cooling MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3381 of 4133

Shown on model 203

Fig. 117: Identifying Pressure Relief Valve And Refrigerant Compressor

- Shown On Model 203

TEMPERATURE CONTROL, FUNCTION - GF83.57-P-2000GH

MODEL 163 up to 31.08.01 with CODE (580) Air conditioning or Tempmatic for USA

Function

The temperature preselected at the temperature selector wheels is reached or kept constant by:

heating up by the heat exchanger,

heating up by the electric heater booster (with engine 612.963 only)

cooling by the evaporator core,

cooling and reheating (reheat mode).

Heating up

The heating system heat exchanger heats the air passing by, which is then conducted into the vehicle interior by

the air ducts.

Heating up by the electric heater booster

Due to the high level of efficiency of the direct-injection diesel engine, the heat output of the coolant is not

sufficient to heat the fresh air. By installing the electric heater booster, behind the heating system heat

exchanger, this heating capacity deficit is compensated.

Pressure relief

valve, positionThe pressure relief valve (3) is located on the refrigerant

compressor (A9).

Pressure relief

valve, taskThe pressure relief valve (3) serves to protect the refrigerant

circuit from damage caused by excess pressure.

Pressure relief

valve, function GF83.55-P-

2104-02P

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 137 © 2006 Mitchell Repair Information Company, LLC.

Page 3382 of 4133

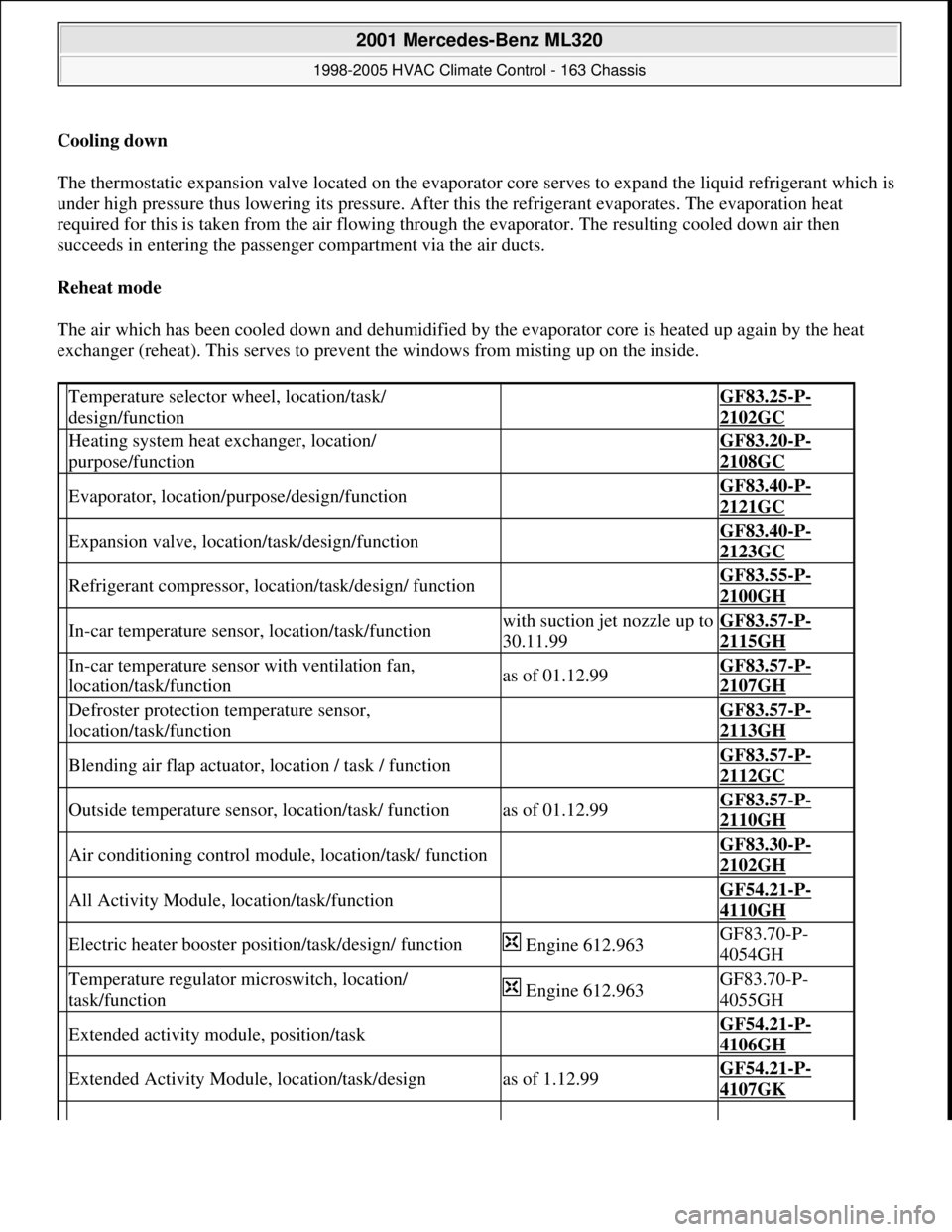

Cooling down

The thermostatic expansion valve located on the evaporator core serves to expand the liquid refrigerant which is

under high pressure thus lowering its pressure. After this the refrigerant evaporates. The evaporation heat

required for this is taken from the air flowing through the evaporator. The resulting cooled down air then

succeeds in entering the passenger compartment via the air ducts.

Reheat mode

The air which has been cooled down and dehumidified by the evaporator core is heated up again by the heat

exchanger (reheat). This serves to prevent the windows from misting up on the inside.

Temperature selector wheel, location/task/

design/function GF83.25-P-

2102GC

Heating system heat exchanger, location/

purpose/function GF83.20-P-

2108GC

Evaporator, location/purpose/design/function GF83.40-P-

2121GC

Expansion valve, location/task/design/function GF83.40-P-

2123GC

Refrigerant compressor, location/task/design/ function GF83.55-P-

2100GH

In-car temperature sensor, location/task/functionwith suction jet nozzle up to

30.11.99GF83.57-P-

2115GH

In-car temperature sensor with ventilation fan,

location/task/functionas of 01.12.99GF83.57-P-

2107GH

Defroster protection temperature sensor,

location/task/function GF83.57-P-

2113GH

Blending air flap actuator, location / task / function GF83.57-P-

2112GC

Outside temperature sensor, location/task/ functionas of 01.12.99GF83.57-P-

2110GH

Air conditioning control module, location/task/ function GF83.30-P-

2102GH

All Activity Module, location/task/function GF54.21-P-

4110GH

Electric heater booster position/task/design/ function Engine 612.963GF83.70-P-

4054GH

Temperature regulator microswitch, location/

task/function Engine 612.963GF83.70-P-

4055GH

Extended activity module, position/task GF54.21-P-

4106GH

Extended Activity Module, location/task/designas of 1.12.99GF54.21-P-

4107GK

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 138 © 2006 Mitchell Repair Information Company, LLC.

Page 3383 of 4133

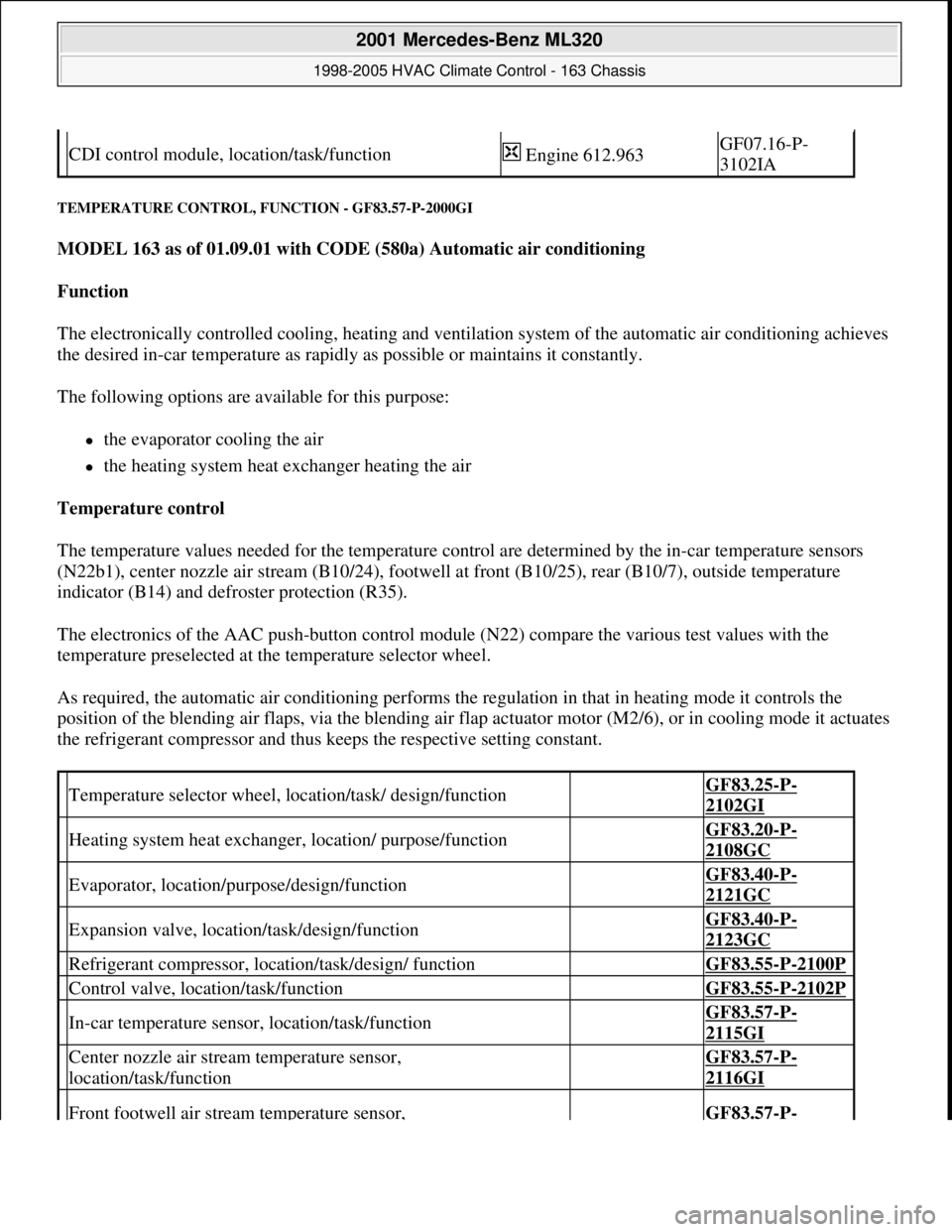

TEMPERATURE CONTROL, FUNCTION - GF83.57-P-2000GI

MODEL 163 as of 01.09.01 with CODE (580a) Automatic air conditioning

Function

The electronically controlled cooling, heating and ventilation system of the automatic air conditioning achieves

the desired in-car temperature as rapidly as possible or maintains it constantly.

The following options are available for this purpose:

the evaporator cooling the air

the heating system heat exchanger heating the air

Temperature control

The temperature values needed for the temperature control are determined by the in-car temperature sensors

(N22b1), center nozzle air stream (B10/24), footwell at front (B10/25), rear (B10/7), outside temperature

indicator (B14) and defroster protection (R35).

The electronics of the AAC push-button control module (N22) compare the various test values with the

temperature preselected at the temperature selector wheel.

As required, the automatic air conditioning performs the regulation in that in heating mode it controls the

position of the blending air flaps, via the blending air flap actuator motor (M2/6), or in cooling mode it actuates

the refrigerant compressor and thus keeps the respective setting constant.

CDI control module, location/task/function Engine 612.963GF07.16-P-

3102IA

Temperature selector wheel, location/task/ design/function GF83.25-P-

2102GI

Heating system heat exchanger, location/ purpose/function GF83.20-P-

2108GC

Evaporator, location/purpose/design/function GF83.40-P-

2121GC

Expansion valve, location/task/design/function GF83.40-P-

2123GC

Refrigerant compressor, location/task/design/ function GF83.55-P-2100P

Control valve, location/task/function GF83.55-P-2102P

In-car temperature sensor, location/task/function GF83.57-P-

2115GI

Center nozzle air stream temperature sensor,

location/task/function GF83.57-P-

2116GI

Front footwell air stream temperature sensor, GF83.57-P-

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 139 © 2006 Mitchell Repair Information Company, LLC.

Page 3398 of 4133

ultimately cause the system to burst. For this reason, all welding and soldering operations on or near closed

air conditioning systems are prohibited. High pressure levels can combine with refrigerant vapors to produce a

mixture that is potentially explosive when exposed to atmospheric air.

Risk of poisoning

Refrigerant can decompose when overheated. The resulting substances are toxic and should never be inhaled.

Risk of injury

Refrigerant vapors are heavier than air; this means that escaping gases pose a risk of suffocation for anyone in a

work pit beneath the vehicle.

Contact with liquid refrigerant may cause chilblain-like damage to the skin (due to under-cooling).

Safety instructions/precautions

All welding, brazing and soldering operations on sealed air conditioning systems and in their

immediate vicinity are prohibited.

Never smoke when working with refrigerant, never expose refrigerant to open flames.

A piercing odor can indicate overheated refrigerant - never inhale these vapors. Leave closed rooms

immediately and ventilate thoroughly.

All refrigerant must be evacuated from the entire air conditioning system prior to doing any repair work

on the air conditioning circuit or components.

Because it poses a hazard to the atmosphere as well as to personal health and safety, discharging

refrigerant directly into the air is prohibited.

Suitable evacuation, treatment and charging devices equipped with integral disposal and treatment

facilities must be used for evacuating refrigerant.

Even after the system has been evacuated, residual pressure may still be present in the system when

loosening couplings. Therefore, loosen the couplings carefully, so that the pressure can dissipate slowly.

Avoid all contact with liquid refrigerant.

Always wear safety glasses and protective gloves when working with refrigerant.

First aid measures

In case of eye contact

Immediately flush with plenty of running water and consult a physician.

In case of skin contact

Consult a physician immediately in case of frostbite. In case of inhalation

of concentrated refrigerant, immediately take victim out into the fresh air and keep victim calm.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 154 © 2006 Mitchell Repair Information Company, LLC.

Page 3402 of 4133

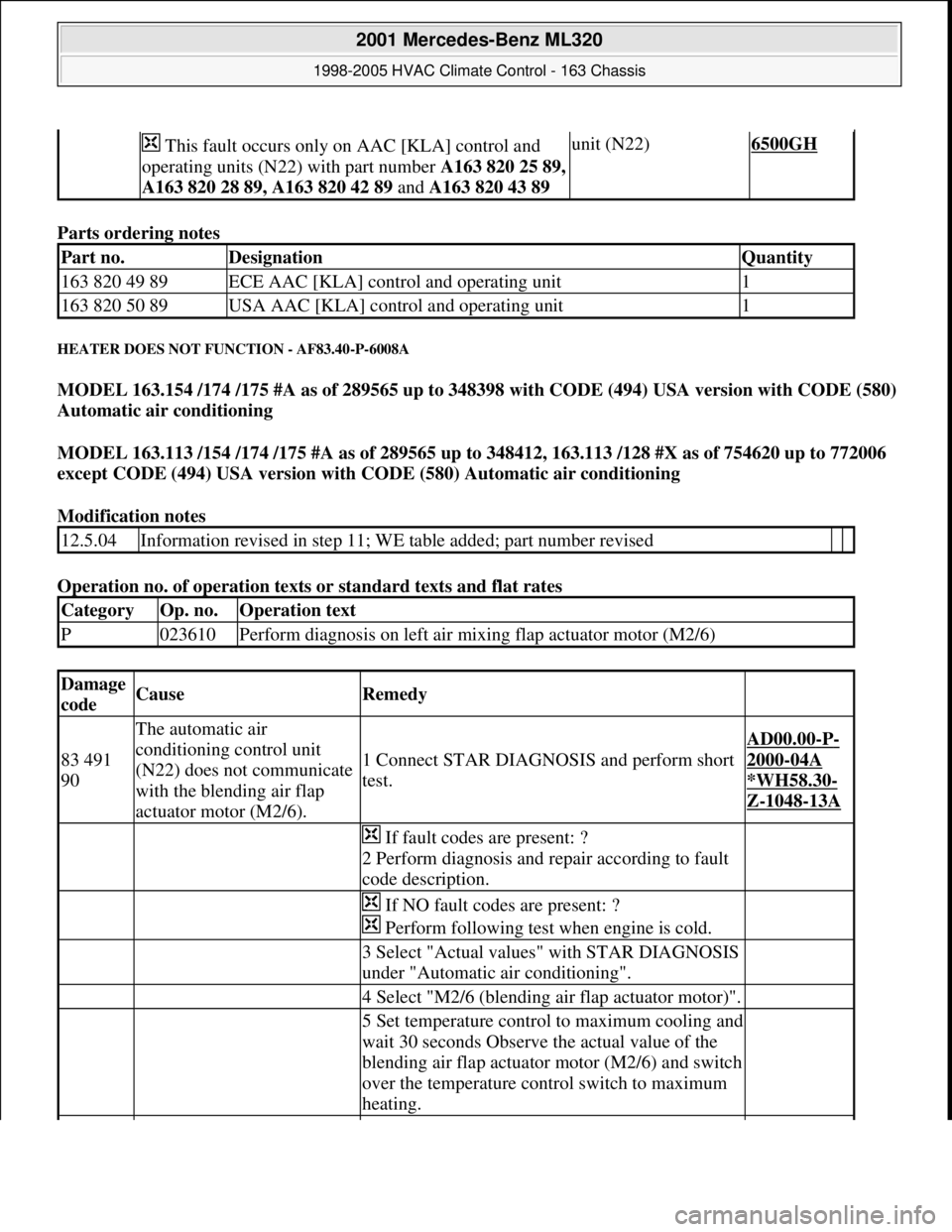

Parts ordering notes

HEATER DOES NOT FUNCTION - AF83.40-P-6008A

MODEL 163.154 /174 /175 #A as of 289565 up to 348398 with CODE (494) USA version with CODE (580)

Automatic air conditioning

MODEL 163.113 /154 /174 /175 #A as of 289565 up to 348412, 163.113 /128 #X as of 754620 up to 772006

except CODE (494) USA version with CODE (580) Automatic air conditioning

Modification notes

Operation no. of operation texts or standard texts and flat rates

This fault occurs only on AAC [KLA] control and

operating units (N22) with part number A163 820 25 89,

A163 820 28 89, A163 820 42 89 and A163 820 43 89 unit (N22)6500GH

Part no.DesignationQuantity

163 820 49 89ECE AAC [KLA] control and operating unit1

163 820 50 89USA AAC [KLA] control and operating unit1

12.5.04Information revised in step 11; WE table added; part number revised

CategoryOp. no.Operation text

P023610Perform diagnosis on left air mixing flap actuator motor (M2/6)

Damage

codeCauseRemedy

83 491

90

The automatic air

conditioning control unit

(N22) does not communicate

with the blending air flap

actuator motor (M2/6).

1 Connect STAR DIAGNOSIS and perform short

test.

AD00.00-P-

2000-04A

*WH58.30

-

Z-1048-13A

If fault codes are present: ?

2 Perform diagnosis and repair according to fault

code description.

If NO fault codes are present: ?

Perform following test when engine is cold.

3 Select "Actual values" with STAR DIAGNOSIS

under "Automatic air conditioning".

4 Select "M2/6 (blending air flap actuator motor)".

5 Set temperature control to maximum cooling and

wait 30 seconds Observe the actual value of the

blending air flap actuator motor (M2/6) and switch

over the temperature control switch to maximum

heating.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 158 © 2006 Mitchell Repair Information Company, LLC.

Page 3404 of 4133

HEATER, DIAGNOSIS, BASIC KNOWLEDGE - AD83.20-P-2000GH

MODEL 163

HEATER CAPACITY, FUNCTION CHECK, HEATER - AD83.20-P-3000-01GH

Test sequence

Heater switch (2) on "red" stop

Blower switch (1) on stage 4

Air distribution switch (3) in 12 o'clock position

Recirculated air button ( ) not pressed (LED does not come on)

Test period > 5 minutes

Engine speed 2000 rpm

Engine coolant temperature > 80°C

Read out temperature measuring instrument (4)

Temperature display > 55°C

If the measured values stated above are not achieved, the following components and functions should be

checked:

Engine coolant temperature

Furring in cooling system and heat exchanger

Blend air flap function

Coolant circulation pump (M13)

WH58.30-Z-1002-08ADigital temperature measuring instrument (measuring range -20° to +70°)

WH58.30-Z-1004-08AAir temperature probe

Electric wiring diagrams, location of ground points and connectors PE83.00-P-1100E

Connection and use of test equipment AD00.00-P-1000AZ

Diagnosis tools, heater AD83.20-P-2000-01GC

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 160 © 2006 Mitchell Repair Information Company, LLC.

Page 3406 of 4133

AIR CONDITIONING (TEMPMATIC) DIAGNOSIS CONTENTS - AD83.30-P-1000GHZ

MODEL 163 with CODE (580) Air conditioning or for USA, Tempmatic

AIR CONDITIONING (TEMPMATIC) PRECONDITIONS FOR OPERATIONAL CHECK - AD83.30-P-2000-01GH

up to 30.11.99

Heater push-button

unit

2

Full heat Heater switch on "red" stopAir outlets, heated

air

Wire cable for

actuating air blend

flap

Heater push-button

unit

3

Recirculated

air mode Heater switch in any position Recirculated

air button ( ) is pressed (LED comes

on)Air flow from

center outlet

increases

noticeably

Cables

Recirculated air

button

Actuator motor for

recirculated air flap

element (M39)

Heater push-button

unit

4

Heat output Connect temperature measuring instrument

Heater switch on "red" stop

Air outlet

temperature at

defroster outlet >

55°C

Engine coolant

temperature

Hot water coolant

circulation pump

Furring in cooling

system and heat

exchanger

Test sequenceAD83.20-P-3000-01GH

K 2.6 [] 11Air conditioning (Tempmatic) (Tempmatic A/C) diagnosis, previous

knowledge AD83.30-P-

2000GH

K 2.6 [] 12Air conditioning (Tempmatic) (Tempmatic A/C) diagnosis, function

check AD83.30-P-

3000GH

K 2.6 [] 13Air conditioning (Tempmatic) (Tempmatic A/C) diagnosis, function

check actual values AD83.30-P-

3001GH

K 2.6 []

14AAir conditioning (Tempmatic) (Tempmatic A/C) diagnosis, fault memory AD83.30-P-

4000GH

K 2.6 [] 21Air conditioning (Tempmatic) (Tempmatic A/C), testing electrical

system AD83.30-P-

6000GH

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 162 © 2006 Mitchell Repair Information Company, LLC.

Page 3425 of 4133

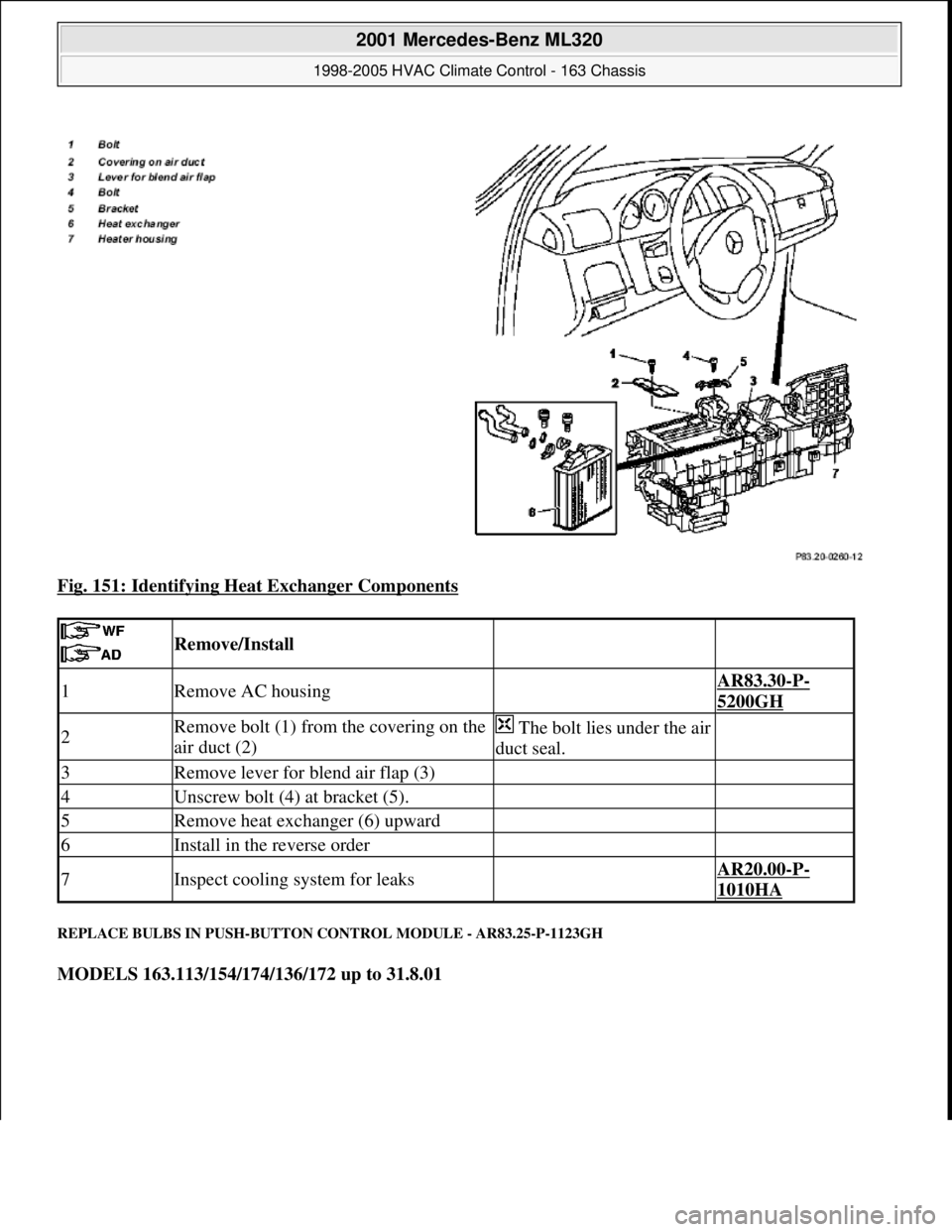

Fig. 151: Identifying Heat Exchanger Components

REPLACE BULBS IN PUSH-BUTTON CONTROL MODULE - AR83.25-P-1123GH

MODELS 163.113/154/174/136/172 up to 31.8.01

Remove/Install

1Remove AC housing AR83.30-P-

5200GH

2Remove bolt (1) from the covering on the

air duct (2)The bolt lies under the air

duct seal.

3Remove lever for blend air flap (3)

4Unscrew bolt (4) at bracket (5).

5Remove heat exchanger (6) upward

6Install in the reverse order

7Inspect cooling system for leaks AR20.00-P-

1010HA

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 181 © 2006 Mitchell Repair Information Company, LLC.

Page 3440 of 4133

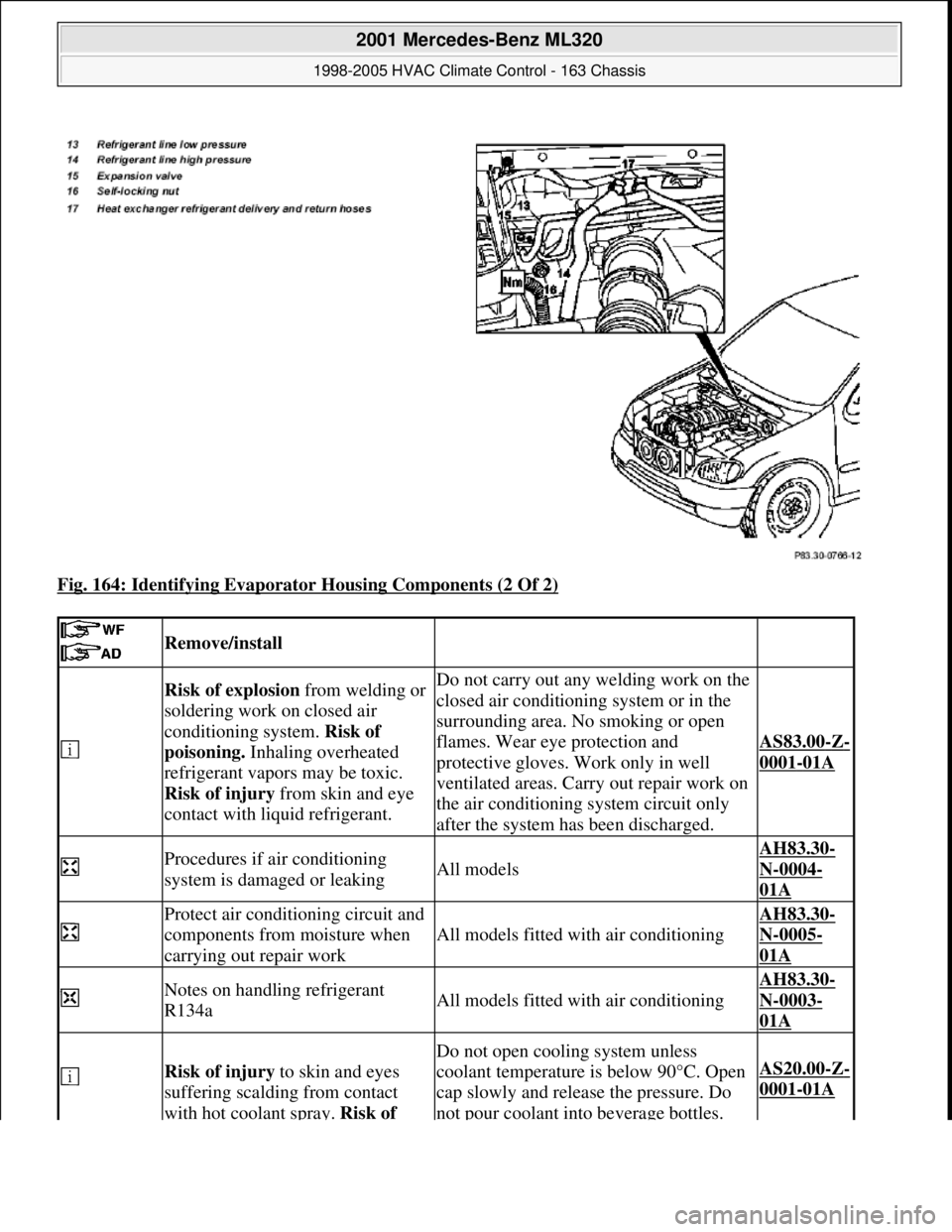

Fig. 164: Identifying Evaporator Housing Components (2 Of 2)

Remove/install

Risk of explosion from welding or

soldering work on closed air

conditioning system. Risk of

poisoning. Inhaling overheated

refrigerant vapors may be toxic.

Risk of injury from skin and eye

contact with liquid refrigerant.Do not carry out any welding work on the

closed air conditioning system or in the

surrounding area. No smoking or open

flames. Wear eye protection and

protective gloves. Work only in well

ventilated areas. Carry out repair work on

the air conditioning system circuit only

after the system has been discharged.

AS83.00-Z-

0001-01A

Procedures if air conditioning

system is damaged or leakingAll models

AH83.30-

N-0004-

01A

Protect air conditioning circuit and

components from moisture when

carrying out repair work

All models fitted with air conditioning

AH83.30-

N-0005-

01A

Notes on handling refrigerant

R134aAll models fitted with air conditioning

AH83.30-

N-0003-

01A

Risk of injury to skin and eyes

suffering scalding from contact

with hot coolant spray. Risk of

Do not open cooling system unless

coolant temperature is below 90°C. Open

cap slowly and release the pressure. Do

not pour coolant into beverage bottles.

AS20.00-Z-

0001-01A

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 196 © 2006 Mitchell Repair Information Company, LLC.

Page 3442 of 4133

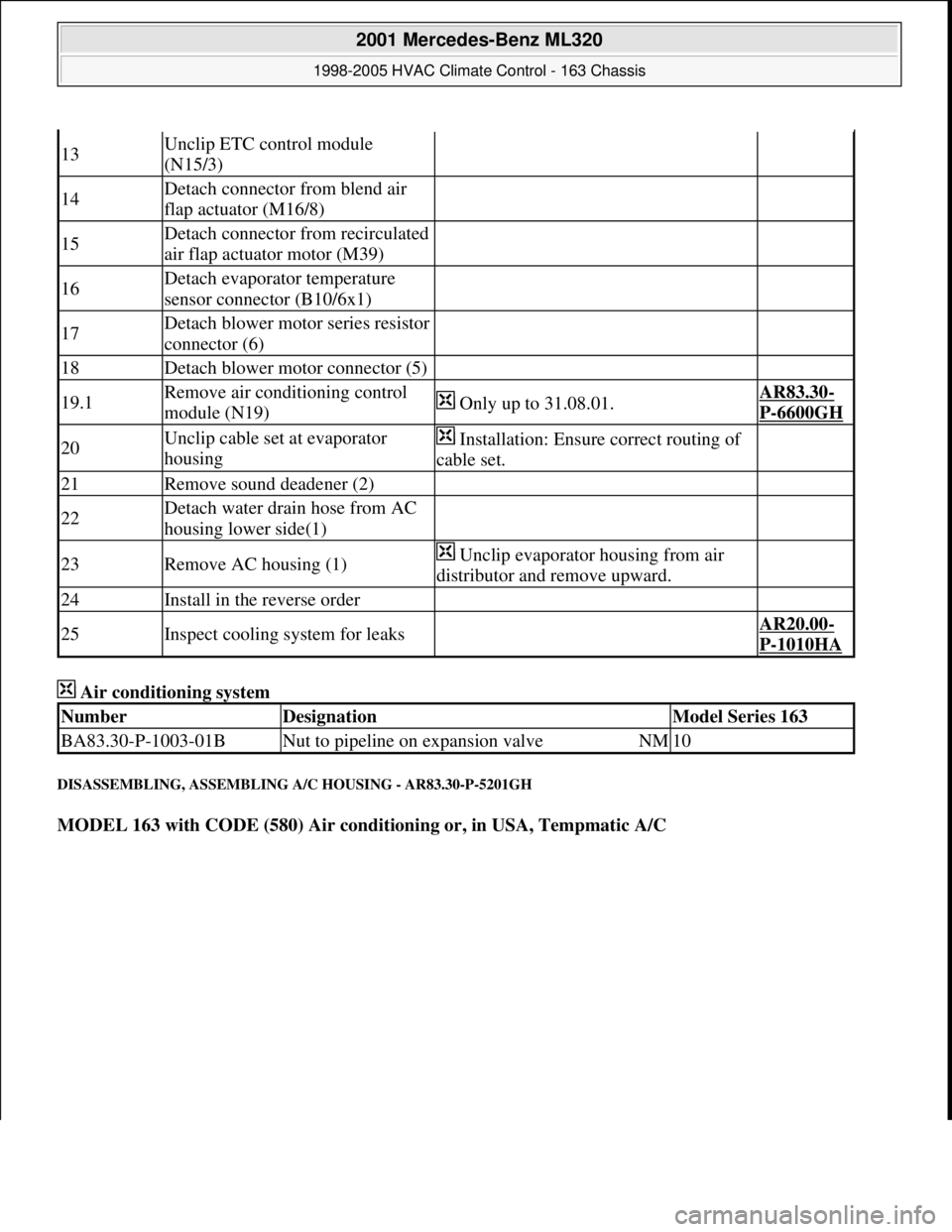

Air conditioning system

DISASSEMBLING, ASSEMBLING A/C HOUSING - AR83.30-P-5201GH

MODEL 163 with CODE (580) Air conditioning or, in USA, Tempmatic A/C

13Unclip ETC control module

(N15/3)

14Detach connector from blend air

flap actuator (M16/8)

15Detach connector from recirculated

air flap actuator motor (M39)

16Detach evaporator temperature

sensor connector (B10/6x1)

17Detach blower motor series resistor

connector (6)

18Detach blower motor connector (5)

19.1Remove air conditioning control

module (N19) Only up to 31.08.01.AR83.30-

P-6600GH

20Unclip cable set at evaporator

housing Installation: Ensure correct routing of

cable set.

21Remove sound deadener (2)

22Detach water drain hose from AC

housing lower side(1)

23Remove AC housing (1) Unclip evaporator housing from air

distributor and remove upward.

24Install in the reverse order

25Inspect cooling system for leaks AR20.00-

P-1010HA

NumberDesignationModel Series 163

BA83.30-P-1003-01BNut to pipeline on expansion valveNM10

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 198 © 2006 Mitchell Repair Information Company, LLC.