light MERCEDES-BENZ GLB SUV 2019 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLB SUV, Model: MERCEDES-BENZ GLB SUV 2019Pages: 689, PDF Size: 11.39 MB

Page 515 of 689

#

When giving starting assis tance, al ways

make sure that you on lyconnect bat‐

te ry term inals with identical polarity. #

During starting assis tance, you must

obse rveth e described order for con‐

necting and disconnecting the jump

lead. #

Do not connect or disconnect the bat‐

te ry cla mp s while the engine is running. &

WARNING Risk ofexplosion during

ch arging process and starting assis tance

During thech arging process and starting

assis tance, the battery may release an explo‐

sive gas mixture. #

Avoid fire , naked flames, creating

spar ksand smoking. #

Make sure that there is suf ficient venti‐

lation du ring thech arging process and

during starting assis tance. #

Do not lean over a batter y. &

WARNING Risk ofexplosion from a fro‐

zen battery

A dischar ged battery may freeze at temp era‐

tures slightly abo veor below freezing point.

During starting assis tance or battery charg‐

ing, bat tery gas can be released. #

Alw ays allow a battery tothaw before

ch arging it or per form ing starting assis‐

ta nce. If

th e indicator/warning lamps in the instrument

clus ter do not light up at low temp eratures, it is

ve ry likely that the dischar ged battery has fro‐

zen. In this case you may neither jump-s tart the

ve hicle nor charge the batter y.

The service life of a battery that has been

th awe d may be dramatically shor tened. The

st arting characteristics may be impaired, espe‐

cially at low temp eratures.

It is recommended that you ha veathaw ed bat‐

te ry checked at a qualified specialist workshop. *

NO

TEDama gecaused bynumerous or

ex tended attem ptsto start the engine Nume

rous or extended attem ptsto start the

engine may damage the catalytic con verter

due tonon-combu sted fuel. #

Avoid numerous and extended attem pts

to start the engine. Obser

vethefo llowing points during starting

assis tance and when charging the battery:

R Only use undamaged jump lead/charging

cables with a suf ficient cross-section and

insula tedte rm inal clamps.

R Non- insulated parts of thete rm inal clamps

must not come into con tact wi thother me tal

parts while the jump lead/charging cable is

connected tothe battery/jump-s tart connec‐

tion point.

R The jump lead/charging cable must not

come into contact wi thany parts which may

mo vewhen the engine is running.

R Alw ays make sure that nei ther you nor the

battery is elect rostatically charge d. 512

Breakdown assis tance

Page 517 of 689

#

During starting assi stance: start the

engine of the donor vehicle and run at idle

speed. #

Connect the negative pole of the donor bat‐

te ry and ear thpoint 3ofyour ow nve hicle

by using the jump lead/charging cable. Begin

with the donor battery firs t. #

During starting assi stance: start the

engine of your ow nve hicle. #

During thech arging process: start the

ch arging process. #

During starting assi stance: letthe engines

ru nfo r se veral minutes. #

During starting assi stance: before discon‐

necting the jump lead, switch on an electrical

consumer in your ow nve hicle, e.g. there ar

wind owheater or lighting.

When thest arting assis tance/charging process

is compl ete: #

First,re mo vethe jump lead/charging cable

from ear thpoint 3and the negative pole of

th e donor batter y,then from positive clamp

2 and the positive pole of the donor bat‐ te

ry. Begin ea chtime wi th the conta cts on

yo ur ow nve hicle firs t. #

Afterre moving the jump lead/charging

cable, close co ver1 of positive clamp 2.

Fu rther information can be obtained at a quali‐

fi ed specialist workshop. Re

placing the 12V battery #

Obser vethe no tes on the12 V battery

(/ page 509).

Mercedes-Benz recommends that you ha vethe

12 V battery replaced at a qualified specialist

wo rkshop, e.g. at a Mercedes-Benz Service

Centre.

Obser vethefo llowing no tes if youwa ntto

re place the battery yourself:

R Alw aysre place a faulty bat tery with a battery

which meets the specific vehicle require‐

ments.

The vehicle is equipped with an AGMtech nol‐

ogy battery (Absorbent Glass Mat). Fullve hi‐

cle functionality is only guaranteed with an AG

M batter y.Fo r saf etyre asons, Mercedes-

Benz recommends that you on lyuse bat ter‐

ies which have been tested and appr ovedfor

yo ur vehicle byMercedes-Benz.

R Carryover de tach able parts, such as vent

hoses, elbow fittings or term inal co vers from

th e battery being replaced.

R Make sure that theve nt hose is al ways con‐

nected tothe original opening on the side of

th e batter y.

Fit any existing or supplied cell caps.

Otherwise, gases or battery acid could

escape.

R Make sure that de tach able parts are recon‐

nected in the same way. To

w- starting or towing away Pe

rm itted towing me thods Mercedes-Benz

recommends transporting your

ve hicle in the case of a breakdown, rath er than

to wing it away. 514

Breakdown assis tance

Page 529 of 689

#

Comply with there commended tyre

pressure and check the tyre pressure of

all tyres including the spare wheel regu‐

larly:

R at least once a month

R when the load changes

R before embarking on a lon ger journey

R if operating conditions change, e.g. off-

ro ad driving #

Adjust the tyre pressure as necessar y.Ty

re pressure which is too high or too low can:

R Shor tenth e service life of the tyres.

R Cause increased tyre damage.

R Adversely af fect driving characteristics and

th us driving saf ety, e.g. due toaquaplaning. &

WARNING Risk of accident from repea‐

te d tyre pressure drop

If th e tyre pressure drops repeatedly, the

wheel, valve or tyre may be damaged. Insuf

ficient tyre pressure can cause the tyres

to bur st. #

Inspect the tyre for signs of fore ign

objects. #

Check whe ther the wheel or valve has a

leak. #

Ifyo u are unable torectify the damage,

conta ct aqualified specialist workshop. Information on

there commended tyre pressure

fo rth eve hicle's factor y-fitted tyres can be found

on the tyre pressure table on the inside of the

fuel filler flap (/ page 526).

Use a suitable pressure gauge tocheck the tyre

pressure. The outer appearance of a tyre does

not permit any reliable conclusion about the tyre

pressure.

Ve hicles with a tyre pressure monitoring sys‐

te m: you can also check the tyre pressure using

th e on-board computer. Only cor

rect tyre pressures when the tyres are

cold. Conditions for cold tyres:

R The vehicle has been par ked with the tyres

out of direct sunlight for at least thre e hours.

R The vehicle has tr avelled less than 1.6 km.

A rise in the tyre temp erature of 10°C increases

th e tyre pressure byappr ox.10 kPa (0.1 bar/

1. 5 psi). Take this into account when checking

th e tyre pressure of warm tyres.

Note s on trailer operation

Alw ays inflate there ar axle tyres tothere com‐

mended tyre pressures on the tyre pressure

ta ble for increased load. Ty

re pressure table The tyre pressure

table is on the inside of the

fuel filler flap. 526

Wheels and tyres

Page 530 of 689

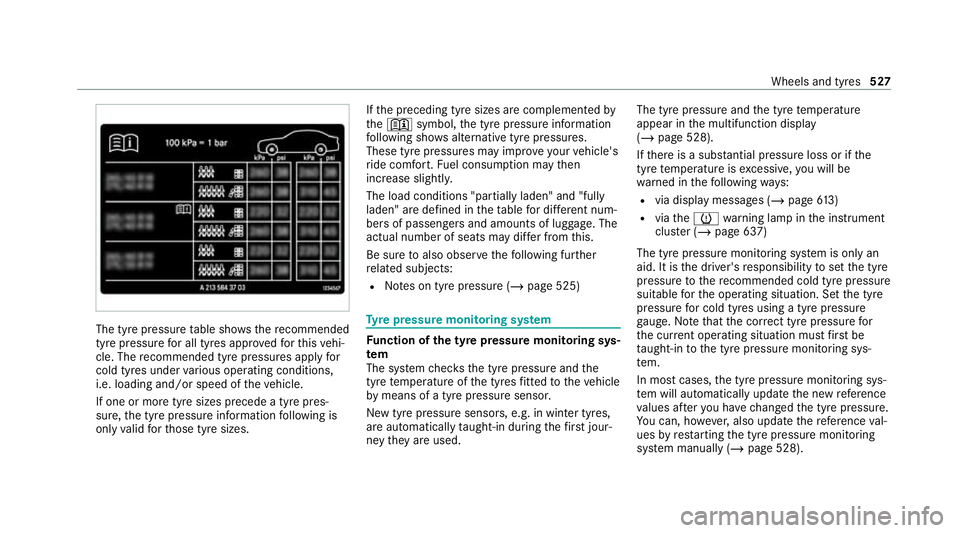

The tyre pressure

table sho ws there commended

tyre pressure for all tyres appro vedfo rth is vehi‐

cle. The recommended tyre pressures apply for

cold tyres under various operating conditions,

i.e. loading and/or speed of theve hicle.

If one or more tyre sizes precede a tyre pres‐

sure, the tyre pressure information following is

only valid forth ose tyre sizes. If

th e preceding tyre sizes are complemented by

th e+ symbol, the tyre pressure information

fo llowing sho wsalternative tyre pressures.

These tyre pressures may impr oveyour vehicle's

ri de comfort. Fuel consum ption may then

increase slightl y.

The load conditions "partially laden" and "fully

laden" are defined in theta ble for dif fere nt num‐

be rs of passengers and amounts of luggage. The

actual number of seats may dif fer from this.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 525) Ty

re pressure moni toring sy stem Fu

nction of the ty repressure moni toring sys‐

tem

The sy stem checks the tyre pressure and the

tyre temp erature of the tyres fitted totheve hicle

by means of a tyre pressu resensor.

New tyre pressure sensors, e.g. in winter tyres,

are automatically taught-in during thefirs t jour‐

ney they are used. The tyre pressure and

the tyre temp erature

appear in the multifunction display

(/ page 528).

If th ere is a subs tantial pressure loss or if the

tyre temp erature is excessive, you will be

wa rned in thefo llowing ways:

R via display messa ges (/ page613)

R viatheh warning lamp in the instrument

clus ter (/ page 637)

The tyre pressu remonitoring sy stem is only an

aid. It is the driver's responsibility toset the tyre

pressure tothere commended cold tyre pressure

suitable forth e operating situation. Set the tyre

pressure for cold tyres using a tyre pressu re

ga uge. No tethat the cor rect tyre pressure for

th e cur rent operating situation mu stfirs t be

ta ught-in tothe tyre pressure monitoring sys‐

te m.

In most cases, the tyre pressure monitoring sys‐

te m will auto maticallyupdate the new refere nce

va lues af teryo u ha vechanged the tyre pressure.

Yo u can, ho wever,also update there fere nce val‐

ues byrestarting the tyre pressure monitoring

sy stem manually (/ page 528). Wheels and tyres

527

Page 549 of 689

#

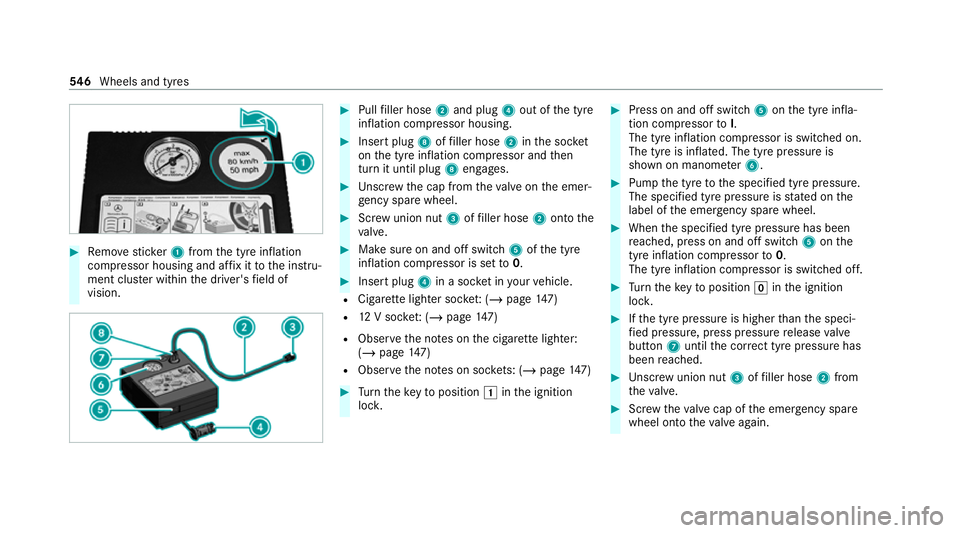

Remo vesticke r1 from the tyre inflation

compressor housing and af fix it tothe instru‐

ment clus ter within the driver's field of

vision. #

Pull filler hose 2and plug 4out of the tyre

inflation compressor housing. #

Insert plug 8offiller hose 2inthe soc ket

on the tyre inflation compressor and then

turn it until plug 8engages. #

Unscr ew the cap from theva lve on the emer‐

ge ncy spa rewheel. #

Screw union nut 3offiller hose 2onto the

va lve. #

Make sure on and off switch 5ofthe tyre

inflation compressor is set to0. #

Insert plug 4in a soc ket in your vehicle.

R Cigar ette lighter soc ket: ( / page 147)

R 12V soc ket: ( / page 147)

R Obse rveth e no tes on the cigar ette lighter:

(/ page 147)

R Obse rveth e no tes on soc kets: (/ page 147) #

Turn theke yto position 1inthe ignition

loc k. #

Press on and off switch 5onthe tyre infla‐

tion compressor toI.

The tyre inflation compressor is switched on.

The tyre is inflated. The tyre pressure is

shown on manome ter6. #

Pump the tyre tothe specified tyre pressure.

The specified tyre pressure is stated on the

label of the emer gency spa rewheel. #

When the specified tyre pressure has been

re ached, press on and off swit ch5 onthe

tyre inflation compressor to0.

The tyre inflation compressor is switched off. #

Turn theke yto position ginthe ignition

loc k. #

Ifth e tyre pressure is higher than the speci‐

fi ed pressure, press pressure release valve

bu tton 7until the cor rect tyre pressure has

been reached. #

Unscr ew union nut 3offiller hose 2from

th eva lve. #

Screw theva lve cap of the emer gency spa re

wheel onto theva lve again. 546

Wheels and tyres

Page 563 of 689

Information on coolant is

available at thefo l‐

lowing locations:

R inthe Mercedes-Benz Specifications for

Operating Fluids 310.1

- at https://be vo.mercedes-benz.com

- inthe Mercedes-Benz BeVo App

R at a qualified specialist workshop *

NO

TEOverheating at high outside tem‐

peratures If an inapp

ropriate coolant is used, the

engine cooling sy stem is not suf ficiently pro‐

te cted against overheating and cor rosion at

high outside temp eratures. #

Alw ays use coolant appr ovedby

Mercedes-Benz. #

Obser vethe instructions in the

Mercedes-Benz Specifications for Oper‐

ating Fluids3 10.1 . Ha

ve the coolant regularly replaced at a qualified

specialist workshop. The proportion of cor

rosion inhibitor/antifreeze

concentrate in the engine cooling sy stem should

be:

R a minimum of 50% (antifreeze pr otection

down toappr oximately -37 °C)

R a maximum of 55% (antifreeze pr otection

down to-45 °C) Note

s on windscreen washer fluid Obser

vethe no tes on operating fluids

(/ page 552). &

WARNING ‑ Risk of fire and injury due to

windscreen washer concentrate

Wi ndsc reen washer concentrate is highly

fl ammable. It could ignite if it comes into

con tact wi thhot engine component parts or

th eex haust sy stem. #

Make sure that no windsc reen washer

concentrate spills out next tothefiller

opening. *

NO

TEDama getotheex terior lighting

due tounsuitable windsc reen washer

fl uid Uns

uitable windsc reen washer fluids may

damage the plastic sur face of theex terior

lighting. #

Only use windscreen washer fluids

which are also suitable for use on plas‐

tic sur faces, e.g. MB SummerFit or MB

Wi nterFit. *

NO

TEBlocked spr aynozzles caused by

mixing windscreen washer fluids #

Do not mix MB SummerFit and MB Win‐

te rFit with other windscreen washer flu‐

ids. Do not use distilled or de-ionised

water asthefill

le ve l sensor may be triggered er roneously.

Re commended windscreen washer fluid:

R Abo vefreezing point: e.g. MB SummerFit

R Below freezing point: e.g. MB WinterFit 560

Tech nical da ta

Page 570 of 689

Occupant saf

ety Display messages

Possible causes/consequences and M

MSolutions

6 Restraint sys. malfunction

Consult workshop *T

herestra int sy stem is malfunctioning (/ page 36). &

WARNING Risk of inju rydue tomalfunctions in there stra int sy stem

If th ere stra int sy stem is malfunctioning, restra int sy stem components may be triggered unintentionally or may

not deploy as intended during an accident. This may af fect the seat belt tensioner or airbag, forex ample. #

Have there stra int sy stem checked and repaired immediately at a qualified specialist workshop. Re

cognition of a restra int sy stem fault:

R The restra int sy stem warning lamp 6does not light up when the ignition is switched on.

R The restra int sy stem warning lamp 6lights up continuously or repeatedly during a journe y. #

Consult a qualified specialist workshop immediatel y.

6

Front left malfunction Con-

sult workshop (examp le) *T

he cor responding restra int sy stem is malfunctioning (/ page 36). &

WARNING Risk of inju rydue tomalfunctions in there stra int sy stem

If th ere stra int sy stem is malfunctioning, restra int sy stem components may be triggered unintentionally or may

not deploy as intended during an accident. This may af fect the seat belt tensioner or airbag, forex ample. #

Have there stra int sy stem checked and repaired immediately at a qualified specialist workshop. Display messages and

warning/indicator lamps 567

Page 571 of 689

Display messages

Possible causes/consequences and M

MSolutions

Re cognition of a restra int sy stem fault:

R The restra int sy stem warning lamp 6does not light up when the ignition is switched on.

R The restra int sy stem warning lamp 6lights up continuously or repeatedly during a journe y. #

Consult a qualified specialist workshop immediatel y.

6

Left windowbag malfunc-

tion Consult work-

shop (examp le) *T

he cor responding window airbag is malfunctioning (/ page 36). &

WARNING Risk of inju ryor fata l injury due toa malfunction in the window airbag

The window airbag might be triggered unintentionally or might not be triggered at all in theeve nt of an accident

wi th high deceleration. #

Have the window airbag checked and repaired immediately at a qualified specialist workshop. #

Consult a qualified specialist workshop immediatel y.

Front-passenger airbag dis-

abled See Owner's Manual *T

he front passenger airbag has been disabled eventh ough an adult or a person with an adult stature is on the front

passenger seat. If additional forc es are applied tothe seat, thewe ight the sy stem de tects may be too lo w. &

WARNING ‑ Risk of inju ryor eve nfa ta l injury when the front passenger airbag is disabled

If th e front passenger airbag is disabled, It will not be deplo yed in theeve nt of an accident and cannot pe rform

its intended pr otective function. 568

Display messages and warning/indicator lamps

Page 576 of 689

Lights

Display messages

Possible causes/consequences and M

MSolutions

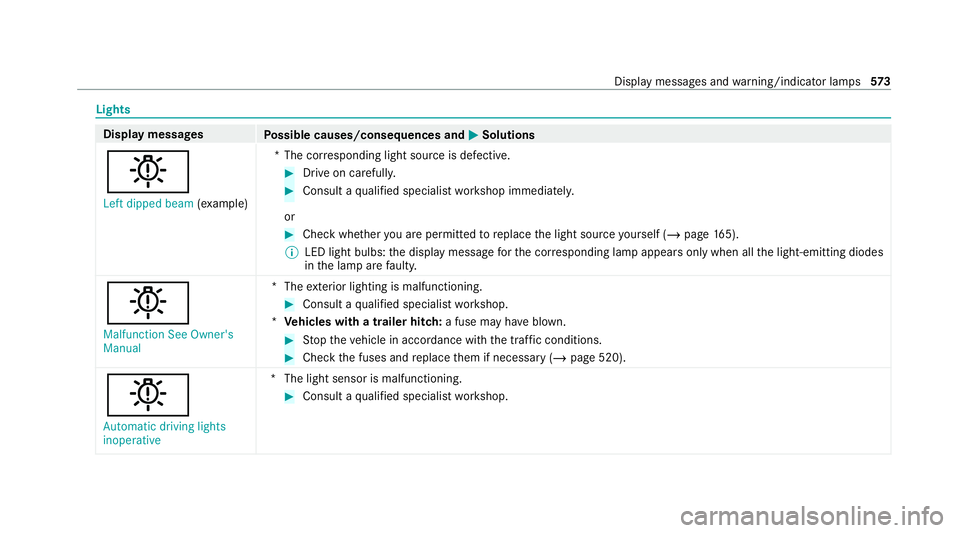

b Left dipped beam (examp le) *T

he cor responding light source is defective. #

Drive on carefully. #

Consult a qualified specialist workshop immediatel y.

or #

Check whe ther you are permit tedto replace the light source yourself (/ page165).

% LED light bulbs: the display message forth e cor responding lamp appears only when allthe light-emitting diodes

in the lamp are faulty.

b

Malfunction See Owner's

Manual *T

heexterior lighting is malfunctioning. #

Consult a qualified specialist workshop.

* Ve hicles with a trailer hitch: a fuse may haveblown. #

Stop theve hicle in accordance with the tra ffic conditions. #

Check the fuses and replace them if necessary (/ page 520).

b

Automatic driving lights

inoperative *T

he light sensor is malfunctioning. #

Consult a qualified specialist workshop. Display messages and

warning/indicator lamps 573

Page 577 of 689

Display messages

Possible causes/consequences and M

MSolutions

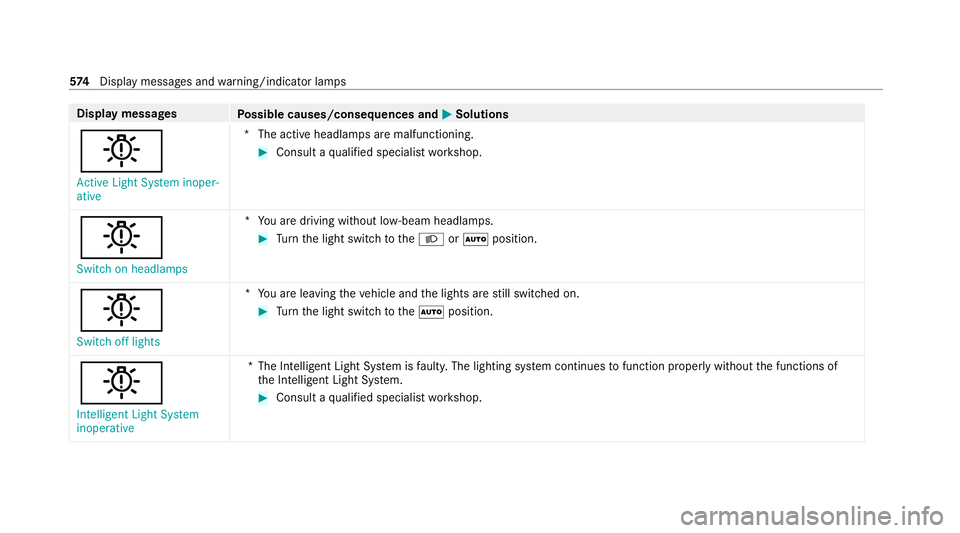

b Active Light System inoper-

ative *T

he active headlamp s are malfunctioning. #

Consult a qualified specialist workshop.

b Switch on headlamps *Y

ou are driving without lo w-beam headlamps. #

Turn the light switch totheL orà position.

b

Switch off lights *Y

ou are leaving theve hicle and the lights are still switched on. #

Turn the light switch totheà position.

b Intelligent Light System

inoperative *T

he Intelligent Light Sy stem is faulty. The lighting sy stem continues tofunction properly without the functions of

th e Intelligent Light Sy stem. #

Consult a qualified specialist workshop. 574

Displaymessa ges and warning/indicator lamps