cooling MERCEDES-BENZ ML320 1997 Complete Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3169 of 4133

provide reliable cooling system protection. In special cases (commercial-vehicle engines, no antifreeze

specification) coolant additives can be used that are primarily corrosion protection additives. In this case

item 2.3 is valid.

As an exception, if neither anticorrosion/antifreeze agent conforming to Sheet 325.0 nor coolant additives

without addition of antifreeze conforming to Sheet 312.0 are available, proceed according to point 2.4

(exception: OM 500 and OM 900). The systems described under items 2.2/2.3/2.4 are not compatible

with each other. It is recommended to mix the entire coolant quantity outside the engine.

2.1 Anticorrosion/antifreeze agent for passenger-car engines

Alongside the correct constitution of the cooling water (point 1.2.2), care must be taken to ensure that

only anticorrosion/antifreeze agents as approved for all engines in accordance with Sheet 325.0 are used.

These products serve to guarantee that, in particular, an effective protection against corrosion is provided

for all light-alloy parts in the cooling system and they are also specified for all passenger-car engines.

In order to ensure that the protection against corrosion is effective, the anticorrosion/antifreeze agent must

remain in the cooling system throughout the year - including when in tropical climates - and regardless of

the operating conditions. In countries with high outside temperatures this is also important in terms of

raising the boiling point.

In the event that these regulations are not observed the cooling system may suffer from damage by

corrosion. As a consequence of corrosion deposits there is a danger that ducts in the radiators (engine

overheating) and heat exchangers (poor heat output) get plugged up thus causing damage to the engine.

As a result of the optimizations we have carried out on the system of engine/coolant/cooling system, in

the majority of our newer passenger cars, a replacement of coolant is not necessary until reaching 15

operating years or 250,000 km (whichever comes first). This may not apply to some models; in these

cases the maintenance booklet will stipulate another regulation.

2.2 Anticorrosion/antifreeze agent for commercial-vehicle engines (normal case)

(not: BR 600, BR 100 and BR 200)

The coolant in commercial-vehicle engines is made up of both water and anticorrosion/antifreeze agent

(refer to item 1.1.1) and as such offers ideal protection against corrosion and cavitation.

All the approved products on the Sheets 325.2, 325.3 or 325.0 which are part of the Specifications for

Operating Fluids can be used to select an anticorrosion/antifreeze agent. However, it should be noted that

passenger vehicle engines built into commercial vehicles must be filled like passenger vehicles (e.g. OM

601 in T1), i.e. a product conforming to Sheet 325.0 and 326.0 must be used.

Products that are not listed in Sheets 325.0 and 326.0, or 325.2 and 326.2, or 325.3 and 326.3 are not

approved and are therefore not to be used under any circumstances.

Anticorrosion/antifreeze agents or coolants conforming to Sheet 325.3 or 326.3 may be used for

longer than other products due to their composition. The change interval is set at 5 years (refer to

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 524 © 2006 Mitchell Repair Information Company, LLC.

Page 3171 of 4133

the regulation filling of 50 vol.% (-37°C). When topping up (after coolant loss), an anticorrosion/

antifreeze agent content in the coolant of at least 50 vol. % (antifreeze protection down to -37°C) must be

ensured, or the concentration regulations according to point 2.3/2.4.1 must be observed. In closing an

example is given in Overview Section 5.

Non observance a observance of these regulations or the use of non-approved products will

result in serious damage.

The corrosion inhibitors diminish during operation and lose their protective capability. Coolant that is too

old, and has lost its important inhibitors and anti-aging additives, becomes strongly corrosive. The

coolant additives as under Sheets 311.0 and 312.0 will also age. This causes a deterioration in the level of

protection capability, and with regard to coolant refining agents this will also cause the emulsion to break

down.

For this reason it is important to replace the coolant, in order to ensure that its corrosion protection

capability is retained. If necessary the cooling system should be thoroughly cleansed before refilling with

the new coolant. A sufficient level of heat dissipation will only be given if the cooler surfaces are clean.

The maximum permissible period of usage for coolant is cited in Overview Section 5.

The use of approved operatin

g fluids, which naturally include the anticorrosion/antifreeze agents, is

a well-known constituent of the warranty conditions.

4.Disposal of coolants

The coolants are biologically-degradable material.

All statutory regulations or waste water regulations in each individual country with regard to the disposal

of used coolant must be observed.

It is recommended to have the possibilities available for disposing of materials explained by the local

responsible water authorities.

Currently in Germany methods are being compiled for the purification of used coolant. The separate

collection of all used operating fluids is highly recommended.

However, as a consequence of the complex tasks asked of a modern coolant, it is on no account advisable

to use an improperly "recycled" coolant, which has only undergone a mechanical pre-purification process

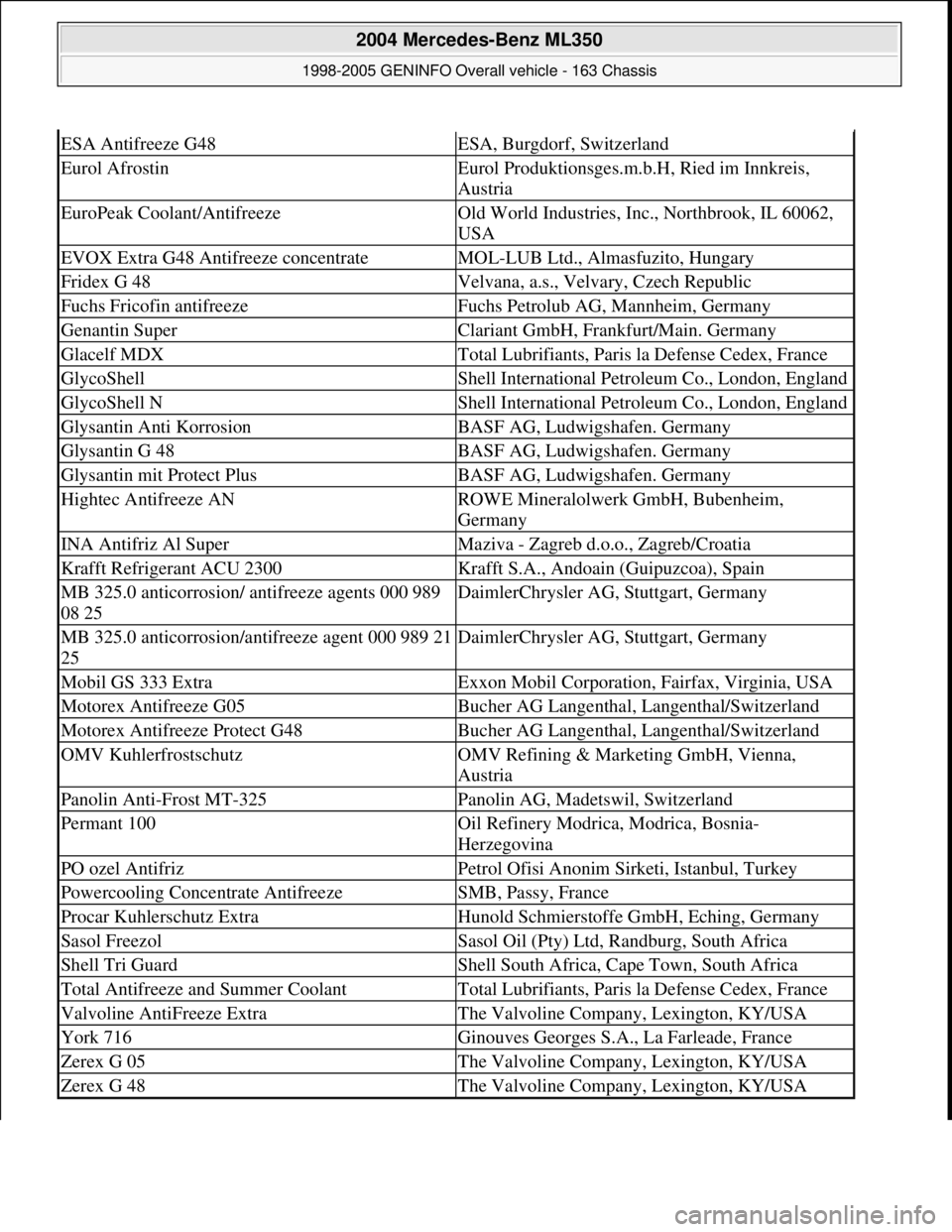

5.Overview

Which coolant additive, what change interval for which engines?

Passenger cars engines

Sheet No.Engine seriesChange interval

years/km

M100/M200OM600

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 526 © 2006 Mitchell Repair Information Company, LLC.

Page 3174 of 4133

ESA Antifreeze G48ESA, Burgdorf, Switzerland

Eurol AfrostinEurol Produktionsges.m.b.H, Ried im Innkreis,

Austria

EuroPeak Coolant/AntifreezeOld World Industries, Inc., Northbrook, IL 60062,

USA

EVOX Extra G48 Antifreeze concentrateMOL-LUB Ltd., Almasfuzito, Hungary

Fridex G 48Velvana, a.s., Velvary, Czech Republic

Fuchs Fricofin antifreezeFuchs Petrolub AG, Mannheim, Germany

Genantin SuperClariant GmbH, Frankfurt/Main. Germany

Glacelf MDXTotal Lubrifiants, Paris la Defense Cedex, France

GlycoShellShell International Petroleum Co., London, England

GlycoShell NShell International Petroleum Co., London, England

Glysantin Anti KorrosionBASF AG, Ludwigshafen. Germany

Glysantin G 48BASF AG, Ludwigshafen. Germany

Glysantin mit Protect PlusBASF AG, Ludwigshafen. Germany

Hightec Antifreeze ANROWE Mineralolwerk GmbH, Bubenheim,

Germany

INA Antifriz Al SuperMaziva - Zagreb d.o.o., Zagreb/Croatia

Krafft Refrigerant ACU 2300Krafft S.A., Andoain (Guipuzcoa), Spain

MB 325.0 anticorrosion/ antifreeze agents 000 989

08 25DaimlerChrysler AG, Stuttgart, Germany

MB 325.0 anticorrosion/antifreeze agent 000 989 21

25DaimlerChrysler AG, Stuttgart, Germany

Mobil GS 333 ExtraExxon Mobil Corporation, Fairfax, Virginia, USA

Motorex Antifreeze G05Bucher AG Langenthal, Langenthal/Switzerland

Motorex Antifreeze Protect G48Bucher AG Langenthal, Langenthal/Switzerland

OMV KuhlerfrostschutzOMV Refining & Marketing GmbH, Vienna,

Austria

Panolin Anti-Frost MT-325Panolin AG, Madetswil, Switzerland

Permant 100Oil Refinery Modrica, Modrica, Bosnia-

Herzegovina

PO ozel AntifrizPetrol Ofisi Anonim Sirketi, Istanbul, Turkey

Powercooling Concentrate AntifreezeSMB, Passy, France

Procar Kuhlerschutz ExtraHunold Schmierstoffe GmbH, Eching, Germany

Sasol FreezolSasol Oil (Pty) Ltd, Randburg, South Africa

Shell Tri GuardShell South Africa, Cape Town, South Africa

Total Antifreeze and Summer CoolantTotal Lubrifiants, Paris la Defense Cedex, France

Valvoline AntiFreeze ExtraThe Valvoline Company, Lexington, KY/USA

York 716Ginouves Georges S.A., La Farleade, France

Zerex G 05The Valvoline Company, Lexington, KY/USA

Zerex G 48The Valvoline Company, Lexington, KY/USA

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 529 © 2006 Mitchell Repair Information Company, LLC.

Page 3214 of 4133

Mode control knob controls air distribution throughout the passenger compartment. Air distribution doors are

controlled by cables activated by the mode control knob. See Fig. 1

. Four mode positions are available with

detents in-between to adjust airflow for personal comfort.

Defrost

Set mode control knob to 12-o'clock position. Air will exit from defrost outlets and side window vents.

Vent

Set mode control knob to 9-o'clock position. Air will exit from instrument panel outlets.

Floor

Set mode control knob to 6-o'clock position. Air will exit from floor outlets.

Blend/Bi-Level

Set mode control knob to 3-o'clock position. Air will exit from defrost, instrument panel, and floor outlets.

TEMPERATURE CONTROL KNOB

Air temperature is controlled by a variable resistor rotary control switch. See Fig. 1 . Switch receives voltage

signal and depending upon position, controls voltage signal sent to air mix damper door motor. See Fig. 2

.

Volta

ge controls position of motor for heating and cooling.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 3 © 2006 Mitchell Repair Information Company, LLC.

Page 3225 of 4133

OUTSIDE TEMPERATURE SENSOR RESISTANCE

READING ACTUAL VALUES WITH HHT

Connect Hand-Held Tester (HHT) to DLC and follow displayed procedures. Actual values displayed on HHT

show normal operation value of A/C systems or components. See ACTUAL VALUES

table. If value is not as

specified, check system or components in order. Repair as necessary.

ACTUAL VALUES

REMOVAL & INSTALLATION

Sensor Temperature - °F (°C)Ohms

68 (20)2100

77 (25)1700

104 (40)900

122 (50)600

Step (1) Test ConditionValueSystem/Component

01.....11-14 VoltsVoltage Supply Wiring (Circuit

No. 30) & Battery

02Engine Operating At

Normal TemperatureAbout 176°F (80°C)Wiring, ECT Sensor & AAM

03Ignition ONAmbient Air Temperature

About 68°F (20°C)Wiring, Outside Temperature

Sensor & AAM

04Ignition ON, Blower At

Stage 4ON/OFFWiring, Blower Motor Relay,

Blower Motor & AAM

05Ignition ONON/OFFWiring, Engine Cooling Fan

Stage 1, Aux. Fan & AAM

08Ignition ONON/OFFWiring, Coolant Circulation Pump

Relay, Coolant Circulation Pump

& AAM

09Engine On, A/C Indicator

On, Blower Motor At

Stage 4Refrigerant Pressure At

174 psi (12 bar)(2) Refrigerant Pressure Sensor

10Engine On, A/C Indicator

On, Blower Motor At

Stage 4ON/OFF(3) AAM, A/C Compressor

11Ignition ON, Activate

A/C SystemYES/NOWiring, A/C Push Button Control

Module, AAM

(1)Step numbers not shown are not used.

(2)Check A/C refrigerant pressure switch. See A/C REFRIGERANT PRESSURE SWITCH under

ELECTRICAL TESTS.

(3)Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 14 © 2006 Mitchell Repair Information Company, LLC.

Page 3228 of 4133

A/C housing. Disconnect control module connector. To install reverse removal procedure. Recode 5-digit radio

security code. Using HHT, check for DTC and erase, and set clock.

A/C PUSH BUTTON CONTROL PANEL

Removal & Installation

1. Obtain 5-digit radio security code from vehicle owner. Disconnect negative battery cable. Using radio

removal plates, remove radio. Disconnect electrical connectors.

2. Remove instrument panel center section. Remove 4 A/C control panel screws and remove control panel.

Release pull cables and disconnect connectors. To install, reverse removal procedure. Recode radio. See

RECODING RADIO

under PROGRAMMING.

BLOWER MOTOR

Removal & Installation

Remove passenger-side instrument panel under cover. Remove blower motor mounting screws from A/C

housing unit. Disconnect blower motor connector and remove blower motor. To install, reverse removal

procedure.

COMPRESSOR

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Remove accessory

drive belt. Disconnect low pressure refrigerant line from compressor. Discard "O" rings. Plug exposed

openings to protect A/C system from debris and moisture.

2. Disconnect high pressure refrigerant line from compressor. Discard "O" rings. Plug exposed openings to

protect A/C system from debris and moisture. Disconnect electrical connector. Remove compressor

mounting bolts.

3. Raise and support vehicle. Remove compressor from under vehicle without spilling refrigerant oil. To

install, reverse removal procedure. Ensure refrigerant oil quantity in compressor is correct. See

COMPRESSOR REFRIGERANT OIL CHECKING under GENERAL SERVICING. Tighten bolts to

specification. See TORQUE SPECIFICATIONS

.

CONDENSER

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Remove cooling fans.

See COOLING FANS

. Disconnect refrigerant line from receiver-drier. See Fig. 5 . Discard "O" rings.

2. Plug exposed openings to protect A/C system from debris and moisture. Remove refrigerant line from

condenser. Remove radiator upper rubber seal. See Fig. 6

. Remove condenser upper mounting screws.

Lift condenser upward and remove. NOTE: Each time A/C compressor is removed and installed, receiver-drier must be

replaced.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 17 © 2006 Mitchell Repair Information Company, LLC.

Page 3232 of 4133

Fig. 6: Removing Cooling Fans & Condenser

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

COOLING FANS

Removal & Installation

Remove headlight units. Remove upper frame crossmember, release hood release control cable and remove

crossmember. See Fig. 6

. Remove 2 cooling fans frame bolts on radiator. Disconnect cooling fan connector.

Release outside temperature sensor wiring harness. Pull up on cooling fan and remove. To install, reverse

removal procedure. Ensure cooling fan bottom guides are properly seated in lower mounts.

EVAPORATOR

Removal & Installation

Remove A/C housing unit. See A/C HOUSING UNIT . Remove expansion valve. See Fig. 5 . Discard "O"

rings. Disassemble A/C housing unit. Remove evaporator. Remove evaporator temperature sensor. To install,

reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. If installing a new or repair

evaporator, add 1.35 ounces of NEW refrigerant oil to evaporator.

EXPANSION VALVE

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Without disconnecting

coolant hoses, remove coolant expansion reservoir and set aside. Remove refrigerant line bracket and

loosen clamps. See Fig. 5

. Pull refrigerant lines out of expansion valve.

2. Remove expansion valve self-locking nut and discard. Remove expansion valve. Discard "O" rings. To

install, reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. Tighten NEW self-

locking nut to specification. See TORQUE SPECIFICATIONS

.

INSTRUMENT PANEL & INSTRUMENT PANEL CARRIER

Removal & Installation

1. Secure vehicle against rolling. Set transmission selector to "D" position. Obtain radio security code.

Disconnect negative battery cable. Remove driver-side air bag.

2. Place match marks on steering wheel and steering shaft. Remove steering wheel, upper steering column

covers and combination switch. Remove instrument cluster cover frame. Remove one instrument panel

lower section bolt.

3. Remove screws in footwell from left side of instrument panel bottom section. Remove instrument panel

center section. Remove 4 A/C control panel screws and remove control panel. See Fig. 1

. Release pull

cables and disconnect connectors.

4. Remove screws from center section. Remove glove box. Remove screws in footwell from right side of

instrument panel bottom section. Remove entry courtesy lights. Remove end covers and screws.

5. Release 4 "A" clips between instrument panel bottom section and upper section. See Fig. 7

. Release

parkin

g brake release cable from handle. With assistance, remove instrument panel bottom section.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 3238 of 4133

Fig. 10: Manual A/C-Heater Systems Wiring Diagram (2000-01 ML 320 Without Cooling Fan Control

Module - 1 Of 2)

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 27 © 2006 Mitchell Repair Information Company, LLC.

Page 3240 of 4133

Fig. 11: Manual A/C-Heater Systems Wiring Diagram (2000-01 ML 320 Without Cooling Fan Control

Module - 2 Of 2)

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 29 © 2006 Mitchell Repair Information Company, LLC.

Page 3242 of 4133

Fig. 12: Automatic A/C-Heater Systems Wiring Diagram (2000-01 ML 320 & ML 430 With Cooling Fan

Control Module - 1 Of 2)

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 31 © 2006 Mitchell Repair Information Company, LLC.