sensor MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3039 of 4133

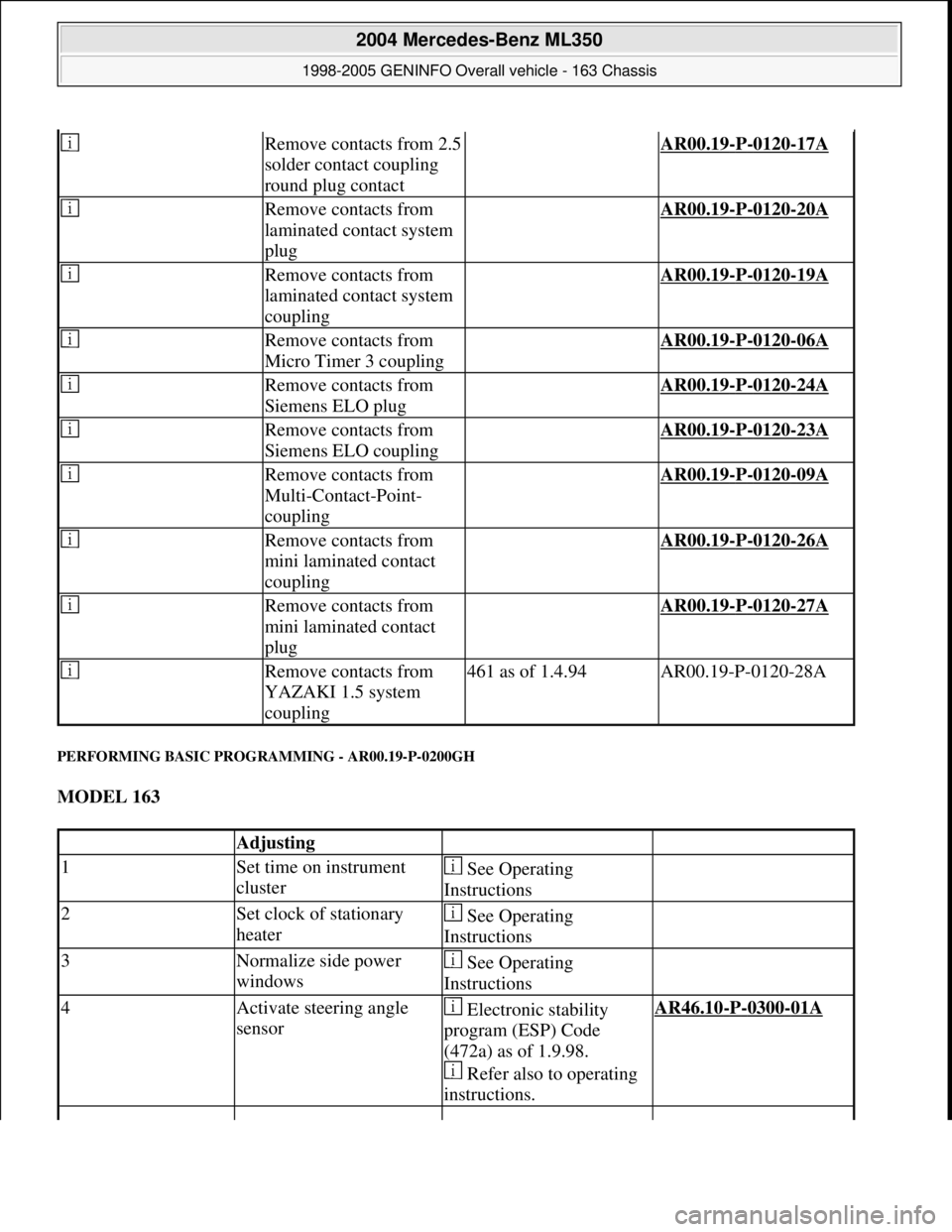

PERFORMING BASIC PROGRAMMING - AR00.19-P-0200GH

MODEL 163

Remove contacts from 2.5

solder contact coupling

round plug contact AR00.19-P-0120-17A

Remove contacts from

laminated contact system

plug AR00.19-P-0120-20A

Remove contacts from

laminated contact system

coupling AR00.19-P-0120-19A

Remove contacts from

Micro Timer 3 coupling AR00.19-P-0120-06A

Remove contacts from

Siemens ELO plug AR00.19-P-0120-24A

Remove contacts from

Siemens ELO coupling AR00.19-P-0120-23A

Remove contacts from

Multi-Contact-Point-

coupling AR00.19-P-0120-09A

Remove contacts from

mini laminated contact

coupling AR00.19-P-0120-26A

Remove contacts from

mini laminated contact

plug AR00.19-P-0120-27A

Remove contacts from

YAZAKI 1.5 system

coupling461 as of 1.4.94AR00.19-P-0120-28A

Adjusting

1Set time on instrument

cluster See Operating

Instructions

2Set clock of stationary

heater See Operating

Instructions

3Normalize side power

windows See Operating

Instructions

4Activate steering angle

sensor Electronic stability

program (ESP) Code

(472a) as of 1.9.98.

Refer also to operating

instructions.AR46.10-P-0300-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 394 © 2006 Mitchell Repair Information Company, LLC.

Page 3191 of 4133

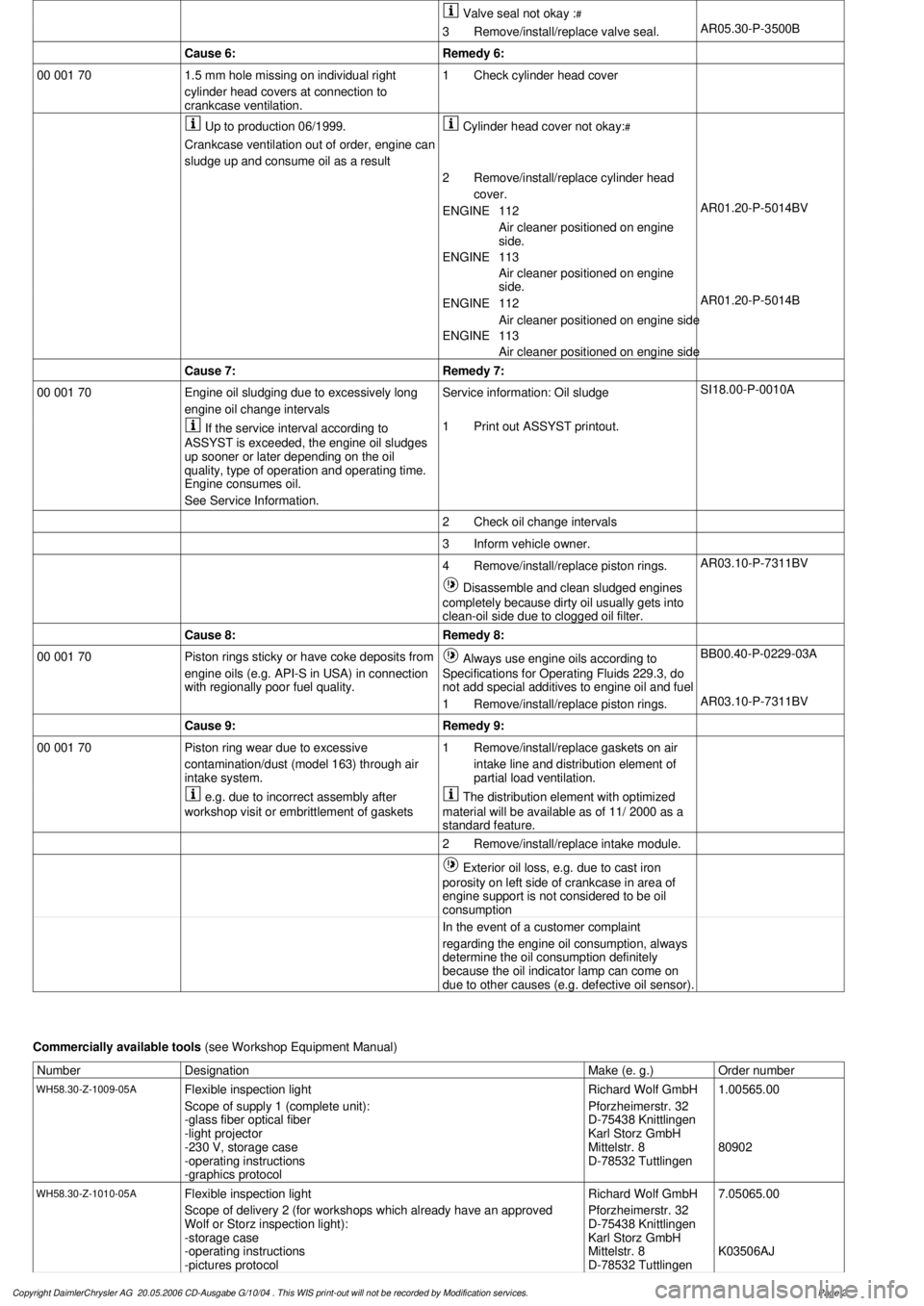

Valve seal not okay :

#

3

Remove/install/replace valve seal.

AR05.30-P-3500B

Cause 6:

Remedy 6:

00 001 70

1.5 mm hole missing on individual right

cylinder head covers at connection to

crankcase ventilation.

1

Check cylinder head cover

Up to production 06/1999.

Crankcase ventilation out of order, engine can

sludge up and consume oil as a result

Cylinder head cover not okay:

#

2

Remove/install/replace cylinder head

cover.

ENGINE

112

Air cleaner positioned on engine

side.

ENGINE

113

Air cleaner positioned on engine

side.

AR01.20-P-5014BV

ENGINE

112

Air cleaner positioned on engine side

ENGINE

113

Air cleaner positioned on engine side

AR01.20-P-5014B

Cause 7:

Remedy 7:

00 001 70

Engine oil sludging due to excessively long

engine oil change intervals

Service information: Oil sludge

SI18.00-P-0010A

If the service interval according to

ASSYST is exceeded, the engine oil sludges

up sooner or later depending on the oil

quality, type of operation and operating time.

Engine consumes oil.

See Service Information.

1

Print out ASSYST printout.

2

Check oil change intervals

3

Inform vehicle owner.

4

Remove/install/replace piston rings.

AR03.10-P-7311BV

Disassemble and clean sludged engines

completely because dirty oil usually gets into

clean-oil side due to clogged oil filter.

Cause 8:

Remedy 8:

00 001 70

Piston rings sticky or have coke deposits from

engine oils (e.g. API-S in USA) in connection

with regionally poor fuel quality.

Always use engine oils according to

Specifications for Operating Fluids 229.3, do

not add special additives to engine oil and fuel

BB00.40-P-0229-03A

1

Remove/install/replace piston rings.

AR03.10-P-7311BV

Cause 9:

Remedy 9:

00 001 70

Piston ring wear due to excessive

contamination/dust (model 163) through air

intake system.

1

Remove/install/replace gaskets on air

intake line and distribution element of

partial load ventilation.

e.g. due to incorrect assembly after

workshop visit or embrittlement of gaskets

The distribution element with optimized

material will be available as of 11/ 2000 as a

standard feature.

2

Remove/install/replace intake module.

Exterior oil loss, e.g. due to cast iron

porosity on left side of crankcase in area of

engine support is not considered to be oil

consumption

In the event of a customer complaint

regarding the engine oil consumption, always

determine the oil consumption definitely

because the oil indicator lamp can come on

due to other causes (e.g. defective oil sensor).

Commercially available tools

(see Workshop Equipment Manual)

Number

Designation

Make (e. g.)

Order number

WH58.30-Z-1009-05A

Flexible inspection light

Scope of supply 1 (complete unit):

-glass fiber optical fiber

-light projector

-230 V, storage case

-operating instructions

-graphics protocol

Richard Wolf GmbH

Pforzheimerstr. 32

D-75438 Knittlingen

Karl Storz GmbH

Mittelstr. 8

D-78532 Tuttlingen

1.00565.00

80902

WH58.30-Z-1010-05A

Flexible inspection light

Scope of delivery 2 (for workshops which already have an approved

Wolf or Storz inspection light):

-storage case

-operating instructions

-pictures protocol

Richard Wolf GmbH

Pforzheimerstr. 32

D-75438 Knittlingen

Karl Storz GmbH

Mittelstr. 8

D-78532 Tuttlingen

7.05065.00

K03506AJ

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3216 of 4133

Fig. 2: Locating Climate Control Components

Courtesy of MERCEDES-BENZ OF NORTH AMERICA

FRESH/RECIRCULATION SWITCH

Fresh/recirculation switch controls voltage signal to fresh air recirculation door motor. See Fig. 1 and Fig. 2 .

With switch indicator light on, air will recirculate. With switch indicator light off, air will enter from outside of

vehicle.

A/C CONTROL MODULE

The A/C control module (A/C amplifier) is the control unit for the A/C system. See Fig. 2 . The module

receives inputs from various sensors and processes the information to control various outputs for the A/C

system for optimal control.

The A/C control module inputs are as follows:

A/C Switch

In-Vehicle Air Temperature Sensor

Temperature Selector Knob

Blower Motor Knob

Evaporator Temperature Sensor

Air Mix Damper Door Position Sensor

The A/C control module output functions are as follows:

Air Mix Damper Door Motor

All Activity Module

Fresh/Recirculation Door Motor

ALL ACTIVITY MODULE

All Activity Module (AAM) receives inputs to determine if specified conditions have been met to allow

operation of A/C-heater system. If conditions are met, the AAM will send signals to the A/C compressor,

condenser fans relay and the blower motor relay to command or enable operation.

IN-VEHICLE TEMPERATURE SENSOR

The in-vehicle temperature sensor is a negative temperature coefficient resistor. Sensor sends signals to the A/C

control module to maintain in-vehicle temperature. Sensor is located on the center panel of the instrument

cluster.

DUST FILTER

A dust filter provides filtering of air entering or recirculating in the passenger's compartment. The dust filter is

mounted between blower motor and evaporator, below passen

ger's side of instrument panel, to left of blower

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 5 © 2006 Mitchell Repair Information Company, LLC.

Page 3218 of 4133

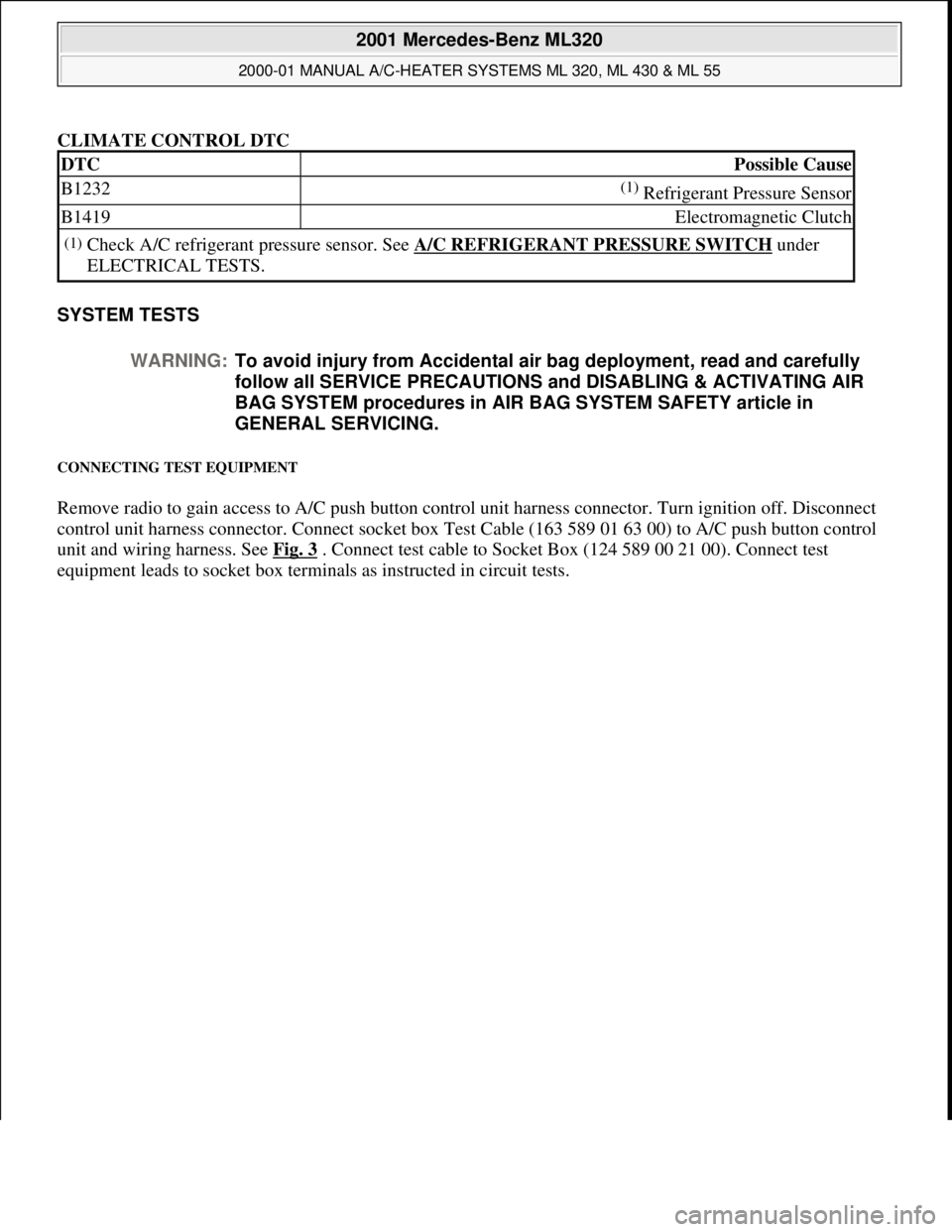

CLIMATE CONTROL DTC

SYSTEM TESTS

CONNECTING TEST EQUIPMENT

Remove radio to gain access to A/C push button control unit harness connector. Turn ignition off. Disconnect

control unit harness connector. Connect socket box Test Cable (163 589 01 63 00) to A/C push button control

unit and wiring harness. See Fig. 3

. Connect test cable to Socket Box (124 589 00 21 00). Connect test

equipment leads to socket box terminals as instructed in circuit tests.

DTCPossible Cause

B1232(1) Refrigerant Pressure Sensor

B1419Electromagnetic Clutch

(1)Check A/C refrigerant pressure sensor. See A/C REFRIGERANT PRESSURE SWITCH under

ELECTRICAL TESTS.

WARNING:To avoid injury from Accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS and DISABLING & ACTIVATING AIR

BAG SYSTEM procedures in AIR BAG SYSTEM SAFETY article in

GENERAL SERVICING.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 7 © 2006 Mitchell Repair Information Company, LLC.

Page 3220 of 4133

FUNCTIONAL TEST PREPARATION

1. Check condition of fuses F16, F41, F43 and F44. See WIRING DIAGRAMS . Repair and/or replace

fuses and necessary.

2. Turn ignition on. Locate in-vehicle temperature sensor aspirator blower vent grille above anti-theft

indicator light. Place a half-inch square of tissue paper over aspirator blower vent grille. If paper stays on

vent grille, go to next step. If paper does not stay on vent grille, correct insufficient aspirator blower

ventilation.

3. Put shift lever in "P" and engage parking brake. Run engine at idle until it reaches normal operating

temperature, about 176°F (80°C). Ensure ambient (outside) temperature is greater than 58°F (15°C).

4. Manually open center and side air outlets. Ensure recirculation button is not depressed. Set blower speed

knob to position No. 1.

FUNCTION TEST

Defrost Mode

To check operation in defrost mode, set temperature selector knob to White range (vertical). Set mode control

knob to 12-o'clock position (vertical). Ensure A/C button indicator is illuminated. Air will vent from defrost and

center outlets and A/C compressor will engage. If operation is not as specified, perform the following in order:

Check voltage supply circuit Z50/2 between No. 16 fuse (15-amp) and connected components. See

VOLTAGE SUPPLY CIRCUIT Z50/2

under ELECTRICAL TESTS.

Check ground circuit. See GROUND CIRCUIT Z50/4 under ELECTRICAL TESTS.

Check in-vehicle temperature sensor signal voltage. See IN-VEHICLE TEMPERATURE SENSOR

under ELECTRICAL TESTS.

Check in-vehicle temperature sensor signal resistance. See IN-VEHICLE TEMPERATURE SENSOR

under ELECTRICAL TESTS.

Check icing protection temperature sensor signal voltage. See ICING PROTECTION

TEMPERATURE SENSOR under ELECTRICAL TESTS.

Check icing protection temperature sensor resistance. See ICING PROTECTION TEMPERATURE

SENSOR under ELECTRICAL TESTS.

Check activation voltage during temperature reduction. See ACTIVATION VOLTAGE

TEMPERATURE under ELECTRICAL TESTS.

Check activation voltage during temperature increase. See ACTIVATION VOLTAGE

TEMPERATURE under ELECTRICAL TESTS.

Check blend air flap actuator motor operation voltage. See BLEND AIR FLAP ACTUATOR MOTOR

under ELECTRICAL TESTS.

Check blend air flap actuator motor resistance. See BLEND AIR FLAP ACTUATOR MOTOR under

ELECTRICAL TESTS.

Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

Check A/C pressure switch. See A/C REFRIGERANT PRESSURE SWITCH under ELECTRICAL NOTE: Function test steps must be performed in order given.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.

Page 3222 of 4133

Ground Circuit Z50/4

1. Connect socket box to A/C push button control unit wiring harness connector. See CONNECTING

TEST EQUIPMENT . Turn ignition off. Ensure A/C push button control unit is not connected to socket

box.

2. Connect ohmmeter positive lead to socket box terminal No. 9 and negative lead to body ground.

Resistance should be zero. If resistance is not as specified, check control unit ground circuit Z50/4. See

WIRING DIAGRAMS

. Repair as necessary.

In-Vehicle Temperature Sensor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 12 and negative lead to

terminal No. 9.

2. Turn ignition on. Turn temperature control knob to Red range detent. Voltage should be 1.9 volts at 68°F

(20°C). If voltage is as specified, go to next step. If voltage is not as specified, check in-vehicle

temperature sensor circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay,

replace in-vehicle temperature sensor.

3. Turn ignition off. Disconnect test cable from A/C push button control unit. Connect ohmmeter positive

lead to socket box terminal No. 2 and negative lead to terminal No. 12. Measure temperature sensor

resistance at specified temperatures. See IN

-VEHICLE TEMPERATURE SENSOR RESISTANCE

table.

4. If resistance is not as specified, check wiring harness and connectors between A/C push button control

unit, in-vehicle temperature sensor, blend air flap actuator position sensor and temperature regulator

switch. Repair as necessary.

IN-VEHICLE TEMPERATURE SENSOR RESISTANCE

Icing Protection Temperature Sensor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 11 and negative lead to

terminal No. 9.

2. Turn ignition on. Voltage should be 2.0-2.4 volts at 32°F (0°C) and 1.4-1.8 volts at 59°F (15°C). If

voltage is as specified, go to next step. If voltage is not as specified, check icing protection temperature

sensor circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace icing

protection temperature sensor.

3. Turn ignition off. Disconnect test cable from A/C push button control unit. Connect ohmmeter positive

lead to socket box terminal No. 3 and negative lead to terminal No. 11. Measure temperature sensor

resistance at specified temperatures. See ICING PROTECTION TEMPERATURE SENSOR

RESISTANCE table.

Sensor Temperature - °F (°C)Ohms

68 (20)2100

77 (25)1700

104 (40)900

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 11 © 2006 Mitchell Repair Information Company, LLC.

Page 3223 of 4133

4. If resistance is not as specified, check wiring harness between temperature sensor and control unit. Repair

as necessary. If wiring harness is okay, replace icing protection temperature sensor.

ICING PROTECTION TEMPERATURE SENSOR RESISTANCE

Activation Voltage Temperature

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 2 and negative lead to

terminal No. 9.

2. Turn ignition on. Turn temperature control knob to Blue range detent. Voltage should be more than 2.0

volts. Turn temperature control knob from Blue range detent to Red range detent. Voltage should be more

than 3.0 volts.

3. If voltage is as specified, go to next step. If voltage is not as specified, check recirculated air switch

circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace recirculated air

switch.

4. Connect voltmeter positive lead to socket box terminal No. 5 and negative lead to terminal No. 9. Turn

ignition on. Turn temperature control knob to Blue range detent. Voltage should be more than 3.0 volts.

Turn temperature control knob from Blue range detent to Red range detent. Voltage should be more than

4.0 volts.

5. If voltage is not as specified, check recirculated air switch circuits. See WIRING DIAGRAMS

. Repair

as necessary. If circuits are okay, replace recirculated air switch.

Blend Air Flap Actuator Motor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 1 and negative lead to

terminal No. 9.

2. Turn ignition on. Turn temperature control knob to Blue range detent. Voltage should be less than one

volt. Turn temperature control knob from Blue range detent to Red range detent. Voltage should be 11.0-

14.0 volts.

3. If voltage is as specified, go to next step. If voltage is not as specified, check blend air flap actuator motor

wiring harness circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace

blend air flap actuator motor.

4. Connect voltmeter positive lead to socket box terminal No. 8 and negative lead to terminal No. 9. Turn

ignition on. Turn temperature control knob to Red range detent. Voltage should be less than one volt.

Turn temperature control knob from Red range detent to Blue range detent. Voltage should be 11.0-14.0

volts.

5. If voltage is as specified, go to next step. If voltage is not as specified, check blend air flap actuator motor

wiring harness circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace

Sensor Temperature - °F (°C)Ohms

43 (6)3600

59 (15)2300

72 (22)1700

77 (25)1500

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 12 © 2006 Mitchell Repair Information Company, LLC.

Page 3224 of 4133

blend air flap actuator motor.

6. Turn ignition off. Disconnect test cable from A/C push button control unit. Connect ohmmeter positive

lead to socket box terminal No. 1 and negative lead to terminal No. 8. Resistance should be 120 ohms.

7. If resistance is not as specified, check blend air flap actuator motor circuits. See WIRING DIAGRAMS

.

Repair as necessary. If circuits are okay, replace blend air flap actuator motor.

A/C Button

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 10 and negative lead to

terminal No. 9.

2. Turn ignition on. Depress A/C button switch to on position and set blower speed knob to position No. 4.

Ensure A/C button indicator is illuminated. Voltage should be less than one volt. Depress A/C button

switch to off position with A/C button indicator not illuminated or set blower speed knob to off position.

Voltage should be 11-14 volts.

3. If voltage is as specified, go to next step. If voltage is not as specified, check A/C button wiring harness

circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace A/C button

switch.

4. Turn ignition on. Depress A/C button switch to on position and set blower speed knob to position No. 4.

Ensure A/C button indicator is illuminated. Connect voltmeter positive lead to socket box terminal No. 4

and negative lead to terminal No. 9. Voltage should be more than 3.0 volts.

5. Connect Fused Jumper Wire (124 589 37 63 00) between socket box terminals No. 4 and 11. Depress A/C

button switch to on position and set blower speed knob to position No. 4. Ensure A/C button indicator is

illuminated. Measure voltage. Voltage should be less than one volt.

6. If voltage is not as specified, check A/C button wiring harness circuits. See WIRING DIAGRAMS

.

Repair as necessary. If circuits are okay, replace A/C button switch.

A/C Refrigerant Pressure Switch

1. Turn ignition off. Disconnect refrigerant pressure sensor connector. Turn ignition on. Connect voltmeter

positive lead to pressure sensor harness connector terminal "B" (Pink wire) and negative lead to terminal

"A" (Tan wire). Voltage should be 4.75-5.25 volts.

2. If voltage is as specified, replace A/C refrigerant pressure sensor. If voltage is not as specified, check

wiring harness between refrigerant pressure sensor and All Activity Module (AAM). See WIRING

DIAGRAMS . Repair as necessary. If circuits are okay, replace AAM and retest A/C system.

Outside Temperature Sensor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Turn ignition off. Connect ohmmeter positive lead to socket box terminal No. 12 and

negative lead to terminal No. 3.

2. Disconnect test cable from A/C push button control unit. See OUTSIDE TEMPERATURE SENSOR

RESISTANCE table. If resistance is not as specified, check wiring harness between outside temperature

sensor and A/C push button control unit. See WIRING DIAGRAMS

. Repair as necessary. If wiring

harness is okay, replace outside temperature sensor.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 13 © 2006 Mitchell Repair Information Company, LLC.

Page 3225 of 4133

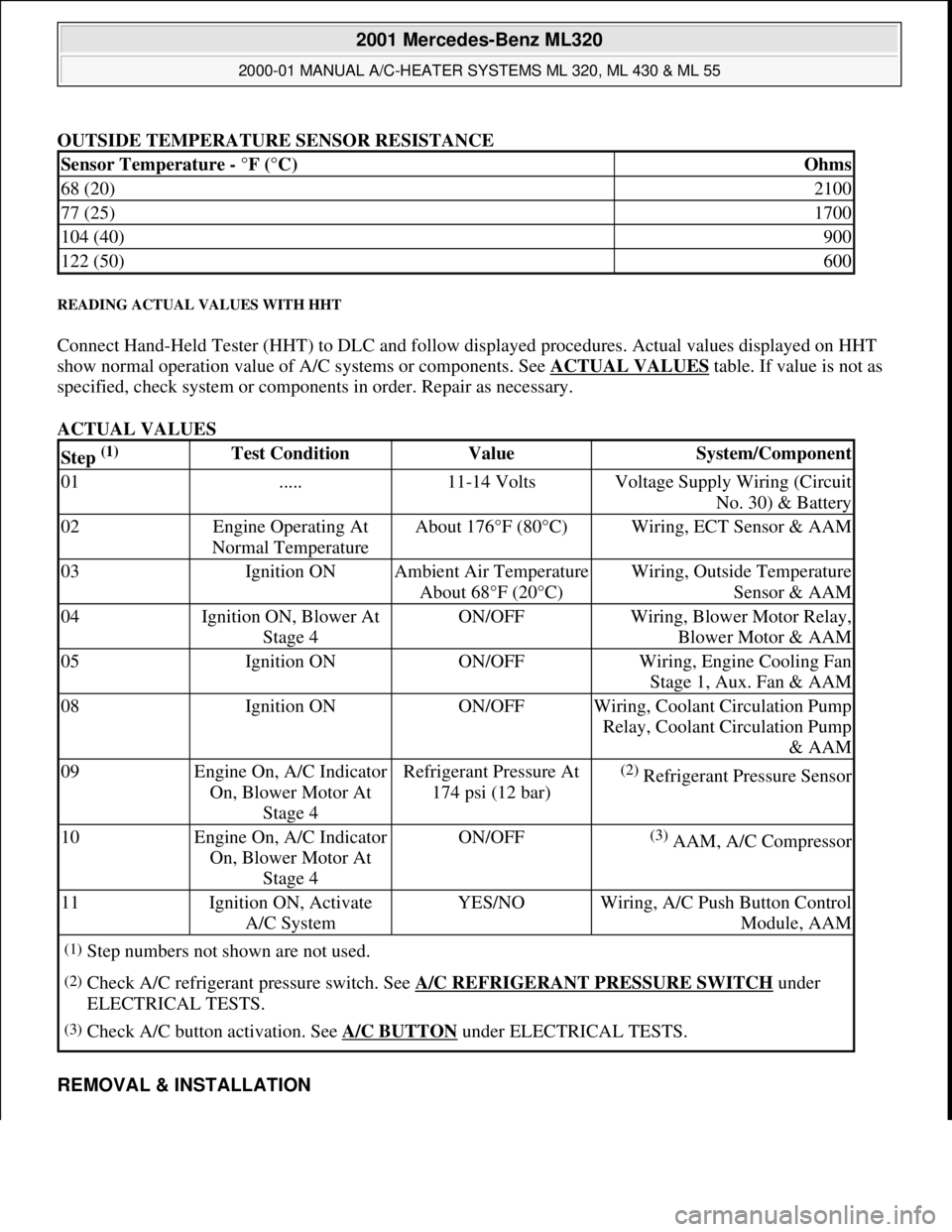

OUTSIDE TEMPERATURE SENSOR RESISTANCE

READING ACTUAL VALUES WITH HHT

Connect Hand-Held Tester (HHT) to DLC and follow displayed procedures. Actual values displayed on HHT

show normal operation value of A/C systems or components. See ACTUAL VALUES

table. If value is not as

specified, check system or components in order. Repair as necessary.

ACTUAL VALUES

REMOVAL & INSTALLATION

Sensor Temperature - °F (°C)Ohms

68 (20)2100

77 (25)1700

104 (40)900

122 (50)600

Step (1) Test ConditionValueSystem/Component

01.....11-14 VoltsVoltage Supply Wiring (Circuit

No. 30) & Battery

02Engine Operating At

Normal TemperatureAbout 176°F (80°C)Wiring, ECT Sensor & AAM

03Ignition ONAmbient Air Temperature

About 68°F (20°C)Wiring, Outside Temperature

Sensor & AAM

04Ignition ON, Blower At

Stage 4ON/OFFWiring, Blower Motor Relay,

Blower Motor & AAM

05Ignition ONON/OFFWiring, Engine Cooling Fan

Stage 1, Aux. Fan & AAM

08Ignition ONON/OFFWiring, Coolant Circulation Pump

Relay, Coolant Circulation Pump

& AAM

09Engine On, A/C Indicator

On, Blower Motor At

Stage 4Refrigerant Pressure At

174 psi (12 bar)(2) Refrigerant Pressure Sensor

10Engine On, A/C Indicator

On, Blower Motor At

Stage 4ON/OFF(3) AAM, A/C Compressor

11Ignition ON, Activate

A/C SystemYES/NOWiring, A/C Push Button Control

Module, AAM

(1)Step numbers not shown are not used.

(2)Check A/C refrigerant pressure switch. See A/C REFRIGERANT PRESSURE SWITCH under

ELECTRICAL TESTS.

(3)Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 14 © 2006 Mitchell Repair Information Company, LLC.

Page 3226 of 4133

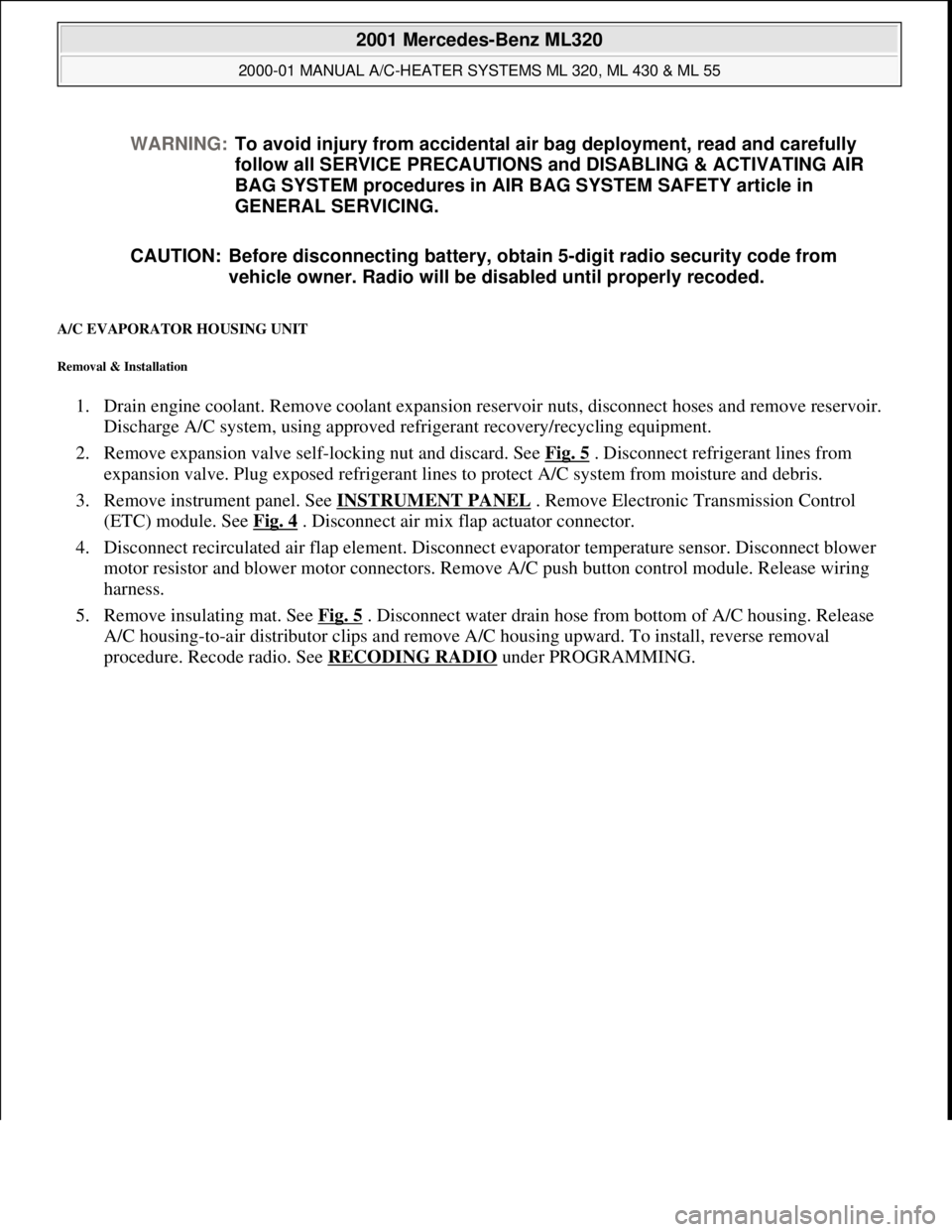

A/C EVAPORATOR HOUSING UNIT

Removal & Installation

1. Drain engine coolant. Remove coolant expansion reservoir nuts, disconnect hoses and remove reservoir.

Discharge A/C system, using approved refrigerant recovery/recycling equipment.

2. Remove expansion valve self-locking nut and discard. See Fig. 5

. Disconnect refrigerant lines from

expansion valve. Plug exposed refrigerant lines to protect A/C system from moisture and debris.

3. Remove instrument panel. See INSTRUMENT PANEL

. Remove Electronic Transmission Control

(ETC) module. See Fig. 4

. Disconnect air mix flap actuator connector.

4. Disconnect recirculated air flap element. Disconnect evaporator temperature sensor. Disconnect blower

motor resistor and blower motor connectors. Remove A/C push button control module. Release wiring

harness.

5. Remove insulating mat. See Fig. 5

. Disconnect water drain hose from bottom of A/C housing. Release

A/C housing-to-air distributor clips and remove A/C housing upward. To install, reverse removal

procedure. Recode radio. See RECODING RADIO

under PROGRAMMING. WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS and DISABLING & ACTIVATING AIR

BAG SYSTEM procedures in AIR BAG SYSTEM SAFETY article in

GENERAL SERVICING.

CAUTION: Before disconnecting battery, obtain 5-digit radio security code from

vehicle owner. Radio will be disabled until properly recoded.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 15 © 2006 Mitchell Repair Information Company, LLC.