lock MERCEDES-BENZ G-CLASS SUV 2016 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2016Pages: 261, PDF Size: 6.01 MB

Page 243 of 261

For further information on displaying this mes-

sage, refe rtothe "Checking the tyre pressure

electronically" section (Y page 240).

Important safety notes It is the driver's responsibility to set the tyre

pressure to the recommended cold tyre pres-

sure suitable for the operating situation

(Y page 238). Note that the correc ttyre pres-

sure for the current operating situation must

first be learnt by the tyre pressure monitor. If a

substantial loss of pressure occurs, the warning threshold for the warning message is aligned to

the learnt reference values. Restart the tyre

pressure monitor after adjusting to the cold tyre pressure (Y page 241). The current pressures

are saved as new reference values. This ensures that awarning message appears only if the tyre

pressure drops significantly.

The tyre pressure monitor does not warn you of

an incorrectly set tyre pressure. Observe the

notes on the recommended tyre pressure

(Y page 238).

The tyre pressure monitor is not abletow arn

you of asudden loss of pressure, e.g. if the tyre

is penetrated by aforeign object. In this event,

bring the vehicle to ahalt by braking carefully.

Avoid abrupt steering manoeuvres.

The tyre pressure monitor has ayellow h

warning lamp on the instrument cluster for indi-

cating apressure loss or malfunction. Depend-

ing on how the warning lamp flashe sorlights up,

at yre pressure that is too low or amalfunction in

the tyre pressure monitor is indicated:

R if the h warning lamp is lit continuously,

the tyre pressure on one or more tyres is sig-

nificantly too low. The tyre pressure monitor

is not malfunctioning.

R if the h warning lamp flashe sfor around a

minute and then remains lit constantly, the

tyre pressure monitor is malfunctioning.

In addition to the hwarning lamp,am essage

appears in the multifunction display. Observe

the information on display messages

(Y page 150).

It may take up to ten minutes for amalfunction

of the tyre pressure monitor to be indicated .A

malfunction willbei ndicated by thehtyre

pressure warning lamp flashing for approx-

imatel yone minute and then remaining lit. When

the faulth as been rectified, the htyre pres-

sure warning lamp goes out after driving for a

few minutes. The tyre pressure values indicated by the on-

board computer may differ from those meas-

ured at

afilling station using apressure gauge.

The tyre pressures shown by the on-board com-

puter refer to those measured at sea level. At

high altitudes, the tyre pressure values indica-

ted by apressure gauge are higher than those

shown by the on-board computer. In this case,

do not reduce the tyre pressures.

The operation of the tyre pressure monitor can

be affected by interferenc efrom radio transmit-

ting equipment (e.g. cordless headphones, two- way radios) that may be being operated in or

near the vehicle.

Checking the tyrep ressureelectroni-

cally X

Make sure that the key is in position 2in the

ignition lock.

X Press the =or; button on the steering

wheel to select the Serv.

Serv. menu.

X Press the 9or: button to select

Tyre pressure

Tyre pressure.

X Press the abutton.

The multifunction display shows the current

tyre pressure of each wheel.

If the vehicle has been parked for over

20 minutes, the Tyre pressures will be Tyre pressures will be

displayed

displayed after a

after afew

fewminutes

minutes of

ofdriv‐

driv‐

ing

ing message appears.

After ateach-in period, the tyre pressure moni-

tor automaticallyd etects new wheels or new

sensors. As long as aclear allocation of the tyre

pressure valuestot he individual wheels is not

possible,t heTyre

Tyre pressure

pressure monitor

monitoractive

active

displaym essage is shown instead of the tyre

pressure display. The tyre pressures are already being monitored.

If as pare wheel is fitted, the system may con-

tinue to show the tyre pressure of the wheel that has been removed for afew minutes. Please

note that in this case, the value displayed for the

replaced wheel does not indicate the current

tyre pressure of the spare wheel.

Warning messages of the tyre pressure monitor If the tyre pressure monitor detects

apressure

loss in one or more tyres, awarning messag eis

shown on the multifunction display. The yellow

h tyre pressure warning lamp then lights up. 240

Tyre pressureWheels and tyres

Page 244 of 261

R

If the Rectify tyre pressure

Rectify tyre pressure message

appears in the multifunction display, the tyre

pressure in at least one tyre is too low. The

tyre pressure must be corrected when the

opportunity arises.

R If the Check Check tyre(s)

tyre(s) message appears in the

multifunction display, the tyre pressure in at

least one tyre has droppe dsignificantly. The

tyres must be checked.

R If the Warning tyre defect Warning tyre defect message

appears in the multifunction display, the tyre

pressure in at least one tyre has droppe dsud-

denly.T he tyres must be checked.

Observe the instructions and safety notes in the display messages in the "Tyres" section

(Y page 150).

If the positio nofthe wheelsont he vehicle is

changed, the tyre pressures may be displayedin the wrong positions for ashort time. After afew

minutes of driving, this is rectified and the tyre

pressures are displayedint he correct positions.

Restarting the tyre pressure monitor When you restart the tyre pressure monitor, all

existing warning messages are deleted and the

h

warning lamp goes out. The monitor uses

the currently set tyre pressures as the reference valuesf or monitoring. In most cases, the tyre

pressure monitor will automatically detect the

new reference values after you have changed

the tyre pressure. However, you can also set

reference values manually as described here.

The tyre pressure monitor then monitors the

new tyre pressure values.

X Use the table on the inside of the fuel filler flap

to ensure that the tyre pressure is set cor-

rectly in all four tyres for the curren toperating

conditions.

Observe the notes on tyre pressure

(Y page 238).

X Make sure that the key is in position 2in the

ignition lock.

X Press the =or; button on the steering

wheel to select the Serv.

Serv. menu.

X Press the 9or: button to select

Tyre pressure Tyre pressure .

X Press the abutton.

The multifunction display shows the current

tyre pressure for each tyre or the Tyre

Tyre pres‐

pres‐ sures

sures

will

willbe

bedisplayed

displayed after a

after afew

few

minutes of driving

minutes of driving message appears.

X Press the :button.

The Use

Use current

current pressures

pressures as

asnew

new ref‐

ref‐

erence

erence values

valuesmessage appears in the mul-

tifunction display.

If you wish to confirm the restart:

X Press the abutton.

The Tyre

Tyre press.

press. monitor

monitor restarted

restarted mes-

sage appears in the multifunction display.

After you have driven for afew minutes, the

system checks whether the current tyre pres-

sures are within the specified range. The new tyre pressures are then accepted as refer-

ence valuesa nd monitored.

If you wish to cancelt he restart:

X Press the %button.

The tyre pressure valuess tored at the last

restart will continue to be monitored.

Radio type approval for the tyre pres-

sure monitor country Radi

otype approva lnumber Argentina Schrader GG4

Numero de Registro CNC:

H-12338

Brazil see below

Abu

Dhabi,

Dubai,

United

Arab Emi-

rates TRA

REGISTERED NO:

ER0099792/12.

DEALER NO: DA0047074/10

European

Union Hereby, Schrader Electronics

Ltd., declare

sthat this TPM Sisin

compliance with the essential

requirements and other provi-

sions of directive 1999/5/EC.

The declaration of conformity

may be consulted at emcteam@

schrader.co.uk Tyre pressure

241Wheels and tyres Z

Page 247 of 261

X

Stop the vehicl eonsolid,non-slipper yand

level ground.

X Appl ythe parking brake.

X Move the front wheel stothe straight-ahead

position.

X Shif tthe automatic transmissio ntoposition

P.

X Switch off the engine.

X Ifat raile risc oupled to the vehicle, uncouple

it.

X Remove the vehicl etool sand jack from the

vehicl e(Ypage 223).

X Remove the spare wheel from the spare wheel

bracket (Y page 223).

X Secure the vehicl eagains trolling away.

Securing the vehicle against rolling

away X

Place chocks or other suitable items under

the front and rea rofthe wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle G

WARNING

If you do not position the jack correctl yatthe

appropriate jacking point of the vehicle, the

jack coul dtip over with the vehicl eraised.

There is arisk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically,d irectly under

the jacking point of the vehicle.

! Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

coul ddamage the vehicle.

Observe the following whenr aisingthe vehi-

cle:

R Use only the vehicle-specific jack that has

been tested and approved by Mercedes-Benz

to rais ethe vehicle. If the jack is used incor-

rectly, it coul dtip over while the vehicl eis

raised.

R The jack is designed only to rais ethe vehicle

for ashort time while awhee lisb eing

changed .Itisnot permissible to use it to per-

form maintenance work under the vehicle. R

Avoid changing the whee lonuphilland down-

hill slopes.

R Before raising the vehicle, secur eitagainst

rolling away by applying the parking brake and

positioning whee lchocks. Do not release the

parking brake whil ethe vehicl eisraised.

R The jack must be place donafirm, flatand

non-slip surface. On aloo se surface, alarge,

fla tload-beari ng underlay must be used .Ona

slippery surface, anon-slip underlay must be

used ,e.g.u se arubber matont iles.

R Do not us ewoode nblocks or similar objects

as ajack underlay .Otherwise, the jack will not

be able to achieve its load-bearing capacity

du etot he restricte dheight.

R Ensure tha tthe distance between the under-

side of the tyr eand the ground does not

exceed 3cm.

R Do not place your hands or fee tunder the

raised vehicle.

R Do not li eunder the raised vehicle.

R Do not start the engine when the vehicl eis

raised.

R Do not open or close adoorw hent he vehicle

is raised.

R Ensure tha tnopersons ar epresent in the

vehicl ewhenr aisin gthe vehicle. X

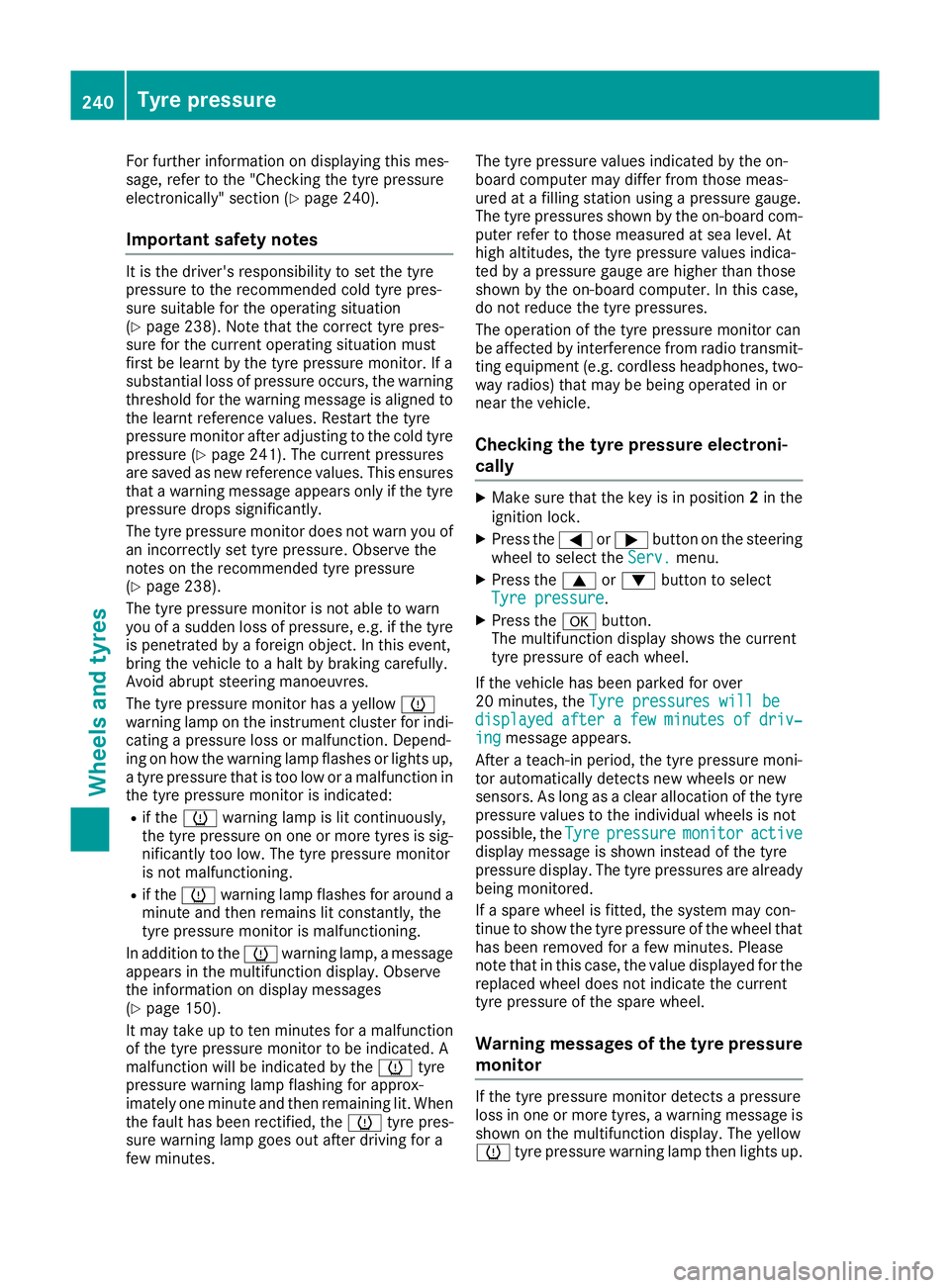

Using wheel wrench :,loosen the bolts on

the wheel you wish to change by abouto ne

full turn. Do not unscrew the bolts completely. 244

Changing

awheelWheels and tyres

Page 248 of 261

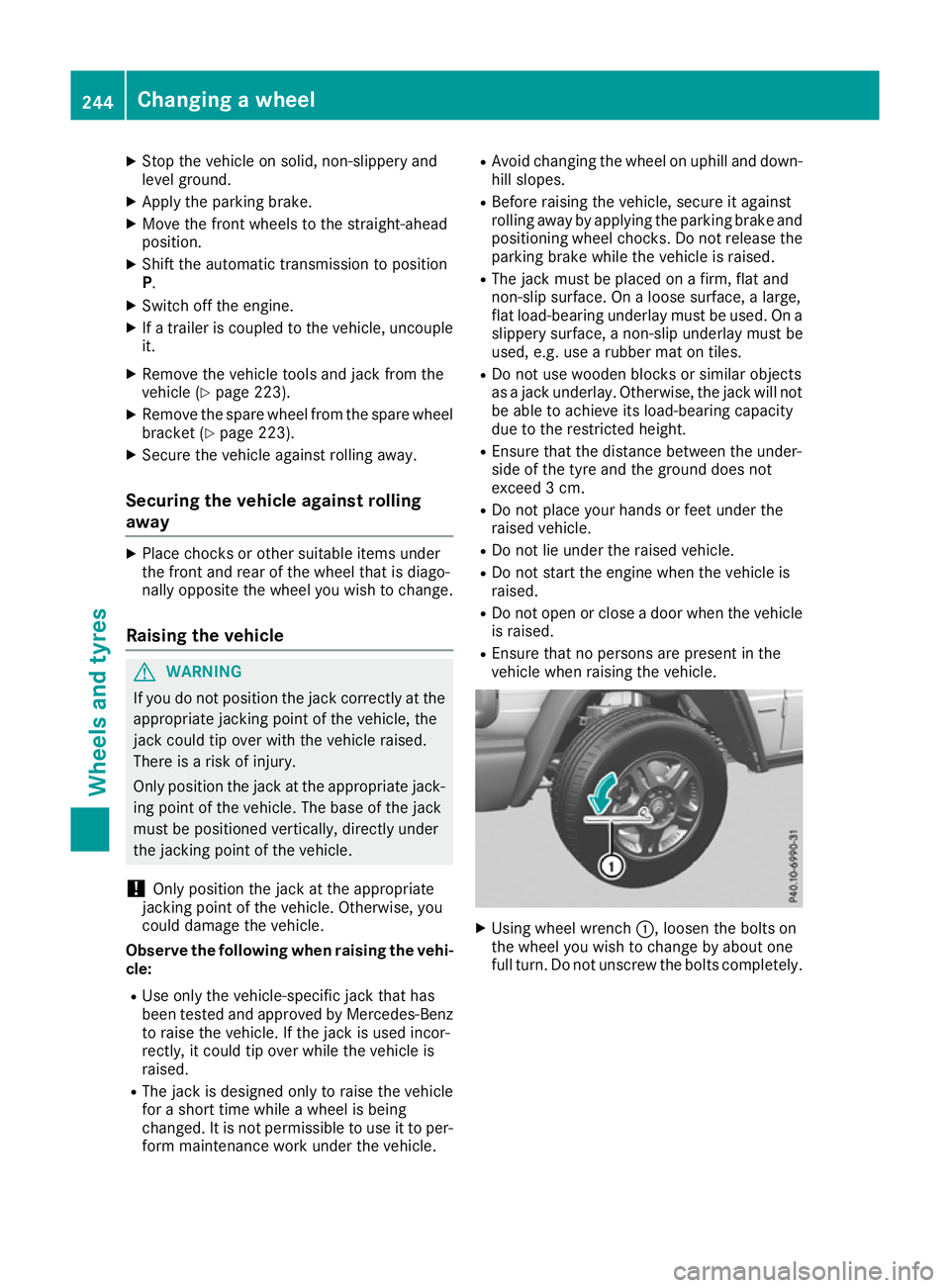

X

Assembl ethe pump lever for the jack from the

vehicl etool kit. X

Tur nlowering screw =on the jack clockwise

as far as it will go using notch ;on the pump

lever.

Pressure release screw =is closed.

i Do not turn pressure release screw

=by

more than one to two revolutions. Otherwise,

hydrauli cfluid could escape. X

Position jack Avertically under the jacking

point of axle carrier tube ?.

X Keep pumping until axle carrier tube ?sits

securely in the recess of jack Aand the base

of the jack lies evenly on the ground. Ensure that th

ejack is locate dverticall yunder

the jacking point.

X Rais ethe vehicl ebypumping unti lthe tyr eis

no mor ethan3cmo ff the ground.

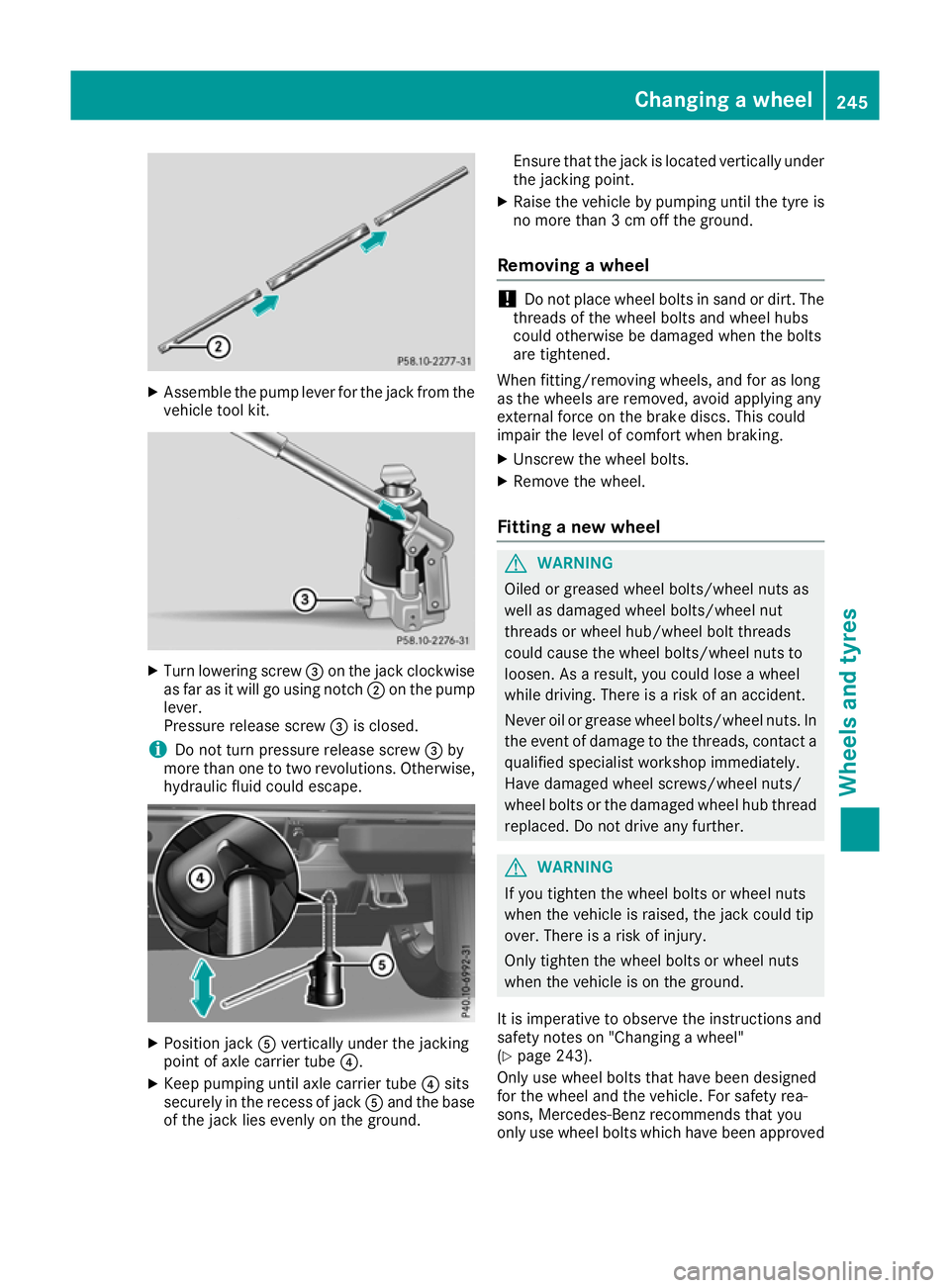

Removing awheel !

Do no

tplace wheel bolts in sand or dirt. The

threads of the wheel bolts and wheel hubs

could otherwise be damagedw hen the bolts

are tightened.

When fitting/removing wheels, and for as long

as the wheels are removed, avoid applying any

external force on the brake discs. This could

impair the level of comfort when braking.

X Unscrew the wheel bolts.

X Remove the wheel.

Fitting anew wheel G

WARNING

Oiled or greased wheel bolts/wheel nuts as

well as damaged wheel bolts/wheel nut

threads or wheel hub/wheel bolt threads

could cause the wheel bolts/wheel nuts to

loosen. As aresult, you coul dlose awheel

while driving. There is arisk of an accident.

Never oil or grease whee lbolts/wheel nuts. In

the event of damage to the threads, contact a

qualified specialist worksho pimmediately.

Have damaged whee lscrews/wheel nuts/

whee lbolts or the damaged whee lhub thread

replaced. Do not drive any further. G

WARNING

If you tighten the whee lbolts or whee lnuts

when the vehicl eisraised, the jack coul dtip

over. There is arisk of injury.

Only tighten the whee lbolts or whee lnuts

when the vehicl eisonthe ground.

It is imperative to observe the instructions and

safety notes on "Changing awheel"

(Y page2 43).

Only use whee lbolts that have been designed

for the whee land the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use whee lbolts which have been approved Changing

awheel

245Wheels an dtyres Z

Page 257 of 261

The antifreeze/corrosion inhibitor concentra-

tion in the engine cooling system should:

R be at least 50%. This will protec tthe engine

cooling system against freezin gdown to

approximately -37 †.

R not exceed 55% (antifreez eprotection down

to -45 †). Heat will otherwise not be dissipa-

ted as effectively.

Mercedes-Benz recommends an antifreeze/

corrosion inhibitor in accordanc ewith MB Spec-

ifications for Servic eProducts 310.1.

i When the vehicle is first delivered, it is filled

with acoolant mixture that ensures adequate

antifreeze and corrosion protection.

i The coolant is checked at specified intervals

at aq ualified specialist workshop. Windscreen and headlamp cleaning

system

Importants afety notes G

WARNING

If windscreen washer concentrate comes into contact with hot components of the engine or

the exhaust system, it can ignite. There is a

risk of fire and injury.

Make sure the windscreen washer concen-

trate does not come into contact with the filler neck.

! Do not use distille

dorde-ionised water in

the washer flui dreservoir. Otherwise, the

leve lsensor may be damaged.

! Only the washer fluids SummerFi

tand Win-

terFit can be mixed. Otherwise, the spraying

nozzles coul dbecome blocked.

Do not use distilledord e-ionised water.Other-

wise, the leve lsensor may give afalser eading.

When handling washer fluid, observe the impor- tant safety notes on service products

(Y page2 50).

At temperatures above freezing:

X Fill the washer flui dreservoir with amixture of

water and washer fluid, e.g. MB SummerFit.

Mix 1part MB SummerFi tto100 parts water. At temperatures belo

wfreezing:

X Fillthe washe rfluid reservoi rwitham ixture of

water and washe rfluid ,e.g.MBW interFit.

For the correct mixing ratio ,refer to the infor-

matio nont he antifreeze reservoir.

i Add washe

rfluid concentrate ,e.g.MBS um-

merFit or MB WinterFit, to the washe rfluid all

year round. Vehicl

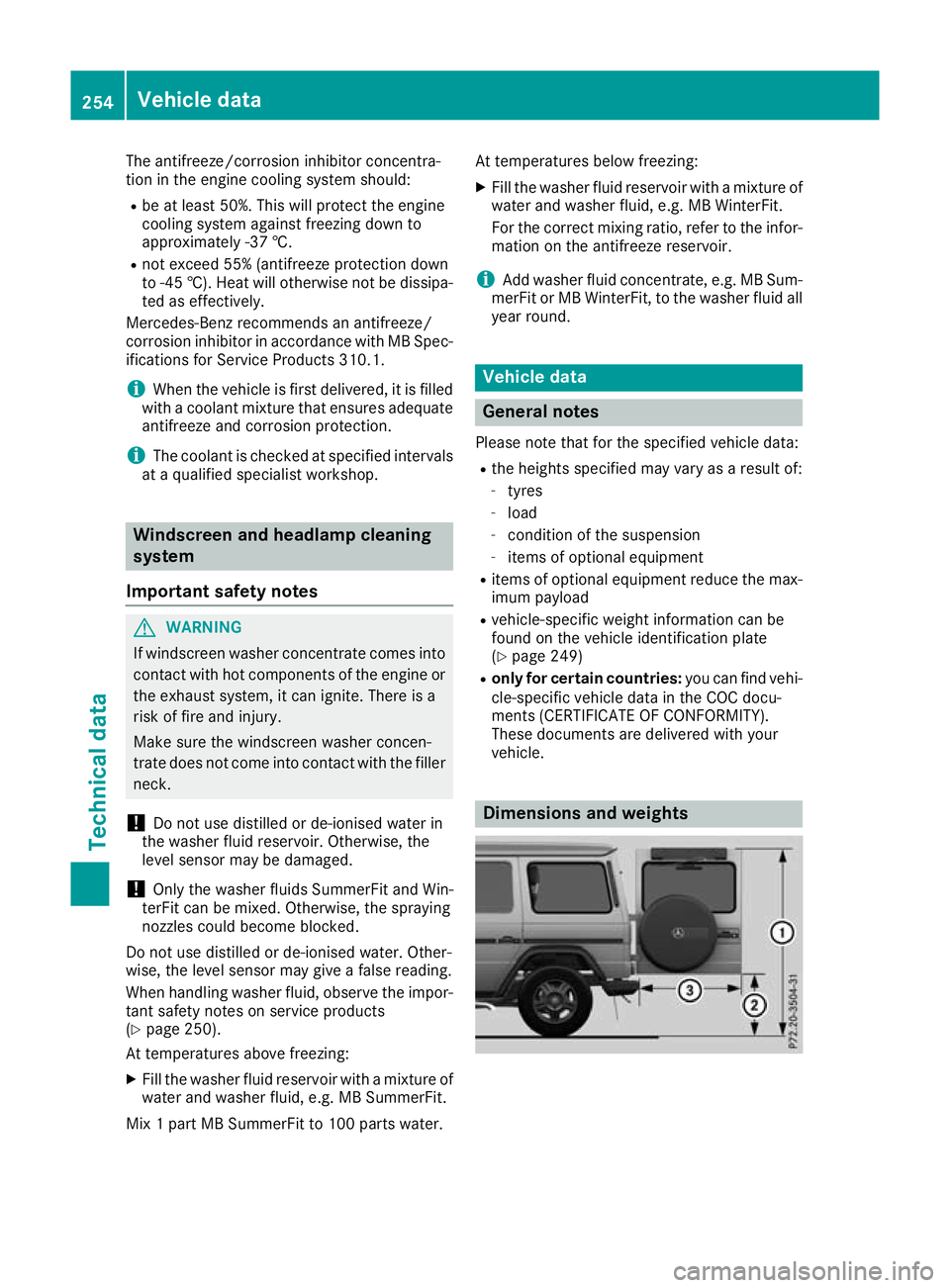

edata General notes

Please note that for the specified vehicle data:

R the heig htss pecified may vary as aresulto f:

- tyres

- load

- condition of the suspension

- items of optional equipment

R items of optional equipment reduce the max-

imum payload

R vehicle-specific weight information can be

found on the vehicle identification plate

(Y page 249)

R onlyf or certain countries: you can find vehi-

cle-specific vehicle data in the COC docu-

ments (CERTIFICATE OF CONFORMITY).

These documents are delivered with your

vehicle. Dimensions and weights254

Vehicle dataTechnical data