air condition MERCEDES-BENZ ML320 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 301 of 4133

251 Battery

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index If a tire constantly loses air, it should be inspected for

damage.

The spare tire should be checked periodically for

condition and inflation. Spare tire will age and become

worn over time even if never used, and thus should be

inspected and replaced when necessary.Battery

Important!

Battery replacement information:

The maintenance-free battery is located in the engine

compartment.

The service life of the battery is dependent on its

condition of charge. The battery should always be kept

sufficiently charged, in order to last an optimum length

of time.

Wa r n i n g !

Do not overinflate tires. Overinflating tires can

result in sudden deflation (blowout) because they

are more likely to become punctured or damaged

by road debris, potholes etc.. Follow recommended

inflation pressures.Do not overload the tires by exceeding the specified

vehicle capacity weight (as indicated by the label

on the driver’s door latch post). Overloading the

tires can overheat them, possibly causing a

blowout.

Wa r n i n g !

Failure to follow these instructions can result in

severe injury or death.Never lean over batteries while connecting, you

might get injured.Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush affected

area with water and seek medical help if necessary.A battery will also produce hydrogen gas, which is

flammable and explosive. Keep flames or sparks

away from battery, avoid improper connection of

jumper cables, smoking etc..

Page 328 of 4133

278 Cleaning and care of the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar careIndex

Cleaning and care of the vehicle

In operation, your vehicle is subjected to varying

external inf luences which, if gone unchecked, can

attack the paintwork as well as the underbody and

cause lasting damage.

Such damage is caused not only by extreme and varying

climatic conditions, but also by air polution, road salt,

tar, gravel and stone chipping. Grease and oil, fuel,

coolant, brake fluid, bird droppings, insects, tree resins

etc. should be removed immediately to avoid paint

damage. Frequent washing reduces and / or eliminates

the aggressiveness and potency of the above adverse

influences.More frequent washings are necessary to deal with

unfavorable conditions; for example, near the ocean, in

industrial areas (smoke, exhaust emissions), or during

winter operation.

You should check your vehicle from time to time for

stone chipping or other damage. Any damage should be

repaired as soon as possible to prevent the start of

corrosion.

In doing so, do not neglect the underside of the vehicle.

A prerequisite for a thorough check is a washing of the

underbody followed by a thorough inspection. Damaged

areas need to be reundercoated.

Your vehicle has been treated at the factory with a wax-

base ru stproof ing in th e body cavities w hich will la st for

the lifetime of the vehicle. Post-production treatment is

neither necessary nor recommended by Mercedes-Benz

because of the possibility of incompatibility between

materials used in the production process and others

applied later.

We have selected car-care products and compiled

recommendations which are specially matched to our

vehicles and which always reflect the latest technology.

You can obtain Mercedes-Benz approved car-care

products at your authorized Mercedes-Benz Light Truck

Center.

Wa r n i n g !

Many cleaning products can be hazardous. Some

are poisonous, others are flammable. Always follow

the instructions on the particular container.

Always open your vehicle’s doors or windows when

cleaning the inside.Never use fluids or solvents that are not designed

for cleaning your vehicle.

Page 333 of 4133

283 Contents - Technical data

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

Technical dataSpare parts service ........................284

Warranty coverage .........................284

Identification labels .......................285

Layout of poly-V-belt drive ............286

Technical data ................................287

Fuels, coolants, lubricants

etc. – capacities .........................292Engine oils ...................................... 294

Engine oil additives ...................... 294

Air conditioner refrigerant .......... 294

Brake fluid ...................................... 294

Premium unleaded gasoline ........ 295

Fuel requirements ........................ 295

Gasoline additives ......................... 296

Coolants .......................................... 296

Consumer information ................. 298

Page 336 of 4133

286 Technical data

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

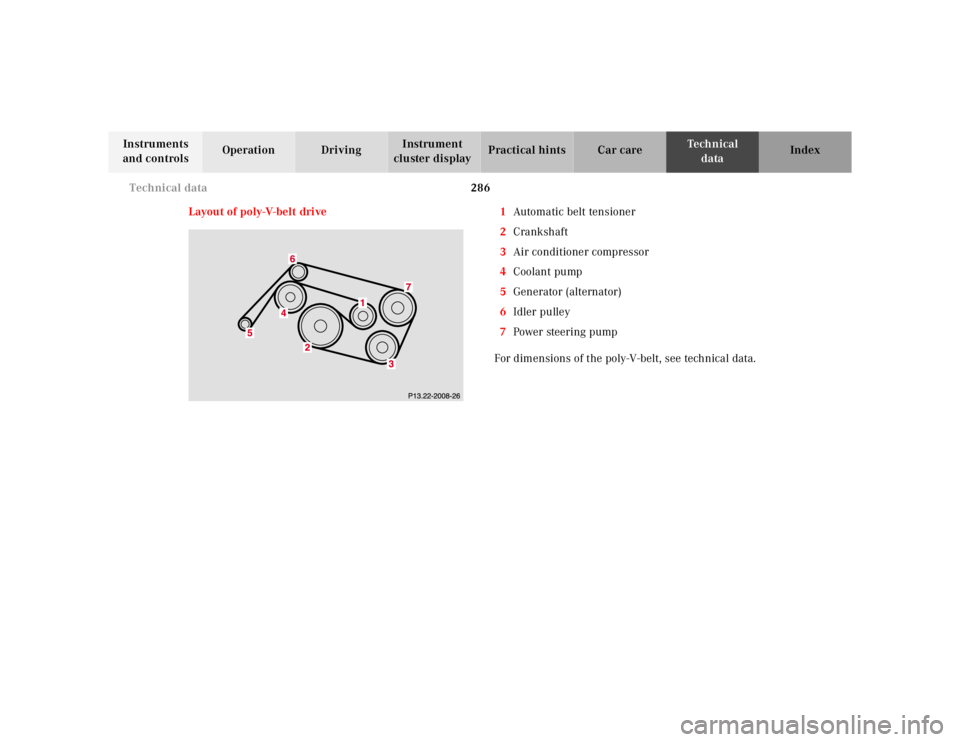

Layout of poly-V-belt drive 1Automatic belt tensioner

2Crankshaft

3Air conditioner compressor

4Coolant pump

5Generator (alternator)

6Idler pulley

7Power steering pump

For dimensions of the poly-V-belt, see technical data.

Page 343 of 4133

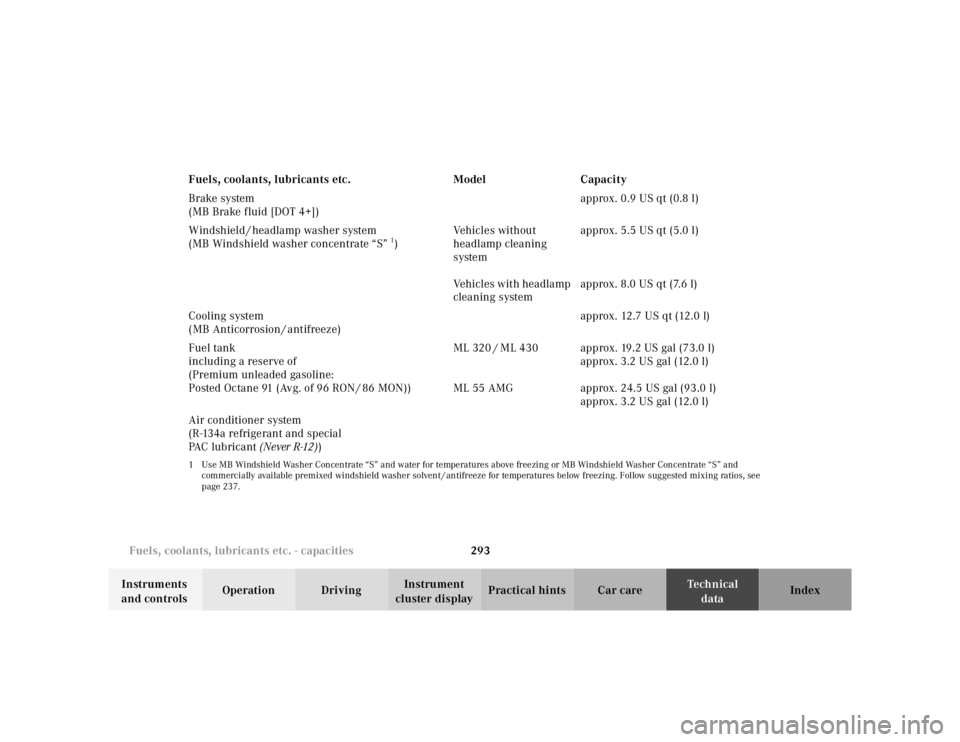

293 Fuels, coolants, lubricants etc. - capacities

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index Brake system

(MB Brake fluid [DOT 4+])approx. 0.9 US qt (0.8 l)

Windshield / headlamp washer system

(MB Windshield washer concentrate “S”

1)Vehicles without

headlamp cleaning

system

Vehicles with headlamp

cleaning systemapprox. 5.5 US qt (5.0 l)

approx. 8.0 US qt (7.6 l)

Cooling system

(MB Anticorrosion / antifreeze)approx. 12.7 US qt (12.0 l)

Fuel tank

including a reserve of

(Premium unleaded gasoline:

Posted Octane 91 (Avg. of 96 RON / 86 MON))ML 320 / ML 430

ML 55 AMGapprox. 19.2 US gal (73.0 l)

approx. 3.2 US gal (12.0 l)

approx. 24.5 US gal (93.0 l)

approx. 3.2 US gal (12.0 l)

Air conditioner system

(R-134a refrigerant and special

PA C l u b r i c a n t (Never R-12))

1 Use MB Windshield Washer Concentrate “S” and water for temperatures above freezing or MB Windshield Washer Concentrate “S” and

commercially available premixed windshield washer solvent / antifreeze for temperatures below freezing. Follow suggested mixing ratios, see

page 237.Fuels, coolants, lubricants etc. Model Capacity

Page 344 of 4133

294 Fuels, coolants, lubricants etc.

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

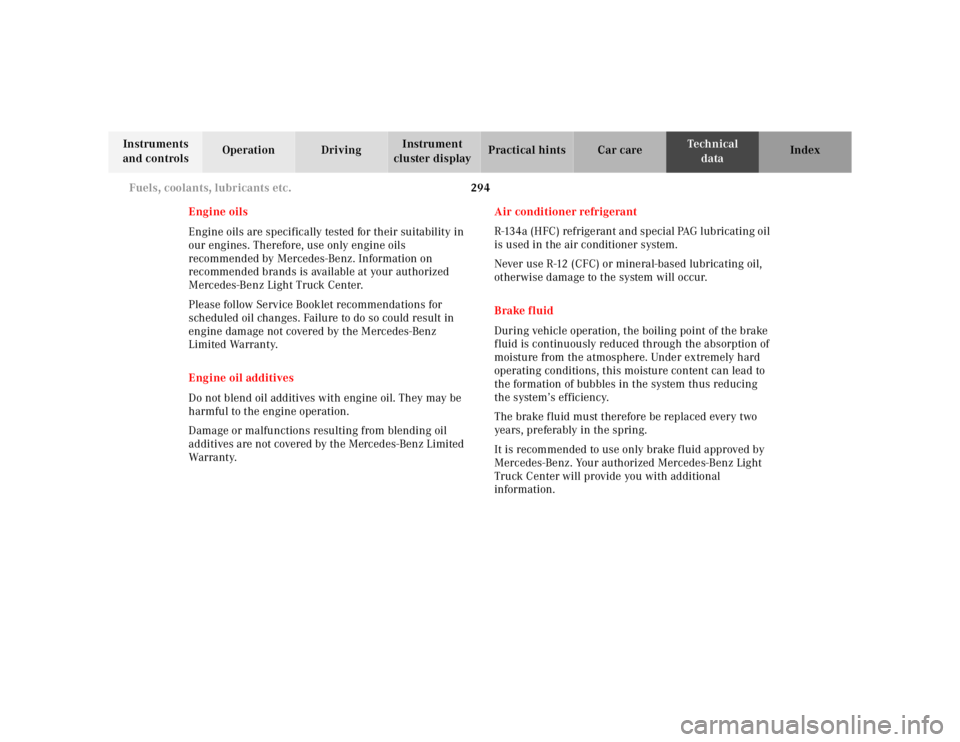

Engine oils

Engine oils are specifically tested for their suitability in

our engines. Therefore, use only engine oils

recommended by Mercedes-Benz. Information on

recommended brands is available at your authorized

Mercedes-Benz Light Truck Center.

Please follow Service Booklet recommendations for

scheduled oil changes. Failure to do so could result in

engine damage not covered by the Mercedes-Benz

Limited Warranty.

Engine oil additives

Do not blend oil additives with engine oil. They may be

harmful to the engine operation.

Damage or malfunctions resulting from blending oil

additives are not covered by the Mercedes-Benz Limited

War ra nt y.Air conditioner refrigerant

R-134a (HFC) refrigerant and special PAG lubricating oil

is used in the air conditioner system.

Never use R-12 (CFC) or mineral-based lubricating oil,

otherwise damage to the system will occur.

Brake fluid

During vehicle operation, the boiling point of the brake

fluid is continuously reduced through the absorption of

moisture from the atmosphere. Under extremely hard

operating conditions, this moisture content can lead to

the formation of bubbles in the system thus reducing

the system’s efficiency.

The brake fluid must therefore be replaced every two

years, preferably in the spring.

It is recommended to use only brake fluid approved by

Mercedes-Benz. Your authorized Mercedes-Benz Light

Truck Center will provide you with additional

information.

Page 350 of 4133

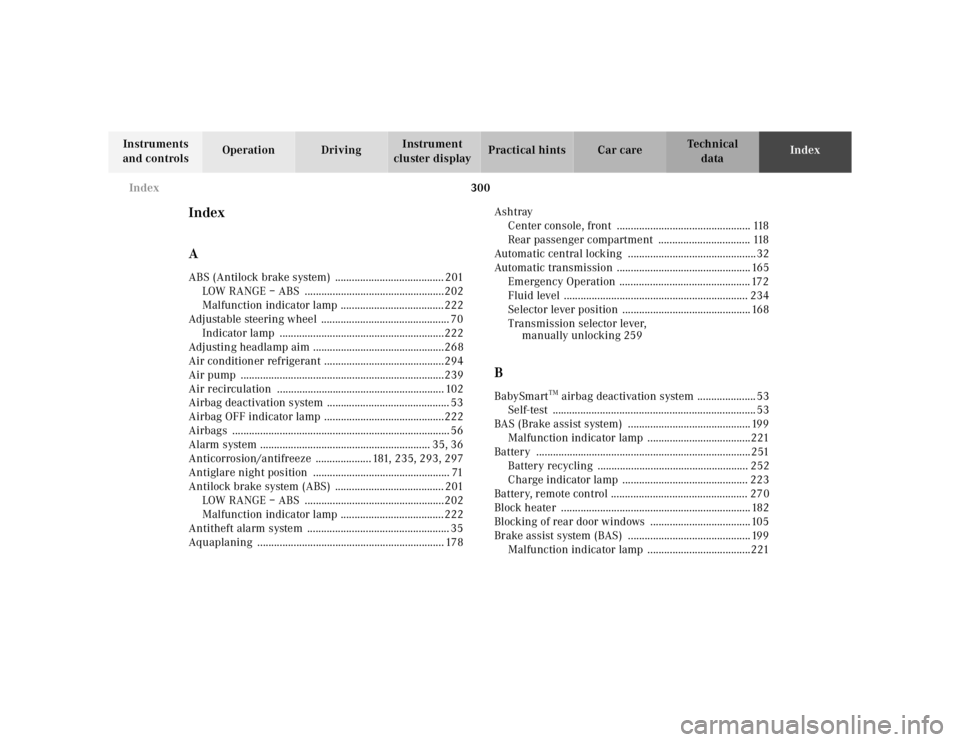

300 Index

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car careIndex

Index

AABS (Antilock brake system) ....................................... 201

LOW RANGE – ABS ..................................................202

Malfunction indicator lamp .....................................222

Adjustable steering wheel .............................................. 70

Indicator lamp ...........................................................222

Adjusting headlamp aim ...............................................268

Air conditioner refrigerant ...........................................294

Air pump .........................................................................239

Air recirculation ............................................................ 102

Airbag deactivation system ............................................ 53

Airbag OFF indicator lamp ...........................................222

Airbags .............................................................................. 56

Alarm system ............................................................. 35, 36

Anticorrosion/antifreeze .................... 181, 235, 293, 297

Antiglare night position ................................................. 71

Antilock brake system (ABS) ....................................... 201

LOW RANGE – ABS ..................................................202

Malfunction indicator lamp .....................................222

Antitheft alarm system ................................................... 35

Aquaplaning ................................................................... 178Ashtray

Center console, front ................................................ 118

Rear passenger compartment ................................. 118

Automatic central locking ..............................................32

Automatic transmission ................................................ 165

Emergency Operation ............................................... 172

Fluid level .................................................................. 234

Selector lever position .............................................. 168

Transmission selector lever,

manually unlocking 259

BBabySmart

TM airbag deactivation system ..................... 53

Self-test ......................................................................... 53

BAS (Brake assist system) ............................................ 199

Malfunction indicator lamp .....................................221

Battery .............................................................................251

Battery recycling ...................................................... 252

Charge indicator lamp ............................................. 223

Battery, remote control ................................................. 270

Block heater .................................................................... 182

Blocking of rear door windows ....................................105

Brake assist system (BAS) ............................................ 199

Malfunction indicator lamp .....................................221

Page 384 of 4133

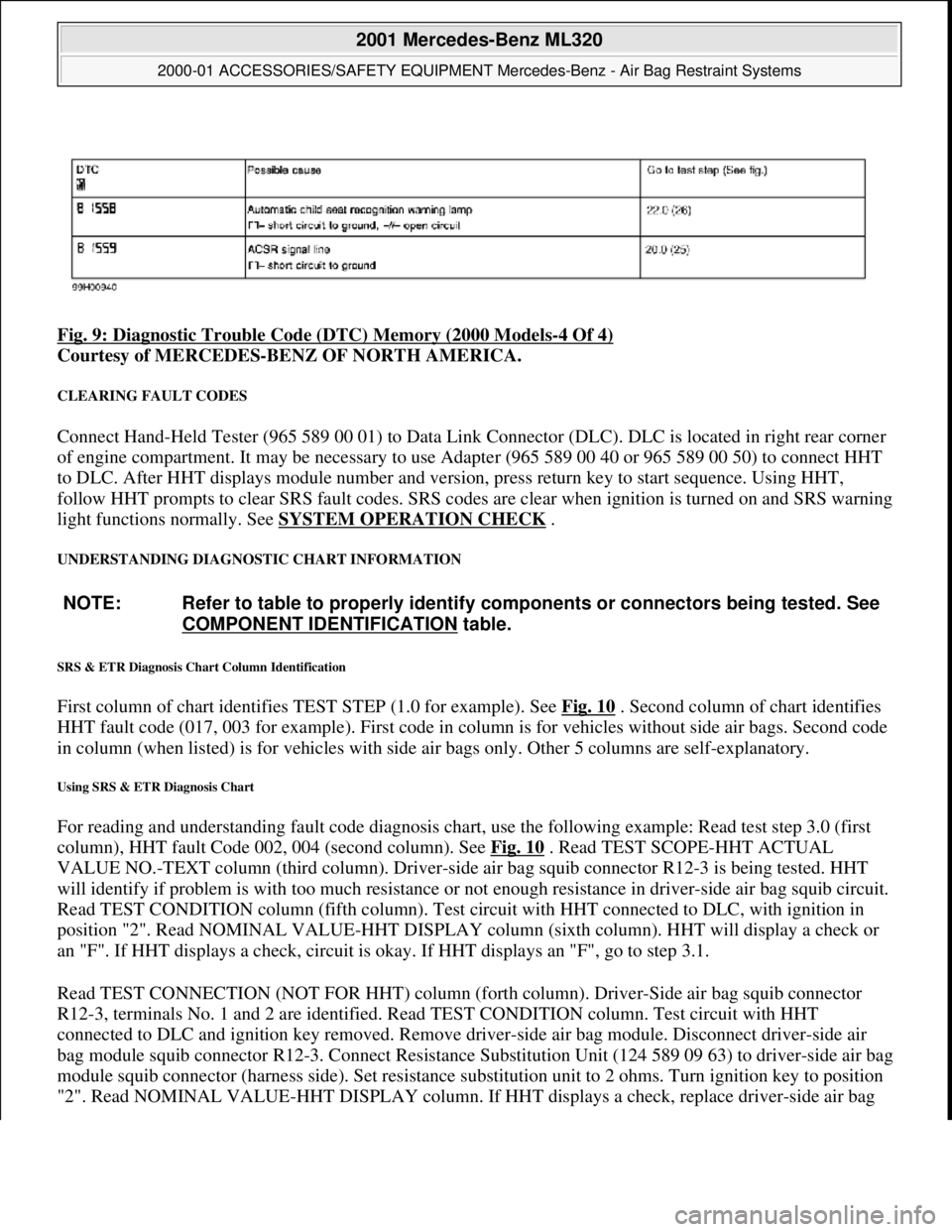

Fig. 9: Diagnostic Trouble Code (DTC) Memory (2000 Models-4 Of 4)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

CLEARING FAULT CODES

Connect Hand-Held Tester (965 589 00 01) to Data Link Connector (DLC). DLC is located in right rear corner

of engine compartment. It may be necessary to use Adapter (965 589 00 40 or 965 589 00 50) to connect HHT

to DLC. After HHT displa ys module number and version, press return key to start sequence. Using HHT,

follow HHT prompts to clear SRS faul t codes. SRS codes are clear when ignition is turned on and SRS warning

light functions normally. See SYSTEM OPERATION CHECK

.

UNDERSTANDING DIAGNOSTIC CHART INFORMATION

SRS & ETR Diagnosis Chart Column Identification

First column of chart identifies TEST STEP (1.0 for example). See Fig. 10 . Second column of chart identifies

HHT fault code (017, 003 for example). First code in column is for ve hicles without side air bags. Second code

in column (when listed) is for ve hicles with side air bags only. Ot her 5 columns are self-explanatory.

Using SRS & ETR Diagnosis Chart

For reading and understanding fault code diagnosis chart, use the following example: Read test step 3.0 (first

column), HHT fault Code 002, 004 (second column). See Fig. 10

. Read TEST SCOPE-HHT ACTUAL

VALUE NO.-TEXT column (third column). Driver-side air bag squib connector R12-3 is being tested. HHT

will identify if problem is with too much resistance or not enough resistance in driver-side air bag squib circuit.

Read TEST CONDITION column (fifth column). Test ci rcuit with HHT connected to DLC, with ignition in

position "2". Read NOMINAL VALUE-HHT DISPLAY column (sixth column). HHT will display a check or

an "F". If HHT displays a check, circuit is okay. If HHT displays an "F", go to step 3.1.

Read TEST CONNECTION (NOT FOR HHT) column (fort h column). Driver-Side air bag squib connector

R12-3, terminals No. 1 and 2 are id entified. Read TEST CONDITION column. Test circuit with HHT

connected to DLC and igni tion key removed. Remove driver-side air bag module. Disconnect driver-side air

bag module squib connector R12-3. Conn ect Resistance Substitution Unit (124 589 09 63) to driver-side air bag

module squib connector (harness side). Set resistance substitution unit to 2 ohms. Turn ignition key to position

"2". Read NOMINAL VALUE-HHT DISPLAY column. If HHT displa

ys a check, replace driver-side air bag

NOTE: Refer to table to properly identify components or connectors being tested. See

COMPONENT IDENTIFICATION

table.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 385 of 4133

module. If HHT displays an "F", go to step 3.2.

Read TEST CONNECTION (NOT FOR HHT) column. Horn -air bag clockspring connector A45x1, terminals

No. 1 and 2 are identified. Read TEST CONDITION column. Test circuit with HHT connected to DLC.

Remove ignition key. Connect Resist ance Substitution Unit (124 589 09 63 00) to horn-air bag clockspring

connector A45x1. Set resistance s ubstitution unit to 2 ohms. Read NOMINAL VALUE-HHT DISPLAY

column. If HHT displays a check, check horn-air ba g clockspring for continuity. Replace horn-air bag

clockspring as necessary. If HHT displays an "F", go to step 3.4.

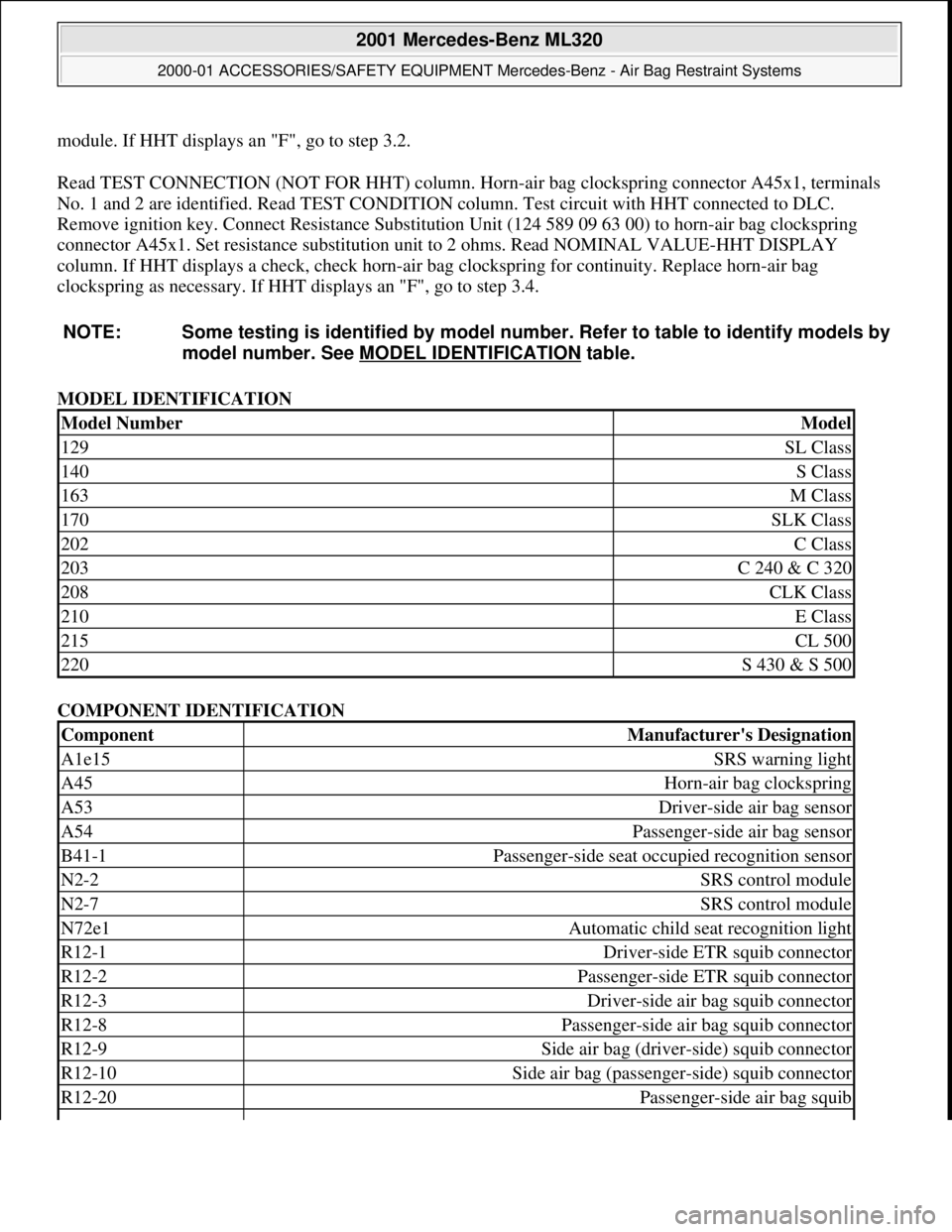

MODEL IDENTIFICATION

COMPONENT IDENTIFICATION

NOTE: Some testing is identified

by model number. Refer to table to identify models by

model number. See MO DEL IDENTIFICATION

table.

Model NumberModel

129SL Class

140S Class

163M Class

170SLK Class

202C Class

203C 240 & C 320

208CLK Class

210E Class

215CL 500

220S 430 & S 500

ComponentManufacturer's Designation

A1e15SRS warning light

A45Horn-air bag clockspring

A53Driver-side air bag sensor

A54Passenger-side air bag sensor

B41-1Passenger-side seat occupied recognition sensor

N2-2SRS control module

N2-7SRS control module

N72e1Automatic child seat recognition light

R12-1Driver-side ETR squib connector

R12-2Passenger-side ETR squib connector

R12-3Driver-side air bag squib connector

R12-8Passenger-side air bag squib connector

R12-9Side air bag (driver-side) squib connector

R12-10Side air bag (passenge r-side) squib connector

R12-20Passenger-side air bag squib

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 386 of 4133

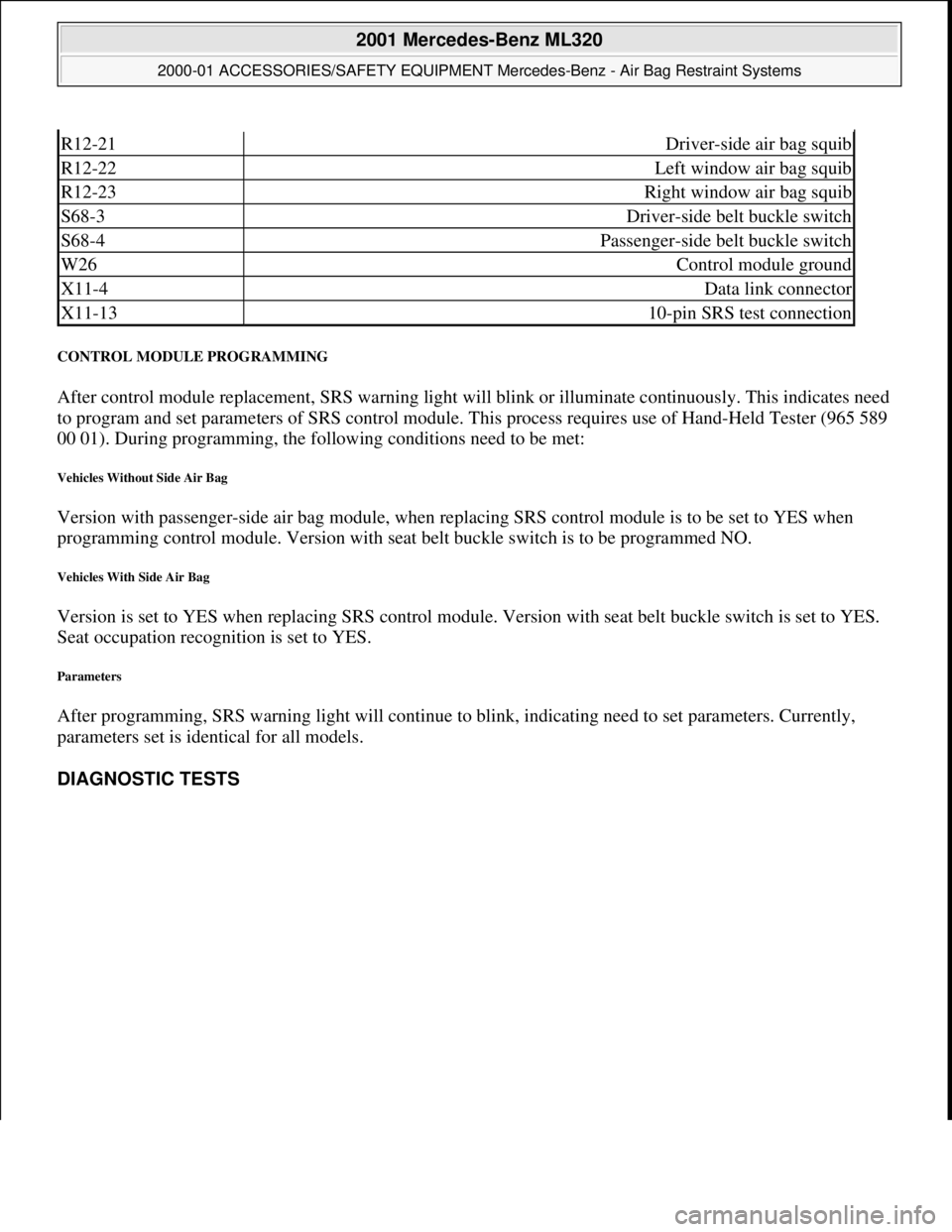

CONTROL MODULE PROGRAMMING

After control module replacement, SRS warning light will blink or illuminate continuously. This indicates need

to program and set paramete rs of SRS control module. This process requires use of Hand-Held Tester (965 589

00 01). During programming, the follow ing conditions need to be met:

Vehicles Without Side Air Bag

Version with passenger-side air bag module, when replac ing SRS control module is to be set to YES when

programming control module. Version with seat belt buckle switch is to be programmed NO.

Vehicles With Side Air Bag

Version is set to YES when replacing SRS control module. Version with seat belt buckle switch is set to YES.

Seat occupation recogni tion is set to YES.

Parameters

After programming, SRS warning light wi ll continue to blink, indicating need to set parameters. Currently,

parameters set is identical for all models.

DIAGNOSTIC TESTS

R12-21Driver-side air bag squib

R12-22Left window air bag squib

R12-23Right window air bag squib

S68-3Driver-side belt buckle switch

S68-4Passenger-side belt buckle switch

W26Control module ground

X11-4Data link connector

X11-1310-pin SRS test connection

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 22 © 2006 Mitchell Repair Information Company, LLC.