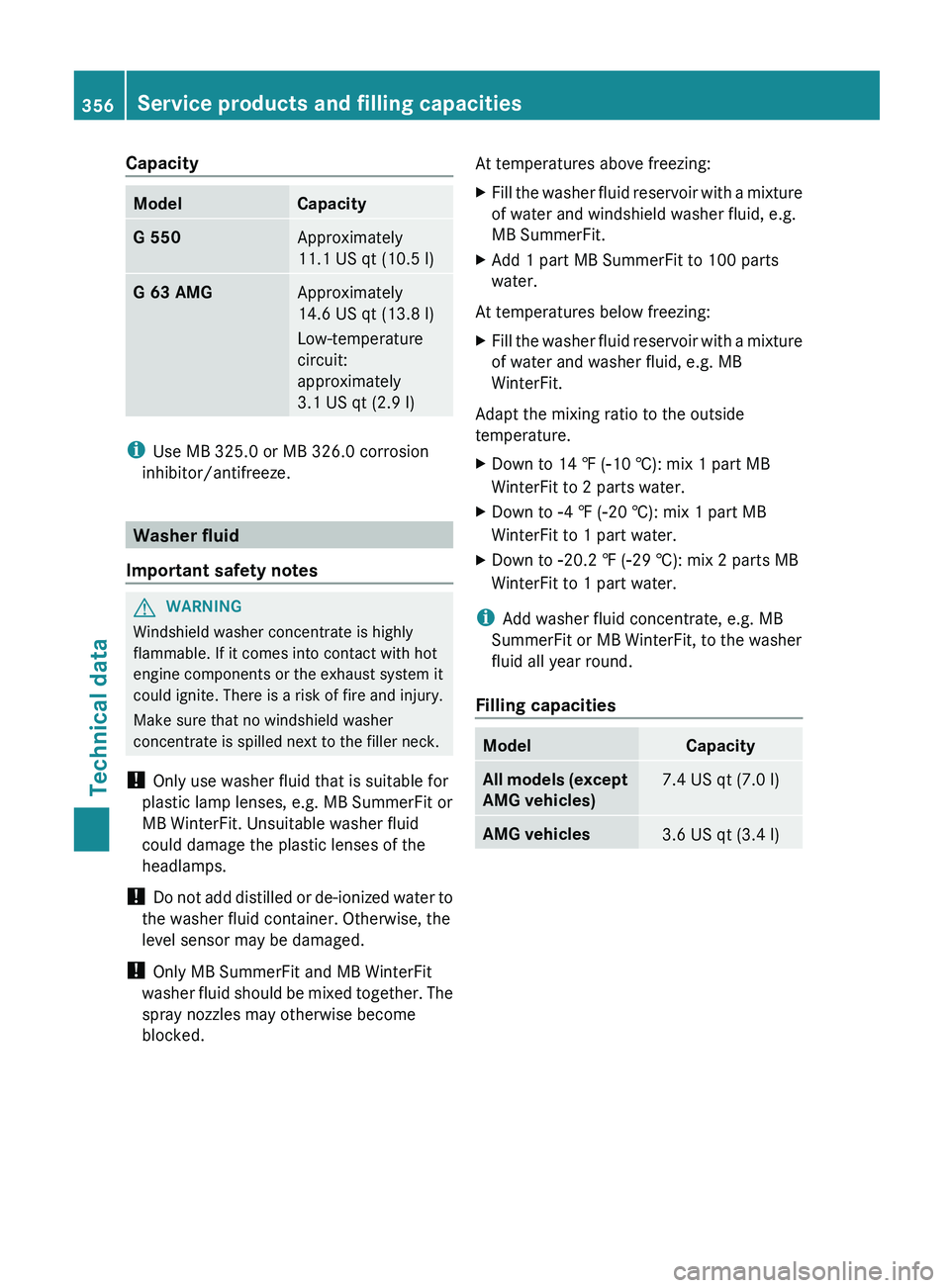

Capacity

Model Capacity

G 550

Approximately

11.1 US qt (10.5 l)

G 63 AMG

Approximately

14.6 US qt (13.8 l)

Low-temperature

circuit:

approximately

3.1 US qt (2.9 l)

i

Use MB 325.0 or MB 326.0 corrosion

inhibitor/antifreeze. Washer fluid

Important safety notes G

WARNING

Windshield washer concentrate is highly

flammable. If it comes into contact with hot

engine components or the exhaust system it

could ignite. There is a risk of fire and injury.

Make sure that no windshield washer

concentrate is spilled next to the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of the

headlamps.

! Do not add distilled

or de-ionized water to

the washer fluid container. Otherwise, the

level sensor may be damaged.

! Only MB SummerFit and MB WinterFit

washer fluid should be mixed together. The

spray nozzles may otherwise become

blocked. At temperatures above freezing:

X

Fill the washer fluid reservoir with a mixture

of water and windshield washer fluid, e.g.

MB SummerFit.

X Add 1 part MB SummerFit to 100 parts

water.

At temperatures below freezing:

X Fill the washer fluid reservoir with a mixture

of water and washer fluid, e.g. MB

WinterFit.

Adapt the mixing ratio to the outside

temperature.

X Down to 14 ‡ (00FC10 †): mix 1 part MB

WinterFit to 2 parts water.

X Down to 00FC4 ‡ (00FC20 †): mix 1 part MB

WinterFit to 1 part water.

X Down to 00FC20.2 ‡ (00FC

29 †): mix 2 parts MB

WinterFit to 1 part water.

i Add washer fluid concentrate, e.g. MB

SummerFit or MB WinterFit, to the washer

fluid all year round.

Filling capacities Model Capacity

All models (except

AMG vehicles)

7.4 US qt (7.0 l)

AMG vehicles

3.6 US qt (3.4 l)356

Service products and filling capacities

Technical data