brake MERCEDES-BENZ METRIS 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2016Pages: 310, PDF Size: 7.28 MB

Page 280 of 310

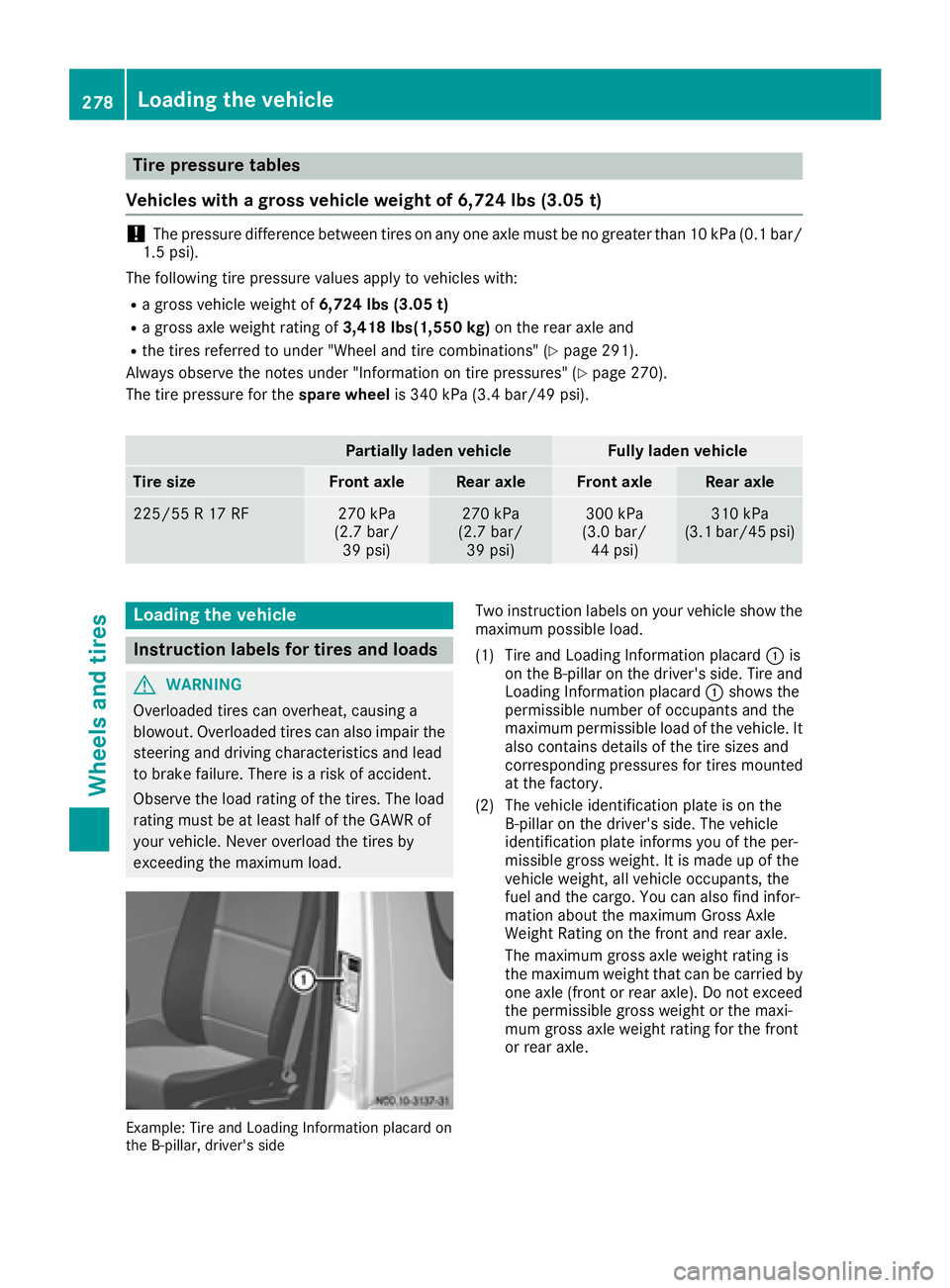

Tire pressure tables

Vehicle swithag ross vehicle weight of 6,724 lb s(3.05 t)

!The pressure differenc ebetween tire sonany one axl emustbenog reaterthan1 0kPa (0.1 ba r/

1.5 psi).

The following tire pressure values apply to vehicles with:

Rag ross vehicle weight of 6,724 lbs (3.05 t)

Ragross axle weight rating of 3,418 lbs(1,550 kg)on the rear axle and

Rthe tires referredtounder"Wheel and tire combinations" (Ypag e291).

Always observe the notes unde r"Information on tire pressures "(

Ypage270).

The tire pressure for the spare wheelis 340 kPa (3.4 bar/49 psi).

Partiallyladen vehicleFully laden vehicle

Tire sizeFron taxleRear axleFron taxleRear axle

225/55 R17RF270 kPa

(2.7 bar/ 39 psi)270 kPa

(2.7 bar/ 39 psi)300 kPa

(3.0 bar/ 44 psi)310 kPa

(3.1 bar/45 psi)

Loading the vehicle

Instruction labels for tires and loads

GWARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the steering and driving characteristics and lead

to brake failure. There is arisk of accident.

Observe the loa drating of the tires. The load

rating must be at least hal fofthe GAWR of

you rvehicle. Never overload the tires by

exceeding the maximu mload.

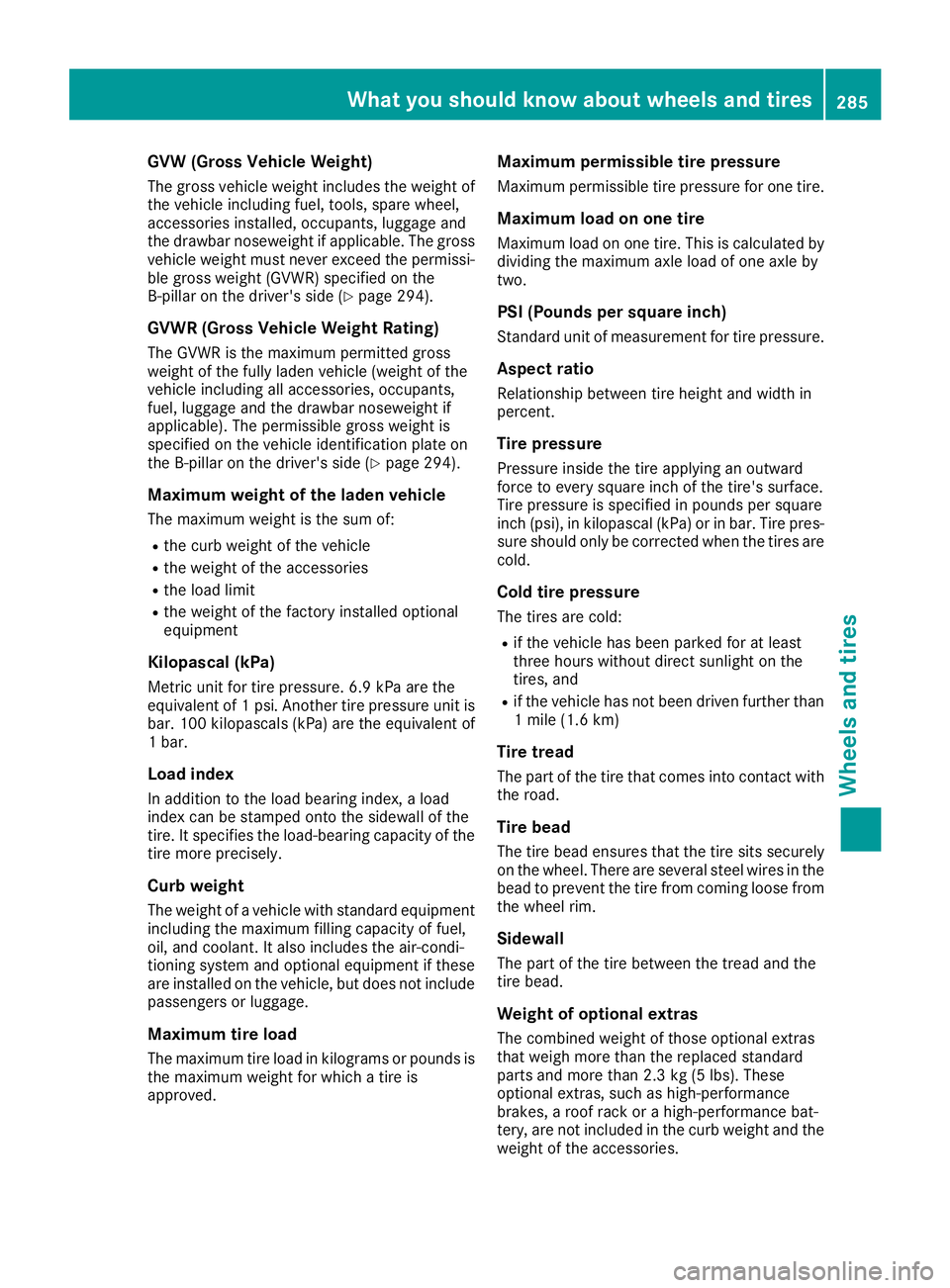

Example: Tire and Loading Information placard on

the B-pillar, driver's side

Two instructio nlab elsony ourvehicle show the

maximu mpossibl eload.

(1) Tire and Loading Information placard :is

on the B-pillar on the driver's side .Tire and

Loading Information placard :showst he

permissible numbe rofoccupants and the

maximu mpermissible loa dofthe vehicle. It

also contains details of the tire sizes and

corresponding pressures for tires mounted

at the factory.

(2) The vehicle identification plate is on the B-pillar on the driver's side .The vehicle

identification plate informs you of the per-

missible gross weight. It is made up of the

vehicle weight, al lvehicle occupants, the

fuel and the cargo .You can also find infor-

matio nabout the maximu mGrossAxle

Weight Rating on the front and rear axle.

The maximu mgross axle weight rating is

the maximu mweight that can be carrie dby

one axle (front or rear axle). Do not exceed the permissible gross weight or the maxi-

mum gross axle weight rating for the front

or rear axle.

278Loading the vehicle

Wheels and tires

Page 287 of 310

GVW (Gross VehicleWeight)

The gross vehicle weight includes the weight of

the vehicle including fuel ,tools, spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight if applicable. The gross

vehicle weight must never exceed the permissi-

ble gross weight (GVWR) specified on the

B-pilla ronthe driver's side (

Ypage 294).

GVWR (Gross Vehicl eWeight Rating)

The GVWR is the maximu mpermitted gross

weight of the full yladen vehicle (weight of the

vehicle including all accessories, occupants,

fuel ,luggage and the drawbar noseweight if

applicable).T he permissibleg ross weight is

specified on the vehicle identification plate on

the B-pilla ronthe driver's side (

Ypage 294).

Maximum weight of the laden vehicle

The maximu mweight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe loadl imit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1psi.A nother tire pressure unit is

bar. 100 kilopascals (kPa) are the equivalent of

1b ar.

Load index

In addition to the loadb earing index,aload

index can be stamped onto the sidewal lofthe

tire. It specifies the load-bearing capacity of the

tire more precisely.

Curb weight

The weight of avehicle with standard equipment

including the maximu mfilling capacity of fuel,

oil, and coolant. It also includes the air-condi-

tioning system and optional equipment if these

are installed on the vehicle ,but does not include

passengers or luggage.

Maximum tire load

The maximu mtire loadink ilograms or pounds is

the maximu mweight for which atire is

approved.

Maximum permissiblet ire pressure

Maximumpermissiblet ire pressure for one tire.

Maximum load on one tire

Maximumloadono ne tire. This is calculated by

dividing

the maximu maxle loadofo ne axle by

two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pressure.

Aspec tratio

Relationshi pbetwee ntire heighta nd width in

percent.

Tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

Tire pressure is specified in pounds per square

inch (psi), in kilopascal (kPa) or in bar. Tire pres-

sure shoul donly be corrected when the tires are

cold.

Col dtire pressure

The tires are cold:

Rif the vehicle has been parked for at least

three hours withou tdirect sunlight on the

tires, and

Rif the vehicle has not been driven further than

1m ile (1.6 km)

Tire tread

The part of the tire that comes into contact with

the road.

Tire bead

The tire beade nsures that the tire sits securely

on the wheel. There are severals teel wiresinthe

beadtop revent the tire from coming loose from

the whee lrim.

Sidewall

The part of the tire betwee nthe tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, aroof rack or ahigh-performance bat-

tery, are not included in the curb weight and the weight of the accessories.

What you shouldk now about wheels and tires285

Wheelsand tires

Z

Page 288 of 310

TIN (Tire IdentificationNumber)

Auniqu eide ntificatio nnumbe rwhich can be

used by atire manufacturer to identify tires, for

exampl efor ap roduct recall ,and thusi dentify

the purchasers. The TIN is compose dofthe

manufacturer identificatio ncode, tire size, tire

model cod eand manufacturing date.

Load bearin gind ex

The load bearing index (als oloa dindex) is acode

thatc ontains the maximu mloadb eari ng capa-

city of atire.

Traction

Tractio nist he resul toffrictio nbetween the tires

and the roa dsurface.

TWR (permissibl etrailer drawbar load)

The TWRist he maximumpermissibl eweigh t

thatm ayact on the ball coupling of the trailer

tow hitch.

Wea rind icator

Narrowb ars( tread wear bars) thata redistrib-

ute doverthe tire tread. If the tire trea dislevel

with the bars, the wear limit of áin (1.6 mm)

hasb eenr eached.

Distribution of the vehicle occupants

The distributio nofvehicleoccupants ove rdes-

ignate dseatp osit ions in avehicle.

Maximum permissible payload weight

Nomina lloa da nd goods/luggage load plus

68 kg (150 lb s)multiplie dbythe number of

seats in the vehicle.

Changing wheels

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severelyi mpair the driving characteristics if

the wheels or tires have different dimensions. The whee lbrakes or suspension components

may als obedamaged. There is arisk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equippedw ithatire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve .This could damage the electronic

components.

Only have tires changed at aqualified spe-

cialist workshop.

Always observe the instructions and safety

notes under "Mounting awheel" (

Ypage 287).

The wea rpatterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before aclear wea rpattern

has formed on the tires. Front tires typically

wea rmore on the shoulders and the rear tires in

the center.

If you rvehicle's tire configuration allows, you

can rotate the wheels according to the intervals

in the tire manufacturer's warranty book in your

vehicled ocuments. If no warranty book is avail-

able, the tires should be rotated every 3,000 to

6,000 mile s(5,000 to 10,000 km) or earlier if

tire wea rrequires. Do not change the direction

of rotation.

Clean the contact surfaces of the whee land the

brake disc thoroughly every time awheelisr ota-

ted. Avoid oily or greas ycleaning agents.

Check the tire pressure and reactivate the tire

pressure monitor if necessary.

Directio nofrotation

Tires with aspecified directio nofrotation have

additional benefits, e.g. if there is arisk of hydro-

planing. You wil lonly gai nthese benefits if the

correct directio nofrotation is observed.

An arrow on the sidewal lofthe tire indicates its

correct directio nofrotation.

You may mount aspare whee lagainst the direc-

tion of rotation. Observe the time restriction on

use as wel lasthe speed limitation specified on

the spare wheel.

Storing wheels

Store wheels that are not being used in acool,

dry and preferably dark place. Protect the tires

from contact with oil, greas eand fuel.

286Changing wheels

Wheel sand tires

Page 289 of 310

Mountingawheel

Vehicle preparation

XStop the vehicleasf ar awayaspossible from

traffic and on alevel, firm and non-slip sur-

face.

XIf you rvehicl eposesar isk to approaching

traffic, switch on the hazar dwarning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XShift the transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the dange rarea

while the whee lisbeing changed .Anyone

who is not directly assisting in the wheel

change should, for example, stand behind the

barrier.

XPlace the warning triangl eorwarning lamp at

as uitable distance.

Observe the lega lrequirements on the cor-

rect use of the warning triangl eorwarning

lamp for the country in which you are cur-

rently driving

XSecure the vehicletop revent it from rolling

away.

Observe the safety notes on parking under

"Driving and parking" (

Ypag e132)

XOn level terrain: place chocks or other suit-

abl eo bjects under the front and rear of the

whee lthat is diagonally opposite the whee lto

be changed.

XOn slight inclines: place chocks or other

suitable objects under the wheels on the front and rear axle sopposite the whee ltobe

changed.

XIf included in the vehiclee quipment, take the

tire-changing tool kit out of the vehiclet ool kit

(

Ypag e260).

Apart from some country-specific variants,

vehicles are not equipped with tire-changing

tools. Some tools for changing awhee lare

specific to the vehicle. Consult aqualified

specialist worksho pfor more information on

which tools are required to perform awheel

change on you rv

ehi cle.

XIf included in the vehiclee quipment, remove

the spare whee lfrom the spare whee lbracket (

Ypag

e292) .Observe the safety notes listed

under "Spare wheel" (Ypag e291).

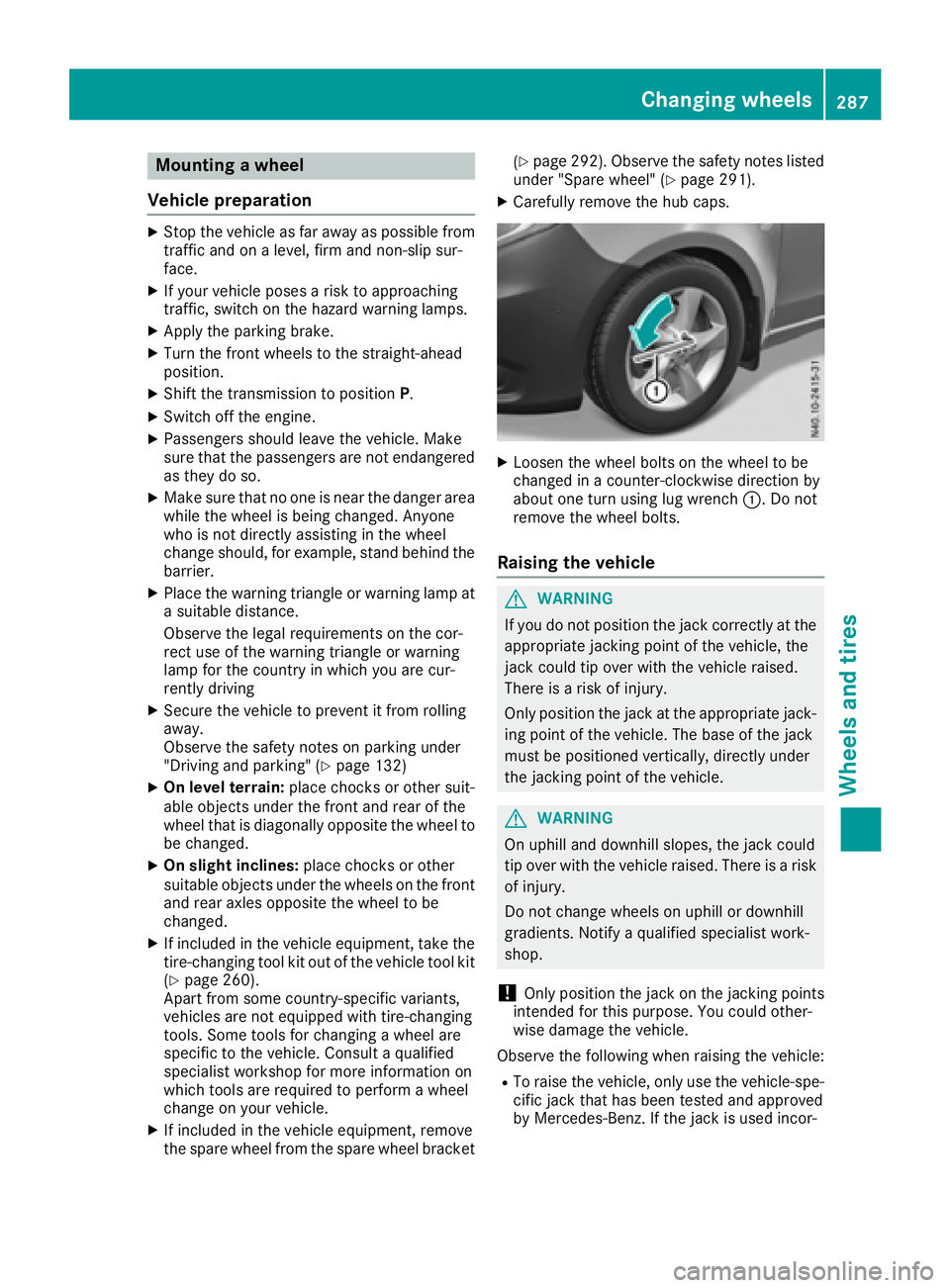

XCarefully remove the hub caps.

XLoosen the whee lbolts on the whee ltobe

changed in acounter-clockwise direction by

about one turn using lug wrench :.Donot

remove the whee lbolts.

Raisingt he vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack coul dtip over with the vehicler aised.

There is arisk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The bas eofthe jack

must be positioned vertically,d irectly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicler aised. There isarisk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify aqualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You coul dother-

wis edamage the vehicle.

Observe the following when raising the vehicle:

RTo rais ethe vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If the jack is use dincor-

Changing wheels287

Wheels and tires

Z

Page 290 of 310

rectly, it could tip over while the vehicleis

raised.

RThe vehicle's jack is intended only to rais ethe

vehicl efor as hort time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the whee lonuphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing awa ybyapplying the parking brake and

inserting whee lchocks. Never disengage the

parking brake while the vehicl eisraised.

RThe jack must be placed on afirm, flat and

non-slip surface. On aloose surface, alarge,

load-bearing underlay must be used .Ona

slippery surface, anon-slip underlay must be

used ,e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place you rhands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicl eis

raised.

RNever open or close adoor or the tailgate/

rear door when the vehicl eisraised.

RMake sure that no persons are present in the

vehicl ewhen the vehicl eisraised.

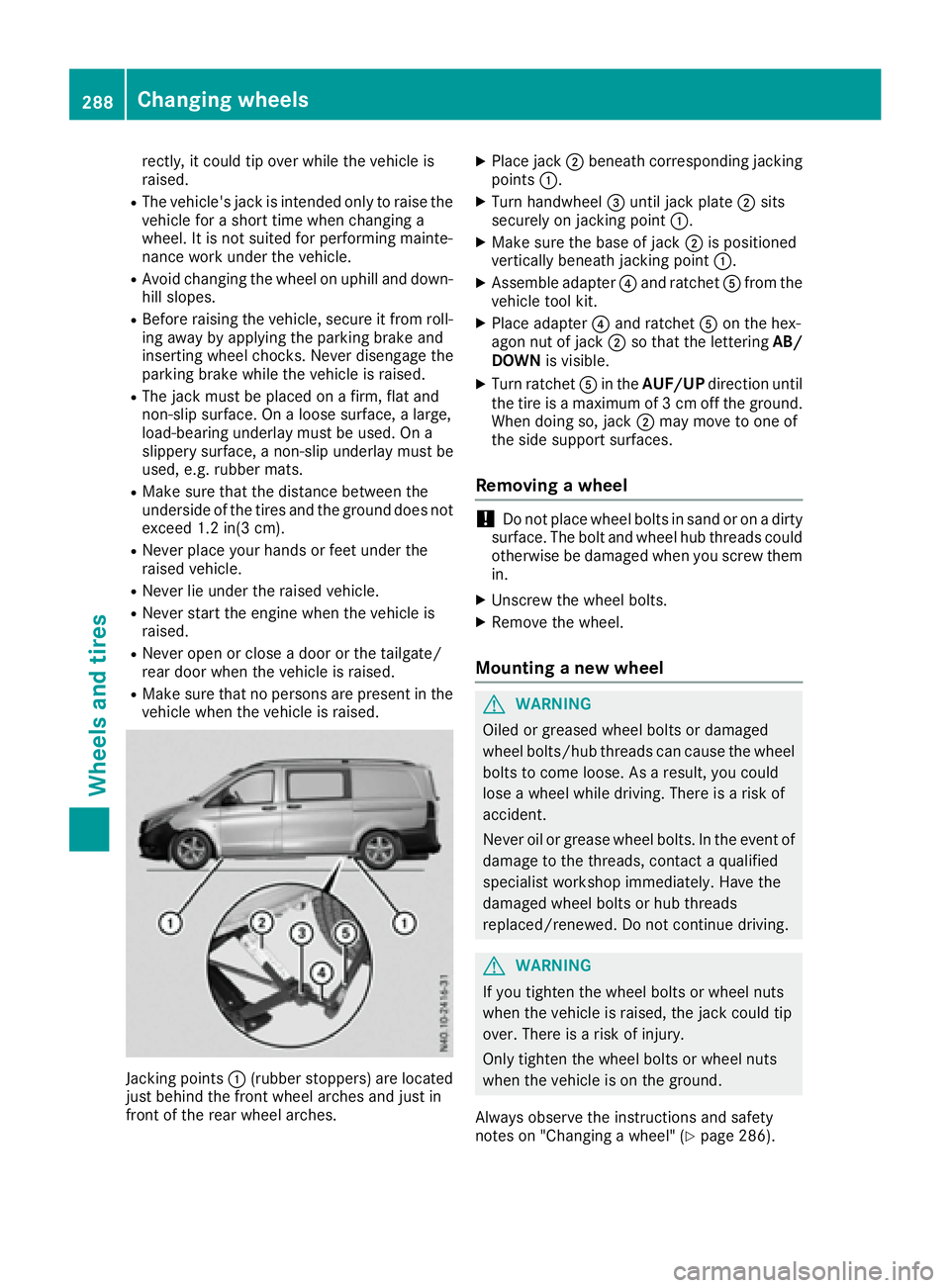

Jacking points :(rubber stoppers)a re located

just behind the front whee larches and just in

front of the rear whee larches.

XPlace jack ;beneath corresponding jacking

points :.

XTurn handwheel =until jack plate ;sits

securely on jacking point :.

XMake sure the base of jack ;is positioned

vertically beneath jacking point :.

XAssembleadapter?and ratchet Afrom the

vehicl etool kit.

XPlace adapter ?and ratchet Aon the hex-

agon nut of jack ;so that the lettering AB/

DOWN is visible.

XTurn ratchet Ain the AUF/UP directionuntil

the tire is amaximu mof3cm off the ground.

When doing so, jack ;may move to one of

the side support surfaces.

Removin gawheel

!Do not place whee lbolts in sand or on adirty

surface. The bolt and whee lhub threads could

otherwise be damaged when you screw them

in.

XUnscrew the whee lbolts.

XRemove the wheel.

Mountin ganew wheel

GWARNING

Oile dorg reased whee lbolts or damaged

whee lbolts/hu bthreads can caus ethe wheel

bolts to come loose .Asaresult, you could

lose awhee lwhile driving. There is arisk of

accident.

Never oil or greas ewhee lbolts. In the event of

damage to the threads ,contact aqualified

specialist workshop immediately. Have the

damaged whee lbolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the whee lbolts or whee lnuts

when the vehicl eisraised, the jack could tip

over. There is arisk of injury.

Only tighten the whee lbolts or whee lnuts

when the vehicl eisonthe ground.

Always observe the instructions and safety

notes on "Changing awheel" (

Ypag e286).

288Changing wheels

Wheels and tires

Page 297 of 310

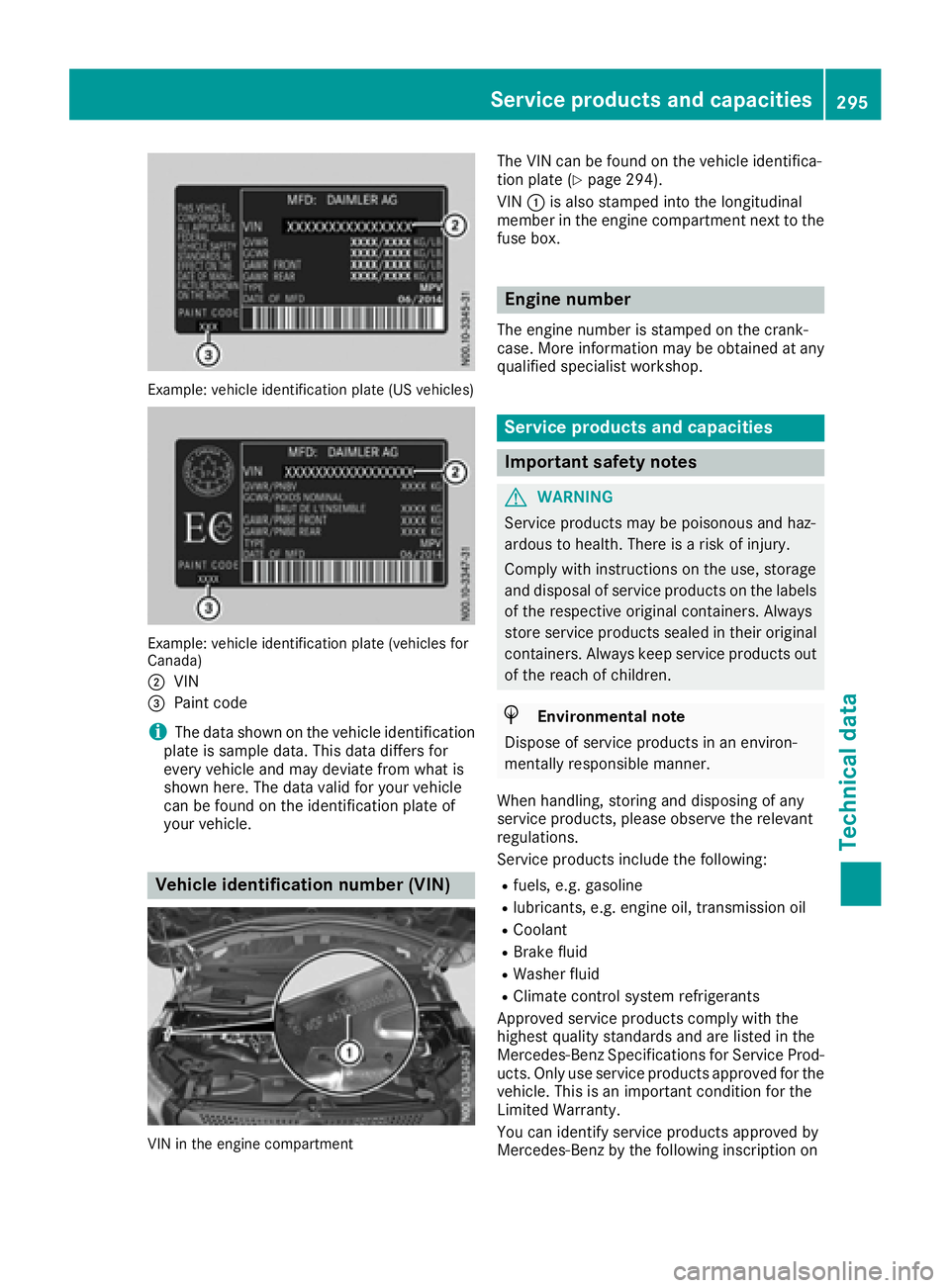

Example: vehicleide ntification plate (US vehicles)

Example: vehicl eide ntification plate (vehicle sfor

Canada)

;

VIN

=Paint code

iThe data shown on the vehicl eide ntification

plate is sampl edata. Thi sdatad iffers for

every vehicl eand mayd eviate from what is

shown here. The data vali dfor your vehicle

can be found on the identificatio nplate of

your vehicle.

Vehicl eidentificatio nnumber (VIN)

VIN in the engine compartment

The VIN can be found on the vehicl eide ntifica-

tio np late (Ypage 294).

VIN :is also stampe dinto the longitudinal

membe rinthe engine compartment next to the

fuse box.

Engine number

The engine numbe risstampe donthe crank-

case. Mor einformatio nmaybe obtained at any

qualified specialist workshop.

Service products and capacities

Important safety notes

GWARNING

Service products maybep oisonousand haz-

ardous to health .There is ariskofi njury.

Compl ywithi nstructions on the use, storage

and disposalofs erviceproducts on the labels

of the respective original containers. Always

stor eservic eproducts seale dintheiroriginal

containers. Alway skeeps ervic eproducts out

of the reach of children.

HEnvironmental note

Dispose of servic eproducts in an environ-

mentall yresponsibl emanner.

Whe nhandling ,storing and disposing of any

servic eproducts, please observe the relevant

regulations.

Service products includ ethe following:

Rfuels, e.g .gasoline

Rlubricants ,e.g.e ngine oil, transmission oil

RCoolant

RBrake fluid

RWashe rfluid

RClimate contro lsystem refrigerants

Approve dservic eproducts comply with the

highest quality standards and ar elisted in the

Mercedes-Benz Specifications for Service Prod-

ucts .Onlyu seservic eproducts approved for the

vehicle. Thi sisanimportant condition for the

Limite dWarranty.

Yo uc an identify servic eproducts approved by

Mercedes-Benz by the following inscription on

Servic eproducts and capacities295

Technica ldata

Z

Page 302 of 310

Rear axle

Serviceproduct: transmission oil

Product name/numberMaintenance

interval

Mobilub eFE 75-W-85

Mobilube FE Plus NG

MB Shee tNo. 235.7—

Further information can be obtained at any

qualified specialist workshop.

Brake fluid

GWARNING

The brake fluid constantly absorbsm oisture

from the air. Thi slowers the boiling point of

the brake fluid .Ifthe boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. Thi swould impai rbraking efficiency.

There is ariskofana ccident.

Yo us houl dhavet he brake fluid renewe dat

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber .Ifp aint, plastic or rubber hasc ome into

contact with brake fluid ,rins ew ithw ater

immediately.

Whe nhandling, storing and disposing of brake

fluid ,pleas eobserve the relevant regulations

and the important safety notes for service prod-

ucts (

Ypage 295).

Overap eriodoft ime,the brake fluid absorbs

moistur efrom the air. Thi sreduce sits boiling

point.

Have the brake fluid renewe devery 2years at a

qualified specialist workshop.

iThere is usuall yanotice in the engine com-

partment to remind yo uwhent he next brake

fluid change is due.

Use only approved brake fluid sthat comply with

the Mercedes-Benz Specifications for Service

Products. Alway scheck for the identification

DOT 4plus.

Information abouta pproved brake fluid scan be

obtained:

Rat any qualified specialist workshop

Ron the Interne tat

http://bevo.merced es-benz.com.

Coolant

Important safety notes

GWARNING

If antifreezec omes intocontac twithh ot com-

ponents in th eenginec ompartment, it may

ignite .Thereisar iskoff irea nd injury.

Let th eenginec ooldown before you add anti-

freeze. Makes ure that antifreezeisn otspilled

next to th efille rneck. Thoroughlyc lean the

antifreezef romc omponents before starting

th ee ngine.

!Takec aren otto spill any coolant on painted

surfaces .You coul dotherwise damag ethe

paintwork.

When handling, storin gand disposingofc oolant

and antifreeze, please observ ethe relevan treg-

ulationsa nd theimportant safety note sfor ser-

vic ep roduct s(

Ypage 295).

Coolan tadditive with corrosion and

antifreeze protection

!Use only approved antifreeze/corrosion

inhibitor that complies withMBS pecification

300Service products and capacities

Technical data

for Service Products, Sheet Number 325.

Using other, non-approved antifreeze/corro-

sion inhibitors may causedamage to the cool-

ant system and reduce the engine' sservice

life